Paper Menu >>

Journal Menu >>

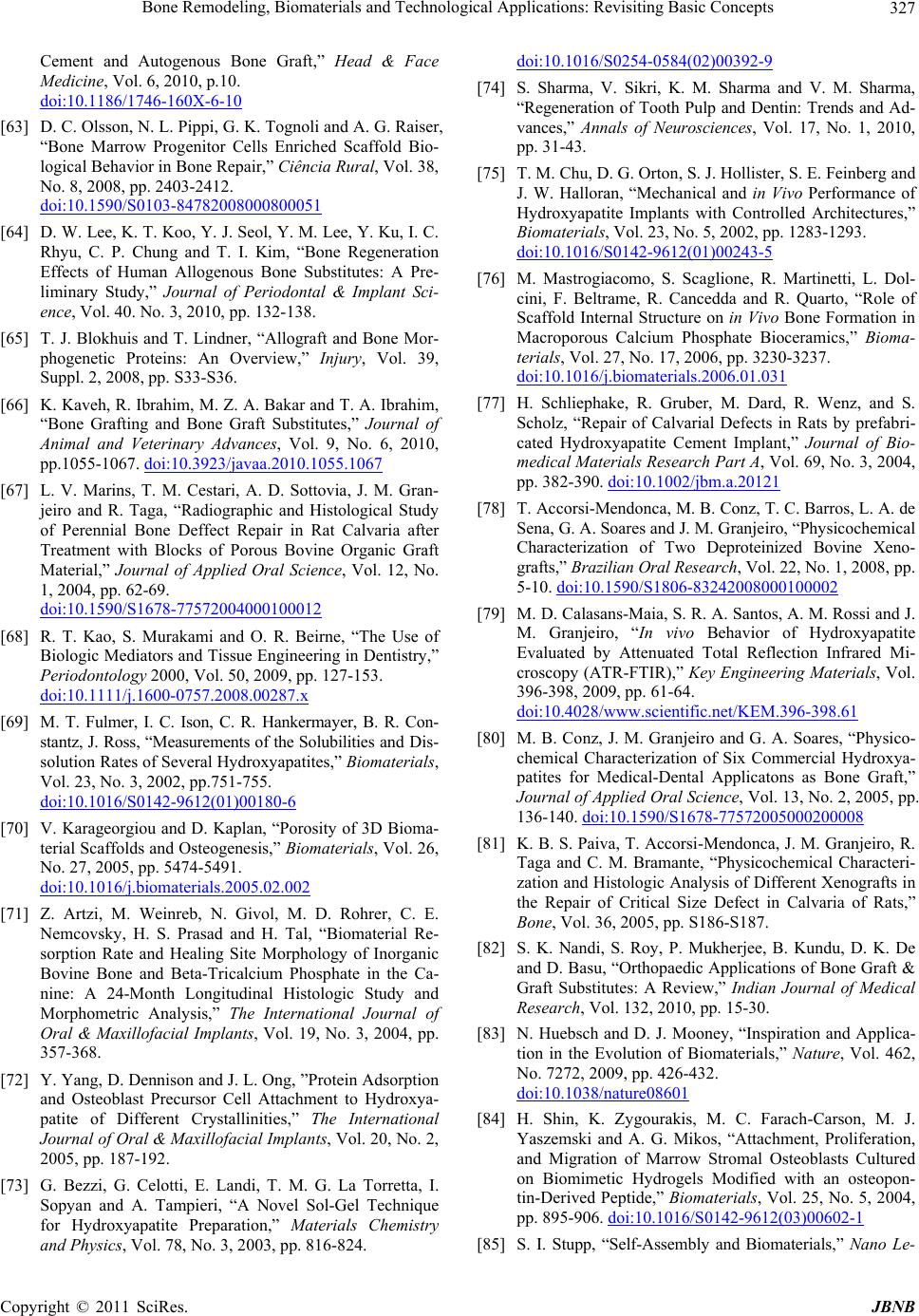

Journal of Biomaterials and Nanobiotechnology, 2011, 2, 318-328 doi:10.4236/jbnb.2011.23039 Published Online July 2011 (http://www.SciRP.org/journal/jbnb) Copyright © 2011 SciRes. JBNB Bone Remodeling, Biomaterials and Technological Applications: Revisiting Basic Concepts Patrícia C. Salgado1, Plínio C. Sathler2,3, Helena C. Castro2,3, Gutemberg G. Alves2, Aline M. de Oliveira4, Rodrigo C. de Oliveira5, Mônica D. C. Maia6, Carlos R. Rodrigues7, Paulo G. Coelho8, Andre Fuly2, Lúcio M. Cabral2, Jose M. Granjeiro2 1Program of Post-Graduation in Medical Sciences, Fluminense Federal University, Niterói, Brazil; 2Post-Graduation in Biology of Interactions, Institute of Biology, Fluminense Federal University, Niterói, Brazil; 3Program of Post-Graduation in Pathology, Fluminense Federal University, Niterói, Brazil; 4Clinical Research Unit, Antonio Pedro Hospital, Nucleus of Cell Therapy, Fluminense Federal University, Niterói, Brazil; 5School of Odontology, Fluminense Federal University, Niterói, Brazil; 6Department of Biological Sciences, Dental School of Bauru, São Paulo University, São Paulo, Brazil; 7School of Pharmacy, Federal University of Rio de Janeiro, Rio de Janeiro, Brazil; 8Department of Biomaterials and Biomimetics, New York University, New York, USA. Email: jmgranjeiro@vm.uff.br, hcastrorangel@yahoo.com.br Received March 24th, 2011; revised April 29th 2011; accepted May 8th, 2011. ABSTRACT Presently, several different graft materials are employed in regenerative or corrective bone surgery. However current misconceptions about these biomaterials, their use and risks may compromise their correct application and develop- ment. To unveil these misconceptions, this work briefly reviewed concepts about bone remodeling, grafts classifica tion and manufacturing processes, with a special focus on calcium phosphate materials as an example of a current em- ployed biomaterial. Thus a search on the last decade was performed in Medline, LILACS, Scielo and other scientific electronic libraries using as keywords biomaterials, bone remodeling, regeneration, biocompatible materials, hy- droxyapatite and therapeutic risks. Our search showed not only an accelerated biotechnological development that brought significant advances to biomaterials use on bone remodeling treatments but also several therapeutic risks that should not be ignored. The biomaterials specificity and limitations to clinical application point to the current need for developing safer products with better interactions with the biological microenvironments. Keywords: Biocompatible Materials, Bone Remodeling, Hydroxyapatite, Therapeutic Risks 1. Introduction In the last ten years, hundreds of thousands of individuals were affected by deficiencies resulting from trauma, ag- ing, degenerations and other pathologies involving the musculoskeletal system. Thus the last decade (2000-2010) was declared by The World Health Organization as the Bone and Joint Decade [1]. As a result of the musculoskeletal-related disease high incidence, the costs and incomes with treatments and medical support to take caring and maintain the quality of life of these individuals had significantly increased. This reinforced the need for novel technologies and me- thods to provide more feasible and efficient therapeutic options such as the biomaterials. In this work, we briefly reviewed several topics related to Biomaterials that are promising therapeutic alterna- tives in bone defect treatment. This review approached different concepts such as bone repair, graft classification and manufacturing technologies, also including their ap- plications, advantages and risks. We also provided a more detailed description of the main characteristics and issues related to calcium phosphate-based biomaterials. This alloplastic materials group is of wide application and is shown as an example of interesting results and first-hand experience. 1.1. Biomaterials: A Brief Beginning The term biomaterials, also referred as biomedical mate- rials, includes any substance (other than drugs) or com- bination of substances, synthetic or natural in origin, which can be used for any period of time, as a whole or as a part of a system, which treats, improves, or replaces any tissue, organ, or function of the body [2,3]. Areas such as odontology adopted testing procedures and im- proved these new biomaterials also allowing fast devel-  Bone Remodeling, Biomaterials and Technological Applications: Revisiting Basic Concepts Copyright © 2011 SciRes. JBNB 319 opment and application processes. In this practice area, the use of biomaterials go as far as bone grafting in re- generative or corrective bone surgeries and in procedures for restoring bone tissue lost during periodontal disease or endodontic lesions [4,5], filling the alveolar of ex- tracted teeth to prevent alveolar ridge volume reduction [6] and lifting maxillary sinus floor and atrophic alveolar ridge reconstructions [7-9], among others [10]. Currently, biomaterials are subjected to specific stan- dards for testing and evaluation [11,12]. According to those, any material intended for clinical use must present significant biocompatibility defined as “the ability of a material to perform with an appropriate host response in a specific application, without eliciting any undesirable local or systemic effects in the recipient or beneficiary of that therapy, but generating the most appropriate benefi- cial cellular or tissue response in that specific situation” [13,14]. Therefore, the biomechanical properties of a biomaterial must be adequate and tolerated by the host tissue [15]. In order to present such desirable features, the bioma- terials are produced associated to several materials and substances [16]. For example, the use of bone grafts to- gether with growth factors such as PDGF, TGF-α and bone morphogenetic proteins (BMPs) is based on the association of natural or recombinant proteins to a carrier such as biological or synthetic polymers (collagen or poly-L-lactic acid, respectively), ceramics (hydr-oxya- patite, inorganic bovine bone) and other materials [17]. A great variety of biomaterials is described in litera- ture for bone bioengineering purposes in cell therapy [18]. In these cases, the carrier must present (Figure 1): 1) adaptability to the damaged area; 2) osteoconductivity, characterized by good adhesion, proliferation and maturation of osteoprogenitor cells; 3) ability of acting as a barrier to surrounding tissues; 4) time of resorption compatible to the requirements for bone formation, without interfering with the substitution of the material by neoformed bone; 5) biocompatibility, non-immunogenicity and atoxic- ity; 6) radioluscence, allowing the radiographic distinction of graft from newly formed bone; Figure 1. Requirements for biomaterials act as substitute in bone bioengineering and cell therapy. 