Open Journal of Business and Management

Vol.05 No.04(2017), Article ID:78731,17 pages

10.4236/ojbm.2017.54053

Bangladesh Invented Bioplastic Jute Poly Bag and International Market Potentials

Shaharia Pavel, Vijit Supinit

Graduate School of Business, Siam University, Bangkok, Thailand

Copyright © 2017 by authors and Scientific Research Publishing Inc.

This work is licensed under the Creative Commons Attribution International License (CC BY 4.0).

http://creativecommons.org/licenses/by/4.0/

Received: July 31, 2017; Accepted: August 22, 2017; Published: August 25, 2017

ABSTRACT

In one minute, one million plastic bags are in use around the world and in Europe, plastic carrier bags are produced 3.4 million tons in a year and average European uses about 500 plastic bags per year that takes 100s of years to degrade and not only contaminates the environment but also directly impairments many living organisms. Bangladeshi scientist invented jute poly bag using jute cellulose that is bio-degradable and bio-plastic in nature, which is substitute of conventional poly bag. It will play a significant role in concern with environment, temperature, air, soil and sea pollution as well as the opportunity to retain the glory of Bangladeshi jute in international market and farmers to keep smile. In the paper, we will analyze international marketing strategy, product positioning, competitiveness and potentiality in international market through SOWT, marketing mix & porter’s five forces analysis. Our observation that newly invented jute biodegradable poly bag will gain market share in international plastic & bioplastic industry as well as the potential market for exporting all over the world and especially in Europe and North America. Bangladesh has both absolute and comparative advantages in producing jute poly bags.

Keywords:

Bioplastic, a Substitute of Poly Bag, Exports Potentiality, International Marketing and Competitive Analysis

1. Introduction

Jute is a cash crop of Bangladesh and the glory & fame of golden fiber is fading gradually due to lack of jute diversified product and competiveness of market with supplementary products. Since last five decades, plastic industry has been dominating jute market by attractiveness, diversity, longevity, and user-friendly as well as cheap compared to jute made product. On the other hand, jute industry could not be able to compete with plastic industry for the lacking of government support, more concentration on plastic industry all over the world, lack of environmental awareness and research on jute diversified products, which are the main reasons of losing glory and fame of jute industry. But by the blessing of people awareness, the situation is gradually improving, which has great concern about the global warming, soil pollution, sea pollution, huge wastage management cost and threatening for animals planets. According to a New York Times article, only plastic bag is used each year 100 million to a trillion but the surprising that only small portion of these bags are recycled takes about 1000 years to go moldy.

Polyethylene bags are the most common plastic bags that are made from crude oil and natural gas. Both oil and gas are nonrenewable energy sources, meaning that they are in limited supply. On the contrary, jute is natural and renewable as much as needed ensuring fresh air and environment. There are a few alternatives of plastic poly bag that is, jute, cotton, canvas, non-woven and bamboo bags which are a safer alternative to plastic bags but all are not convenience as plastic bag in use for bringing liquids and warping wet foods. But in right time, Bangladeshi scientists are able to invent substitute of poly bag as the same strength. The happiest news that scientist had already been able to produce bio-plastic from algae has huge positive impact, rather than uses of corn to produce bio-plastic.

Bangladesh National Jute Fair (2017) [1] , the Bangladesh Jute Mills Corporation (BJMC) have participated with the aim of showcasing unique bio-degradable and eco-friendly products that are supplementary of poly bag. Jute Diversification Promotion Centre (JDPC) and the textiles ministry jointly organized the fair to draw an attention of domestic entrepreneurs & buyers and foreign buyers. Though yet no commercial name is set, it could be mentioned as “Jute Poly Bag”.

The plastic is derived from natural materials rather that from crude oil or petroleum and it could be bio-degradable or non-bio-degradable. So, the jute poly bag is made of bio-plastic that is bio-degradable (two to three months). Through the analysis we focused on world bio-plastic industry and positioning the newly invented jute poly bag as well as finding the appropriate market and marketing strategies.

