Paper Menu >>

Journal Menu >>

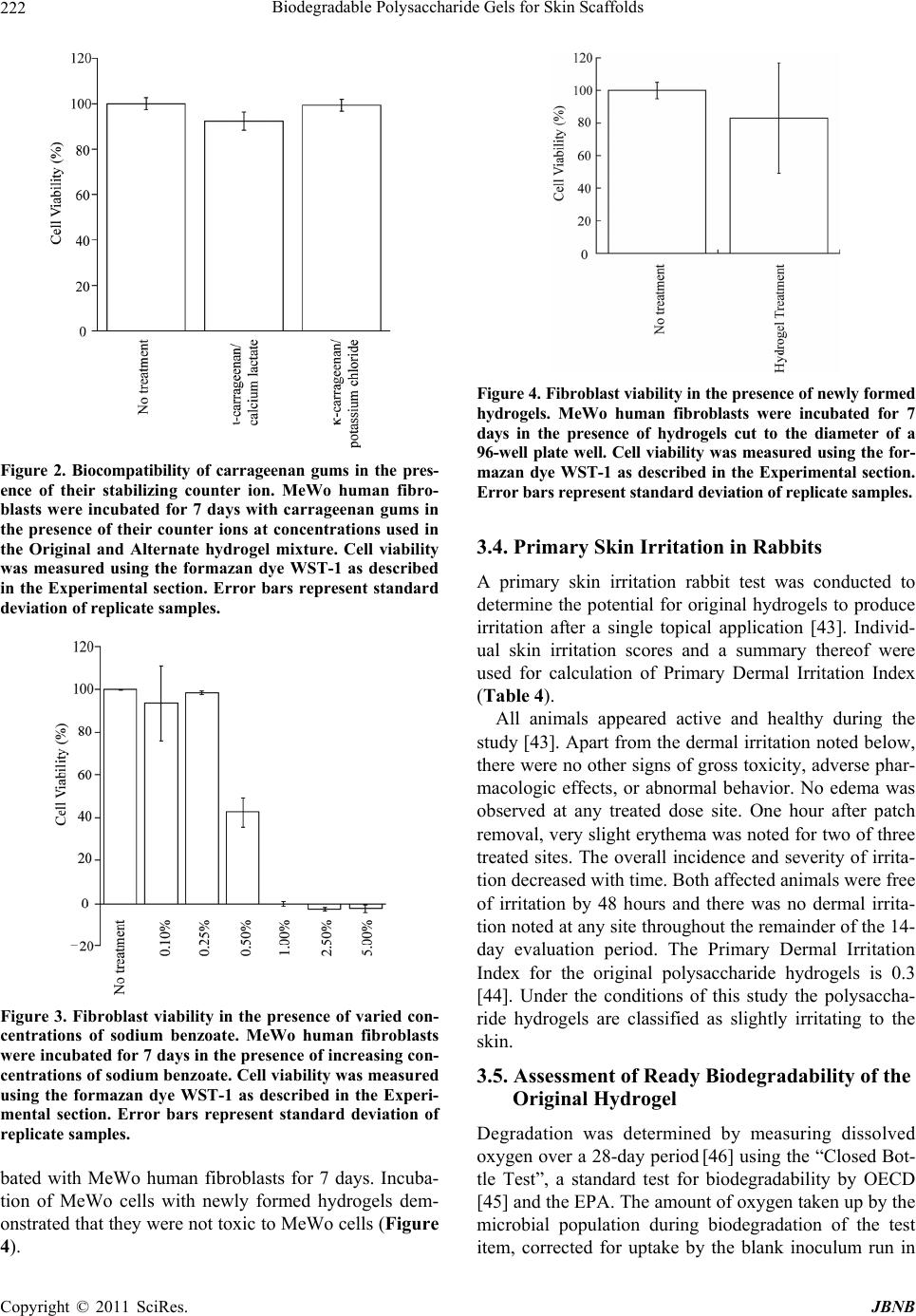

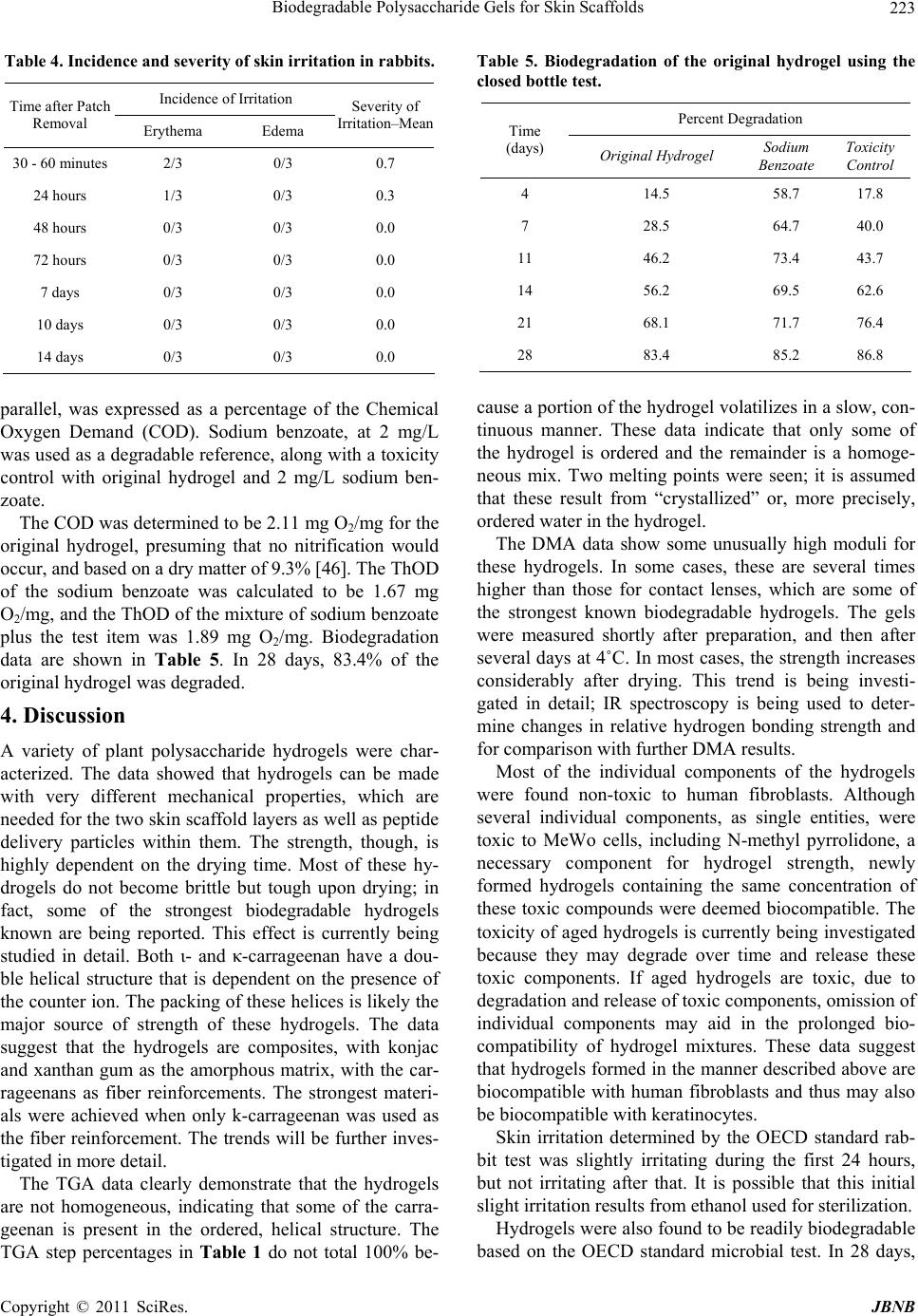

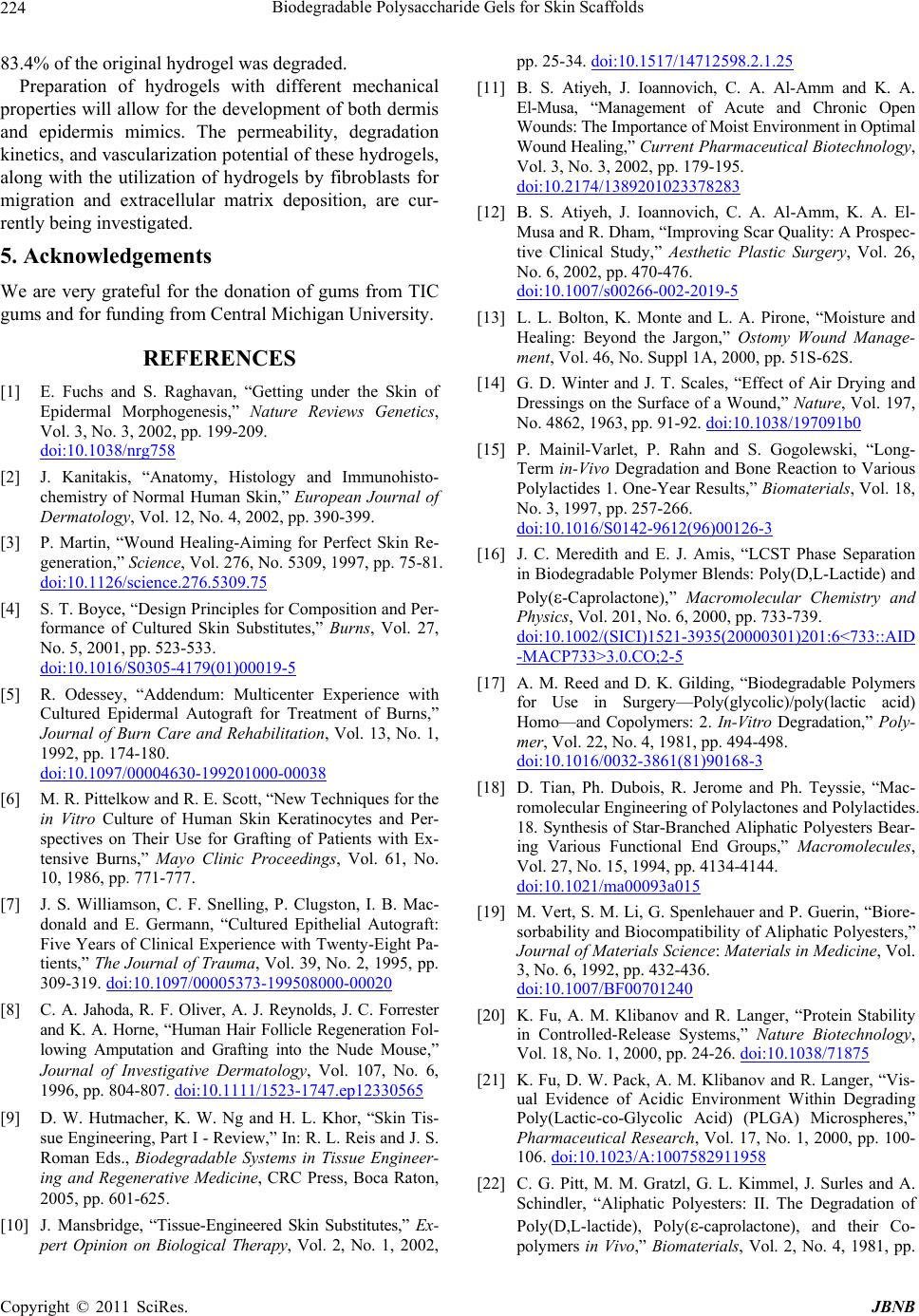

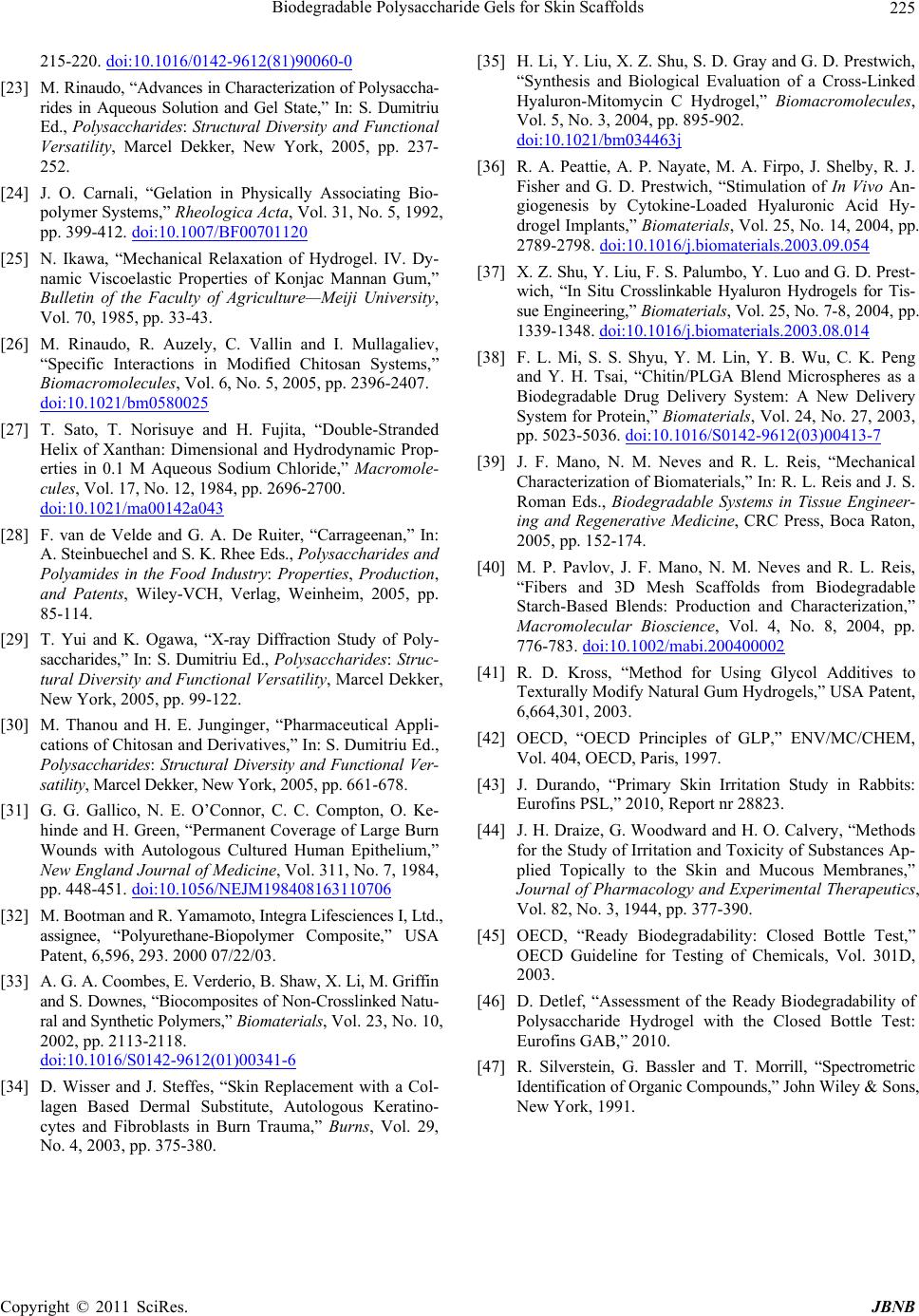

Journal of Biomaterials and Nanobiotechnology, 2011, 2, 216-225 doi:10.4236/jbnb.2011.23027 Published Online July 2011 (http://www.SciRP.org/journal/jbnb) Copyright © 2011 SciRes. JBNB Biodegradable Polysaccharide Gels for Skin Scaffolds Stephen J. Juris1, Anja Mueller1, Brian T. L. Smith1, Samantha Johnston1, Robert Walker1, Robert D. Kross2 1Central Michigan University, Mt. Pleasant, USA; 2Kross Link Labs, Bellmore, USA. Email: juris1sj@cmich.edu, muell1a@cmich.edu Received March 2nd, 2011; revised May 2nd 2011; accepted June 10th, 2011. ABSTRACT A variety of skin substitutes are used in the treatment of full-thickness burns. Substitutes made from skin can harbor latent viruses, and artificial skin grafts can heal with extensive scarring, failing to regenerate structures such as glands, nerves, and hair follicles. Biodegradable and biocompatible hydrogels, however, rarely mimic the strength of the epi- dermis. Therefore, novel and practical skin scaffold materials remain to be developed. Polysaccharides form hydrogels with predicted inherent biocompatibility. This paper describes the preparation and biocompatibility of unique hydrogel skin scaffolds from plant-extracted polysaccharide mixtures of specific sources, types, and molecular weight fractions. These hydrogels have a range of mechanical and degradation properties with the potential to fulfill the multiple, di- verse functions of artificial skin, including protection, compatibility with different cell types, biodegradation, and re- lease of needed signals for cell growth and wound healing. Keywords: Hydrogel, Polysaccharides, Skin Scaffold 1. Introduction The skin is the largest organ in the body and serves many important functions, such as protection against infection, immune surveillance, perception of touch, and tempera- ture regulation [1,2]. Skin contains two layers: the strong epidermis, which is composed mainly of keratinocytes that form the thick protective layer with hair follicles and glands, and the dermis, which contains many different cell types, including collagen-producing fibroblasts, blood vessel-forming endothelial cells, motor and sensory neu- rons, and immunoregulatory cells. When skin is superficially damaged the wound is rap- idly repaired. However, when the injury destroys both epidermis and dermis, patients often die from infection or loss of plasma [3]. If patients survive with the help of skin grafts, skin often heals with the formation of scar tissue without the regeneration of some cell types [4-7], in- cluding hair follicles and sebaceous glands [8]. Thus, an improved scaffold should release cytokines to promote healing and cell differentiation. Also, artificial skin often contains animal material, such as collagen, which may contain infectious material. Due to these problems, there is a need for improved methods and materials for fabri- cating artificial skin [9,10]. Unfortunately, there are limited biocompatible and biodegradable materials avai- lable. Hydrogels have been used as an alternate artificial skin, because good hydration is the most important ex- ternal factor responsible for optimal wound healing [11- 14], as water is necessary for transport of nutrients to the growing cells. Hydrogels, however, are commonly not physically strong enough to mimic the tough, thin dermis [9]. The polymer most often used in skin scaffold synthesis is a polyester based on lactic acid (PLA) and glycolic acid (PGA) [15-19]. However, these polyesters have been shown to degrade to their monomeric components, re- sulting in high local acidity that can destroy proteins [20-22]. Thus, a material that avoids acidity and is capa- ble of delivering bioactive molecules would be more useful. Polysaccharides are biopolymers with predicted bio- compatibility, and many polysaccharides form physical hydrogels [23]. There are also a variety of polysaccha- rides that form helical structures and thus are stronger materials. In this study, we used four different gel- forming polysaccharides: ι-carrageenan, κ-carrageenan, xanthan gum, and konjac gum [24-26]. The two carra- geenans and xanthan form strong double helical confor-  Biodegradable Polysaccharide Gels for Skin Scaffolds Copyright © 2011 SciRes. JBNB 217 mations with specific cations present [27,28], and konjac forms a partially-ordered single helix with the right car- bocation [29]. Xanthan and konjac gum are mostly used as thickeners, as are the carrageenans, which are also known to form H-bond-stabilizing reversible gels [23]. Gel formation is a two-step process induced by specific counterions; first the double helices aggregate, then the aggregates combine at a certain combination of tempera- ture and concentration, stiffening the gel. Konjac and xan- than gum gel formation seems to be dependent mostly on ionic strength (which also drives helix formation), con- centration, and temperature [24,25]. Polysaccharides may indeed be a useful material as a skin scaffold with the capability of delivering molecules involved in wound healing; some polysaccharides even improve wound healing [9,30]. Mostly natural polysac- charides have been investigated as biomaterials, such as chitosan [5,7,31], cellulose [32], collagen [33,34], and hyaluronic acid [35-37]. Chitin/poly(lactic acid-co-gly- colic acid) (PGLA) blends [38] and starch-based blends [39,40] have been reported for protein drug delivery and tissue engineering scaffolds, respectively. A crosslinked