Paper Menu >>

Journal Menu >>

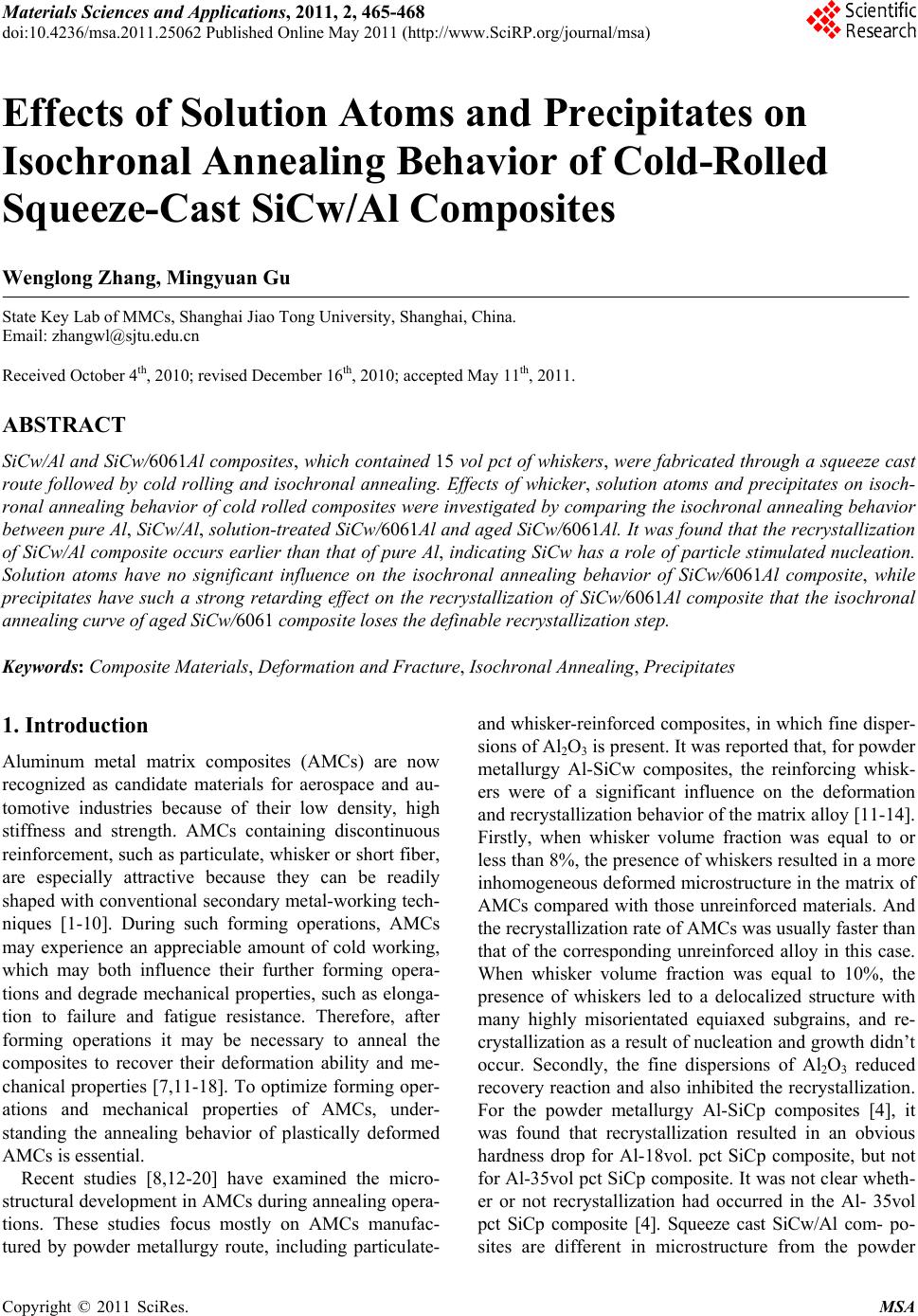

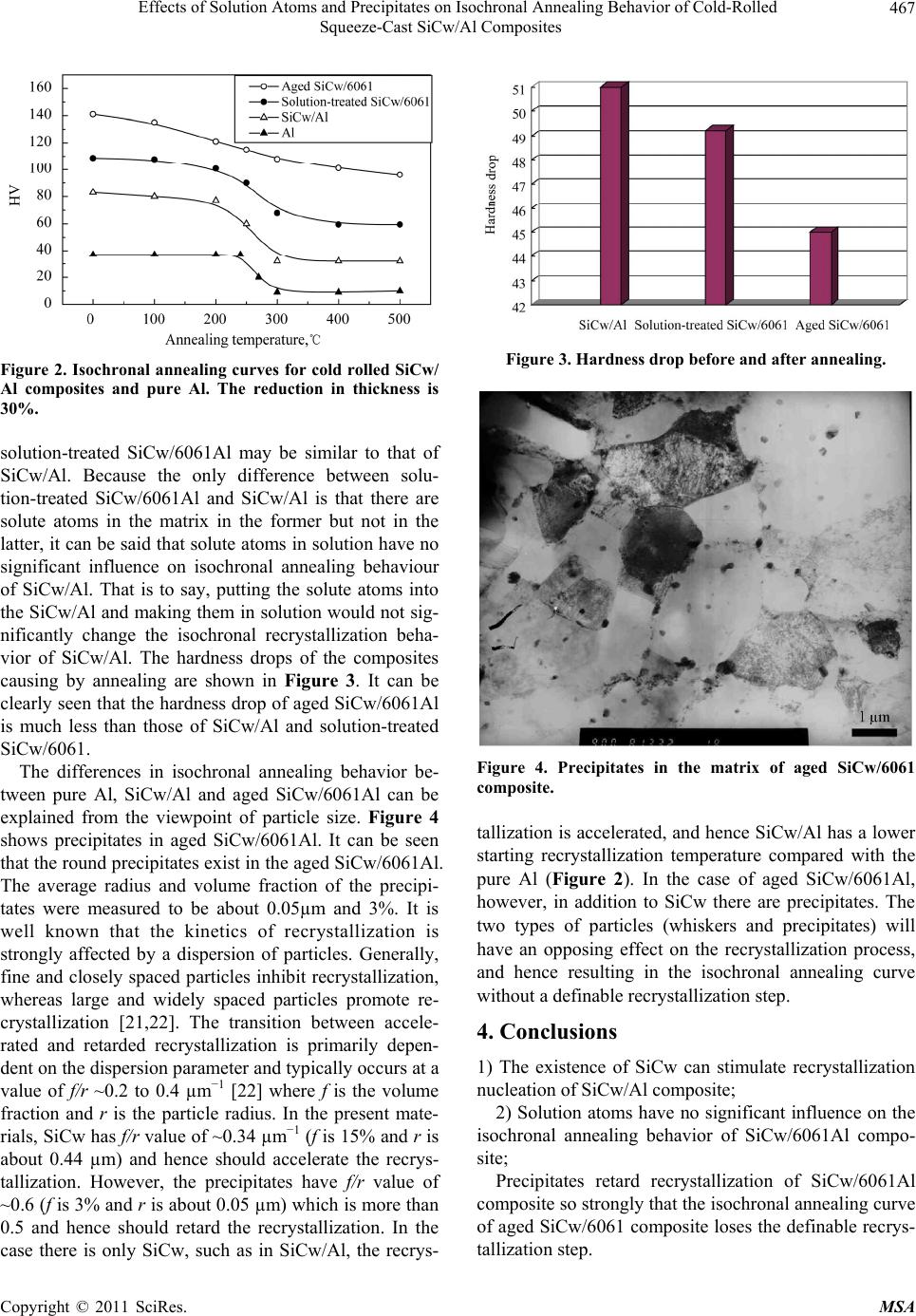

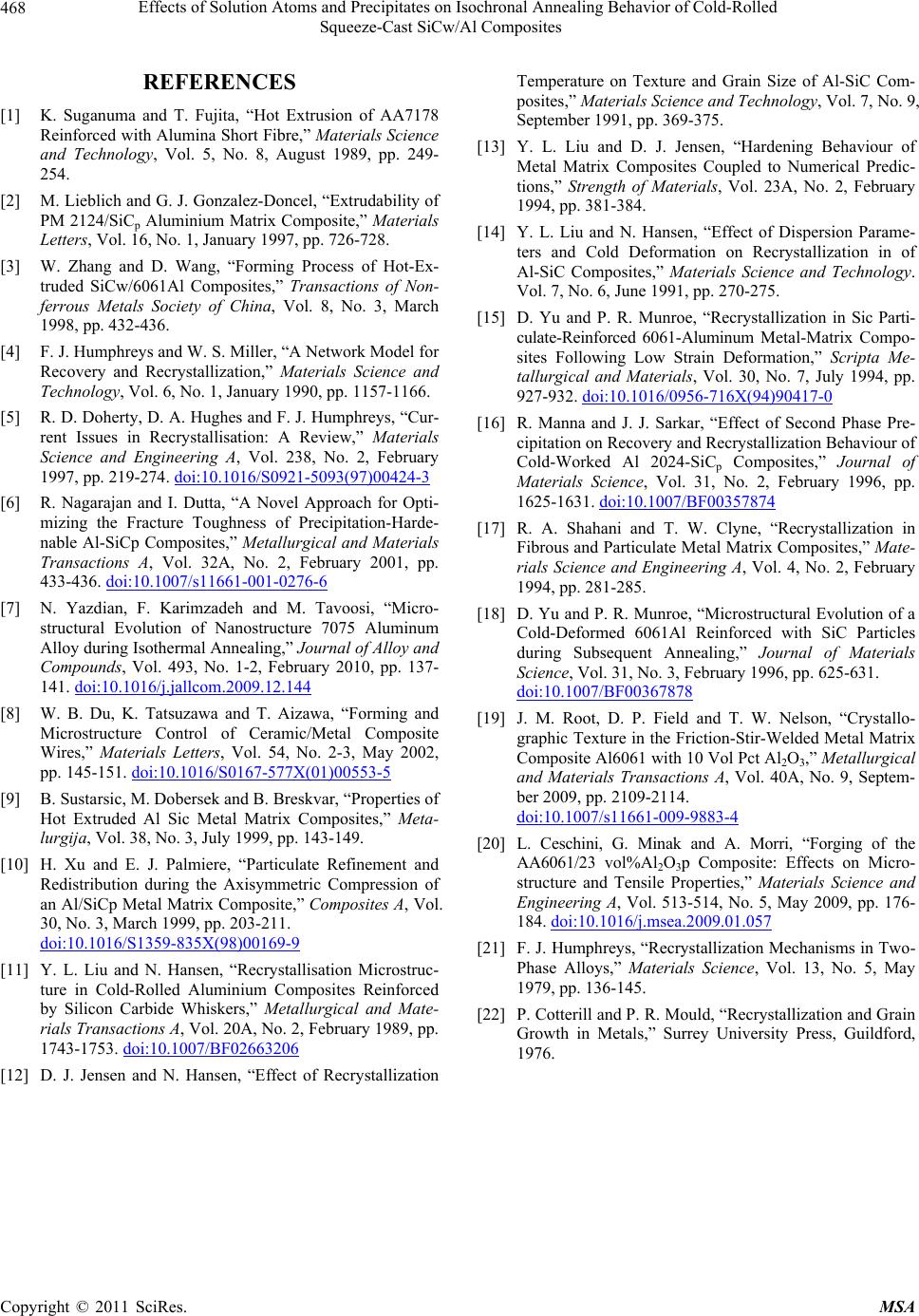

Materials Sciences and Applications, 2011, 2, 465-468 doi:10.4236/msa.2011.25062 Published Online May 2011 (http://www.SciRP.org/journal/msa) Copyright © 2011 SciRes. MSA 465 Effects of Solution Atoms and Precipitates on Isochronal Annealing Behavior of Cold-Rolled Squeeze-Cast SiCw/Al Composites Wenglong Zhang, Mingyuan Gu State Key Lab of MMCs, Shanghai Jiao Tong University, Shanghai, China. Email: zhangwl@sjtu.edu.cn Received October 4th, 2010; revised December 16th, 2010; accepted May 11th, 2011. ABSTRACT SiCw/Al and SiCw/6061Al composites, which contained 15 vol pct of whiskers, were fabricated through a squeeze cast route followed by cold rolling and isochronal annealing. Effects of whicker, solution atoms and precipitates on isoch- ronal annealing behavior of cold rolled composites were investigated by comparing the isochronal annealing behavior between pure Al, SiCw/Al, solution-treated SiCw/6061Al and aged SiCw/6061Al. It was found that the recrystalliza tion of SiCw/Al compo site occurs earlier than that of p ure Al, indicating SiCw has a role of particle stimulated nucleation. Solution atoms have no significant influence on the isochronal annealing behavior of SiCw/6061Al composite, while precipitates have such a strong retarding effect on the recrystallization of SiCw/6061Al composite that the isochronal annealing curve of aged SiCw/6061 composite loses the definable recrystallization step. Keywords: Composite Materials, Deformation and Fracture, Isochronal Annealing, Precipitates 1. Introduction Aluminum metal matrix composites (AMCs) are now recognized as candidate materials for aerospace and au- tomotive industries because of their low density, high stiffness and strength. AMCs containing discontinuous reinforcement, such as particulate, whisker or short fiber, are especially attractive because they can be readily shaped with conventional secondary metal-working tech- niques [1-10]. During such forming operations, AMCs may experience an appreciable amount of cold working, which may both influence their further forming opera- tions and degrade mechanical properties, such as elonga- tion to failure and fatigue resistance. Therefore, after forming