22 R. Fang et al. / Natural Science 1 (2009) 17-22

Copyright © 2009 SciRes. OPEN ACCESS

0100200 300 400 500 600700 800 900

10

20

30

40

50

60

70

80

90

100

Dosage of coagulant (mg/L)

EH-lignin

Graft copolymer

TOC removal rate of dye wastewater(%)

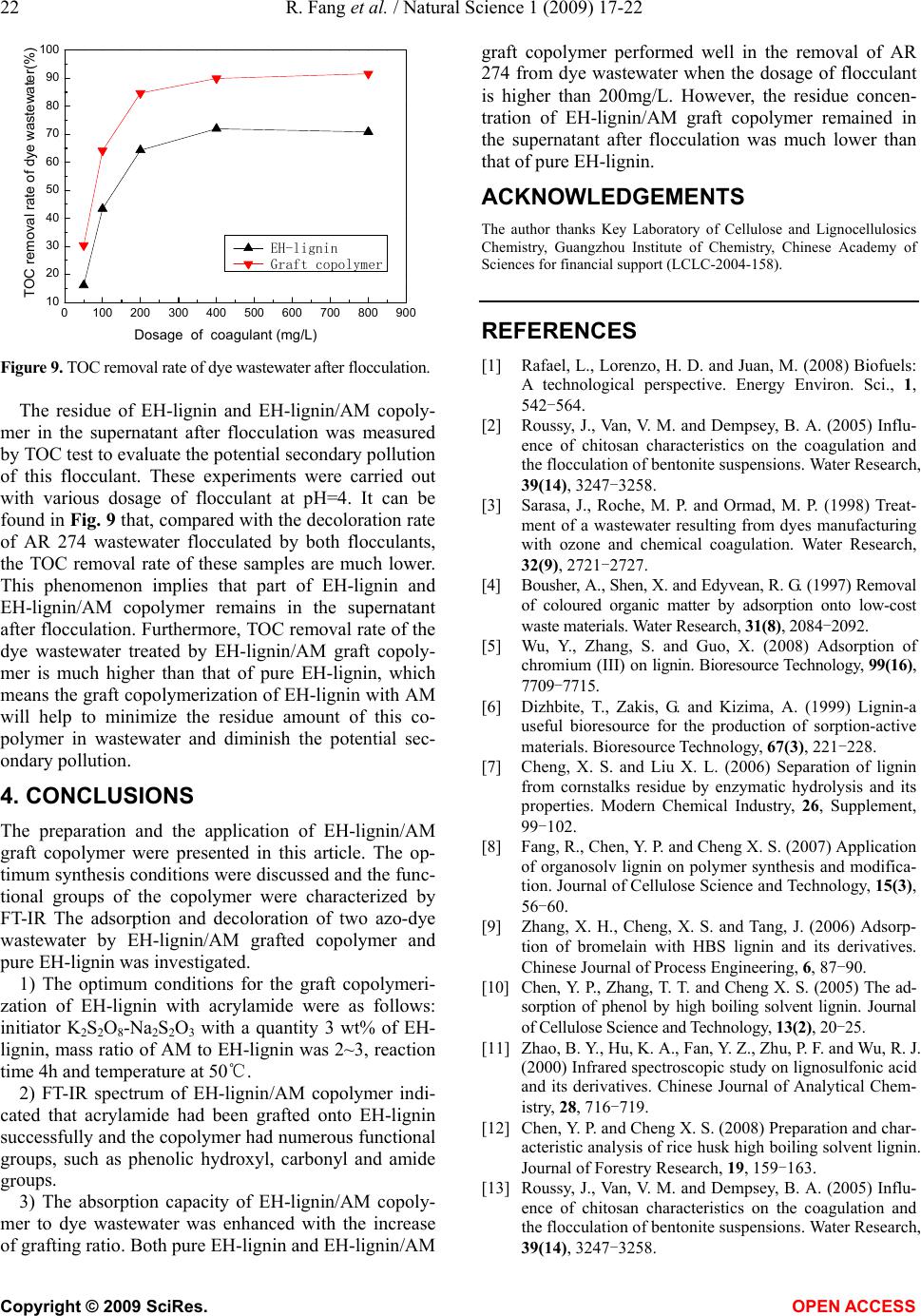

Figure 9. TOC removal rate of dye wastewater after flocculation.

The residue of EH-lignin and EH-lignin/AM copoly-

mer in the supernatant after flocculation was measured

by TOC test to evaluate the potential secondary pollution

of this flocculant. These experiments were carried out

with various dosage of flocculant at pH=4. It can be

found in Fig. 9 that, compared with the decoloration rate

of AR 274 wastewater flocculated by both flocculants,

the TOC removal rate of these samples are much lower.

