Paper Menu >>

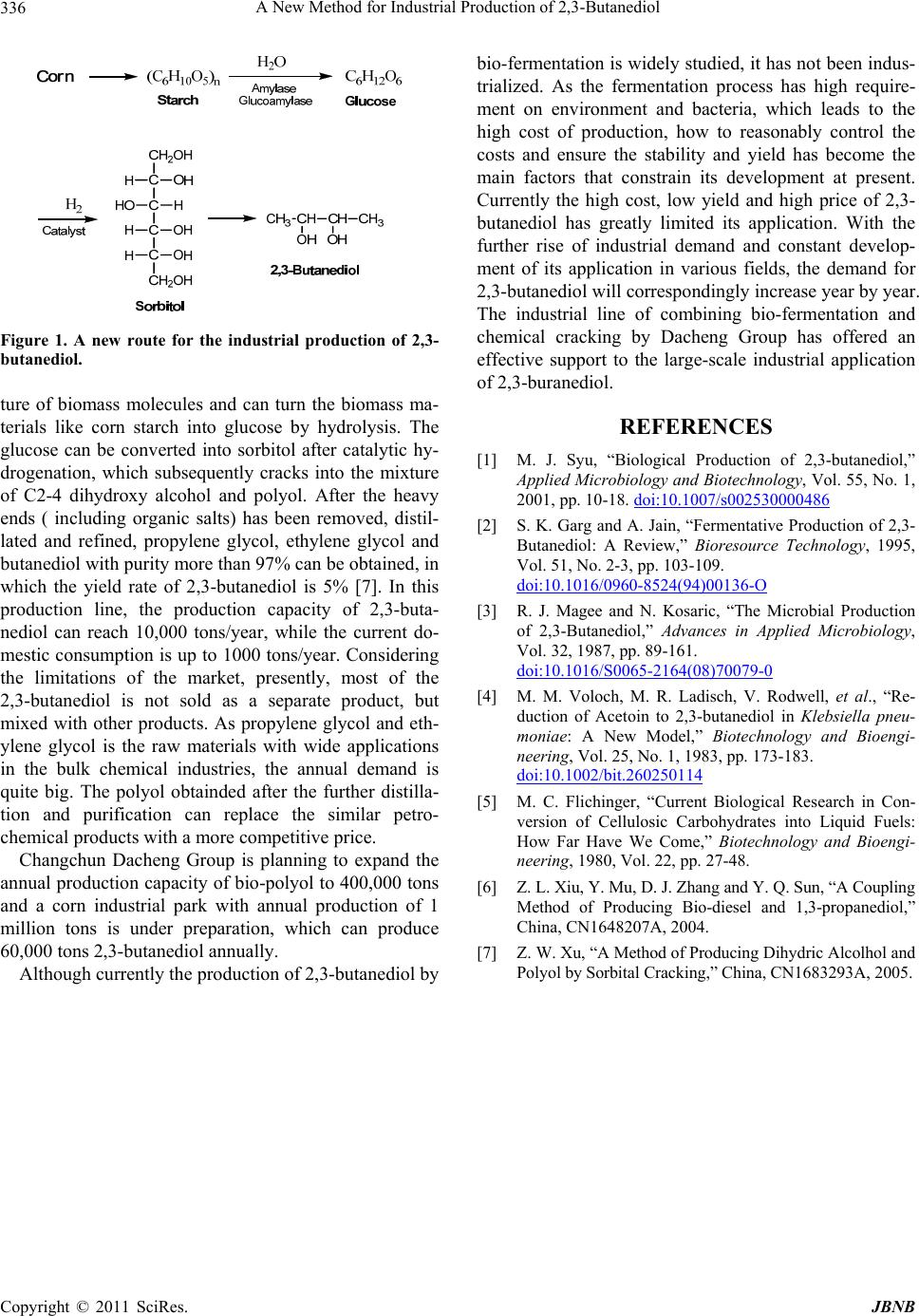

Journal Menu >>

Journal of Biomaterials and Nanobiotechnology, 2011, 2, 335-336 doi:10.4236/jbnb.2011.23041 Published Online July 2011 (http://www.SciRP.org/journal/jbnb) Copyright © 2011 SciRes. JBNB 335 A New Method for Industrial Production of 2,3-Butanediol* Lan Ge1, Xiaomin Wu1, Jianwen Chen1, Jialin Wu2 1Dachen Group Shanghai Branch, Shanghai, China; 2College of Material Science and Engineering, Donghua University, Shanghai, China. Email: jlwu@dhu.edu.cn Received October 9th, 2010; revised May 20th 2011; accepted June 9th, 2011. ABSTRACT A new industrial production method of 2,3-butanediol is discussed in this paper. C2-4 bio-polyol is prepared by combin- ing biological fermentation and chemical cleavage, with corn starch as raw material. In this industrial method, high purity 2,3-butanediol can be obtained after distillation and purification. Low p rod uction cost of this method provides an effective support for 2,3-butaned iol large-scaled application. Keywords: 2,3-Butanediol, Bio-glycol, Corn, Sorbitol 2,3-butanediol is an odorless, colorless and transparent liquid at normal temperature, which is widely used in chemical, food, fuel , aeronautical and other fields; Methyl- ethyl-ketone, the dehydration product of 2,3-butanediol can be used for resins, paints and other solvents; The dehydration esterification forms of 2,3-butanediol is the synthesis of polyimide precursors, which can be applied to drugs, cosmetics, lotion, etc; 2,3-butanediol can be fur- ther converted to 1,3-butadiene, which can be used for synthetic rubber, polyester and polyurethane and due to the greet need for synthetic rubber in World War II, 2,3-butanediol became even more important than be- fore.2,3-butanedio l itself can serve as a monomer used to synthesize polymer and its levorotatory forms can be used as antifreeze for its low freezing point [1,2]. After catalytic dehydrogenation, the 2-acetyl forms of 2,3-bu- tanediol can be used as food additives for high-value spices and in China, 2,3-butanediol have been added to the spirits in order to improve the wine flavor [3,4]. 2,3-buta- nediol is a highly valuable fuel with the burning value of 27198 J/g, which is comparable to other liquid fuels as ethanol (29055 J/g) and methanol (22081 J/g); it can also be converted to methyl-ethyl-ketone by sulfuric acid ca- talyzed dehydration, which is considered as an effective liquid fuel additive for its higher burning value than ethanol. After combination with methyl-ethyl-ketone an d hydrogenation reaction, 2,3-butanediol can be converted to octane, which is used to