7) easy manufacture and sterilization; 8) easy handling during surgery, avoiding complex preoperatory procedures which increase the risk of infec- tion and 9) adequate microarchitecture, including interconnec- tions and porosities (200 - 900 µm), allowing the pene- tration of osteocompetent and endothelial cells and the vascularization of the neoformed tissue [18,19]. Several protocols for new biomaterials production and testing have been described in the last few years, and some are used regularly in areas such as Odontology and Orthopedics. However, to understand the principles and functioning of these biomaterials and their protocols, first it is necessary to take a look into the targets and bio- logical systems affected by them. 1.2. Tissue and Bone Repair: Knowing the Target Bone represents a specialized conjunctive tissue, charac- terized by the mineralization of the extracellular matrix (bone matrix), which can be composed of intramembra- nous or endochondral ossifications [20]. Intramembra- nous ossification occurs in the inner portions of the con- junctive membrane, where mesenchymal cells differenti- ate in osteoblasts starting bones formation (i.e. mandible body, frontal, parietal, temporal, maxillary and parts of the occipital). Differently, in endochondral ossifications bone is formed over a cartilaginous frame, which is gradually substituted by bone tissue [21]. At the molecular level, bone is constituted by an or- ganic portion, representing 35% of the bone matrix com- posed mostly by type I collagen fibers (95%), together with proteoglycans, glycoproteins and growth factors [22]. The remaining inorganic components correspond to 65% of bone weight and include calcium phosphate crystals with apatite structure. Those crystals are depos- ited along the collagen fibers and are responsible for the toughness and resistance of bone tissue [23]. Bone tissue usually presents a remarkable capacity of repair and regenerated tissue is very similar to the origin- nal bone. This is in contrast to other tissues that present the formation of fibrous connective tissue during repair (i.e. muscle and tendons) [24]. However, there are some conditions in which bone tis- sue is unable to regenerate correctly. Bone tissue devel- opment and repair are extremely dependent on extracel- lular matrix remodeling and local angiogenesis. There- fore several bone diseases result from the unbalance of those processes [21,25,26]. In the last decades, some studies have focused on the role and regulation of bone remodeling through apposition and resorption [27]. One of their main purposes was to identify signaling proteins and their role in such processes [21,25,28].  Bone Remodeling, Biomaterials and Technological Applications: Revisiting Basic Concepts Copyright © 2011 SciRes. JBNB 320 Literature described the bone remodeling dependence on growth factors, cytokines, BMPs, matrix metallopro- teinases (MMPs), alkaline phosphatase, tartrate-resistant acid phosphatase (TRAP) and nitric oxide (NO) [29], which regulate apposition and resorption in a structured way. Bone repair also depends on an adequate blood supply, mechanical stability cell migration, matrix depo- sition and remodeling, among other processes [21,30-32] (Figure 2). The use of biomaterials as promoters of bone repair may lead to: 1) formation of a surrounding fibrous con- nective tissue, known as repair by cicatrization that is an undesired process, or 2) material absorption and close integration to the tissue, known as repair by regeneration that is desirable to clinical use [33-35]. The regenerative bone repair processes become more predictable with the Guided Tissue Regeneration (GTR) technique. It is characterized by a physical barrier that is placed around to the damaged area or to the biomaterial, to promote bone cells proliferation and exclude undesir- able cells. The bone cells proliferation is responsible for the regeneration of the damaged or lost tissue [36-39] (Figure 2). 1.3. Biomaterials and Blood: Feeding the System The survival of osteocytes in grafted bone is directly re- lated not only to blood vessels support but also to viable surfaces of both endosteum and periosteum. Usually, grafts originated from bone marrow present a higher probability of helping cell survival by improving nutrient diffusion and promoting revascularization [17]. Besides nutrient and oxygen supply, the coagulation is another important aspect of the close relation between biomaterials and blood. Although many osteoconductive and degradable biomaterials are available, some interfere with platelet function or the coagulation cascade. There- fore the risk of thrombus formation during, and after prosthetic surgery increases for the patient [40]. Sometimes postoperative deep vein thrombosis occurs due to the biomaterial release into circulation (i.e. Bone Cement Implantation Syndrome - BCIS) [41-43]. In other cases, soluble components on bone cements are consid- ered toxic (i.e. methacrylate monomers) [40,44]. The contact between blood and a specific biomaterial may lead to several other coagulopathies and vascular disorders, as well as pulmonary, renal and neuronal dys- functions [45]. Usually, these disorders are associated with mild to strong inflammatory reactions. Indeed, the activation of blood plasma cascade systems (coagulation, complement and kallikrein systems) occurs right after blood contact with the biomaterial with subsequent ad- sorption of plasma proteins, depending on the biomate- rial structural and chemical features [46,47]. Figure 2. Stages of process bone tissue repair. Inflamma- tory, proliferative and remodeling phases. Usually the inflammatory response to biomaterials starts with the activation of the complement system and C3b deposition on the biomaterial surface. The sub-sequent gen- eration of C3a and C5a triggers leukocyte release of cyto- kines, prostaglandins and leukotrienes, with a wide range of pharmacological effects on cells [48,49] (Figure 3). The activation of complement also induces platelet aggregation as well as the coagulation system. Even tough these mechanisms are not fully understood, the participa- tion of the intrinsic and extrinsic pathways as a whole has been reported [48,50,51]. Therefore, safety evaluation is almost as important as the development of new biomaterials for any area of use. This should be prior and during the biomaterial appli- cation and obviously includes studies involving the bio- materials interaction with all blood systems. 