In Bangladesh, many jute factories have already been closed to overcome overhead cost but now by the invention of eco-friendly jute poly bag and by getting the opportunity to enter in highly demandable bio-plastic industry, the fame and glory of jute could be retained. As moving to new industry, the analysis will be focused on analysis of world bio-plastic demand and prospect of Bangladesh jute poly bag as well as specify the target market and find the answer of important question:

1. What are the strength and weakness of Bangladesh jute industry?

2. What are the competitive factors in international bio-plastic market?

3. What are the recommendations to get market share in bio-plastic industry?

4. What will be entry mode in international market?

5. Which market segment has potentiality for Bangladeshi jute poly bag?

The main objectives of this study:

1. To find a strategic way to introduce jute poly bags in international market.

2. To understand capacity of Bangladesh jute industry.

3. To find best entry mode in international market.

4. To recognize target segment of potential customers.

5. To assess the competitive factors Bio-plastic industry.

6. To classify the proper strategies for successful intervention in international market.

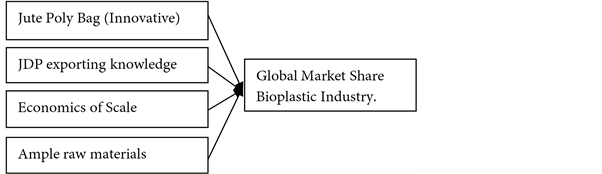

To meet above objectives, here we draw a conceptual framework that will help us to understand the variables that helps to gain market share in international potential markets.

Jute poly bag is an innovative as well as value added product that helps to gain market share. Economics of scale helps to gain market share through mass production and minimizing overhead cost to maximize profit. On the other hand, knowledge on exporting jute diversified product (JDP) in international market will help to maintain supply chain efficiency and lastly, the available raw materials in production in demand will also help to gain economic scale in product and operations and finally to gain market share.

1.1. Graphical Presentation of Jute Production and Product Demand All over the World

The Bar charts (Figure 1) shows the export of raw jute in over the world and it mentioned that Bangladesh is the key exporter of raw jute all over the world. The Bar charts (Figure 2) represents in raw jute production both Bangladesh and India play key role in the world. The Bar chart (Figure 3) denotes that Bangladesh has the highest market share in exporting of jute products and the pie chart (Figure 4) illustrates world’s import of jute products and the near East (Egypt, Iran, Saudi Arabia, Sudan, Syria, Turkey) segment holds 34% of world jute products and Europe imports 15% as well as Nepal & Thailand jointly 15% [2] .

Figure 1. World raw jute production. X axis (Period 2008-2014) & Y axis (100 K Bales where as 1 bales = 180 kg). Source: Indian Jute mills association and FAO Statistic, December 2014 & author calculation [2] .

Figure 2. World raw jute export. X axis (Time period 2008-2014) & Y axis (Raw jute export in 100 K bales). Source: Indian Jute mills association and FAO Statistic, December 2014 & author calculation [2] .

Figure 3. World jute product export. X axis (period 2008-2014) and Y axis (Export Jute product in 1 K tones). Source: Indian Jute mills association and FAO Statistic, December 2014 & author calculation [2] .

Figure 4. World jute product import (import of Jute products all over the world in %). Source: Indian Jute mills association and FAO Statistic, December 2014 & author calculation [2] .

1.2. Invented Jute Poly Bag

Figures 5-7 Bangladeshi scientist Dr. Mubarak Ahmad Khan, presently working as scientific advisor of Bangladesh Jute Mills Corporation (BJMC) and former Chief Scientific Officer of Bangladesh Atomic Energy Commission invented a biodegradable and eco-friendly bag from jute cellulose.

It seems to Poly Bag [1] but in reality the bag is made by jute it has similar strength of polythene bag that is 100% eco-friendly, recyclable and will be amalgamated with soil within 3 - 4 months. Main chemical ingredients are Jute cellulose, Synthetic polymer as binder (biodegradable) & Cross-linker for chemical reaction. Jute holds about 72% - 75% cellulose and 50% - 55% could be extracted.

According to Dr. Mubarak Ahmad Khan the product could be used in garments packaging, food packaging, cover ice-cream, readymade garments, rice, sugar and even dairy milk. They have tested for a long time to test quality change and contamination but there was no contamination or quality problem. That means the bag is not harmful for human health.

1.3. World Potential Bioplastic Market

Energy and Gold Ltd. (2016) [3] presented an interesting analysis on global growth of Bio-industry from the source of Grand view Research (2014), European Bio plastics (2013), BCC Research 2014, Nexant Inc. (2012) that forecasted that in 2019 the total plastic industry value will be $561 billion and the Bio-plastic industry will $21 billion (4% market share) and in 2030, total plastic market value will $1127 Billion and Bio-plastic market value $ 324 Billion (40% market share). They also mentioned that bio-plastic market expected to grow at 30% CAGR 2013-2030 but the traditional plastic industry growth only 3% annually.