hyaluronic acid hydrogel has been loaded with bioactive cytokines and successfully induced angiogenesis [36]. This paper reports the preparation of hydrogels made from plant polysaccharides with different mechanical strengths and activities. Mixtures of these extracted poly- saccharides have already been used successfully in the development of a skin patch for drug delivery [41]. Developed polysaccharide skin scaffolds are required to be biocompatible, promote healing, and mimic the strength of dermis and epidermis in order to prevent fur- ther tissue damage. This skin scaffold will be made of two layers, a dense, strong top layer for keratinocytes mimicking the epidermis, and a porous, softer layer for fibroblasts, mimicking the dermis. This paper reports the testing of biocompatibility and strength of polysaccha- rides and polysaccharide hydrogels synthesized from plant extracts, as well as their method of preparation. 2. Materials and Methods 2.1. Materials EMD Chemicals: HPLC grade water, 30% hydrogen peroxide; Fisher Scientific: potassium phosphate mono- basic and dibasic, potassium chloride (KCl), calcium lactate (C6H10CaO6), hydrogen chloride (HCl); Sigma: Triton X-100, Bovine Serum Albumin (BSA); TIC Gums: κ-carrageenan (Colloid 710 H Powder), ι-carrageenan (Colloid 881 M Powder), Xanthan (Ticaxan Rapid Pow- der), Konjac (Konjac High Viscosity), Ticagel (121-AGF Powder); Arch Personal Care Produces (ARCH): Cosmo- cil preservative; Aldrich: sodium benzoate (NaC6H5CO2), N-methyl pyrrolidone, glucose (C6H12O6), glycerin (C3H5(OH)3); Hyclone: Heat inactivated fetal bovine se- rum; American Type Culture Collection: MeWo human fibroblast cell line; Invitrogen: Minimum Essential Me- dia (MEM), L-glutamine, penicillin/streptomycin, Tryp- sin/EDTA; Roche Biochemicals: formazan dye WST-1. Water was purified through a Barnstead E-pure filter system and collected at 18 MOhm. 2.2. Instrumentation 1) UV spectra were obtained on an Agilent 8453 UV/Vis Spectrometer utilizing Agilent ChemStation software. 2) Gel permeation chromatography was conducted on a Waters Breeze system consisting of a Waters 1515 iso- cratic pump, 717+ autosampler, and 2414 refractive in- dex detector, a column heater, and with Breeze software, with Fluka polyethylene glycol (PEG) standards on two Tosohaas TSK-Gel 7.5 mm × 30 cm columns in series, with deionized ultra-filtered (DIUF) water as solvent at 1.0 mL/min and 30˚C. 3) IR spectroscopy was performed with KCl pellets on a Nicolet Magna IR 560 spectrome- ter. 4) Differential scanning calorimetry (DSC) was car- ried out at a heating rate of 10˚C/min using a TA Instru- ments Inc. model 2100 with a 2910 DSC cell at 50 mL/min. 5) Thermal gravimetric analysis (TGA) meas- urements used a TA Instruments 2950 with a Thermal Analyst 2100 control unit and a 10˚C/min heating rate in nitrogen atmosphere. 6) A TAQ800 Dynamic Mechani- cal Analyzer (DMA) was used for mechanical analysis at a strain ramp from 0.01% - 0.4%. The modulus was cal- culated from the slope of the linear region of a stress vs. strain curve. 7) Cell viability, as measured by hydrolysis of the formazan dye WST-1, was measured using a Spec- tramax microplate spectrometer. Measurements were taken at 450 nm, and the 650 nm reference absorbance was subtracted from all samples before subtracting media reading from experimental samples. 2.3. Preparation of the Hydrogels Hydrogels were prepared following Dr. Kross’ patent [41]. To prepare the “original” hydrogel, konjac gum (0.168 g), xanthan gum (0.112 g), κ-carrageenan (0.08 g), and ι-carrageenan (0.16 g) were initially dispersed in N-methyl pyrrolidone (1.2 g), and the mixture was stirred into water (17.09 g). Potassium chloride (0.08 g), cal- cium lactate (0.16 g), sodium benzoate (0.02 g), and Cosmocil CQ (0.02 g) were added, and the mixture was stirred until all dissolved. Glucose (0.90 g) and malic acid (0.05 g) were mixed initially and then stirred in slowly until the solution became more viscous. The solu- tion was weighed, heated to 85˚C to initiate gelling, and reweighed. The water lost in heating was re-added to the  Biodegradable Polysaccharide Gels for Skin Scaffolds Copyright © 2011 SciRes. JBNB 218 mixture, which was again heated to 85˚C. The gel was then poured into five separate Petri dishes (5 cm diameter) in 2 g quantities and allowed to cool and gel at 4˚C. Gels produced had a thickness of about 0.9 mm, which re- duced up to 0.3 mm over time as water was lost. The variability between the different compositions was +/– 0.15 mm. The preparation of the “alternative” hydrogel also fol- lowed the patent [41]. Ticagel 121-AGF Powder (0.5 g), sodium benzoate (0.02 g) and Cosmocil CQ (0.02 g) were added to preweighed glycerin (1.0 g) and stirred. DIUF water (18.46 g) was added to the beaker and the mixture stirred until thickened by heating, as above, and the liquid then similarly poured and allowed to gel during cooling. Variations of the original composition included: 150% konjac, elimination of KCl, xanthan, one of the carra- geenans, or Cosmocil. When the release of Bovine Serum Albumin (BSA) from the gel was to be measured, BSA was added directly to the pre-gel mixture before heating. Variations of the alternate composition included reducing the amount of water. The method for the respective preparations of these mixtures was exactly the same as above. 