1.4. How and Why Classify Biomaterials? Biomaterials may be classified based on different bio- logical features including postgrafting action and origin. These features are important to the procedures and the required attention as well as the further studies for fully understand of the biomaterial effects (Table 1). 1.5. Postgrafting Action Bone grafts can be classified as osteogeneic, osteoinduc-  Bone Remodeling, Biomaterials and Technological Applications: Revisiting Basic Concepts Copyright © 2011 SciRes. JBNB 321 Figure 3. Complement syste m activation through binding to the biomaterial surface. The activated complement attracts immune cells and triggers inflammation. Table 1. Comparison of biological characteristics of bioma- terials based on their origin and biological profile. Classification Based on Type Biological Characte r i s tic Osteogeneic Living bone cells are inserted onto a receptor site and maintains the capacity of generating novel bone tissue Osteoinductive Mesenchymal stem cells of graft site surroundings are induced to differentiate into osteogeneic cell lineages Osteoconductive able to orient the formation of new bone tissue through its support matrix, acting as a scaffold that can be simultaneously absorbed and substituted by bone tissue Biological profile Osteopromotive Allows Guided Tissue Regeneration (GTR) Autogeneic obtained from unaffected donor sites from the own receptor individual Allogeneic obtained from the bone tissue of an individual of the same species of the receptor Xenogeneic obtained from individuals of different species from the donor Origin Alloplastic synthetic materials, manufactured in different shapes, textures, sizes and compositions tive, osteoconductive and/or osteopromotive based on their biological effects after implantation onto a bone defect. Some materials may be classified into more than one functional class, thus requiring attention and further stud- ies for fully understand of the biomaterial effects. Osteogeneic: in osteogeneic grafts, living bone cells are inserted onto a receptor site and maintains the capac- ity of generating novel bone tissue. Autogeneic bone represents the main example of a graft material with os- teogeneic properties, since it is able to form bone tissue even in the absence of undifferentiated mesenchymal cells. In fact, autogeneic graft materials are also able to induce osteoinduction, osteoconduction and osteopromo- tion [24], as described in the following sections. Osteoinductive: This is a common classification for some graft materials in which mesenchymal stem cells of graft site surroundings are stimulated to differentiate into osteogeneic cell lineages. This mechanism is directly related to the activity of BMPs [52,53]. Osteoinductive grafts contribute significantly to the formation of new tissue during bone remodeling processes. This is mainly observed by using platelet-rich plasma, growth factors, demineralized lyophilized bone or frozen/irradiated autogeneic bone [54]. Osteoconductive: This biomaterial is able to orient the formation of new bone tissue through its support matrix, acting as a scaffold that can be simultaneously absorbed and substituted by bone tissue [55]. Osteoconductive biomaterials allow for bone apposition on their surfaces, guiding the repair from the border of the lesion to its center. Osteoconductive media do not promote osteoblast differentiation but ease inner bone growth and fibrovas- cular tissue formation on the graft area [56,57]. Cortical autogeneic bone, allogeneic mineralized tissue from bone banks and alloplastic or synthetic materials such as ce- ramics, polymers and composites are examples of osteo- conductive materials. Osteopromotive: The principle of osteopromotion is related to the Guided Tissue Regeneration (GTR) and the properties of physical membranes or barriers. Currently, two classes of barriers can be used for such purpose: a) absorbable (ex: polylactic acid, polyglycolic acid or type I and type III collagen) and b) non-absorbable mem- branes (ex: expanded-polytetrafluorethylene – e-PTFE). The barrier selection is directly linked to defect type, cost/benefit ratio and availability and/or interest of the patient in submitting to a second surgery for the removal of non-absorbable membranes [37,58,59]. Those barriers, when employed on GTR, should obey the following criteria: 1) biocompatibility; 2) permeability, allowing the diffusion of plasma and nutrients, but impending the transit of cells; 3) provide physical support to surrounding soft tissues, preventing them to collapse into the blood clot space; 4) protect blood vessels while the clot undergoes a re- organizing process; 5) exclude competitive cells; 6) prevent the formation of scars 7) present easy handling [37].  Bone Remodeling, Biomaterials and Technological Applications: Revisiting Basic Concepts Copyright © 2011 SciRes. JBNB 322 1.6. Origin Another classification for biomaterials is based on their origin, which include autogeneic, allogeneic, xenogeneic or alloplastic. These classes are briefly described below with the advantages and disadvantages, including a more detailed description of allogeneic calcium phosphate ma- terials [60]. Autogenous bone grafts: Also known as autografts, they are obtained from unaffected donor sites from the own receptor individual. The regeneration of the bone defect occurs by mechanisms involving osteogenesis, osteoinduction and osteoconduction [17,46,61,62]. These are the most used grafts due to their biocompatibility and non-immunogenicity, being considered sometimes as standards for bone-grafting [61]. In this graft type, the autogeneic bone matrix allows for the transference of living bone cells from the donor site to the receptor re- gion. Autogeneic grafts can be extracted from cortical bones, their medullary portions or a combination of both [17]. According to literature, bone-marrow grafts are most efficient due to their higher content of osteoprogenitor cells [63]. They can be obtained by both extraoral (iliac crest, tibia or skull) or intraoral areas (retromolar region, mandibular symphisys and maxillary tuberosities), de- pending on the volume and composition of the desired graft [10]. Once collected, the autogeneic material should be used immediately or stored in lactated Ringer medium or saline physiological solution to maintain cell viability. In the other hand, autogeneic grafts present some dis- advantages/risks, which for extraoral grafts, include: 1) patient hospitalization, 2) morbidity of the donor site, 3) post operatory scars and 4) discomfort during recovery. Differently, for intraoral grafts they are 1) higher pa- tient’s morbidity and 2) limited quantity and quality of material available for collecting [16,23,61]. These risks have stimulated the development of bone grafts from alternative biomaterials. Allogenous bone