Figure 5. Optical microscopic image.

Figure 6. Jute poly bag’ sample.

Figure 7. Garment products and food products are packed for quality testing.

In Figure 8 these data show the potentially of future market of bio-plastic industry as well as the Europe is the largest regional market for bio plastic packaging, with close to one-third of world consumption in 2015. North America, Asia and South & Central America are forecast to show higher growth rates than Europe for bio plastic packaging over the forecast period, according to the report.

1.4. World Bioplastic Production Capacity and Forecasting

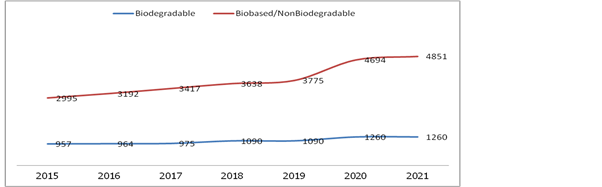

Figure 9, the world bio-degradable plastic production capacity is expected to be 1260 thousand tons in 2021. Bangladeshi jute poly bag also in the category of bio-degradable plastic and aiming that the production capacity will increase when Bangladesh will go for production. But the world production capacity is still insufficient to meet demand and supply equilibriums in international market of bio-plastic [4] .

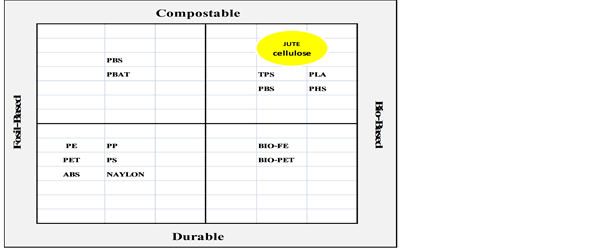

1.5. Jute Cellulose Poly Bag Positioning

Figure 10, in general there are three kinds of plastics are used such as bio-plastic, bio-degradable polythene & conventional plastic. Bio-plastic could be two types [5] such as bio-degradable-bio-plastic and no-bio-degradable. Basically bio-plastic is made of corn starch to produce PLA (Polylactide acid), sugarcane ethanol to produce Bio-Pet, Bio-PE, Bio-Pa, Bio-Poly lactic acid. The Bio-degradable plastics are made of conventional plastic but it could be degradable by sun-light and present of Oxygen that is called photodegradable, oxy-degradable or bio-degradable. The third one is recycle able that the conventional plastic products and some bio-plastic are recycle able for reuse. In conventional poly Bags, High Density Polyethylene (HDPE) Bags are commonly used in supermarkets, service stations and food outlets is manufactured from

Figure 8. Global bioplastics for packaging. Source: Smithers Pira.

Figure 9. World bioplastic prodution capacity forcasting (1000 Tons). Source: European Bio-plastics, Nova Institute (2016).

Figure 10. Product positioning.

ethylene and a by-product of gas or oil refining, these types of bags are fully recyclable but do not biodegrade. Low Density Polyethylene (LDPE) branded bags and used as “boutique” bags at stores selling higher value goods at department stores. LDPE is manufactured from ethylene, a by-product of gas or oil refining. Like HDPE, LDPE does not biodegrade.

Bangladesh invented jute bio-degradable poly bag (Jute cellulose) are similar to bio-plastic and high & low density, that is bio-degradable as well as compostable (two-three months). So, the bio-plastic industry will be the main competitor of the product and other industry conventional [6] and durable bio-plastic industry will also be factor to entry in international market. The bio-plastic industry is growing industry in the world due to the big concern of environment and awareness of end used and decreasing uses of non-renewable resources pushing back conventional plastic industry. But still conventional plastic industry is the most active player in the world market which has the maximum market share.

2. Literature Reviews

MA Jalil, MN Mian, MK Rahman (2013) [7] analyzed on the plastic bags and its damaging impact on environment and agriculture and suggested to use alternative of poly bags like jute, bio-degradable plastic compare to less harmful on environment.