2.4. Determination of Relative Hydrogen Bonding Strength The broad –OH absorption peak, present on the spectra at 3000 - 3500 cm–1, was used to quantify the relative av- erage strength of H-bonding present in the various gels. The calculation involves the initial vertical subdivision of the –OH peak into ~50 cm–1 increments. The heights of each of these increments from the base of the spectrum to the peak were then measured, in millimeters, and totaled. This sum divided by 100 became the division factor. Be- ginning at the higher frequency end of the peak, each increment was numbered and the sum then divided by the division factor resulting in a weighted average. This total number was reflective of the degree of overall H-bonding strength. Higher values (lower frequency vibrations) in- dicate less relative hydrogen bonding strength. If the sample contains –NH bonds as well, only samples with the same amount of –OH and –NH peaks can be com- pared with each other. 2.5. Cell Culture The human fibroblast cell line MeWo was cultured in MEM supplemented with 10% heat-inactivated fetal bo- vine serum, 2 mM L-glutamine, 100 U/ml penicillin, and 100 μg/mL streptomycin. Cells were incubated at 37˚C in 5% CO2. Cells were passaged using 0.25% Trypsin/ EDTA and centrifuged for 5 minutes at 200 x g. 2.6. Cell Viability Assay Individual components of prepared polysaccharide skin scaffolds, except konjac gum and Ticagel (due to insolu- bility), were tested for toxicity with human fibroblasts by incubating the individual components with 5 × 104 MeWo cells for either 3 or 7 days. Hydrogels were also tested by cutting formed hydrogels to the diameter of a 96-well plate and incubating them with 5 × 104 MeWo cells for 7 days. The formazan dye WST-1 was used to measure the metabolic activity of cells per manufacturer’s instruc- tions. Samples were read at both 450 nm (sample reading) and 650 nm (reference). Samples were tested on at least three replicates and the error reported as the standard deviation of the mean of each sample. 2.7. Primary Skin Irritation in Rabbits The Primary Skin Irritation study followed the Organiza- tion for Economic Cooperation and Development (OECD) Guidelines for the Testing of Chemicals, Test No. 404 [42], and was performed by Eurofins PSL (725 Cranbury Road, East Brunswick, NJ 08816) [43]. NIH guidelines for the care and use of laboratory animals (NIH Publica- tion #85-23 Rev. 1985) have been observed. An original gel was prepared under sterile conditions and addition- ally sterilized with ethanol and stored under moist condi- tions. In short, three naïve, male New Zealand albino rabbits (young adults) were kept in controlled conditions for 13 days. A 0.5 g, 1 in2 piece of the original hydrogel was applied to one 6-cm2 intact dose site on each animal. In- dividual dose sites were scored according to the Draize scoring system [44] at approximately 30 - 60 min, 24, 48, and 72 h, and at 7, 10, and 14 days after patch removal. The resulting Primary Dermal Irritation Index (PDII) was classified as follows: 0, non-irritating; >0 - 2.0, slightly irritating; 2.1 - 5.0, moderately irritating; >5.0, severely irritating. The animals were observed for signs of gross toxicity and behavioral changes at least once daily during the test period. 2.8. Assessment of the Ready Biodegradability of the Original Hydrogel with the Closed Bottle Test The assessment of the Ready Biodegradability of the original hydrogel was determined via a standard test for biodegradability [45], and was performed by Eurofins GAB (Eutinger Str. 24, D-75223 Niefern-Öschlebronn, Germany). In short, closed glass bottles were filled with aerated and inoculated test medium [46]. O2 consumption was measured with an Oximeter and a calibrated electrode. Sodium benzoate at 2 mg/L was used to check the activ-  Biodegradable Polysaccharide Gels for Skin Scaffolds Copyright © 2011 SciRes. JBNB 219 ity of the inoculum. In accordance with the regulations, the biochemical oxygen demand (BOD) for the reference item should be >60% of the theoretical oxygen demand (ThOD) within 14 days. The effluent of the municipal activated sludge plant of Pforzheim/Germany was taken as the inoculum. The de- gradability of the original hydrogel was determined in an aqueous test solution at a concentration of 2 mg/L, based on dry matter content. The solution was inoculated with a small number of microorganisms from a mixed popula- tion and maintained in closed bottles in the dark at a con- stant temperature between 19.1˚C and 22.6˚C. The hydrogel can be assumed to be inhibitory, if in a toxicity test containing both the test item (2 mg/L) and the reference item (2 mg/L), less than 25% degradation occurs, based on the theoretical and chemical oxygen de- mand (COD). The ThOD of the toxicity control was cal- culated from the proportionate amounts of ThOD and COD. The test was performed in closed BOD flasks in single, 2-, and 3-fold test assays for each of the 6 measurement dates (4, 7, 11, 14, 21, and 28 days). Ultra pure grade water was strongly aerated for 10 min to achieve oxygen saturation and allowed to stand for 24 h without aeration at test temperature. The O2 content was measured at the start of the test. Subsequently, each flask was inoculated with 2 mL of inoculum and the volume was made up to 5 L with oxygen-saturated water. Oxygen concentrations were measured in one vessel from each treatment group. The exerted BOD was calculated by subtracting the oxygen concentration (mg O2/L) of the mean initial in- oculum blank from that of the other study groups. Then, the measured values of the corresponding controls were subtracted. This corrected depletion was divided by the concentration (mg/L) of the test item, to obtain the spe- cific BOD as mg oxygen per mg test item. The percent- age biodegradation was calculated by dividing the spe- cific BOD by the specific oxygen demand, calculated from the molecular formula in accordance with the OECD guideline (BOD = mg O2/mg hydrogel; COD = chemical oxygen demand of the test item). 