grafts: They are obtained from the bone tissue of an individual of the same species of the receptor. The allogeneic grafts present osteoinduction and osteoconduction abilities, being processed in sterile conditions and stored in bone banks [16,23,64]. The ad- vantages of allogeneic bone grafts are 1) no need of a donor site, 2) reduced use of anesthetics, 3) less bleed- ings, 4) unlimited amounts of graft material and 5) lower risks of surgical complications. Their main disadvantages include mostly 1) risk of transmission of infectious dis- eases, 2) host immune response and 3) lower predictabil- ity for the grafting outcome. Allogeneic grafts can be commercialized in several different forms, reflecting on different production costs and efficacies including: 1) frozen grafts, known as the most antigenic form; 2) lyophilized grafts, produced by washing the cortical and medullary bone from the donor, followed by tritu- rating, nitrogen freeze-drying, sterilization by ethylene oxide or irradiation and storage; 3) lyophilized and demineralized grafts, through a pre- vious treatment with 0.6 M nitric or chloridric acid and 4) irradiated grafts, which present some controversies by the lack of references on safety and efficacy of their osteoinductive properties [65]. Xenogenous bone grafts: They are also known as xenografts and are obtained from individuals of different species from the donor [66]. The most common grafts are collected from bovine bone, but literature also described porcine or caprine materials [23]. Their use presents similar advantages of allogeneic grafts, with predictable results when surgical rules are followed [67]. On the other hand, there are also disadvantages including: 1) the risk of interspecific transmission of infectious diseases, 1) host immune response and 3) lower acceptance by pa- tients and professionals due to cultural and religious as- pects of using animals material. Alloplastic bone grafts: These are synthetic materials manufactured in different shapes, textures, sizes and compositions. This category includes metallic grafts and their alloys, calcium phosphate ceramics (hydroxyapatite and tricalcium phosphate), calcium carbonate, calcium sulphate, Hard Tissue Replacement (HTR) polymers and bioglass [68]. These materials can be classified based on their porosity (dense, microporous or macroporous), crystallinity (crystalline or amorphous) and solubility (absorbable or unabsorbable) [69,70]. Synthetic grafts are associated to an osteoconductive action, characterized by bone growth into the graft mate- rial matrix, which acts as a scaffold to the regeneration of lost bone tissue [16,61,63,69]. Besides their biological properties, these materials also present relevant chemical (main composition, impurities and ionic reposition) and physical characteristics (shape, porosity, surface area and crystallinity), which directly affect material absorption function, velocity and range [65,71]. Other characteristics such as morphology, roughness, wettability and surface energy of the employed biomate- rial also affects cell adhesion, proliferation and differen- tiation, specially on osteoblasts, contributing to the for- mation of either fibrous or bone tissue [65,72]. Therefore, the manufacture of alloplastic materials for bone regen- eration purposes must be submitted to accurate controls that verify the physical, chemical and mechanical proper- ties of the material [73].  Bone Remodeling, Biomaterials and Technological Applications: Revisiting Basic Concepts Copyright © 2011 SciRes. JBNB 323 1.7. Biomaterials Based on Calcium Phosphate Calcium phosphates have been used for a long time as alloplastic materials for bone grafts or as a cover for dental implants. They are known as bioactive materials, due to their capacity of actively participating on both cicatrization and regeneration of bone tissue [74]. This capacity results from the similarity between calcium phosphate materials and the apatites found on bone tissue [23,63,69]. The major advantage of calcium phosphate-based graft materials is that both calcium and phosphate ions do not interfere on cell function and physiology of adjacent tis- sues. This feature grants a favorable tissue response to treatment with adequate toughness and mechanical resis- tance to compression. Furthermore, due to partial disso- lution onto the physiological medium, these materials release phosphate and free calcium ions. These ions seem to act as catalysts for bone formation and precipitation of a carbonated apatite layer over the surface of the bioma- terial, which allow the chemical bonding to the neo- formed bone [57,63]. Calcium phosphates can be manufactured on micro- porous (dense) or macroporous forms. Microporous ce- ramics present maximum porosity of 5% per volume, with a maximum pore diameter of 1 μm. This results in highly dense materials, with elevated resistance to com- pression [70]. Macroporous calcium phosphates, on the other hand, present 100 μm to 500 μm diameter pores, which comprise 15% or more of the total volume of the material. Its inner architecture, including size, shape and communication among pores, have an important role on the in vivo behavior of the biomaterial [75-77]. Therefore, for biomaterials with the same chemical composition, the highest is the porosity, the fastest is the absorption speed for the graft material [70]. A combination of analytical techniques is recom- mended to address the crystalline properties of calcium phosphate-based biomaterials. Such techniques include X-ray diffraction (XRD), Fourier transform infrared spectroscopy (FT-IR), scan (SEM) and transmission electron microscopy (TEM) and solubility assays [78-81]. Each one of those approaches provide specific data, and present particular limitations, causing the need for their combined use to characterize correctly the material [80]. 