Journal of Minerals and Materials Characterization and Engineering

Vol.03 No.02(2015), Article ID:54505,8 pages

10.4236/jmmce.2015.32011

Performance Assessment of Selected Nigerian Vegetable Oils as Quenching Media in Hardening Process for Medium Carbon Steel

Joseph Babalola Agboola1*, Oladiran Abubakre Kamardeen1, Edeki Mudiare1, Michael Bolaji Adeyemi1, Samuel Ayo Afolabi2

1Department of Mechanical Engineering, Federal University of Technology, Minna, Nigeria

2Department of Civil and Chemical Engineering, University of South Africa (Unisa), Johannesburg, South Africa

Email: *joe_agboola@yahoo.com

Copyright © 2015 by authors and Scientific Research Publishing Inc.

This work is licensed under the Creative Commons Attribution International License (CC BY).

http://creativecommons.org/licenses/by/4.0/

Received 10 February 2015; accepted 6 March 2015; published 10 March 2015

ABSTRACT

A comparative study was carried out to investigate the suitability of some selected Nigerian vegetable oils as alternative quenchant to SAE40 engine oil for industrial heat treatment of Medium Carbon steels. The study involved the characterization of physicochemical properties and fatty acid profile of cotton seed oil, palm kernel oil, neem seed oil and palm oil. The quenching performance of these vegetable oils was conducted at quenchant bath temperatures of 34˚C, 50˚C, 70˚C, and 100˚C. SAE40 engine oil (Standard quenchant) and tap water served as control. The effect of cooling rates of the quenching media on mechanical properties and microstructure of the quenched steel samples were investigated. The results obtained show that the different vegetable oils have different viscosity and viscosity-temperature behavior just as their molecular structures were different. The mechanical properties of the as-quenched specimens in these oils show that the hardness of steel quenched in palm kernel oil was highest 40.85HRC. As received sample absorbed the highest amount of energy (183 J) before fracture while sample quenched in water absorbs least energy (28 J). Hence vegetable oil is suitable as alternative quenchant to petroleum based SAE40 engine oil for quenching medium carbon steels, without cracking or distortion, the most suitable among them being palm kernel oil.

Keywords:

Quenching, Vegetable Oil, Fatty Acid, Mechanical Properties, Microstructure

1. Introduction

Most steel parts such as gears, precision guages, bearings, tools and dies produced today are heat treated before being put into service. Parts are heat treated to enhance particular properties, such as hardness, toughness and corrosion resistance, and to improve uniformity of properties. The exact heat treatment applied depends on both the type of alloy and the intended service conditions [1] . The main types of heat treatments often used to modify the microstructure and mechanical properties of engineering materials particularly steels are annealing, normalizing, hardening and tempering [2] .

Quenching of steels involves the process of heating a part above upper critical temperature to austenitizing temperature and holding at this temperature for a specified soaking time followed by intense cooling in a suitable quench medium. Quenching prevents the formation of ferrite or pearlite and allows the formation of bainite or martensite [3] .

Quench hardening is one of the most important processes of heat treatment that can improve the performance of steel greatly. It is also one of the major causes of rejected components and production losses due to cracks and distortion in the material. Achieving desired mechanical properties and minimizing the possibility of occurrence of quenching cracks are the key indicators of successful hardening process. Quenching to develop martensitic structures without warping or cracking depends on the hardenability of the steel part, the quenching temperature and the severity of quenching medium [4] .

Therefore, the technical challenge of quenching is to select the quenching medium and process that will minimize the various stresses that develop within the part to reduce cracking and distortion, while at the same time providing heat transfer rates sufficient to yield the desired as-quenched properties.

Over the years, water, brine and mineral based oils are the most commonly used to harden steel because they are readily available. The relative severity of quench of these media rates brine as having the highest severity while oil is considerably less drastic [5] . Although water quenching is faster and less costly than oil quenching, the degree of distortion that accompany water quenching can be very high, therefore oil quenching which is less severe than water quenching is generally preferred [6] . However, because of environmental concerns and growing regulations over contamination and pollution, associated with petroleum based oils, it is of continuing interest to identify a safer, renewable and biodegradable alternative quenchant to petroleum based oil. Vegetable oils are currently one of the most commonly identified environmentally friendly renewable, biodegradable and less toxic alternatives [7] .

Vegetable oils are natural products of plant origin consisting of ester mixtures derived from glycerol with chains of fatty acid containing about 14 to 20 carbon atoms with different degree of unsaturation [8] . Physicochemical properties of triglyceride and its applications depend upon fatty acid constituents in their molecule. However, the differences are due primarily to chain length, degree and position of unsaturation. No oil has any fixed combination of the different fatty acids present in it, but the proportions of these will vary with locality, soil, season, and other factors. This accounts for differences between the same species of oil from different places, or harvested at different times. It is also the reason why different vegetable oils exhibit different inherent properties or why one vegetable oil may be favoured for an application, such as quenching relative to another [9] .