Rahima Akter (2015) [8] noted that Australia would be a potential market for Bangladesh jute diversified product and getting benefits of duty free access as listed in LDC and also mentioned that the competitive advantage of Bangladesh jute products are based on both the product differentiation and cost leadership.

According to plasticbagfreeday.org (2017) [9] shows that most bags are simply thrown out and Less than 1% is recycled. They are mostly made from Polyethylene that takes 100 years to degrade. To produce one ton plastic bags nearly 11 barrels oils is required. Every year we use 100 million tons of plastic and 10% of this plastic end up in the oceans and without punishment. It takes 100s of years to degrade and they not only contaminate the environment but actually directly harm many living organisms and most are made of crude oil that is a finite resource.

Daily Sun online newspaper (2017) [10] reported on Bangladesh newly invented poly bag and mentioned that the Textiles and Jute Ministry has commenced a pilot project to produce biodegradable poly bags from jute as a substitute to polythene at Latif Bawani Jute Mills in Demra, Dhaka.

CPD Occasional Paper Series (2011) [11] Bangladesh’s performance in FY2009-10 indicates that growth of jute export has once again bounced back in recent times, with export of raw jute and jute goods posting robust growth rates of 32.5 per cent and 100.6 per cent respectively. She has a unique opportunity now to regain her past glory in jute in view of the emerging global market opportunities. They also suggested that both market and product diversification are important and the key to attaining both of these will be Bangladesh’s ability to raise her competitive strength. In all probability the size of the global jute market is set to grow in the coming years. Bangladesh’s strategy should be to enhance her market share in the growing global market.

Textile today (2017) also reported on Jute poly bag discovered by [1] Dr. Mubarak and it could begin a new era of reviving jute, mentioned that Bangladesh can claim its geographical indication (GI) product in future like Jamdani saree which will enhance its global value and can protect its right to Bangladesh. If the govt. encourages the jute cultivators and give facilities then very soon the proposed “Sonali Bag” will be new optimism for Bangladesh moreover the world and the people will get appropriate substitute of plastic bag.

Thegardian (2010) reported that [12] Bangkok is holding a “No Bag, No Baht” campaign to reduce the 600,000 plastic bags the Thai capital consumes every day BMA figures show that every day, more than 600,000 plastic bags are used in this city of nine million people. Their annual disposal cost reaches more than 600 million baht (18.4 million dollars), city officials have said. Local media have quoted BMA deputy governor Porntep Techapaibul as saying that of the city’s daily 10,000 tonnes of trash, about 1800 tonnes are plastic bags, a number projected to increase by about 20 percent each year.

3. Research Methodology

Throughout the research, we use descriptive analysis using SOWT analysis to find out strength and weakness of Bangladesh jute industry and Bio-plastic industry competitiveness analysis with Porter’s five forces model and 4p’s of marketing mix concept. All data are collected from secondary sources i.e. Organization of Plastic Bag Free World, Plastic Industry Association of Washington, Indian Jute mills associations, Smithers Pira, Bangladesh Jute Mills Corporations, European commission online website, Online magazine Packaging Strategies, Energy and Gold Ltd., Daily-Sun newspaper, the largest petrochemical market information provider―ICIS, One line newspaper Textile Today, The Guardian, Thailand Board of Investment, Biotic organization of Thailand as well as article of different journals.

4. Analysis, Findings and Results

4.1. SWOT Analysis

Through the SWOT analysis we have observed that the strengths of Bangladesh are fertile land for jute production, experienced farmer and friendly weather for jute cultivation, low labor cost ($68) [13] , Government support, Ongoing research on jute diversified product (JDP) and bioplastic. Bangladesh is one of the highest among jute production and exporting countries and Jute products are environment friendly, biodegradable and new product line in Bio-plastic. In addition, Factor of productions are in favor of Bangladesh for Bio-plastic (land, labor, capital and entrepreneurship). Though, there are some weakness such as lack of infrastructure development, less investment in research and development, experienced marketer to compete with conventional Plastic and Bio-plastic industry in international market. But Bangladesh has many opportunities i.e. increasing demand of JDP and bio-plastic in world market, changing consumer mind to shift to eco-friendly products, countries are banding and encouraging to use jute product, increasing concern of environmental issues. The main threats are conventional plastic industry for their convenience, user friendly, cheaper and attractiveness. By inventing Bio-Plastic poly bags and increasing demand could be big strength in future for Bangladesh jute industry. Taking this opportunity Bangladesh could overcome the weakness of infrastructure development and more investment in research and production of quality jute and products. As Bangladesh has absolute & comparative advantage in jute producing that will help to get cost leadership through mass production and strengthen ability to face the threat of conventional and Bio-plastic poly bag industry. More attention in research in development and holistic approach in training, planning, executing and marketing will help minimize the weakness and to avoid threats.

