Applied Mathematics, 2011, 2, 625-632 doi:10.4236/am.2011.25083 Published Online May 2011 (http://www.SciRP.org/journal/am) Copyright © 2011 SciRes. AM Generalized Thermo Elasticity in an Infinite Nonhomogeneous Solid Having a Spherical Cavity Using DPL Model Ahmed Elsayed Abouelrega Department of Mat hematics, Fac ul t y of Sci ence, Mansoura Universit y , Mansoura, Egypt E-mail: ahabogal@mans.edu.eg Received January 2, 2011; revised March 39, 2011; accepted April 2, 2011 Abstract The induced temperature, displacement, and stress fields in an infinite nonhomogeneous elastic medium having a spherical cavity are obtained in the context dual-phase-lag model. The surface of the cavity is stress free and is subjected to a thermal shock. The material is elastic and has an in homogeneity in the radial direc- tion. The type of non homogeneity is such that the elastic constants, thermal conductivity and density are proportional to the nth power of the radial distance. The solutions are obtained analytically employing the Laplace transform technique. The numerical inversion of the transforms is carried out using Fourier series expansions. The stresses, temperature and displacement are computed and presented graphically. A com- parison of the results for different theories is presented. Keywords: Generalized Thermo Elasticity, Nonhomogeneous, Functionally Graded Material (FGM), Laplace Transform, Three-Phase-Lag Model 1. Introduction The increasing use of anisotropic material in engineering application has resulted in considerable research activity in this area in recent years. An understanding of thermally induced stresses in an isotropic bodies is essential for a comprehensive study of their response due to an exposure to a temperature field, which may in turn occurs in service or during the manufacturing stages. For example, during the curing stages of lament wound bodies, thermal str- esses may be induced from the heat buildup and cooling processes. The level of these stresses may be exceeding the ultimate strength. The generalized thermoelasticity theories have been developed with the aim of removing the paradox of infi- nite speed of heat propagation inherent in the classical coupled dynamical thermo elasticity theory (C-D), see Biot [1]. Many new theories have been proposed to take care of this physical absurdity. Lord and Shulman [2] (L -S) first modified Fourier's law by introducing the term representing the thermal relaxation time. The heat equa- tion associated this theory is a hyperbolic type and hence, eliminates the paradox of infinite speed of propagation. Following Green and Lindsay [3] (G-L) developed a more general theory of thermoelasticity, in which Fourier's law of heat conduction is unchanged, where as the classical energy equation and Duhamel-Neumann's relations are modified by introducing two constitutive constants having the dimensions of time. Recently, relevant theoretical developments on this su- bject are due to Green and Naghdi [4] (G-N) to establish a theory of thermoelasticity that permits propagation of the- rmal waves at a finite speed, where its evolution equations are hyperbolic. An important characteristic feature of this theory, which is not present in other thermoelastic theo- ries, is that this theory does not accommodate dissipation of thermal energy. Tzou [5,6] proposed the dual-phase-lag (DPL) model, which describes the interactions between phonons and electrons on the microscopic level as retarding sources causing a delayed response on the macroscopic scale. For macroscopic formulation, it would be convenient to use the DPL mode for investigation of the micro-structural effect on the behavior of heat transfer. The physical meanings and the applicability of the DPL mode have been supported by the experimental results [7]. The dual-phase-lag (DPL) proposed by Tzou [7] is such a modification of the classical thermoelastic model in  A. E. ABOUELREGA 626 which the Fourier law is replaced by an approximation to a modified Fourier law with tow different time transla- tions: a phase-lag of the heat flux q and a phase-lag of temperature gradient . A Taylor series approximation of the modified Fourier law, together with the remaining field equations leads to a complete system of equations describing a dual-phase-lag thermoelastic model. The model transmits thermoelastic disturbance in a wave-like manner if the approximation is linear with respect to q and , and 0 ≤ <q ; or quadratic in q and li- near in , with q >0 and > 0. This theory is deve- loped in a rational way to produce a fully consistent the- ory which is able to incorporate thermal pulse transmis- sion in a very logical manner. Each of models has been introduced in the literature in an attempt to eliminate shortcomings of the classical dy- namical thermo elasticity such as: 1) infinite velocity of thermoelastic disturbances, 2) unsatisfactory thermoelas- tic response of a solid to short laser pulses, and 3) poor description of thermoelastic behavior at low temperature [17]. Attempts to present a theory of thermoelastic waves that would be attractive to both the basic and applied re- searchers have been continued in the literature to date. Also, a stream of papers devoted to theoretical and ap- plied aspects of the generalized thermoelasticity that started with publications on the wave equation for a rigid heat conductor in the 1940s has increased greatly to date. Although the five theories are not the only ones that have been proposed so far, they are, in the authors opinion, re- presentative in discussing the subject [17]. Allam, et. al. [11] investigated the thermal stress dis- tributions in a harmonic field for a homogeneous, iso- tropic infinite body with a circular cylindrical hole based on a Green and Naghdi theory. Sinha and Elsibai [10] studied generalized thermoelastic interactions for an in- finite body with a spherical cavity and for an isotropic solid sphere. Mukhopadhyay [12] discussed the thermally induced vibration in a homogeneous and isotropic un- bounded body with a spherical cavity using the Green and Naghdi model of thermo elasticity without energy dissi- pation. Mukhopadhyay and Kumar [13] studied the thermoelastic interactions in an unbounded elastic me- dium with a spherical cavity in the context of four dif- ferent theories of thermoelasticity, namely: the classical coupled dynamical thermoelasticity, the extended ther- moelasticity, the temperature-rate-dependent thermoelas- ticity and the thermoelasticity without energy dissipation in a unified way. Roychoudhuri [14] studied one-dimen- sional thermoelastic wave propagation in an elastic half- space in the context of dual-phase-lag mode. Functionally graded materials (FGMs) are a type of nonhomogeneous materials in which the composition changes gradually with a corresponding change in the properties. FGMs are usually designed to be used under high temperature environments. Thermal shock loading conditions may be involved with high thermal stresses when a sudden heating or cooling happens. As a result, thermal fracture problems may be usually met. Therefore, it is significant to analyze the transient thermal fracture behavior of FGMs. Functionally graded material (FGM) as a new kind of composites was initially designed as thermal barrier ma- terials for aerospace structures, in which the volume fra- ctions of different constituents of composites vary con- tinuously from one side to another [15]. These novel non- homogeneous materials have excellent thermo-mecha- nical properties to withstand high temperature and have extensive applications to important structures, such as aerospace, nuclear reactors, pressure vessels and pipes, chemicals plants, etc. The use of FGMs can eliminate or control thermal stresses in structural components [16]. Laplace transform technique is used to solve the prob- lem. The main difficulty encountered in solving problems of coupled or generalized thermoelasticity theory is that of inversion of the Laplace transforms used. This is mainly due to the fact that the contour integral of Laplace transforms complex inversion formula contains compli- cated branch points in its integral. The inverse Laplace transforms are obtained numerically using a method based on Fourier expansion techniques. The present paper is organized as follows. Section 2 describes the formulation of the problem and basic equa- tions. Section 3 discusses the Laplace transform technique and the solution in the transformed domain is obtained using a potential function. Section 4 summarizes the in- verse Laplace transforms using a numerical method based on Fourier expansion techniques. The last section is de- voted to the numerical example for finding the tempera- ture, displacement and the stress. The numerical results are presented graphically and compared it in the different theories of thermoelasticity and