The objective of this work is to explore the suitability of cotton seed oil, palm kernel oil, neem seed oil and palm oil as alternative quenchant to SAE40 engine oil and tap water by studying the effect of the physicochemical properties and molecular structure of the oils on their quenching performance.

2. Materials and Methods

2.1. Materials

The materials used for this study was medium carbon steel obtained from Ajaokuta steel company limited, Ajaokuta, Kogi State, Nigeria. The average chemical composition of the steel is given in Table 1. The oils under investigation (palm kernel oil, cotton seed oil, neem seed oil and palm oil) are typical vegetable oils produced in Nigeria. A total of six quenching media comprising of palm kernel oil, cotton seed oil, neem seed oil, palm oil, SAE40 engine oil and tap water were studied. The SAE40 engine oil and tap water served as control used for comparison in this study.

2.2. Method

2.2.1. Determination of Physicochemical Properties of the Oils

Investigation of the oils properties in this study considered those properties that directly affect the use of oil as quenchant. Properties such as i) Viscosity, ii) Flash point, iii) Pour point, iv) Acid value, v) Iodine value. The viscosity of each sample of the oils was measured according to ASTM D445-06. The viscosity index (VI) was determined according to ASTM D2270-04. The Acid number (AN) was determined by a titration procedure using potassium hydroxide (KOH) and was reported as milligrams of KOH per gram of sample (mgKOH/g). Acid number (AN) is given by the expression:

(1)

(1)

where 56.1 = molar mass of the KOH;

V = Volume of KOH solution in ml;

N = Normality of KOH solution;

W = Weight of sample in g.

Iodine number of each oil was determined according to ASTM D5554-95. Flash point of oil was measured using the Pensky-Martens closed Tester (PMC) procedure. The fatty acid ester composition of the four vegetable oils were determined by a gas chromatographic analysis procedure using a Model GCMS-QP2010 PLUS Shimadzu, Japan gas chromatograph equipped with a flame ionization detector set to 300˚C and a “split” injection system ratio of 1:30 at 280˚C.

2.2.2. Mechanical Properties Determination

Hardness values determinations were carried out on test?pieces cut from the middle portion of the as-quenched specimens. The hardness impressions were taken transversely in two perpendicular directions along the cross- section of the quenched steel specimens using Rockwell hardness testing machine (Leco LM 700 AT) under applied load of 490.3 MN and dwell time of 10 sec. on a “C” scale (HRC). Hardness values were recorded at different points to obtain an average value. Two repeat tests were performed for each quenching medium and the average taken as representative of the hardness obtained for each treatment.

Tensile tests were conducted on an Instron Universal Testing machine Model 3369 by using standard tensile test specimens of 5.0 mm in diameter and gauge length of 20 mm. The tensile strength, percentage reduction in area and percentage elongation were determined from the Load-extension curves. The impact energy test was carried out to measure the toughness of the as-quenched steel specimens on Izod impact testing machine Model IT-30 according to ASTM D256 in various selected quenching media.

3. Results and Discussion

The average chemical composition of the steel used is given in Table 1. The physicochemical properties and the fatty acid ester compositions of the quenching media are entered in Table 2 and Table 3 respectively. The acid, the iodine, the viscosity values, flash point and thermal conductivity based on this current study are entered in Table 2. The effect of selected quenching media on the mechanical properties of the quenched medium carbon steel is entered in Table 4. Figures 1-4 are the bar charts of hardness values, tensile strength, percentage elongation, and impact energy of the quenched medium carbon steel. The various microstructures developed after quenching the carbon steel in selected quenching media are presented in Table 4 and Micrographs 1-7.

This study has shown the oils under investigation to contain mainly fatty acids in their chemical composition (Table 3). The saturated fatty acid contents of these vegetable oils are lauric, myristic, palmitic, stearic while the unsaturated fatty acids include oleic and linoleic.

The quenching characteristics of medium carbon steel in the selected vegetable oils were studied in this research work to evaluate the possibility of using vegetable oils as alternative quenchant to SAE40 engine oil for industrial heat treatment of Medium Carbon steels. The hardness, tensile strength, percent elongation, percent reduction in area and impact energy were used as major criteria in assessing each vegetable oil under investigation. The photomicrographs of the as-quenched specimen were used to correlate the mechanical properties values obtained.