4.2. Porter’s Five Forces Analysis

4.2.1. The Intensity of Competitive Rivalry

Research & Market (Biodegradable Plastics Market by Type, 2015) Biodegradable plastics market in the global is still youth and accounts for less than 1% of the overall plastics market. The latest market data study by European Bio plastics shows that wrapping remains the largest fields of application for bio plastics with almost 40% of the total bio plastics market in 2016. The data also confirms a significant amount of acceptance of bio plastics materials in many other sectors, including consumer goods (22%) and applications in the automotive and transport sector (14%) and the construction and building sector (13%), where technical performance polymers are being used. In bio-plastic industry there are a few well known producers for example Solegear Bioplastics (SGB.V) which has developed proprietary high-performance bio-plastics that it customizes to produce finished end user products and packaging. Another big producer, Solegear which has taken a different approach from other bioplastic companies by using an outsourced production model to lower overall costs, deliver capital efficiency and global distribution. Metabolix, Inc. (MBLX) has developed and commercializing speciality high-performance biopolymers based on a PHA platform (polyhydroxyalkanoates) that also are an environmentally sustainable alternative to petroleum-based plastics. In this industry entry barrier is moderate due to huge capital investment and government support is needed to gain market share. But exit barrier is high as huge investment in technology and in production.

4.2.2. Threat of New Entrances

Siam Commercial Bank, Thailand (2014) [14] Prospects of demand increasing to 5 - 6 million tons in 2016 production capacity has to increase to catch up demand, in which most of the additional bioplastic plants will be in Asia and South America. Still market competition is not significant in measure but in coming year market will be much more competitive due to ongoing research and interest to investment. Bio-plastic market is less competitive in nature and the main competition with conventional plastic where as bio-plastic gains only 1% of international market share. To enter into bio-plastic industry, government support, innovation and capital investment are required to gain economics of scale and for mass production. But still there are many companies are in this industry but they didn’t able to gain economics of scale compare to conventional plastic industry. The main raw materials of bio plastic are PLA which is still costly compare to petroleum or crude oil. On the other hand, Bangladesh has the possibility to gain economics of scale and gain market share in world bio-plastic packing industry. Entry barrier in this industry is high compare to conventional plastic industry. There are many sole proprietorship companies could be found in conventional plastic but a few chances to enter in bio plastic industry for sole & partnership companies or SME’s due to adequate land, labour and capital as well as innovation product is the key success factor.

4.2.3. The Threat of Substitute Products

Bangladesh bio-plastic poly bag is the substitute of conventional plastic poly bag and some bio-degradable poly bags. But all over the world countries are discoursing in using, producing and distributing. Many countries have already banned plastic poly bags China, India, Somalia, Uganda, Rwanda Botswana, South Africa, Kenya & Ethiopia including Bangladesh [15] introduced a strict ban in 2002. The environmentalists are the strongest opposition of traditional plastic bags and the present innovation of bio-plastic day by day getting market share all over the world. At first phase Bangladesh will produce poly bag that main customers are food packing industry. European Bio-plastic organization (2016) [16] shown that all over the world 4.16 million tones bio-plastic was produced but 39% was used for packing industry. That means near about 1.62 million tons bio-plastic used by packing industry including food packing. On the other hand, the demand of plastic poly bags near about 10 million tons (the world counts, 2017) but the production of Bio-plastic only 1.62 million the gap still huge. The main substitute of Bangladeshi Jute poly bag is those bags that are made by Bio-plastic. But in terms of cost of production the threat will be manageable in world market.

The PLA (poly lactic acid) segment is the highest growing segments in the biopolymers market. PLA is one of the commonly accepted biodegradable polyesters and can be synthesized using either renewable or non-renewable routes that is water-resistant and decomposes within three weeks into the industrial composting process. That’s why PLA is used in the packaging sector and textile industry. In terms of materials, the global bio-plastics market is segmented as bio-PET, bio-PE, bio-PA, bio-degradable polyesters, PLA & PLA blends, starch blends, PHA and others. But still PLA producing is costly [17] that is derived from renewable sources basically maize and sugarcane. Davies (2011, Marketing Director, Nature works) PLA is marketed under Nature Works’ Ingeo brand name is priced at $0.90 - 1.00/lb [18] delivered in bulk in the US, close to the prices of conventional polymers such as PP and PS.