operations it may be necessary to anneal the composites to recover their deformation ability and me- chanical properties [7,11-18]. To optimize forming oper- ations and mechanical properties of AMCs, under- standing the annealing behavior of plastically deformed AMCs is essential. Recent studies [8,12-20] have examined the micro- structural development in AMCs during annealing opera- tions. These studies focus mostly on AMCs manufac- tured by powder metallurgy route, including particulate- and whisker-reinforced composites, in which fine disper- sions of Al2O3 is present. It was reported that, for powder metallurgy Al-SiCw composites, the reinforcing whisk- ers were of a significant influence on the deformation and recrystallization behavior of the matrix alloy [11-14]. Firstly, when whisker volume fraction was equal to or less than 8%, the presence of whiskers resulted in a more inhomogeneous deformed microstructure in the matrix of AMCs compared with those unreinforced materials. And the recrystallization rate of AMCs was usually faster than that of the corresponding unreinforced alloy in this case. When whisker volume fraction was equal to 10%, the presence of whiskers led to a delocalized structure with many highly misorientated equiaxed subgrains, and re- crystallization as a result of nucleation and growth didn’t occur. Secondly, the fine dispersions of Al2O3 reduced recovery reaction and also inhibited the recrystallization. For the powder metallurgy Al-SiCp composites [4], it was found that recrystallization resulted in an obvious hardness drop for Al-18vol. pct SiCp composite, but not for Al-35vol pct SiCp composite. It was not clear wheth- er or not recrystallization had occurred in the Al- 35vol pct SiCp composite [4]. Squeeze cast SiCw/Al com- po- sites are different in microstructure from the powder  Effects of Solution Atoms and Precipitates on Isochronal Annealing Behavior of Cold-Rolled Squeeze-Cast SiCw/Al Composites Copyright © 2011 SciRes. MSA 466 metallurgy ones. One of the main differences is that squeeze cast SiCw/Al composites contain no fine disper- sions of Al2O3. This may lead to an annealing behavior in squeeze cast composites which is different from that in powder metallurgy ones. The reason why powder metal- lurgy composites of Al-10vol. pct SiCw didn’t show re- crystallization behavior may be