1.8. Future Perspective Biomaterials are artificial or natural materials that may help on restoring form and function of organs and func- tional sites and structures. Thus they not only directly help in improving human quality of life but also attend the aging population needs [3]. The future of biosynthetic bone implants still point to autologous bone grafts. There is an increasing interest in combining osteoconductive proteins in osteoconductive carrier media to facilitate timed-release delivery and/or to provide a material scaffold for bone formation. Further, advances in tissue engineering, which integrate the bio- logical, physical and engineering sciences allow the gen- eration of new carriers to repair, regenerate and restore tissue to its functional state. These new products modu- late different growth factors, evolving biological scaf- folds and incorporation of mesenchymal stem cells. Ul- timately, the development of ex vivo bioreactors with biomechanical features may provide tissue-engineered constructs for using directly in the skeletal system. The future of bone graft substitutes continues to be an expanding topic of interest [82]. The current biomaterials are not able to replicate the surface totally and/or the properties of the replaced bone, leading to failure due to insufficient bonding with juxtaposed bone, bone loss, implant loosening and/on fracture. Nanophase materials possess unique surface and me- chanical properties similar to the bone and, hence are considered to be the future generation of orthopedic biomaterials [3]. In fact, lately, the engineering devel- opment (i.e. nanotechnology) is greatly increasing bio- materials complexity as well as their biological functions [83]. Biomaterials academic research data such as the analysis of interaction with the host (i.e. binding interac- tions with cell surface receptors) and applied methodo- logical data such as self-assembly have been used for designing new biomaterials capable of modulating the maintenance and regeneration of specific tissues in the body [84,85]. Currently, to produce new more effective and safer biomaterials, the researchers should consider that bioma- terials may modulate specific cell populations distant from the implant site. This can be done either by target- ing the material to specific cells or anatomical locations or by controlling the trafficking of target cell populations. Recent reports showed biomaterials as regulators of the immune system and polymeric nano particles designed for non-invasive delivery into the body [86] and for traf- ficking through the lymphatic vessels to target T cells in the lymph nodes [87]. Similarly, nanoparticles are being designed to exploit the chemical and physical differences between normal and tumor-associated vasculature to concentrate the particles selectively within or near tu- mors, allowing subsequent drug-induced cell death [88]. Materials can also be designed to regulate outward mi- gration of transplanted stem cells, or their differentiated progeny to fulfill damaged tissues and promote regenera- tion efficiently [89]. Clearly the advances in biomaterials will include the development of more functional medical materials and  Bone Remodeling, Biomaterials and Technological Applications: Revisiting Basic Concepts Copyright © 2011 SciRes. JBNB 324 the expanded use of biomaterials into new applications. Thus, to mimic important biological processes and/or their functional behavior, it is necessary to fully under- stand these processes complexity and dynamic, which knowledge is not currently available in most cases. The application of the molecular templating of viruses to op- toelectronic device fabrication is an example of this ap- proach [83,90]. Biological systems have already in- spired the development of cell-programming matrices based on knowledge about infection process, and these matrices accomplish their task with a small subset of key molecular stimuli [91]. The biomaterials research including those with aca- demic and/or industry application purposes is quickly growing and should be redefined. This new definition may include materials that are able to modulate biologi- cal processes and those whose design and functions are inspired by natural materials since they may be crucial for improving human quality of life. 2. Conclusions This brief review showed that the biotechnological de- velopment initiated in the 50’s was accelerated in the last ten years with significant advances for using biomaterials on treating bone remodeling related processes (i.e. or- thopedic and odontological treatments). Particularly, cal- cium phosphates have performed as important biocom- patible materials to bone tissue reposition. However to- gether with these innovations, critical risks were identi- fied that can be controlled or avoided by the knowledge about the product features and their interactions with the biological microenvironments. Based on these data, all future research may focus on addressing both chemical and physical characteristics of biomaterials to better interact with these microenviron- ments. On that purpose the biological and toxicological profile of each biomaterial must be determined previ- ously to its clinical application to establish its limitation and specificity. Special attention must be given to the principles that rule a new interface, to obtain safer and effective therapeutic treatments. 3. Acknowledgments We thank the Conselho Nacional de Desenvolvimento Científico e Tecnológico (CNPq), Coordenação de Aperfeiçoamento de Pessoal Docente (CAPES-Edital Nanobiotecnologia 2008) and Fundação de Amparo à Pesquisa do Estado do Rio de Janeiro (FAPERJ) for the financial support and fellowships. REFERENCES [1] J. M. Hazes and A. D. Woolf, “The Bone and Joint Dec- ade 2000-2010,” The Journal of Rheumatology, Vol. 27, No. 1, 2000, pp. 1-3. [2] D. Williams, “Definitions in Biomaterials,” Proceedings of a Consensus Conference of the European Society for Biomaterials, Chester, 3-5 March 1986, pp. 1-72. [3] M. Geethaa, A. K. Singhb, R. Asokamania and A. K. Gogiac, “Ti Based Biomaterials, the Ultimate Choice for Orthopaedic Implants—A Review,” Progress in Materi- als Science, Vol. 54, No. 3, 2009, pp. 397-425. [4] A. Sculean, D. Nikolidakis and F. Schwarz, “Regenera- tion of Periodontal Tissues: Combinations of Barrier Membranes and Grafting Materials—Biological Founda- tion and Preclinical Evidence: A Systematic Review,” Journal of Clinical Periodontology, Vol. 35, No. 8, 2008, 106-116. doi:10.1111/j.1600-051X.2008.01263.x [5] Y. Lin, G. O. Gallucci, D. Buser, D. Bosshardt, U. C. Belser and P. C. Yelick, “Bioengineered Periodontal Tis- sue Formed on Titanium Dental Implants,” Journal of Dental Research, Vol. 90, No. 2, 2011, pp. 251-256. doi:10.1177/0022034510384872 [6] G. Serino, W. Rao, G. Iezzi and A. Piattelli, “Polylactide and Polyglycolide Sponge Used in Human Extraction Sockets: Bone Formation Following 3 Months After Its Application,” Clinical Oral Implants Research, Vol. 19, No. 1, 2008, pp. 26-31. [7] H. Browaeys, P. Bouvry and B. H. De, “A Literature Review on Biomaterials in Sinus Augmentation Proce- dures,” Clinical Implant Dentistry and Related Research, Vol. 9, No. 3, 2007, pp. 166-177. doi:10.1111/j.1708-8208.2007.00050.x [8] M. Esposito, M. G. Grusovin, P. Coulthard and H. V, Worthington, “The Efficacy of Various Bone Augmenta- tion Procedures for Dental Implants: A Cochrane Sys- tematic Review of Randomized Controlled Clinical tri- als,” The International Journal of Oral & Maxillofacial Implants, Vol. 21, No. 5, 2006, pp. 696-710. [9] P. S. Tiwana, G. M. Kushner and R. H. Haug, “Maxillary Sinus