4.2.4. The Bargaining Power of Customers/Buyers

Technavio (2016) leading vendors in Bio-plastic market are BASF, Nature, WorksArkema, Novamont, Plantic. In addition to big brand owners including Danone, Coca-Cola, PepsiCo, Heinz, Tetra Pak, Unilever and L’Occitane in the packaging market, or Ford, Mercedes, VW, Toyota in the automotive market have launched or integrated bioplastic products [19] . With strong brand names driving the development, market penetration is gaining speed. All these brands company has great influence in the global market but the demand and production capacity in world market still imbalance that will create pressure on vendor bargain power. On the other hand, Bangladesh is the only country that are using jute to produce poly bag that will be more cheaper compare to existing Bio-poly Bag.

4.2.5. Bargaining Power of Supplier

Farmers are the producer of the raw jute that is purchased by some intermediaries and sales to spinners, mills, exporter of raw jutes and farmers also directly sale to jute mills. In between some government agencies monitor the price and transactional activities. So, there are very few changes of increase barging power of jute producer in a sudden. In the content of Bangladesh, supplier bargaining power is avoidable.

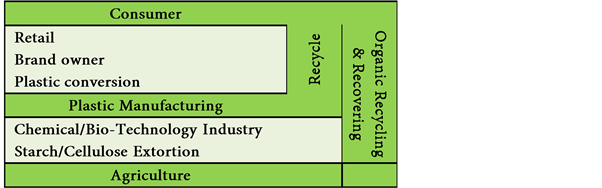

5. Bioplastic Industry Value Chain

The figure shows (Figure 11) in value chain of bioplastic industry, the first initiative comes from agriculture and through the process the value added product goes to customer. Here noted that the value chain compare between Bioplastic

Figure 11. Value chain of bioplastic industry. Source: European Bio plastics e.v.

and conventional plastic industry that in the bioplastic industry the plastic wastage goes to manufacturer for reusing or it is goes to green field to decompose without any environmental hazardous. In Bio-Plastic industry agriculture sector is the key input player in value chain where renewable source and eco-friendly raw materials are used to produce bio-plastic. In Bangladesh Jute will be used to produce bio-plastic poly bag that is a natural plant which helps to environment to balance CO2. Jute cultivation is dependent on the climate, season, and soil. Almost 85% of the world’s jute cultivation is concentrated in the Ganges Delta. This fertile geographic region is shared by both Bangladesh and India (mainly West Bengal). As the invented bio-plastic poly bag will be made from raw jute cellulose for that the farmer could directly supply to factory without intermediary. Then finally the target retailer and brand owner will be food packing industry that uses near about 40% of global bio-plastic production in national and international market. In the end the consumed product is recycled by the natural way without or less impact in environment.

6. International Marketing Strategy

6.1. Target Market

Figure 8 shows market consumption of bio-plastic for packing and Europe and North America consumption 35% & 27%. On the other hand, Europe imports 15% of world jute goods. The EU is Bangladesh’s most important trading partner, accounting for around 24% of Bangladesh’s total trade in 2015. EU imports from Bangladesh are dominated by clothing, accounting for over 90% of the EU’s total imports from Bangladesh. Bangladesh has a good trade relationship with Europe that could be also a potential market for Bangladeshi bio-plastic. Packing Strategies magazine (2017) noted that the largest regional market for bioplastic packaging is [20] Europe with 31% share of the global bioplastic packaging consumption. In terms of end-use categories, non-food is the largest area of application for bioplastic packaging in 2017, accounting for almost 46% of global consumption. This reflects significant bioplastics consumption for garbage bags and carry-out bags. Food is the second largest end-use sector, followed by beverage bottles. Bioplastic beverage bottle consumption has grown dramatically since 2012, following the introduction of bio-derived PET for soft drinks bottles, and will account for almost 22% of bioplastics for packaging consumption in 2017.