3. Results 3.1. Preparation of the Hydrogels All gels are based on the mixture of either N-methyl pyrrolidone, konjac gum, xanthan gum, κ-carrageenan gum, ι-carrageenan gum, potassium chloride, calcium lac- tate, sodium benzoate, Cosmocil CQ, glucose, and malic acid (“Original”); or glycerin, Ticagel, sodium benzoate, and Cosmocil CQ (“Alternate”) developed by Dr. Kross [41]. Konjac gum is derived from the Araceae plant fam- ily and contains 40% glucomannan gum (β1-4 man- nose-glucose, 1.6:1 ratio, with β1-6 branching). It is used as a thickener as a substitute for gelatin. Xanthan gum is made by the Xanthomonas campestris bacterium. Xan- than contains β1-4 mannose, glucose, and glucuronic acid with β1-3 branching. Some of the sugars are also acetylated or modified by pyruvate. Carrageenans are water-soluble sulfated galactans with alternating β1-3- and β1-4-bonds and some 4-linked 3,6-anhydrogalactose. ι-carrageenan and κ-carrageenan both form gels, but dif- fer in the amount of sulfonation: ι-carrageenan is sul- fonated on every sugar in the chain, whereas κ-carra- geenan is sulfonated on every second sugar. Both carra- geenans form double helices in the presence of salt, ι-carrageenan in the presence of Ca2+-ions, κ-carrageenan in the presence of K+-ions. Ticagel is a mixture of carra- geenan and carboxymethyl cellulose. Variations were made by removing components or by reducing or increas- ing the amount of components. Cosmocil and sodium benzoate are antimicrobials. N-methyl pyrrolidone, glucose, and glycerin are added to regulate the viscosity. Malic acid is added for pH ad- justment. Glucose has also additional protein-protective properties. 3.2. Characterization of Physical, Thermal, and Mechanical Properties IR spectroscopy was used to analyze the relative amount of hydrogen bonding (the higher the value, the lower the average relative strength of hydrogen bonding). This me- thod is based on the frequency shift in the OH stretching peak resulting from hydrogen bonding [47]. The integra- tion across the peak reveals a shift to more or less average relative hydrogen bonding strength if the same type of materials (i.e. the same amount of ratio and amount of functional groups) are compared. Differential scanning calorimetry (DSC) was used to measure the glass transi- tion temperature (Tg) and melting point (Mp). Thermal gravimetric analysis (TGA) was used to determine the thermal stability. Discrete melting points in the DSC data indicate the presence of crystalline regions in the other- wise amorphous hydrogels. In general, the TGA graphs show continuous loss of material with increasing heat, but all show distinct rapid loss steps with the percent of gel lost in that step (Tables 1-3). These data indicate that there are distinct regions in the gel that are phase- sepa- rated, suggesting that the gel is not homogeneous. The weight of the gels was determined over time to measure water loss. Dynamic mechanical analysis (DMA) was used to determine the mechanical strengths of the pre- pared hydrogels. Initial results are summarized in Tables 1-3. The original mixture showed a high Young’s modulus, which was comparable to the modulus of contact lenses  Biodegradable Polysaccharide Gels for Skin Scaffolds Copyright © 2011 SciRes. JBNB 220 Table 1. Characterization of hydrogels—original with variations in konjac and xanthan gum. Mixture H-bonding (day) TGA (˚C) Tg (˚C) Mp (˚C)Modulus in MPa (day)Poissons Ratio (day) Weight Loss in % (day) Original 690 (d69) 52 (52%) 183 (14%) –32.2 –14.19 0.02 (d3) 0.13 (d6) 24.01 (d8) 0.04 (d6) 0.07 (d8) 34% (d6) 66% (d8) Original without konjac 701 (d38) 95 (63.5%) 184 (8.6%) 215 (2%) –21.78–7.92 Sample broke (d1,2) 38.0 (d3) Sample broke Sample broke Original 150% konjac 901 (d1) 183 (34%) NA NA 0.014 (d1) 0.019 (d2) Sample broke (d3) Sample broke (d1) 0.58 (d2) 4.92 (d3) 53% (d2) 57% (d3) Original without xanthan 626 (d17) 47 (32.5%) 180 (61%) –32.14Not seen 0.015 (d1) 0.019 (d2) 0.020 (d3) Sample broke (d1) 7.05 (d2) 19.61 (d3) 49% (d2) 93% (d3) NA: Not Available. Table 2. Characterization of hydrogels—original with variations in κ- and ι-carrageenan gum. Mixture H-bonding (day) TGA (°C) Tg (˚C) Mp (˚C)Modulus in MPa (day)Poissons Ratio (day) Weight Loss in % (day) Original 690 (d69) 52 (52%) 183 (14%) –32.2 –14.19 0.02 (d3) 0.13 (d6) 24.01 (d8) 0.04 (d6) 0.07 (d8) 34% (d6) 66% (d8) Original without -carrageenan 698 (d33) 69 (74%) 172 (10%) –32.16Not seenBroke (d1,4) 0.019 (d2) Broke Broke Original 150% -carrageenan 691 (d14) 186 (25.5%) NA Not seen 0.024 (d1) 0.045 (d3) 21.75 (d5) 0.30 (d3) 0.92 (d5) 23% (d3) 83% (d5) Original without KCl 727 (d34) 183 (27%) NA Not seen Broke (d1) 5.51 (d2) 12.70 (d3) 0.91 (d2) 0.63 (d3) 88% (d2) 94% (d3) Original without -carrageenan 713 (d29) 69 (73.5%) 179 (8.5%) –32.5 Not seen Broke (d1) 0.077 (d2) 56.21 (d3) 7.87 (d2) 5.24 (d3) 56% (d2) 82% (d3) Original without calcium lactate 716 (d77) 203 (5%) 224 (7.5%) NA NA 6.99 (d77) NA NA NA: Not Available. Table 3. Characterization of hydrogels based on the alternate mixture. Mixture H-bonding (day) TGA (˚C) Tg (˚C) Mp (˚C) Modulus in MPa (day) Alternate 627 175 (25%) 263 (30%) NA NA 27.68 Alternate, 90% H2O, without Cosmocil CQ 862 (d4) 57 (35%) 201 (15%) 274 (4%) 773 (9%) –33 NA Broke 2.46 (d14) Alternate, 85% H2O, without Cosmocil CQ 863 (d4) 74 (21%) 174 (11%) 250 (10%) 266 (7%) NA NA 0.06 (d18) 0.35 (d18) Alternate, 80% H2O, without Cosmocil CQ 844 187 (6%) 267 (1.5%) –33.5 NA 0.01 (d11) NA: Not Available.  