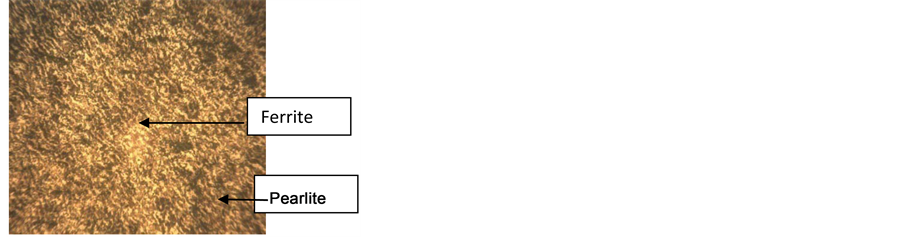

The microstructure of the as-received medium carbon steel is composed of a mixture of pearlite and ferrite

Figure 1. Average hardness values of steel samples quenched in different quench media.

Figure 2. Tensile strength of steel samples quenched in different quench media.

Figure 3. % elongation of steel samples quenched in different quench media.

Table 1. Chemical composition (wt %) of the medium carbon steel used.

Figure 4. Impact values of steel samples quenched in different quench media.

Micrograph 1. Microstructure of as-received medium carbon steel sample. The structure consists of pearlite (dark) in the matrix of ferrite (white) (400×).

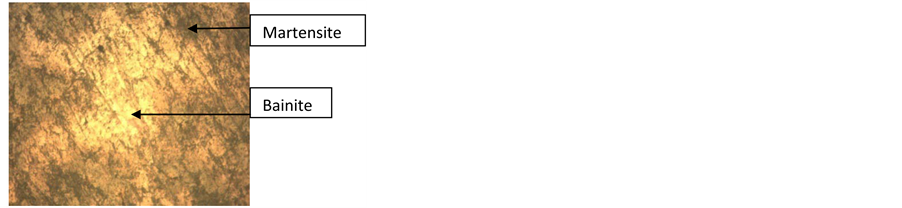

Micrograph 2. Microstructure of cotton seed oil quenched sample showing martensite structure (dark) with bainite (grey) and retained austenite (white) (400×).

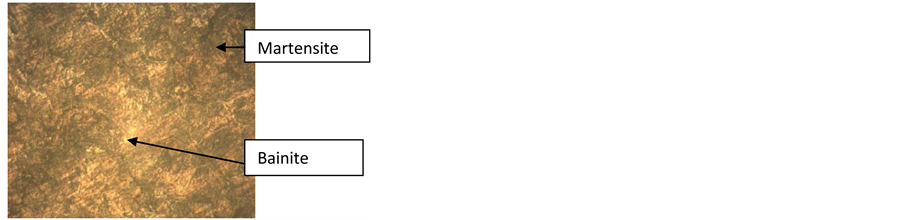

Micrograph 3. Microstructure of palm kernel oil quenched sample. Predominantly martensite (dark) with some bainite (grey) (400×).

Micrograph 4. Microstructure of neem seed oil quenched steel sample. Predominantly martensite (dark) and pearlite (grey) (400×).

Micrograph 5. Microstructure of palm-oil quenched steel sample. Predominantly martensite (dark) and pearlite (Grey) (400×).

Micrograph 6. Microstructure of SAE40 engine oil quenched steel sample. Structure consists of martensite (dark) and pearlite (light) (400×).

Micrograph 7. Microstructure of steel sample quenched in tap-water. Structure consists predominantly of martensite (dark) (400×).

Table 2. Summary of physicochemical properties of the quenching media.

Table 3. Percentage fatty acids of selected vegetable oils (w%).

*saturated; **unsaturated; Note: 1. Percentages may not add up to 100% due to presence of other minor constituents not listed.

(see Micrograph 1 and Table 4). The microstructures obtained in the as-quenched specimens affect the mechanical properties measurement results.

The photomicrographs of the carbon steel sample quenched in palm kernel oil and water reveal predominately martensitic structure (see Micrograph 3 and Micrograph 7 and Table 4), while the specimens quenched in cotton seed oil, neem seed oil and SAE40 engine oil (standard quenchant) show mainly a mixture of martensitic structure and bainite (lower bainite) (see Micrograph 2, Micrograph 4 and Micrograph 6 and Table 4).

The micrograph of the specimen quenched in palm oil reveal mainly a mixture of martensite and bainite (upper bainite) structure (see Micrograph 5 and Table 4) The different microstructures observed are as a result of the different rates of cooling in different quenching media used as shown in Table 4. Essentially, all the microstructures observed were ferrite, pearlite, bainite and martensite.

As compared to the ductile behaviour of the as-received medium carbon steel, specimens quenched in the six quenching media exhibited brittle fracture as indicated by the almost zero value of percentage elongation (Table 4). It was observed that higher hardness values were obtained for the palm kernel oil and cotton seed oil quenched specimens but lower than water quenched specimen. While lower hardness values were obtained for

Table 4. Effects of quenching media on mechanical properties of medium carbon steel.

the neem seed oil and palm oil quenched specimens than both the SAE40 engine oil and water quenched specimens. The hardness value of the water quenched specimen and the observed microstructure conform to the expectation.