due in part to the role of fine dispersions of Al2O3. In order to both eliminate ef- fects of solution atoms and precipitates existing in matrix and make a direct comparison between reinforced and unreinforced materials, research on recrystallization has been carried out on a range of MMCs with commercially pure aluminum as the matrix [11,13, 14]. However, MMCs with pure aluminum as matrix are rarely used in engineering applications; therefore it is necessary to in- vestigate the recrystallization of MMCs with aluminum alloys as matrix from the point of view of engineering applications. Because the existence of alloying elements, the annealing behavior of the composites with aluminum alloys as matrix may be much different from that of the composites with pure aluminum as matrix. In this study, two composites (squeeze cast SiCw/Al and SiCw/6061Al composites), which contained 15 vol. pct of whiskers, was cold rolled and annealed. Effects of solution atoms and precipitates on isochronal annealing behavior of the cold rolled composite were investigated. 2. Materials and Methods The composites used in this study were reinforced with type SiC whiskers, 0.1 - 1.0 m in diameter and 30 - 100 m in length. The matrix is commercially pure aluminum (99.5 wt pct Al) or 6061 alloy. The composites were fabricated through a squeeze-cast route and had a SiC whisker volume fraction, Vf, of 15%. It was difficult to cold deform the as-cast composites due to its bad ductil- ity. To obtain a higher cold deformation degree, the as-cast composites were subjected to a hot extrusion with an extrusion ratio of 18:1 before cold rolling. It was found that the capability of cold deformation of SiCw/Al composites could be greatly improved by the pre-hot- extrusion. The as-extruded composites were then cold- rolled along the extrusion direction to about 30 pct re- duction in thickness. The spatial distribution of SiC whiskers in cold-rolled sheets was fairly uniform and highly aligned along the rolling direction i.e. the extru- sion direction, as shown in Figure 1. For SiCw/6061Al composites, solution treatment was carried out at 520˚C and water quenched. Then some of the solution-treated composites were aged at 170˚C for 10 h. Isochronal an- nealing was performed for 1 h in a temperature range from 100 to 500˚C. Vickers macrohardness measurement Figure 