Biodegradable Polysaccharide Gels for Skin Scaffolds Copyright © 2011 SciRes. JBNB 221 (Table 1). When konjac gum was removed from the mix- ture, hydrogen bonding strength decreased by a small amount, and the modulus increased by about 50%. These gels required three days to dry at 4˚C before they could be handled successfully. On the other hand, when the amount of konjac gum was increased by 50%, hydrogen bonding strength and the modulus decreased significantly. Xanthan gum in the mixture increased hydrogen bonding strength, but decreased the modulus significantly. These mixtures also lost water significantly faster than the other hydrogels described so far. It is unexpected that increased hydrogen bonding strength corresponds to weaker materials. These data could possibly be explained by the amount of water pre- sent in the mixture, such that less water leads to a higher modulus. These data correlate well with this explanation, as the modulus increased over time, which was accom- panied by weight loss (and with that, water loss). In the last three mixtures, the weight loss step that oc- curs around 180˚C in the TGA became the major step (Table 1). The early weight loss step (observed around 50˚C) is still present in the sample without xanthan, but has disappeared from the other mixtures. When either of the carrageenans was removed from the mixture, the early weight loss step in the TGA was seen again, and in fact the weight loss increased (Table 2). When the amount of κ-carrageenan was increased or KCl was removed from the mixture, the higher tempera- ture weight loss step was the only one present. When calcium lactate was removed, this high temperature weight loss step occurred at temperatures above 200˚C and less weight was lost. These data indicated that this last mixture is the most homogeneous of these gels. The carrageenans form helices, especially with certain ions present, such as K+ as in KCl for κ-carrageenan and Ca2+ as in calcium lactate for ι-carrageenan. Unexpectedly, some of the highest moduli were seen when ι-carrageenan or the salts were removed (Table 2). These results, in combination with the TGA data, might indicate that ho- mogeneity increases strength, and that the thermally la- bile phase is mechanically very stable. Some of the samples overall also contracted signifi- cantly when water was lost and, in extreme cases, this effect was larger than the effect of thinning during exten- sion, yielding unusual Poisson’s ratio values. The alternate mixture has a similar modulus as the original mixture (Table 3). When Cosmocil CQ, an anti- microbial agent that reduces skin cell growth, was re- moved, the strength of the gels was significantly reduced. 3.3. Determination of Toxicity of Hydrogel Components and Formed Hydrogels The biocompatibility of hydrogel components present in the skin scaffolds was tested by incubating each compo- nent with MeWo human fibroblasts for 3 or 7 days. The individual components xanthan gum, κ-carrageenan, cal- cium lactate, and sodium benzoate, all demonstrated biocompatibility, with greater than 90% of the cells re- maining viable after 7 days (Figure 1). ι-carageenan de- monstrated biocompatibility after 3 days, but was toxic to cells after 7 days (Figure 1). However, after testing the carrageenan components with their proper counterions, ι-carrageenan was found to be completely biocompatible (Figure 2). When present as individual components, N-methyl pyrrolidone, Cosmocil CQ, malic acid, and potassium chloride were toxic after 3 days (Figure 1). Glucose and glycerin were slightly toxic to MeWo cells, only allowing for approximately 50% survival (Figure 1). Since the antibacterial agent Cosmocil CQ was toxic to MeWo cells at its use concentration, increasing con- centrations of the antimicrobial agent sodium benzoate were tested to determine how much could be tolerated by fibroblasts. Whereas 0.25% sodium benzoate did not affect cell viability, 0.5% sodium benzoate caused cell toxicity (Figure 3). In order to test the biocompatibility of hydrogels with human fibroblasts, cut segments of hydrogel were incu- – Figure 1. Biocompatibility of individual hydrogel compo- nents with human fibroblasts. MeWo human fibroblasts were incubated with individual components at concentra- tions used in the Original and Alternate hydrogel mixture for either 3 days (black bars) or 7 days (white bars). Cell viability was measured using the formazan dye WST-1 as described in the Experimental section. Error bars represent standard deviation of replicate samples.  Biodegradable Polysaccharide Gels for Skin Scaffolds Copyright © 2011 SciRes. JBNB 222 ι Figure 2. Biocompatibility of carrageenan gums in the pres- ence of their stabilizing counter ion. MeWo human fibro- blasts were incubated for 7 days with carrageenan gums in the presence of their counter ions at concentrations used in the Original and Alternate hydrogel mixture. Cell viability was measured using the formazan dye WST-1 as described in the Experimental section. Error bars represent standard deviation of replicate samples. – Figure 3. Fibroblast viability in the presence of varied con- centrations of sodium benzoate. MeWo human fibroblasts were incubated for 7 days in the presence of increasing con- centrations of sodium benzoate. Cell viability was measured using the formazan dye WST-1 as described in the Experi- mental section. Error bars represent standard deviation of replicate samples. bated with MeWo human fibroblasts for 7 days. Incuba- tion of MeWo cells with newly formed hydrogels dem- onstrated that they were not toxic to MeWo cells (Figure 4). Figure 4. Fibroblast viability in the presence of newly formed hydrogels. MeWo human fibroblasts were incubated for 7 days in the presence of hydrogels cut to the diameter of a 96-well plate well. Cell viability was measured using the for- mazan dye WST-1 as described in the Experimental section. Error bars represent standard deviation of replicate samples. 