Augmentation,” Dental Clinics of North America, Vol. 50, No. 3, 2006, pp. 409-24. doi:10.1016/j.cden.2006.03.004 [10] M. A. Reynolds, M. E. Ichelmann-Reidy, G. L. Branch- Mays and J. C. Gunsolley, “The Efficacy of Bone Re- placement Grafts in the Treatment of Periodontal Osseous Defects. A Systematic Review,” Annals of Periodontol- ogy, Vol. 8, No. 1, 2003, pp. 227-265. doi:10.1902/annals.2003.8.1.227 [11] D. E. Albert, “The Important Role of Material and Che- mical Characterisation in Device Evaluation,” Medical Device Technology, Vol. 15, No. 5, 2004, pp.15-18. [12] P. E. Murray, G. C. Garcia and G. F. Garcia, “How is the Biocompatibilty of Dental Biomaterials Evaluated?” Me- dicina Oral, Patologia Oral y Cirugia Bucal, Vol. 12, No, 3, 2007, pp. E258-E266. [13] D. Williams, “Revisiting the Definition of Bio-compatibility,” Medical Device Technology, Vol. 14, No. 8, 2003, pp. 10-13. [14] M. B. Nasab and M. R. Hassan, “Metallic Biomaterials of  Bone Remodeling, Biomaterials and Technological Applications: Revisiting Basic Concepts Copyright © 2011 SciRes. JBNB 325 Knee and Hip—A Review,” Trends in Biomaterials & Artificial Organs, Vol. 24, No. 1, 2010, pp. 69-82. [15] M. Navarro, A. Michiardi, O. Castano and J. A. Planell, “Biomaterials in Orthopaedics,” Journal of the Royal So- ciety Interface, Vol. 5, No. 27, 2008, pp. 1137-1158. doi:10.1098/rsif.2008.0151 [16] M. A. Merkx, J. C. Maltha and P. J. Stoelinga, “Assess- ment of the Value of Anorganic Bone Additives in Sinus Floor Augmentation: A Review of Clinical Reports,” In- ternational Journal of Oral and Maxillofacial Surgery, Vol. 32, No. 1, 2003, pp.1-6. doi:10.1054/ijom.2002.0346 [17] M. Hallman and A. Thor, “Bone Substitutes and Growth Factors as an Alternative/Complement to Autogenous Bone for Grafting in Implant Dentistry,” Periodontology 2000, Vol. 47, No. 1, 2008, pp. 172-192. doi:10.1111/j.1600-0757.2008.00251.x [18] D. Logeart-Avramoglou, F. Anagnostou, R. Bizios and H. Petite, “Engineering Bone: Challenges and Obstacles,” Journal of Cellular and Molecular Medicine, Vol. 9, No. 1, 2005, pp. 72-84. doi:10.1111/j.1582-4934.2005.tb00338.x [19] M. Rumpler, A. Woesz, J. W. Dunlop, J. T. Van Dongen and P. Fratzl, “The Effect of Geometry on Three- Dimen- sional Tissue Growth,” Journal of the Royal Society In- terface, Vol. 5, No. 27, 2008, pp. 1173-1180. doi:10.1098/rsif.2008.0064 [20] F. Forriol and F. Shapiro, “Bone Development: Interac- tion of Molecular Components and Biophysical Forces,” Clinical Orthopaedics and Related Research, Vol. 432, 2005, pp.14-33. [21] F. Shapiro, “Bone Development and Its Relation to Frac- ture Repair. The Role of Mesenchymal Osteoblasts and Surface Osteoblasts,” European Cells & Materials, Vol. 15, 2008, pp. 53-76. [22] I. Fernández-Tresguerres-Hernández-Gil, M. A. Obera- Gracia, M. Del-Canto-Pingarron and L. Blanco-Jerez, “Physiological Bases of Bone Regeneration I. Histology and Physiology of Bone Tissue,” Medicina Oral, Patolo- gia Oral y Cirugia Bucal, Vol. 11, No. 1, 2006, pp. E47- E51. [23] R. Murugan and S. Ramakrishna, “Development of Nano- composites for Bone Grafting,” Composites Science and Technology, Vol. 65, No. 15-16, 2005, pp. 2385-2406. doi:10.1016/j.compscitech.2005.07.022 [24] K. A. Hing, “Bone Repair in the Twenty-First Century: Biology, Chemistry or Engineering?” Philosophical Tran- sactions. Series A, Mathematical, Physical, and Engi- neering Sciences, Vol. 362, No. 1825, 2004, pp. 2821- 2850. [25] G. A. Rodan and T. J. Martin, “Therapeutic Approaches to Bone Diseases,” Science, Vol. 289, No, 5484, 2000, pp. 1508-1514. doi:10.1126/science.289.5484.1508 [26] J. Street, M. Bao, L. de Guzman, S. Bunting, J. F. V. Peale, N. Ferrara, H. Steinmetz, J. Hoeffel, J. L. Cleland, A. Daugherty, N. van Bruggen, H. P. Redmond, R. A. Carano and E. H. Filvaroff, “Vascular Endothelial Growth Factor Stimulates Bone Repair by Promoting Angiogenesis and Bone Turnover,” Proceedings of the National Academy of Sciences of the USA, Vol. 99, No. 15, 2002, pp. 9656- 9661. doi:10.1073/pnas.152324099 [27] E. Neovius and T. Engstrand, “Craniofacial Reconstruc- tion with Bone and Biomaterials: Review over the Last 11 Years,” Journal of Plastic, Reconstructive & Aesthetic Surgery, Vol. 63, No. 10, 2010, pp. 1615-23. [28] B. Baroli, “From Natural Bone Grafts to Tissue Engi- neering Therapeutics: Brainstorming on Pharmaceutical Formulative Requirements and Challenges,” Journal of Pharmaceutical Sciences, Vol. 98, No. 4, 2009, pp. 1317- 1375. doi:10.1002/jps.21528 [29] T. Martin, J. H. Gooi and N. A. Sims, “Molecular Mechanisms in Coupling of Bone Formation to Resorp- tion,” Critical Reviews in Eukaryotic Gene Expression, Vol. 19, No. 1, 2009, pp. 73-88. [30] B. Clarke, “Normal Bone Anatomy and Physiology,” Clinical Journal of the American Society of Nephrology, Vol. 3, Supplement 3, 2008, pp. S131-S139. [31] M. Degidi, L. Artese, C. Rubini, V. Perrotti, G. Iezzi and A. Piattelli, “Microvessel Density and Vascular Endothe- lial Growth Factor Expression in Sinus Augmentation Using Bio-Oss,” Oral Diseases, Vol. 12, No. 5, 2006, pp. 469-475. doi:10.1111/j.1601-0825.2006.01222.x [32] L. J. Raggatt and N. C. Partridge, “Cellular and Molecular Mechanisms of Bone Remodeling,” The Journal of Bio- logical Chemistry, Vol. 285, No. 33, 2010, pp. 25103- 25108. doi:10.1074/jbc.R109.041087 [33] K. S. Jones, “Effects of Biomaterial-Induced Inflamma- tion on Fibrosis and Rejection,” Seminars in Immunology, Vol. 20, No. 2, 2008, pp. 130-136. doi:10.1016/j.smim.2007.11.005 [34] D. F. Larosa, A. H. Rahman and L. A. Turka, “The Innate Immune System in Allograft Rejection and Tolerance,” Journal of Immunology, Vol. 178, No. 12, 2007, pp. 7503- 7509. [35] A. Shekaran and A. J. García, “Extracellular Matrix-Mi- metic Adhesive Biomaterials for Bone Repair,” Journal of Biomedical Materials Research. Part A, Vol. 96, No. 1, 2011, pp. 261-272. doi:10.1002/jbm.a.32979 [36] R. C. de Oliveira, E. Carneiro, T. M. Cestari, R. Taga and J. M. Granjeiro, “Dynamics of Subcutaneous Tissue Re- sponse to the Implantation of Tetracycline-Treated or Un- treated Membrane of Demineralized Bovine Cortical Bone in Rats,” Journal of Biomaterials Applications, Vol. 21, No. 2, 2006, pp. 167-178. doi:10.1177/0885328206059798 [37] R. C. de Oliveira, R. Menezes, T. M. Cestari, E. M. Taga, R. Taga, M. A. Buzalaf and J. M. Granjeiro, “Tissue re- sponse to a Membrane of Demineralized Bovine Cortical Bone Implanted in the Subcutaneous Tissue of Rats,” Brazilian Dental Journal, Vol. 15, No, 1, 2004, pp. 3-8. [38] K. El Helow and S. El Askary Ael, “Regenerative Barri- ers in Immediate Implant Placement: A Literature Review,” Implant Dentistry, Vol. 17, No, 3, 2008, pp. 360-371. doi:10.1097/ID.0b013e3181813406  Bone Remodeling, Biomaterials and Technological Applications: Revisiting Basic Concepts Copyright © 2011 SciRes. JBNB 326 [39] M. V. Thomas and D. A. Puleo, “Infection, Inflammation, and Bone Regeneration: A Paradoxical Relationship,” Journal of Dental Research, 2011, In Press. doi:10.1177/0022034510393967 [40] A. Blinc, M. Bozic, R. Vengust and M. Stegnar, “Methyl- Methacrylate Bone Cement Surface Does Not Promote Platelet Aggregation or Plasma Coagulation in Vitro,” Thrombosis Research, Vol. 114, No. 3, 2004, pp. 179-184. doi:10.1016/j.thromres.2004.05.010 [41] M. T. Clarke, J. S. Green, W. M. Harper and P. J. Gregg, “Cement as a Risk Factor for Deep-Vein Thrombosis. Comparison of Cemented TKR, Uncemented TKR and Cemented THR,” Journal of Bone and Joint Surgery (British Volume), Vol. 80, No. 4, 1998, pp. 611-613. doi:10.1302/0301-620X.80B4.8612 [42] A. J. Donaldson, H. E. Thomson, N. J. Harper and N. W. Kenny, “Bone Cement Implantation Syndrome,” British Journal of Anaesthesia, Vol. 102, No. 1, 2009, pp. 12-22. doi:10.1093/bja/aen328 [43] H. Aita, N. Tsukimura, M. Yamada, N. Hori, K. Kubo, N. Sato, H. Maeda, K. Kimoto and T. Ogawa, “N-Acetyl Cysteine Prevents Polymethyl Methacrylate Bone Cement Extract-Induced Cell Death and Functional Suppression of Rat Primary Osteoblasts,” Journal of Biomedical Ma- terials Research Part A, Vol. 92, No 1, 2010, pp. 285-296. doi:10.1002/jbm.a.32336 [44] P. H. Nilsson, A. E. Engberg, J. Bäck, L. Faxälv, T. L. Lindahl, B. Nilsson and K. N. Ekdahl, “The Creation of an Antithrombotic Surface by Apyrase Immobilization,” Biomaterials, Vol. 31, No. 16, 2010, pp. 4484-4491. doi:10.1016/j.biomaterials.2010.02.036 [45] A. P. McGuigan and M. V. Sefton, “The Influence of Biomaterials on Endothelial Cell Thrombogenicity,” Bio- materials, Vol. 28, No. 16, 2007, pp. 2547-2571. doi:10.1016/j.biomaterials.2007.01.039 [46] Y. X. Wang, J. L. Robertson, W. B. J. Spillman and R. O. Claus, “Effects of the Chemical Structure and the Surface Properties of Polymeric Biomaterials on Their Biocom- patibility,” Pharmaceutical Research, Vol. 21, No. 8, 2004, 1362-1373. doi:10.1023/B:PHAM.0000036909.41843.18 [47] B. F. Lai, A. L. Creagh, J. Janzen, C. A. Haynes, D. E. Brooks and J. N. Kizhakkedathu, “The Induction of Thrombus Generation on Nanostructured Neutral Poly- mer Brush Surfaces,” Biomaterials, Vol. 31, No. 26, 2010, pp. 6710-6718. doi:10.1016/j.biomaterials.2010.05.052 [48] J. Hong, E. K. Nilsson, H. Reynolds, R. Larsson and B. Nilsson, “A New in vitro Model to Study Interaction be- tween Whole Blood and Biomaterials. Studies of Platelet and Coagulation Activation and the Effect of Aspirin,” Biomaterials, Vol. 20, No. 7, 1999, pp. 603-11. doi:10.1016/S0142-9612(98)00210-5 [49] D. Ricklin, G. Hajishengallis, K. Yang and J. D. Lambris, “Complement: A Key System for Immune Surveillance and Homeostasis,” Nature Immunology, Vol. 11, No. 9, 2010, pp. 785-797. doi:10.1038/ni.1923 [50] E. Cenni, D. Granchi, M. Vancini and A. Pizzoferrato, “Platelet Release of Transforming Growth Factor-Beta and Beta-Thromboglobulin after in vitro Contact with Acrylic Bone Cements,” Biomaterials, Vol. 23, No. 6, 2002, pp. 1479-1484. doi:10.1016/S0142-9612(01)00273-3 [51] E. A. Vogler and C. A. Siedlecki, “Contact Activation of Blood-Plasma Coagulation,” Biomaterials, Vol. 30, No. 10, 2009, pp. 1857-1869. doi:10.1016/j.biomaterials.2008.12.041 [52] D. M. Smith, G. M. Cooper, M. P. Mooney, K. G. Marra and J. E. Losee, “Bone Morphogenetic Protein 2 Therapy for Craniofacial Surgery,” The Journal of Craniofacial Surgery, Vol. 19, No. 5, 2008, pp. 1244-1259. doi:10.1097/SCS.0b013e3181843312 [53] M. O. Klein, P. W. Kämmerer, T. Scholz, M. Moergel, C. M. Kirchmaier and B. Al-Nawas, “Modulation of Platelet Activation and Initial Cytokine Release by Alloplastic Bone Substitute Materials,” Clinical Oral Implants Re- search, Vol. 21, No. 3, 2010, pp. 336-345. doi:10.1111/j.1600-0501.2009.01830.x [54] C. T. J. Vangsness, I. A. Garcia, C. R. Mills, M. A. Kai- ner, M. R. Roberts and T. M. Moore, “Allograft Trans- plantation in the Knee: Tissue Regulation, Procurement, Processing, and Sterilization,” The American Journal of Sports Medicine, Vol. 31, No. 3, 2003, pp. 474-481. [55] L. K. Cannada, “Viable Bone and Circulatory Factors Required for Survival of Bone Grafts,” The Orthopedic Clinics of North America, Vol. 41, No. 1, 2010, pp. 5-13. doi:10.1016/j.ocl.2009.07.008 [56] C. N. Cornell and J. M. Lane, “Current Understanding of Osteoconduction in Bone Regeneration,” Clinical Ortho- paedics and Related Research, Vol. 355, 1998, pp. S267-S273. doi:10.1097/00003086-199810001-00027 [57] R. Z. LeGeros, “Properties of Osteoconductive Biomate- rials: Calcium Phosphates,” Clinical Orthopaedics and Related Research , Vol. 395, 2002, pp. 81-98. [58] M. L. Taga, J. M. Granjeiro, T. M. Cestari and R. Taga, “Healing of Critical-Size Cranial Defects in Guinea Pigs Using a Bovine Bone-Derived Resorbable Membrane,” The International Journal of Oral & Maxillofacial Im- plants, Vol. 23, No. 3, 2008, pp. 427-36. [59] M. Retzepi and N. Donos, “Guided Bone Regeneration: Biological Principle and Therapeutic Applications,” Cli- nical Oral Implants Research, Vol. 21, No. 6, 2010, pp. 567-576. doi:10.1111/j.1600-0501.2010.01922.x [60] R. V. Shevchenko, S. L. James and S. E. James, “A Re- view of Tissue-Engineered Skin Bioconstructs Available for Skin Reconstruction,” Journal of the Royal Society Interface, Vol. 7, No. 43, 2010, pp. 229-258. doi:10.1098/rsif.2009.0403 [61] H. Chim and A. K. Gosain, “Biomaterials in Craniofacial Surgery: Experimental Studies and Clinical Application,” Journal of Craniofacial Surgery, Vol. 20, No. 1, 2009, pp. 29-33. doi:10.1097/SCS.0b013e318190dd9e [62] E. Puricelli, A. Corsetti, D. Ponzoni, G. L. Martins, M. G. Leite and L. A. Santos, “Characterization of Bone Repair In Rat Femur after Treatment with Calcium Phosphate  Bone Remodeling, Biomaterials and Technological Applications: Revisiting Basic Concepts Copyright © 2011 SciRes. JBNB 327 Cement and Autogenous Bone Graft,” Head & Face Medicine, Vol. 6, 2010, p.10. doi:10.1186/1746-160X-6-10 [63] D. C. Olsson, N. L. Pippi, G. K. Tognoli and A. G. Raiser, “Bone Marrow Progenitor Cells Enriched Scaffold Bio- logical Behavior in Bone Repair,” Ciência Rural, Vol. 38, No. 8, 2008, pp. 2403-2412. doi:10.1590/S0103-84782008000800051 [64] D. W. Lee, K. T. Koo, Y. J. Seol, Y. M. Lee, Y. Ku, I. C. Rhyu, C. P. Chung and T. I. Kim, “Bone Regeneration Effects of Human Allogenous Bone Substitutes: A Pre- liminary Study,” Journal of Periodontal & Implant Sci- ence, Vol. 40. No. 3, 2010, pp. 132-138. [65] T. J. Blokhuis and T. Lindner, “Allograft and Bone Mor- phogenetic Proteins: An Overview,” Injury, Vol. 39, Suppl. 