6.2. Market Access

As a Least Developed Country (LDC) [21] , Bangladesh benefits from the most favourable administration available under the EU’s Generalized Scheme of Preferences (GSP), duty free quota and free access to the European Union for exports of all products and EU imports 15% of world jute products that mostly export from Bangladesh. Bangladeshi exporter has skilled and knowledge on the European Union market as well as distribution channel that will make ease to export bio-plastic in it.

6.3. Market Entry

As the green field of the bio-plastic production in Bangladesh therefore very few chances to relocate the green field plant to other countries due to availability of raw jute, low labour cost, fertile land and government support. So, the best way to get access in international market through export marketing that could be direct and indirect exporting.

6.4. Marketing Mix

6.4.1. Product

Innovation is the best idea of gaining market share in international market by finding the market gap and taking cost leadership a company can gain monopolistic business opportunity. The product that Bangladesh going to offer in international market that has the quality and opportunity to attain market leader hip specially in packing and poly bag segment in both conventional and bioplastic industry. The main ingredient of the product is jute cellulose and biodegradable synthetic polymer as binder that is very similar to Poly Bag but in actuality the bag is made by jute it has same potency of polythene bag that is 100% eco-friendly, recyclable and will be merged with soil within 3 - 4 months.

6.4.2. Promotion

By organizing and participating in international trade fair. Pay attention to international media about the new innovation and offering to environmental and health benefits. Using more in readymade garments and foods packing that is exported to international market.

6.4.3. Price

Price of the product would be less than or similar the conventional poly bag but not more than bioplastic poly bag. As the poly bag will be made from jute and Bangladesh is number one exporting country of JDP. So, it will able to get the challenge of cost leader ship in international market.

6.4.4. Distribution

From domestic market to export destinations, there are four more members― transporting agencies, shipping companies, freight forwarders, wholesaler/ distributors in export market, retails or small shop and finally customers. The best way is to use same distribution channel that is used for JDP and readymade garments to export world market.

7. Conclusions & Recommendation

There are a few alternatives of plastic poly bags which are as convenient as poly bags. A few companies are producing bio-degradable poly bags that are made by crude oil and natural gas non-renewable sources which are not bio-plastic. Bio-plastics are made from natural sources basically collected through cultivation in green field, though it is contradictory of gaining benefits because of crop production [22] which needs water, oil & land and some are essential food for human & animal. But Bangladesh invented bioplastic and biodegradable poly bags that are more encouraging compared to corn based bio-plastic because jute production takes less effort for bulk production and not eatable. Although some scientists are hoping to produce bio-plastic from algae but it is still not sufficient and ongoing research.

The strength of Bangladesh, one of the highest jute producing countries of the world, farmers are well experienced to produce high quality jute and the newly invented jute poly bag that is a value added product which will help to gain global market share. We also found that the main competitors are PLA producing countries but still producing PLA (Ploy lactide acid, Corn starch) is costly that’s why in the past many start-up companies were not able to sustain in long run but some organizations are producing & marketing all over the world by getting help from government and environmentalist. Through the competitive analysis, we understand that there are monopolistic markets for Jute poly bags and negligible threat of substitute as well as bargaining power of supplier and consumer that will not affect all due to world demand and supply which is still a far way to get equilibrium.

Bangladesh has sufficient knowledge in exporting jute & readymade garments all over the world for a long time especially in European Union where she gets duty free export opportunity mostly in all products and we suggest focusing EU to get cost leadership in known market at first phase. We also suggest concentrating on Asian market especially in India and China though this market will be competitive in near future due to availability of resources in corn starch production where forecasted that China will be a leader in Asian as well as world market in producing corn starch. Most of the currently [20] planned volume production facilities are being implemented in Thailand, India and China, and over 1/3 quarters of bioplastics will be produced in Asia by 2022.

Branding and marketing through international media and more participation in international trade fair demonstrate the benefits and usefulness.

To strengthen absolute advantage, Bangladesh should encourage and support SME’s to get more involvement in production and distribution. Product diversification, usefulness, low pricing strategy are the most important to sustain in international market. Furthermore, investment in research and technological improvement should be taken in consideration to get economics of scale in innovation, production and operations.