3.4. Primary Skin Irritation in Rabbits A primary skin irritation rabbit test was conducted to determine the potential for original hydrogels to produce irritation after a single topical application [43]. Individ- ual skin irritation scores and a summary thereof were used for calculation of Primary Dermal Irritation Index (Table 4). All animals appeared active and healthy during the study [43]. Apart from the dermal irritation noted below, there were no other signs of gross toxicity, adverse phar- macologic effects, or abnormal behavior. No edema was observed at any treated dose site. One hour after patch removal, very slight erythema was noted for two of three treated sites. The overall incidence and severity of irrita- tion decreased with time. Both affected animals were free of irritation by 48 hours and there was no dermal irrita- tion noted at any site throughout the remainder of the 14- day evaluation period. The Primary Dermal Irritation Index for the original polysaccharide hydrogels is 0.3 [44]. Under the conditions of this study the polysaccha- ride hydrogels are classified as slightly irritating to the skin. 3.5. Assessment of Ready Biodegradability of the Original Hydrogel Degradation was determined by measuring dissolved oxygen over a 28-day period [46] using the “Closed Bot- tle Test”, a standard test for biodegradability by OECD [45] and the EPA. The amount of oxygen taken up by the microbial population during biodegradation of the test item, corrected for uptake by the blank inoculum run in  Biodegradable Polysaccharide Gels for Skin Scaffolds Copyright © 2011 SciRes. JBNB 223 Table 4. Incidence and severity of skin irritation in rabbits. Incidence of Irritation Time after Patch Removal Erythema Edema Severity of Irritation–Mean 30 - 60 minutes 2/3 0/3 0.7 24 hours 1/3 0/3 0.3 48 hours 0/3 0/3 0.0 72 hours 0/3 0/3 0.0 7 days 0/3 0/3 0.0 10 days 0/3 0/3 0.0 14 days 0/3 0/3 0.0 parallel, was expressed as a percentage of the Chemical Oxygen Demand (COD). Sodium benzoate, at 2 mg/L was used as a degradable reference, along with a toxicity control with original hydrogel and 2 mg/L sodium ben- zoate. The COD was determined to be 2.11 mg O2/mg for the original hydrogel, presuming that no nitrification would occur, and based on a dry matter of 9.3% [46]. The ThOD of the sodium benzoate was calculated to be 1.67 mg O2/mg, and the ThOD of the mixture of sodium benzoate plus the test item was 1.89 mg O2/mg. Biodegradation data are shown in Table 5. In 28 days, 83.4% of the original hydrogel was degraded. 4. Discussion A variety of plant polysaccharide hydrogels were char- acterized. The data showed that hydrogels can be made with very different mechanical properties, which are needed for the two skin scaffold layers as well as peptide delivery particles within them. The strength, though, is highly dependent on the drying time. Most of these hy- drogels do not become brittle but tough upon drying; in fact, some of the strongest biodegradable hydrogels known are being reported. This effect is currently being studied in detail. Both ι- and κ-carrageenan have a dou- ble helical structure that is dependent on the presence of the counter ion. The packing of these helices is likely the major source of strength of these hydrogels. The data suggest that the hydrogels are composites, with konjac and xanthan gum as the amorphous matrix, with the car- rageenans as fiber reinforcements. The strongest materi- als were achieved when only k-carrageenan was used as the fiber reinforcement. The trends will be further inves- tigated in more detail. The TGA data clearly demonstrate that the hydrogels are not homogeneous, indicating that some of the carra- geenan is present in the ordered, helical structure. The TGA step percentages in Table 1 do not total 100% be- Table 5. Biodegradation of the original hydrogel using the closed bottle test. Percent Degradation Time (days) Original Hydrogel Sodium Benzoate Toxicity Control 4 14.5 58.7 17.8 7 28.5 64.7 40.0 11 46.2 73.4 43.7 14 56.2 69.5 62.6 21 68.1 71.7 76.4 28 83.4 85.2 86.8 cause a portion of the hydrogel volatilizes in a slow, con- tinuous manner. These data indicate that only some of the hydrogel is ordered and the remainder is a homoge- neous mix. Two melting points were seen; it is assumed that these result from “crystallized” or, more precisely, ordered water in the hydrogel. The DMA data show some unusually high moduli for these hydrogels. In some cases, these are several times higher than those for contact lenses, which are some of the strongest known biodegradable hydrogels. The gels were measured shortly after preparation, and then after several days at 4˚C. In most cases, the strength increases considerably after drying. This trend is being investi- gated in detail; IR spectroscopy is being used to deter- mine changes in relative hydrogen bonding strength and for comparison with further DMA results. Most of the individual components of the hydrogels were found non-toxic to human fibroblasts. Although several individual components, as single entities, were toxic to MeWo cells, including N-methyl pyrrolidone, a necessary component for hydrogel strength, newly formed hydrogels containing the same concentration of these toxic compounds were deemed biocompatible. The toxicity of aged hydrogels