produce high-quality aviation fuel. Nowadays, thanks to the need for the pro- duction of polybutylene terephthalate resin, butyrolactone and elastic fibers, the production of 2,3-butanediol is growing at an- nual rate of 4 - 7 percent [5]. In recent years, with the v ig- orous development of industrial production and decreasing oil resources, the demand for 2,3-butanediol is increasing year by year. Because of the unique structure and costly chemical synthesis, 2,3-butanediol has not been produced on a large scale and its high price (60,000 - 130,000 yuan/ton) also leads to the inadequate development of its applica- tion. Therefore, although the fermentation process of 2,3-butanediol has basically reached the level of alcohol industry, it has not been industrialized. In recent years, with the rapid development of bio-diesel industry and the year-by-year increase of its by-product glycerol, a co- generation routing of bio-diesel and 1,3-propanediol has been developed in order to make full use of glycerol and 2,3-butanediol is one of the by-pr o duct o f th i s rout e [6] . As a bio-polyol project with the annual output of 200,000 tons has been put into production by Changchun Dacheng Group, a new route for the production of 2,3- butanediol has cone out in Figure 1. By the independent innovation and the use of biomass as raw materials, Changchun Dacheng Group has successfully developed the catalyst technology needed in that project. This cata- lyst has a high selectivity to the unique hydroxyl struc- *The project to support the revitalization of the industry in northeast China by Science and Technology Commission of Shanghai Munici- p ality in 2007(07125820 7) .  A New Method for Industrial Production of 2,3-Butanediol Copyright © 2011 SciRes. JBNB 336 Figure 1. A new route for the industrial production of 2,3- butanediol. ture of biomass molecules and can turn the biomass ma- terials like corn starch into glucose by hydrolysis. The glucose can be converted into sorbitol after catalytic hy- drogenation, which subsequently cracks into the mixture of C2-4 dihydroxy alcohol and polyol. After the heavy ends ( including organic salts) has been removed, distil- lated and refined, propylene glycol, ethylene glycol and butanediol with purity more than 97% can be obtain ed, in which the yield rate of 2,3-butanediol is 5% [7]. In this production line, the production capacity of 2,3-buta- nediol can reach 10,000 tons/year, while the current do- mestic consumption is up to 1000 tons/year. Con sidering the limitations of the market, presently, most of the 2,3-butanediol is not sold as a separate product, but mixed