All the vegetable oil quenched specimens exhibited higher Izod impact values than the water-quenched specimen and no cracks were observed in the specimens indicating suitability of the media for quenching of this particular steel alloy. Palm kernel oil quenched sample exhibited superior mechanical properties in relation to hardness values compared to other vegetable oils used.

The viscosity index of each of the vegetable oil used is shown in Table 2. It has been established in this research work that palm oil have the highest viscosity value followed by cotton seed oil, neem seed oil, palm kernel oil and then SAE40 engine oil.

The unsaturated/saturated ratio of Cotton seed oil, neem seed oil, palm kernel oil and palm oil are in the order of: Palm kernel oil < palm oil < Cotton seed oil < Neem seed oil.

Among the vegetable oils evaluated, palm kernel oil is the most saturated and most stable with respect to quenching while Neem seed oil is the least (see Table 3).

4. Conclusions

From the results obtained, it can be concluded that:

Extensive characterization of all the vegetable oils used was carried out and the correlation between physicochemical properties, fatty acid profile and their quenching characteristics were established.

Viscosity Index (VI) of Palm kernel oil, neem seed oil, cotton seed oil and palm oil are higher than that of SAE40 which means that their viscosity is less sensitive to temperature variation than SAE40 engine oil.

The two most common saturated fatty esters in the vegetable oils used for this study are palmitic and stearic, while the unsaturated ester are oleic and linoleic. The degree of saturation is in the order of: Palm kernel oil > palm oil > cotton seed oil > neem seed oil.

Average hardness value ranked in descending order as:

Water > palm kernel oil > cotton seed oil > SAE40 > palm oil > Neem seed oil.

Two of the vegetable oils (palm kernel and cotton seed) exhibited substantially fast cooling during the quenching period as reflected by their hardness values obtained which suggest that they would be suitable as alternative to petroleum based SAE40 engine oil for quenching low hardenability steels such as medium carbon steels without cracking or distortion. The most suitable among them being palm kernel oil based on mechanical properties of its quenched steel sample as compared to others.

Based on the heat flow parameters, palm kernel oil can be used as fast quench medium while cotton seed oil and neem seed oil may be used as slow quench oil. Among the oils tested, palm oil exhibited the least quenching ability.

References

- Adeyemi, M.B. and Adedayo, S.M. (2009) Vegetable Oils as Quenchants for Hardening Medium Carbon Steel. Journal of Applied Science and Technology, 14, 74-78.

- Agboola, J.B. (2014) Performance Assessment of Selected Nigerian Vegetable Oils as Quenching Media during Heat Treatment of Medium Carbon Steel. Ph.D. Thesis, Department of Mechanical Engineering, Federal University of Technology, Minna.

- Fadare, D.A., Fadara, T.G. and Akanbi, O.Y. (2011) Effect of Heat Treatment on Mechanical Properties and Microstructure of NST37-2 Steel. Journal of Minerals and Materials Characterization and Engineering, 10, 299-308.

- Fernandez, P. and Prabhu, K.N. (2008) Comparative Study of Heat Transfer and Wetting Behavior of Conventional and Bioquenchants for Industrial Heat Treatment. International Journal of Heat and Mass Transfer, 51, 526-538. http://dx.doi.org/10.1016/j.ijheatmasstransfer.2007.05.018

- Hassan, S.B, Agboola, J.B., Aigbodion, V.S. and Williams, E.J. (2010) Hardening Characteristics of Plain Carbon Steel and Ductile Cast Iron Using Neem Oil as Quenchant. Journal of Minerals and Materials Characterization and Engineering, 5, 31-36.

- Kobasco, N.I., Carvalhode Souza, E., Canale, L.C.F. and Totten, G.E. (2010) Vegetable Oil Quenchants: Calculation and Comparison of the Cooling Properties of a Series of Vegetable Oils. Journal of Mechanical Engineering-Slovenia, 56, 131-142.

- Prabhu, K.N. and Fernandez, P. (2007) Determination of Wetting Behaviour Spread Activation Energy and Quenches Severity of Bioquenchants. Metallurgical and Materials Transaction, 38, 631-640.

- Souza, E.C., Fernandes, M.R., Augustinho, C.M., Campos, F.C. and Totten, G.E. (2009) Comparison of Structure and Quenching Performance of Vegetable Oils. Journal of ASTM International, 6.

- Totten, G.E., Bates, C.E. and Clinton, N.A. (1993) Handbook of Quenchants and Quenching Technology. ASM International, 62, 140-144.

NOTES

*Corresponding author.