2, 2008, pp. S33-S36. [66] K. Kaveh, R. Ibrahim, M. Z. A. Bakar and T. A. Ibrahim, “Bone Grafting and Bone Graft Substitutes,” Journal of Animal and Veterinary Advances, Vol. 9, No. 6, 2010, pp.1055-1067. doi:10.3923/javaa.2010.1055.1067 [67] L. V. Marins, T. M. Cestari, A. D. Sottovia, J. M. Gran- jeiro and R. Taga, “Radiographic and Histological Study of Perennial Bone Deffect Repair in Rat Calvaria after Treatment with Blocks of Porous Bovine Organic Graft Material,” Journal of Applied Oral Science, Vol. 12, No. 1, 2004, pp. 62-69. doi:10.1590/S1678-77572004000100012 [68] R. T. Kao, S. Murakami and O. R. Beirne, “The Use of Biologic Mediators and Tissue Engineering in Dentistry,” Periodontology 2000, Vol. 50, 2009, pp. 127-153. doi:10.1111/j.1600-0757.2008.00287.x [69] M. T. Fulmer, I. C. Ison, C. R. Hankermayer, B. R. Con- stantz, J. Ross, “Measurements of the Solubilities and Dis- solution Rates of Several Hydroxyapatites,” Biomaterials, Vol. 23, No. 3, 2002, pp.751-755. doi:10.1016/S0142-9612(01)00180-6 [70] V. Karageorgiou and D. Kaplan, “Porosity of 3D Bioma- terial Scaffolds and Osteogenesis,” Biomaterials, Vol. 26, No. 27, 2005, pp. 5474-5491. doi:10.1016/j.biomaterials.2005.02.002 [71] Z. Artzi, M. Weinreb, N. Givol, M. D. Rohrer, C. E. Nemcovsky, H. S. Prasad and H. Tal, “Biomaterial Re- sorption Rate and Healing Site Morphology of Inorganic Bovine Bone and Beta-Tricalcium Phosphate in the Ca- nine: A 24-Month Longitudinal Histologic Study and Morphometric Analysis,” The International Journal of Oral & Maxillofacial Implants, Vol. 19, No. 3, 2004, pp. 357-368. [72] Y. Yang, D. Dennison and J. L. Ong, ”Protein Adsorption and Osteoblast Precursor Cell Attachment to Hydroxya- patite of Different Crystallinities,” The International Journal of Oral & Maxillofacial Implants, Vol. 20, No. 2, 2005, pp. 187-192. [73] G. Bezzi, G. Celotti, E. Landi, T. M. G. La Torretta, I. Sopyan and A. Tampieri, “A Novel Sol-Gel Technique for Hydroxyapatite Preparation,” Materials Chemistry and Physics, Vol. 78, No. 3, 2003, pp. 816-824. doi:10.1016/S0254-0584(02)00392-9 [74] S. Sharma, V. Sikri, K. M. Sharma and V. M. Sharma, “Regeneration of Tooth Pulp and Dentin: Trends and Ad- vances,” Annals of Neurosciences, Vol. 17, No. 1, 2010, pp. 31-43. [75] T. M. Chu, D. G. Orton, S. J. Hollister, S. E. Feinberg and J. W. Halloran, “Mechanical and in Vivo Performance of Hydroxyapatite Implants with Controlled Architectures,” Biomaterials, Vol. 23, No. 5, 2002, pp. 1283-1293. doi:10.1016/S0142-9612(01)00243-5 [76] M. Mastrogiacomo, S. Scaglione, R. Martinetti, L. Dol- cini, F. Beltrame, R. Cancedda and R. Quarto, “Role of Scaffold Internal Structure on in Vivo Bone Formation in Macroporous Calcium Phosphate Bioceramics,” Bioma- terials, Vol. 27, No. 17, 2006, pp. 3230-3237. doi:10.1016/j.biomaterials.2006.01.031 [77] H. Schliephake, R. Gruber, M. Dard, R. Wenz, and S. Scholz, “Repair of Calvarial Defects in Rats by prefabri- cated Hydroxyapatite Cement Implant,” Journal of Bio- medical Materials Research Part A, Vol. 69, No. 3, 2004, pp. 382-390. doi:10.1002/jbm.a.20121 [78] T. Accorsi-Mendonca, M. B. Conz, T. C. Barros, L. A. de Sena, G. A. Soares and J. M. Granjeiro, “Physicochemical Characterization of Two Deproteinized Bovine Xeno- grafts,” Brazilian Oral Research, Vol. 22, No. 1, 2008, pp. 5-10. doi:10.1590/S1806-83242008000100002 [79] M. D. Calasans-Maia, S. R. A. Santos, A. M. Rossi and J. M. Granjeiro, “In vivo Behavior of Hydroxyapatite Evaluated by Attenuated Total Reflection Infrared Mi- croscopy (ATR-FTIR),” Key Engineering Materials, Vol. 396-398, 2009, pp. 61-64. doi:10.4028/www.scientific.net/KEM.396-398.61 [80] M. B. Conz, J. M. Granjeiro and G. A. Soares, “Physico- chemical Characterization of Six Commercial Hydroxya- patites for Medical-Dental Applicatons as Bone Graft,” Journal of Applied Oral Science, Vol. 13, No. 2, 2005, pp. 136-140. doi:10.1590/S1678-77572005000200008 [81] K. B. S. Paiva, T. Accorsi-Mendonca, J. M. Granjeiro, R. Taga and C. M. Bramante, “Physicochemical Characteri- zation and Histologic Analysis of Different Xenografts in the Repair of Critical Size Defect in Calvaria of Rats,” Bone, Vol. 36, 2005, pp. S186-S187. [82] S. K. Nandi, S. Roy, P. Mukherjee, B. Kundu, D. K. De and D. Basu, “Orthopaedic Applications of Bone Graft & Graft Substitutes: A Review,” Indian Journal of Medical Research, Vol. 132, 2010, pp. 15-30. [83] N. Huebsch and D. J. Mooney, “Inspiration and Applica- tion in the Evolution of Biomaterials,” Nature, Vol. 462, No. 7272, 2009, pp. 426-432. doi:10.1038/nature08601 [84] H. Shin, K. Zygourakis, M. C. Farach-Carson, M. J. Yaszemski and A. G. Mikos, “Attachment, Proliferation, and Migration of Marrow Stromal Osteoblasts Cultured on Biomimetic Hydrogels Modified with an osteopon- tin-Derived Peptide,” Biomaterials, Vol. 25, No. 5, 2004, pp. 895-906. doi:10.1016/S0142-9612(03)00602-1 [85] S. I. Stupp, “Self-Assembly and Biomaterials,” Nano Le-  Bone Remodeling, Biomaterials and Technological Applications: Revisiting Basic Concepts Copyright © 2011 SciRes. JBNB 328 tters, Vol. 10, 2010, pp. 4783-4786. doi:10.1021/nl103567y [86] N. Tsapis, D. Bennett, B. Jackson, D. A. Weitz and D. A. Edwards, “Trojan Particles: Large Porous Carriers of Na- noparticles for Drug Delivery,” Proceedings of the Na- tional Academy of Sciences of the USA, Vol. 99, No. 19, 2002, pp. 12001-12005. doi:10.1073/pnas.182233999 [87] S. T. Reddy, A. J. van der Vlies, E. Simeoni, V. Angeli, G. J. Randolph, C. P. O’Neil, L. K. Lee, M. A. Swartz and J. A. Hubbell, “Exploiting Lymphatic Transport and Complement Activation in Nanoparticle Vaccines,” Na- ture Biotechnology, Vol. 25, No. 10, 2007, pp. 1159-1164. doi:10.1038/nbt1332 [88] J. H. Park, G. von Maltzahn, L. Zhang, A. M. Derfus, D. Simberg, T. J. Harris, E. Ruoslahti, S. N. Bhatia and M. J. Sailor, “Systematic Surface Engineering of Magnetic Na- noworms for in Vivo Tumor Targeting,” Small, Vol. 5, No. 6, 2009, pp. 694-700. doi:10.1002/smll.200801789 [89] E. A. Silva, E. S. Kim, H. J. Kong and D. J. Mooney, “Material-Based Deployment Enhances the Efficacy of Endothelial Progenitor Cells,” Proceedings of the Na- tional Academy of Sciences of the USA, Vol. 105, No. 38, 2008, pp. 14347-14352. doi:10.1073/pnas.0803873105 [90] D. J. Needleman, M. A. Ojeda-Lopez, U. Raviv, H. P. Miller, L. Wilson and C. R. Safinya, “Higher-Order Ass- embly of Microtubules by Counterions: From Hexagonal Bundles to Living Necklaces,” Proceedings of the Na- tional Academy of Sciences of the USA, Vol. 101, No. 46, 2004, pp. 16099-16103. doi:10.1073/pnas.0406076101 [91] J. L. Tan, J. Tien, D. M. Pirone, D. S. Gray, K. Bhadriraju and C. S. Chen, “Cells Lying on a Bed of Microneedles: An Approach to Isolate Mechanical Force,” Proceedings of the National Academy of Sciences of the USA, Vol. 100, No, 4, 2003, pp. 1484-1489. doi:10.1073/pnas.0235407100 |