is currently being investigated because they may degrade over time and release these toxic components. If aged hydrogels are toxic, due to degradation and release of toxic components, omission of individual components may aid in the prolonged bio- compatibility of hydrogel mixtures. These data suggest that hydrogels formed in the manner described above are biocompatible with human fibroblasts and thus may also be biocompatible with keratinocytes. Skin irritation determined by the OECD standard rab- bit test was slightly irritating during the first 24 hours, but not irritating after that. It is possible that this initial slight irritation results from ethanol used for sterilization. Hydrogels were also found to be readily biodegradable based on the OECD standard microbial test. In 28 days,  Biodegradable Polysaccharide Gels for Skin Scaffolds Copyright © 2011 SciRes. JBNB 224 83.4% of the original hydrogel was degraded. Preparation of hydrogels with different mechanical properties will allow for the development of both dermis and epidermis mimics. The permeability, degradation kinetics, and vascularization potential of these hydrogels, along with the utilization of hydrogels by fibroblasts for migration and extracellular matrix deposition, are cur- rently being investigated. 5. Acknowledgements We are very grateful for the donation of gums from TIC gums and for funding from Central Michigan University. REFERENCES [1] E. Fuchs and S. Raghavan, “Getting under the Skin of Epidermal Morphogenesis,” Nature Reviews Genetics, Vol. 3, No. 3, 2002, pp. 199-209. doi:10.1038/nrg758 [2] J. Kanitakis, “Anatomy, Histology and Immunohisto- chemistry of Normal Human Skin,” European Journal of Dermatology, Vol. 12, No. 4, 2002, pp. 390-399. [3] P. Martin, “Wound Healing-Aiming for Perfect Skin Re- generation,” Science, Vol. 276, No. 5309, 1997, pp. 75-81. doi:10.1126/science.276.5309.75 [4] S. T. Boyce, “Design Principles for Composition and Per- formance of Cultured Skin Substitutes,” Burns, Vol. 27, No. 5, 2001, pp. 523-533. doi:10.1016/S0305-4179(01)00019-5 [5] R. Odessey, “Addendum: Multicenter Experience with Cultured Epidermal Autograft for Treatment of Burns,” Journal of Burn Care and Rehabilitation, Vol. 13, No. 1, 1992, pp. 174-180. doi:10.1097/00004630-199201000-00038 [6] M. R. Pittelkow and R. E. Scott, “New Techniques for the in Vitro Culture of Human Skin Keratinocytes and Per- spectives on Their Use for Grafting of Patients with Ex- tensive Burns,” Mayo Clinic Proceedings, Vol. 61, No. 10, 1986, pp. 771-777. [7] J. S. Williamson, C. F. Snelling, P. Clugston, I. B. Mac- donald and E. Germann, “Cultured Epithelial Autograft: Five Years of Clinical Experience with Twenty-Eight Pa- tients,” The Journal of Trauma, Vol. 39, No. 2, 1995, pp. 309-319.doi:10.1097/00005373-199508000-00020 [8] C. A. Jahoda, R. F. Oliver, A. J. Reynolds, J. C. Forrester and K. A. Horne, “Human Hair Follicle Regeneration Fol- lowing Amputation and Grafting into the Nude Mouse,” Journal of Investigative Dermatology, Vol. 107, No. 6, 1996, pp. 804-807. doi:10.1111/1523-1747.ep12330565 [9] D. W. Hutmacher, K. W. Ng and H. L. Khor, “Skin Tis- sue Engineering, Part I - Review,” In: R. L. Reis and J. S. Roman Eds., Biodegradable Systems in Tissue Engineer- ing and Regenerative Medicine, CRC Press, Boca Raton, 2005, pp. 601-625. [10] J. Mansbridge, “Tissue-Engineered Skin Substitutes,” Ex- pert Opinion on Biological Therapy, Vol. 2, No. 1, 2002, pp. 25-34.doi:10.1517/14712598.2.1.25 [11] B. S. Atiyeh, J. Ioannovich, C. A. Al-Amm and K. A. El-Musa, “Management of Acute and Chronic Open Wounds: The Importance of Moist Environment in Optimal Wound Healing,” Current Pharmaceutical Biotechnology, Vol. 3, No. 3, 2002, pp. 179-195. doi:10.2174/1389201023378283 [12] B. S. Atiyeh, J. Ioannovich, C. A. Al-Amm, K. A. El- Musa and R. Dham, “Improving Scar Quality: A Prospec- tive Clinical Study,” Aesthetic Plastic Surgery, Vol. 26, No. 6, 2002, pp. 470-476. doi:10.1007/s00266-002-2019-5 [13] L. L. Bolton, K. Monte and L. A. Pirone, “Moisture and Healing: Beyond the Jargon,” Ostomy Wound Manage- ment, Vol. 46, No. Suppl 1A, 2000, pp. 51S-62S. [14] G. D. Winter and J. T. Scales, “Effect of Air Drying and Dressings on the Surface of a Wound,” Nature, Vol. 197, No. 4862, 1963, pp. 91-92.doi:10.1038/197091b0 [15] P. Mainil-Varlet, P. Rahn and S. Gogolewski, “Long- Term in-Vivo Degradation and Bone Reaction to Various Polylactides 1. One-Year Results,” Biomaterials, Vol. 18, No. 3, 1997, pp. 257-266. doi:10.1016/S0142-9612(96)00126-3 [16] J. C. Meredith and E. J. Amis, “LCST Phase Separation in Biodegradable Polymer Blends: Poly(D,L-Lactide) and Poly(-Caprolactone),” Macromolecular Chemistry and Physics, Vol. 201, No. 6, 2000, pp. 733-739. doi:10.1002/(SICI)1521-3935(20000301)201:6<733::AID -MACP733>3.0.CO;2-5 [17] A. M. Reed and D. K. Gilding, “Biodegradable Polymers for Use in Surgery—Poly(glycolic)/poly(lactic acid) Homo—and Copolymers: 2. In-Vitro Degradation,” Poly- mer, Vol. 22, No. 4, 1981, pp. 494-498. doi:10.1016/0032-3861(81)90168-3 [18] D. Tian, Ph. Dubois, R. Jerome and Ph. Teyssie, “Mac- romolecular Engineering of Polylactones and Polylactides. 