1. Whisker morphology in cold rolled SiCw/Al com- posites. The reduction in thickness is 30%. was carried out using 5 kg load on the cold-rolled and annealed specimens. On an average, ten hardness mea- surements were performed on each specimen for each date point. Microstructures of the cold-rolled and aged samples were studied by scanning electron microscopy (SEM) and transmission electron microscopy (TEM). 3. Results and Discussion Figure 2 shows the isochronal annealing curves of the cold rolled composites and pure Al. It can be seen from the figure that, for all the materials, hardness decreases with the increase in annealing temperature. For solu- tion-treated SiCw/6061Al, SiCw/Al and Al, the isoch- ronal annealing curves are similar in shape and show definable transition steps from the higher to the low hardness values. For aged SiCw/6061, however, the isochronal annealing curve is nearly linear in shape and without a definable recrystallization step. Comparing the isochronal annealing curve of pure Al with that of its composite (SiCw/Al), it is found that the starting recrys- tallization temperature of SiCw/Al (about 200˚C) is lower than that of pure Al (about 240˚C), indicating that SiCw may play a big role in stimulating recrystallization nucleation. The similar isochronal annealing curve shape between solution-treated SiCw/6061Al and SiCw/Al suggests that the isochronal recrystallization behaviour of  Effects of Solution Atoms and Precipitates on Isochronal Annealing Behavior of Cold-Rolled Squeeze-Cast SiCw/Al Composites Copyright © 2011 SciRes. MSA 467 Figure 2. Isochronal annealing curves for cold rolled SiCw/ Al composites and pure Al. The reduction in thickness is 30%. solution-treated SiCw/6061Al may be similar to that of SiCw/Al. Because the only difference between solu- tion-treated SiCw/6061Al and SiCw/Al is that there are solute atoms in the matrix in the former but not in the latter, it can be said that solute atoms in solution have no significant influence on isochronal annealing behaviour of SiCw/Al. That is to say, putting the solute atoms into the SiCw/Al and making them in solution would not sig- nificantly change the isochronal recrystallization beha- vior of SiCw/Al. The hardness drops of the composites causing by annealing are shown in Figure 3. It can be clearly seen that the hardness drop