8. Limitation and Future Research

As the product is newly invented and still in production phase for that, the details of usefulness, customer acceptance, quality of the product and final production capacities to meet demand are still not tested. One of the big challenges is insufficient data to measure and forecast future adaptability. In future, research could be conducted on customer acceptance and environmental effectiveness of newly invested poly bags and on how to get involvement of SME’s in bioplastic industry to strengthen absolute advantage where as huge investment and research required compared to conventional plastic industry. In conventional plastic industry, many SME’s are involved in production and marketing but in bioplastic industry, SME’s involvement is still a big challenge.

Cite this paper

Pavel, S. and Supinit, V. (2017) Bangladesh Invented Bioplastic Jute Poly Bag and International Market Potentials. Open Journal of Business and Management, 5, 624-640. https://doi.org/10.4236/ojbm.2017.54053

References

- 1. TextileToday (2017) Jute Poly Bag’ Discovered by Dr. Mubarak Could Begin a New Era of Reviving Jute. http://www.textiletoday.com.bd/jute-poly-bag-discovered-bjmc-begin-new-era-reviving-jute/

- 2. Production of Raw Jute, World Jute Products Statistics, Data (2015). http://www.ijma.org/world-jute.html

- 3. Global Bioplastics Market Predicted to Grow 350%. http://energyandgold.com/2016/03/10/an-enormous-investment-opportunity-in-a-rapidly-growing-space/

- 4. Compostable Plastic Bags Carry Goods and Hopes for the Future (2016). http://www.bioplasticsmagazine.com/en/news/meldungen/05042016-new-nova-report.php

- 5. Lertvilai, P. (2016) Bio Plastic Industry in Thailand the Development Update. http://www.biotec.or.th/Bioeconomy2016/images/document/3%20Dr.Pisuth%20Lertvilai.pdf

- 6. Thai Plastics Industry Adding Value, Environment Protection (2012). http://www.boi.go.th/tir/issue/201210_22_10/42.htm

- 7. Jalil, A., Mian, N. and Rahman, M.K. (2013) Using Plastic Bags and Its Damaging Impact on Environment and Agriculture: An Alternative Proposal. International Journal of Learning and Development, 3, 1-14. https://doi.org/10.5296/ijld.v3i4.4137

- 8. Akter, R. (2015) Jute Goods Exports to Australia: An Analysis of Market Potentials for Bangladeshi Jute Products. Vol. 5, 21-29.

- 9. A Plastic Bag Free World! International Plastic Bag Free Day (2011). https://www.plasticbagfreeday.org/facts

- 10. Government Launches Project to Produce Poly Bags from Jute (2017). http://www.daily-sun.com/post/225927/Government-launches-project-to-produce-poly-bags-from-jute

- 11. Rahman, M. and Khaled, N. (2011) Global Market Opportunities in Export of Jute. http://www.cpd.org.bd/pub_attach/op93.pdf

- 12. Theguardian (2010) Thailand Fights Addiction to Plastic Bags. https://www.theguardian.com/environment/2010/jun/28/thailand-plastic-bags

- 13. http://www.nytimes.com/2013/11/05/world/asia/bangladesh-takes-step-toward-raising-38-a-month-minimum-wage.html

- 14. https://www.scbeic.com/en/detail/product/467

- 15. National Roadmap for the Development of Bioplastics Industry (2008-2012). http://www.nia.or.th/bioplastics/download/bioplast_roadmap_en.pdf

- 16. http://www.european-bioplastics.org/about-us/organisation/

- 17. Leuven, K. (2015) Producing Biodegradable Plastic Just Got Cheaper and Greener. https://phys.org/news/2015-07-biodegradable-plastic-cheaper-greener.html#jCp

- 18. High Polymer Prices Make PLA an Attractive Alternative—Nature Works (2011). https://www.icis.com/resources/news/2011/05/20/9462068/high-polymer-prices-make-pla-an-attractive-alternative-natureworks/

- 19. https://www.technavio.com/report/global-computing-devices-interactive-projectors-market

- 20. Global Bioplastics for Packaging Forecast to Grow by 17% CAGR to 2022 (2017). http://www.packagingstrategies.com/articles/89742-global-bioplastics-for-packaging-forecast-to-grow-by-17-cagr-to-

- 21. Bangladesh—European Commission (2017). http://ec.europa.eu/echo/where/asia-and-oceania/bangladesh_en

- 22. Bioplastics—Plastics Industry Association (2016). http://www.plasticsindustry.org/sites/plastics.dev/files/2016PMWBioplasticsIA.pdf