18. Synthesis of Star-Branched Aliphatic Polyesters Bear- ing Various Functional End Groups,” Macromolecules, Vol. 27, No. 15, 1994, pp. 4134-4144. doi:10.1021/ma00093a015 [19] M. Vert, S. M. Li, G. Spenlehauer and P. Guerin, “Biore- sorbability and Biocompatibility of Aliphatic Polyesters,” Journal of Materials Science: Materials in Medicine, Vol. 3, No. 6, 1992, pp. 432-436. doi:10.1007/BF00701240 [20] K. Fu, A. M. Klibanov and R. Langer, “Protein Stability in Controlled-Release Systems,” Nature Biotechnology, Vol. 18, No. 1, 2000, pp. 24-26.doi:10.1038/71875 [21] K. Fu, D. W. Pack, A. M. Klibanov and R. Langer, “Vis- ual Evidence of Acidic Environment Within Degrading Poly(Lactic-co-Glycolic Acid) (PLGA) Microspheres,” Pharmaceutical Research, Vol. 17, No. 1, 2000, pp. 100- 106.doi:10.1023/A:1007582911958 [22] C. G. Pitt, M. M. Gratzl, G. L. Kimmel, J. Surles and A. Schindler, “Aliphatic Polyesters: II. The Degradation of Poly(D,L-lactide), Poly(-caprolactone), and their Co- polymers in Vivo,” Biomaterials, Vol. 2, No. 4, 1981, pp.  Biodegradable Polysaccharide Gels for Skin Scaffolds Copyright © 2011 SciRes. JBNB 225 215-220.doi:10.1016/0142-9612(81)90060-0 [23] M. Rinaudo, “Advances in Characterization of Polysaccha- rides in Aqueous Solution and Gel State,” In: S. Dumitriu Ed., Polysaccharides: Structural Diversity and Functional Versatility, Marcel Dekker, New York, 2005, pp. 237- 252. [24] J. O. Carnali, “Gelation in Physically Associating Bio- polymer Systems,” Rheologica Acta, Vol. 31, No. 5, 1992, pp. 399-412.doi:10.1007/BF00701120 [25] N. Ikawa, “Mechanical Relaxation of Hydrogel. IV. Dy- namic Viscoelastic Properties of Konjac Mannan Gum,” Bulletin of the Faculty of Agriculture—Meiji University, Vol. 70, 1985, pp. 33-43. [26] M. Rinaudo, R. Auzely, C. Vallin and I. Mullagaliev, “Specific Interactions in Modified Chitosan Systems,” Biomacromolecules, Vol. 6, No. 5, 2005, pp. 2396-2407. doi:10.1021/bm0580025 [27] T. Sato, T. Norisuye and H. Fujita, “Double-Stranded Helix of Xanthan: Dimensional and Hydrodynamic Prop- erties in 0.1 M Aqueous Sodium Chloride,” Macromole- cules, Vol. 17, No. 12, 1984, pp. 2696-2700. doi:10.1021/ma00142a043 [28] F. van de Velde and G. A. De Ruiter, “Carrageenan,” In: A. Steinbuechel and S. K. Rhee Eds., Polysaccharides and Polyamides in the Food Industry: Properties, Production, and Patents, Wiley-VCH, Verlag, Weinheim, 2005, pp. 85-114. [29] T. Yui and K. Ogawa, “X-ray Diffraction Study of Poly- saccharides,” In: S. Dumitriu Ed., Polysaccharides: Struc- tural Diversity and Functional Versatility, Marcel Dekker, New York, 2005, pp. 99-122. [30] M. Thanou and H. E. Junginger, “Pharmaceutical Appli- cations of Chitosan and Derivatives,” In: S. Dumitriu Ed., Polysaccharides: Structural Diversity and Functional Ver- satility, Marcel Dekker, New York, 2005, pp. 661-678. [31] G. G. Gallico, N. E. O’Connor, C. C. Compton, O. Ke- hinde and H. Green, “Permanent Coverage of Large Burn Wounds with Autologous Cultured Human Epithelium,” New England Journal of Medicine, Vol. 311, No. 7, 1984, pp. 448-451.doi:10.1056/NEJM198408163110706 [32] M. Bootman and R. Yamamoto, Integra Lifesciences I, Ltd., assignee, “Polyurethane-Biopolymer Composite,” USA Patent, 6,596, 293. 2000 07/22/03. [33] A. G. A. Coombes, E. Verderio, B. Shaw, X. Li, M. Griffin and S. Downes, “Biocomposites of Non-Crosslinked Natu- ral and Synthetic Polymers,” Biomaterials, Vol. 23, No. 10, 2002, pp. 2113-2118. doi:10.1016/S0142-9612(01)00341-6 [34] D. Wisser and J. Steffes, “Skin Replacement with a Col- lagen Based Dermal Substitute, Autologous Keratino- cytes and Fibroblasts in Burn Trauma,” Burns, Vol. 29, No. 4, 2003, pp. 375-380. [35] H. Li, Y. Liu, X. Z. Shu, S. D. Gray and G. D. Prestwich, “Synthesis and Biological Evaluation of a Cross-Linked Hyaluron-Mitomycin C Hydrogel,” Biomacromolecules, Vol. 5, No. 3, 2004, pp. 895-902. doi:10.1021/bm034463j [36] R. A. Peattie, A. P. Nayate, M. A. Firpo, J. Shelby, R. J. Fisher and G. D. Prestwich, “Stimulation of In Vivo An- giogenesis by Cytokine-Loaded Hyaluronic Acid Hy- drogel Implants,” Biomaterials, Vol. 25, No. 14, 2004, pp. 2789-2798.doi:10.1016/j.biomaterials.2003.09.054 [37] X. Z. Shu, Y. Liu, F. S. Palumbo, Y. Luo and G. D. Prest- wich, “In Situ Crosslinkable Hyaluron Hydrogels for Tis- sue Engineering,” Biomaterials, Vol. 25, No. 7-8, 2004, pp. 1339-1348. doi:10.1016/j.biomaterials.2003.08.014 [38] F. L. Mi, S. S. Shyu, Y. M. Lin, Y. B. Wu, C. K. Peng and Y. H. Tsai, “Chitin/PLGA Blend Microspheres as a Biodegradable Drug Delivery System: A New Delivery System for Protein,” Biomaterials, Vol. 24, No. 27, 2003, pp. 5023-5036.doi:10.1016/S0142-9612(03)00413-7 [39] J. F. Mano, N. M. Neves and R. L. Reis, “Mechanical Characterization of Biomaterials,” In: R. L. Reis and J. S. Roman Eds., Biodegradable Systems in Tissue Engineer- ing and Regenerative Medicine, CRC Press, Boca Raton, 2005, pp. 152-174. [40] M. P. Pavlov, J. F. Mano, N. M. Neves and R. L. Reis, “Fibers and 3D Mesh Scaffolds from Biodegradable Starch-Based Blends: Production and Characterization,” Macromolecular Bioscience, Vol. 4, No. 8, 2004, pp. 776-783.doi:10.1002/mabi.200400002 [41] R. D. Kross, “Method for Using Glycol Additives to Texturally Modify Natural Gum Hydrogels,” USA Patent, 6,664,301, 2003. [42] OECD, “OECD Principles of GLP,” ENV/MC/CHEM, Vol. 404, OECD, Paris, 1997. [43] J. Durando, “Primary Skin Irritation Study in Rabbits: Eurofins PSL,” 2010, Report nr 28823. [44] J. H. Draize, G. Woodward and H. O. Calvery, “Methods for the Study of Irritation and Toxicity of Substances Ap- plied Topically to the Skin and Mucous Membranes,” Journal of Pharmacology and Experimental Therapeutics, Vol. 82, No. 3, 1944, pp. 377-390. [45] OECD, “Ready Biodegradability: Closed Bottle Test,” OECD Guideline for Testing of Chemicals, Vol. 301D, 2003. [46] D. Detlef, “Assessment of the Ready Biodegradability of Polysaccharide Hydrogel with the Closed Bottle Test: Eurofins GAB,” 2010. [47] R. Silverstein, G. Bassler and T. Morrill, “Spectrometric Identification of Organic Compounds,” John Wiley & Sons, New York, 1991. |