of aged SiCw/6061Al is much less than those of SiCw/Al and solution-treated SiCw/6061. The differences in isochronal annealing behavior be- tween pure Al, SiCw/Al and aged SiCw/6061Al can be explained from the viewpoint of particle size. Figure 4 shows precipitates in aged SiCw/6061Al. It can be seen that the round precipitates exist in the aged SiCw/6061Al. The average radius and volume fraction of the precipi- tates were measured to be about 0.05µm and 3%. It is well known that the kinetics of recrystallization is strongly affected by a dispersion of particles. Generally, fine and closely spaced particles inhibit recrystallization, whereas large and widely spaced particles promote re- crystallization [21,22]. The transition between accele- rated and retarded recrystallization is primarily depen- dent on the dispersion parameter and typically occurs at a value of f/r ~0.2 to 0.4 µm−1 [22] where f is the volume fraction and r is the particle radius. In the present mate- rials, SiCw has f/r value of ~0.34 µm−1 (f is 15% and r is about 0.44 µm) and hence should accelerate the recrys- tallization. However, the precipitates have f/r value of ~0.6 (f is 3% and r is about 0.05 µm) which is more than 0.5 and hence should retard the recrystallization. In the case there is only SiCw, such as in SiCw/Al, the recrys- Figure 3. Hardness drop before and after annealing. Figure 4. Precipitates in the matrix of aged SiCw/6061 composite. tallization is accelerated, and hence SiCw/Al has a lower starting recrystallization temperature compared with the pure Al (Figure 2). In the case of aged SiCw/6061Al, however, in addition to SiCw there are precipitates. The two types of particles (whiskers and precipitates) will have an opposing effect on the recrystallization process, and hence resulting in the isochronal annealing curve without a definable recrystallization step. 4. Conclusions 1) The existence of SiCw can stimulate recrystallization nucleation of SiCw/Al composite; 2) Solution atoms have no significant influence on the isochronal annealing behavior of SiCw/6061Al compo- site; Precipitates retard recrystallization of SiCw/6061Al composite so strongly that the isochronal annealing curve of aged SiCw/6061 composite loses the definable recrys- tallization step.  