This phenomenon implies that part of EH-lignin and

EH-lignin/AM copolymer remains in the supernatant

after flocculation. Furthermore, TOC removal rate of the

dye wastewater treated by EH-lignin/AM graft copoly-

mer is much higher than that of pure EH-lignin, which

means the graft copolymerization of EH-lignin with AM

will help to minimize the residue amount of this co-

polymer in wastewater and diminish the potential sec-

ondary pollution.

4. CONCLUSIONS

The preparation and the application of EH-lignin/AM

graft copolymer were presented in this article. The op-

timum synthesis conditions were discussed and the func-

tional groups of the copolymer were characterized by

FT-IR The adsorption and decoloration of two azo-dye

wastewater by EH-lignin/AM grafted copolymer and

pure EH-lignin was investigated.

1) The optimum conditions for the graft copolymeri-

zation of EH-lignin with acrylamide were as follows:

initiator K2S2O8-Na2S2O3 with a quantity 3 wt% of EH-

lignin, mass ratio of AM to EH-lignin was 2~3, reaction

time 4h and temperature at 50.℃

2) FT-IR spectrum of EH-lignin/AM copolymer indi-

cated that acrylamide had been grafted onto EH-lignin

successfully and the copolymer had numerous functional

groups, such as phenolic hydroxyl, carbonyl and amide

groups.

3) The absorption capacity of EH-lignin/AM copoly-

mer to dye wastewater was enhanced with the increase

of grafting ratio. Both pure EH-lignin and EH-lignin/AM

graft copolymer performed well in the removal of AR

274 from dye wastewater when the dosage of flocculant

is higher than 200mg/L. However, the residue concen-

tration of EH-lignin/AM graft copolymer remained in

the supernatant after flocculation was much lower than

that of pure EH-lignin.

ACKNOWLEDGEMENTS

The author thanks Key Laboratory of Cellulose and Lignocellulosics

Chemistry, Guangzhou Institute of Chemistry, Chinese Academy of

Sciences for financial support (LCLC-2004-158).

REFERENCES

[1] Rafael, L., Lorenzo, H. D. and Juan, M. (2008) Biofuels:

A technological perspective. Energy Environ. Sci., 1,

542-564.

[2] Roussy, J., Van, V. M. and Dempsey, B. A. (2005) Influ-

ence of chitosan characteristics on the coagulation and

the flocculation of bentonite suspensions. Water Research,

39(14), 3247-3258.

[3] Sarasa, J., Roche, M. P. and Ormad, M. P. (1998) Treat-

ment of a wastewater resulting from dyes manufacturing

with ozone and chemical coagulation. Water Research,

32(9), 2721-2727.

[4] Bousher, A., Shen, X. and Edyvean, R. G. (1997) Removal

of coloured organic matter by adsorption onto low-cost

waste materials. Water Research, 31(8), 2084-2092.

[5] Wu, Y., Zhang, S. and Guo, X. (2008) Adsorption of

chromium (III) on lignin. Bioresource Technology, 99(16),

7709-7715.

[6] Dizhbite, T., Zakis, G. and Kizima, A. (1999) Lignin-a

useful bioresource for the production of sorption-active

materials. Bioresource Technology, 67(3), 221-228.

[7] Cheng, X. S. and Liu X. L. (2006) Separation of lignin

from cornstalks residue by enzymatic hydrolysis and its

properties. Modern Chemical Industry, 26, Supplement,

99-102.

[8] Fang, R., Chen, Y. P. and Cheng X. S. (2007) Application

of organosolv lignin on polymer synthesis and modifica-

tion. Journal of Cellulose Science and Technology, 15(3),

56-60.

[9] Zhang, X. H., Cheng, X. S. and Tang, J. (2006) Adsorp-

tion of bromelain with HBS lignin and its derivatives.

Chinese Journal of Process Engineering, 6, 87-90.

[10] Chen, Y. P., Zhang, T. T. and Cheng X. S. (2005) The ad-

sorption of phenol by high boiling solvent lignin. Journal

of Cellulose Science and Technology, 13(2), 20-25.

[11] Zhao, B. Y., Hu, K. A., Fan, Y. Z., Zhu, P. F. and Wu, R. J.

(2000) Infrared spectroscopic study on lignosulfonic acid

and its derivatives. Chinese Journal of Analytical Chem-

istry, 28, 716-719.

[12] Chen, Y. P. and Cheng X. S. (2008) Preparation and char-

acteristic analysis of rice husk high boiling solvent lignin.

Journal of Forestry Research, 19, 159-163.

[13] Roussy, J., Van, V. M. and Dempsey, B. A. (2005) Influ-

ence of chitosan characteristics on the coagulation and

the flocculation of bentonite suspensions. Water Research,

39(14), 3247-3258.