with other products. As propylene glycol and eth- ylene glycol is the raw materials with wide applications in the bulk chemical industries, the annual demand is quite big. The polyol obtainded after the further distilla- tion and purification can replace the similar petro- chemical products with a more competitive price. Changchun Dacheng Group is planning to expand the annual production cap acity of bio-polyol to 400,000 tons and a corn industrial park with annual production of 1 million tons is under preparation, which can produce 60,000 tons 2,3-butanediol annually. Although currently the production of 2,3-butanediol by bio-fermentation is widely studied, it has not b een indus- trialized. As the fermentation process has high require- ment on environment and bacteria, which leads to the high cost of production, how to reasonably control the costs and ensure the stability and yield has become the main factors that constrain its development at present. Currently the high cost, low yield and high price of 2,3- butanediol has greatly limited its application. With the further rise of industrial demand and constant develop- ment of its application in various fields, the demand for 2,3-butanediol will corresponding ly in crease year by year. The industrial line of combining bio-fermentation and chemical cracking by Dacheng Group has offered an effective support to the large-scale industrial application of 2,3-buranediol. REFERENCES [1] M. J. Syu, “Biological Production of 2,3-butanediol,” Applied Microbiology and Biotechnology, Vol. 55, No. 1, 2001, pp. 10-18.doi:10.1007/s002530000486 [2] S. K. Garg and A. Jain, “Fermentative Production of 2,3- Butanediol: A Review,” Bioresource Technology, 1995, Vol. 51, No. 2-3, pp. 103-109. doi:10.1016/0960-8524(94)00136-O [3] R. J. Magee and N. Kosaric, “The Microbial Production of 2,3-Butanediol,” Advances in Applied Microbiology, Vol. 32, 1987, pp. 89-161. doi:10.1016/S0065-2164(08)70079-0 [4] M. M. Voloch, M. R. Ladisch, V. Rodwell, et al., “Re- duction of Acetoin to 2,3-butanediol in Klebsiella pneu- moniae: A New Model,” Biotechnology and Bioengi- neering, Vol. 25, No. 1, 1983, pp. 173-183. doi:10.1002/bit.260250114 [5] M. C. Flichinger, “Current Biological Research in Con- version of Cellulosic Carbohydrates into Liquid Fuels: How Far Have We Come,” Biotechnology and Bioengi- neering, 1980, Vol. 22, pp. 27-48. [6] Z. L. Xiu, Y. Mu, D. J. Zhang and Y. Q. Sun, “A Coupling Method of Producing Bio-diesel and 1,3-propanediol,” China, CN1648207A, 2004. [7] Z. W. Xu, “A Method of Producing Dihy dric Alcolhol and Polyol b y Sorbital Cracking,” China, CN1683293A, 2005. |