Effects of Solution Atoms and Precipitates on Isochronal Annealing Behavior of Cold-Rolled Squeeze-Cast SiCw/Al Composites Copyright © 2011 SciRes. MSA 468 REFERENCES [1] K. Suganuma and T. Fujita, “Hot Extrusion of AA7178 Reinforced with Alumina Short Fibre,” Materials Science and Technology, Vol. 5, No. 8, August 1989, pp. 249- 254. [2] M. Lieblich and G. J. Gonzalez-Doncel, “Extrudability of PM 2124/SiCp Aluminium Matrix Composite,” Materials Letters, Vol. 16, No. 1, January 1997, pp. 726-728. [3] W. Zhang and D. Wang, “Forming Process of Hot-Ex- truded SiCw/6061Al Composites,” Transactions of Non- ferrous Metals Society of China, Vol. 8, No. 3, March 1998, pp. 432-436. [4] F. J. Humphreys and W. S. Miller, “A Network Model for Recovery and Recrystallization,” Materials Science and Technology, Vol. 6, No. 1, January 1990, pp. 1157-1166. [5] R. D. Doherty, D. A. Hughes and F. J. Humphreys, “Cur- rent Issues in Recrystallisation: A Review,” Materials Science and Engineering A, Vol. 238, No. 2, February 1997, pp. 219-274. doi:10.1016/S0921-5093(97)00424-3 [6] R. Nagarajan and I. Dutta, “A Novel Approach for Opti- mizing the Fracture Toughness of Precipitation-Harde- nable Al-SiCp Composites,” Metallurgical and Materials Transactions A, Vol. 32A, No. 2, February 2001, pp. 433-436. doi:10.1007/s11661-001-0276-6 [7] N. Yazdian, F. Karimzadeh and M. Tavoosi, “Micro- structural Evolution of Nanostructure 7075 Aluminum Alloy during Isothermal Annealing,” Journal of Alloy and Compounds, Vol. 493, No. 1-2, February 2010, pp. 137- 141. doi:10.1016/j.jallcom.2009.12.144 [8] W. B. Du, K. Tatsuzawa and T. Aizawa, “Forming and Microstructure Control of Ceramic/Metal Composite Wires,” Materials Letters, Vol. 54, No. 2-3, May 2002, pp. 145-151. doi:10.1016/S0167-577X(01)00553-5 [9] B. Sustarsic, M. Dobersek and B. Breskvar, “Properties of Hot Extruded Al Sic Metal Matrix Composites,” Meta- lurgija, Vol. 38, No. 3, July 1999, pp. 143-149. [10] H. Xu and E. J. Palmiere, “Particulate Refinement and Redistribution during the Axisymmetric Compression of an Al/SiCp Metal Matrix Composite,” Composites A, Vol. 30, No. 3, March 1999, pp. 203-211. doi:10.1016/S1359-835X(98)00169-9 [11] Y. L. Liu and N. Hansen, “Recrystallisation Microstruc- ture in Cold-Rolled Aluminium Composites Reinforced by Silicon Carbide Whiskers,” Metallurgical and Mate- rials Transactions A, Vol. 20A, No. 2, February 1989, pp. 1743-1753. doi:10.1007/BF02663206 [12] D. J. Jensen and N. Hansen, “Effect of Recrystallization Temperature on Texture and Grain Size of Al-SiC Com- posites,” Materials Science and Technology, Vol. 7, No. 9, September 1991, pp. 369-375. [13] Y. L. Liu and D. J. Jensen, “Hardening Behaviour of Metal Matrix Composites Coupled to Numerical Predic- tions,” Strength of Materials, Vol. 23A, No. 2, February 1994, pp. 381-384. [14] Y. L. Liu and N. Hansen, “Effect of Dispersion Parame- ters and Cold Deformation on Recrystallization in of Al-SiC Composites,” Materials Science and Technology. Vol. 7, No. 6, June 1991, pp. 270-275. [15] D. Yu and P. R. Munroe, “Recrystallization in Sic Parti- culate-Reinforced 6061-Aluminum Metal-Matrix Compo- sites Following Low Strain Deformation,” Scripta Me- tallurgical and Materials, Vol. 30, No. 7, July 1994, pp. 927-932. doi:10.1016/0956-716X(94)90417-0 [16] R. Manna and J. J. Sarkar, “Effect of Second Phase Pre- cipitation on Recovery and Recrystallization Behaviour of Cold-Worked Al 2024-SiCp Composites,” Journal of Materials Science, Vol. 31, No. 2, February 1996, pp. 1625-1631. doi:10.1007/BF00357874 [17] R. A. Shahani and T. W. Clyne, “Recrystallization in Fibrous and Particulate Metal Matrix Composites,” Mate- rials Science and Engineering A, Vol. 4, No. 2, February 1994, pp. 281-285. [18] D. Yu and P. R. Munroe, “Microstructural Evolution of a Cold-Deformed 6061Al Reinforced with SiC Particles during Subsequent Annealing,” Journal of Materials Science, Vol. 31, No. 3, February 1996, pp. 625-631. doi:10.1007/BF00367878 [19] J. M. Root, D. P. Field and T. W. Nelson, “Crystallo- graphic Texture in the Friction-Stir-Welded Metal Matrix Composite Al6061 with 10 Vol Pct Al2O3,” Metallurgical and Materials Transactions A, Vol. 40A, No. 9, Septem- ber 2009, pp. 2109-2114. doi:10.1007/s11661-009-9883-4 [20] L. Ceschini, G. Minak and A. Morri, “Forging of the AA6061/23 vol%Al2O3p Composite: Effects on Micro- structure and Tensile Properties,” Materials Science and Engineering A, Vol. 513-514, No. 5, May 2009, pp. 176- 184. doi:10.1016/j.msea.2009.01.057 [21] F. J. Humphreys, “Recrystallization Mechanisms in Two- Phase Alloys,” Materials Science, Vol. 13, No. 5, May 1979, pp. 136-145. [22] P. Cotterill and P. R. Mould, “Recrystallization and Grain Growth in Metals,” Surrey University Press, Guildford, 1976. |