discussed the differences due to the presence of dual phase lags. 2. Mathematical Formulation of the Problem and Basic Equations We consider a nonhomogeneous thermal and mechanical material properties in the radial direction infinite solid having a spherical cavity of radius a. The surface of the cavity is stress free and is suddenly heated and kept at constant temperature. We also assume that neither the body forces nor the heat sources are acting inside the medium. We use spherical polar coordinates ,,r with the origin at the center of the cavity and we consider those thermoelastic interactions which are spherically symmet- ric. It follows that all interactions considered depend on Copyright © 2011 SciRes. AM  A. E. ABOUELREGA627 the radial distance r and the time t then only the radial component of the displacement and the nor- mal stress components ,uurt , rr '' 12 C e '' 22 Ce 22 2, will appear in the analysis. The nonhomogeneous character of the material is dis- cussed by considering that the elastic constants, density and the thermal conductivity are given by some power law of variation with radial distance r. For a spherically orthotropic thermoelastic solid, the constitutive equations will take the following forms: 1,ebT ' 23 2 Ce bT ' ' 11rr rr Ce (1) 12 rr Ce (2) where '' ' 1111 1 bC C '' ' 212122 C' 223 C2 bC in which ij Care elastic constants, Tis the temperature excess over 0, and 1 T ,2 are the coefficients of linear thermal expansion along the radial and tangential direc- tions. The equation of motion in absence of any body forces becomes 2 2 2 rr u rr t rr (3) The non-zero components of strain are , u ee rr u e rr (4) then the normal stresses are '' 1112 1 2, rr uu CCb rr ' T (5) ''' 122223 2 uuu CCCb rrr ' T 0. (6) In an attempt to model ultrafast processes of thermoe- lasticity Tzou (1997) proposed a dual-phase-lag model (DPL) ofthermoelasticity in which the MaxwellCattaneo equation is replaced by the relation . , qq qtqKTtTt t (7) Equation (7) together with the energy balance equation led to the heat conduction equation 2 ' 10 2 2 2 2 1 1 qE r n tCTbT tr t T trK tr r r u r (8) where q and tt stand for the heat flux and temperature gradient phase-lags, respectively, r is the is coefficient of thermal conductivity along radial direction, C is specific heat at constant strain, is the density . Clearly, a DPL model covers the hyperbolic L-S model when 00 q tt , and 0t . We assume that the functionally graded spherical that has nonhomogeneous thermal and mechanical properties in the radial direction. In order to incorporate the non- homogeneity of the material, we assumed to take the following forms ' 0 nn n ij ijr CrCr KrK ,, 0 , (9) where 0 , 0 and ij are nonzero constants (they are the values of in a homogeneous matter when C 0n ). Substituting from Equation (9) into Equations (5) and (6), we obtain 11 12 2uu C rr 1 n rr rC bT (10) 12 22 u 23 2 nu rCC CbT rr (11) where 1111 122 2,bC C 212223 2 C C 12 bC Using Equations (10) and (11), we have from Equation (3) the displacement formulation of the equation of mo- tion 2 1111122223 22 2 110 2 2 22 unu u CC CCC rr rr TTu bnbb rr t 2 21 n (12) 2 010 2 2 02 2 2 Tb tr 1 qE n tCTu trr t TnT Kt r r (13) The problem is to solve Equations (12) and (13) subject to the boundary conditions 1) Traction-free cavity surface ,0 rr at ,t0 (14) 2) The surface of the cavity is considered to be main- tained at a constant temperature To 0 ,Tat T,t0 (15) The initial and regularity conditions may be put as ,0t, Tu Tu ar rr , ,0,,0,atTrt urtr (16) The following non-dimensional quantities are intro- duced as Copyright © 2011 SciRes. AM  A. E. ABOUELREGA 628 ** * ,, , ii r rttt iq aaa,, ** 2 11 11 001 ,, C T Tuu TaTb , C (17) ** 01 01 ,. rr rr nn rTbrTb Using these non-dimensional variables, Equations (10)- (13) take the form (dropping the asterisks for conven- ience): 12 11 2 n rr C uu r rCr T (18) 22 232 12 1 nCC b uu rT rCrb (19) 22 222 2unuuuT T mh rrr r rrt (20) 2 0 2 2 2 2 2 1 qn tT tr t TnT ttrr r u r (21) where 12222312 11 1 21 22 , nC CCnbb mh Cb 2 10 0 00 , EE bT K CaC 3. Solution of the Problem Applying the Laplace transform to Equations (18)-(21), we get the field equations in the Laplace transform space as 1112 1 d2 d n rr uu rC CbT rr , (22) 22 232 12 1 d d nCC b uu rT rCrb (23) 2 2 2 d2d2 dd d ununuT su rr rrr r d , (24) 2 22 2 d2d d2 dd d nn T rrr r r u (25) where we assume and 0, 2hmn 21. 1 q s The boundary conditions in the Laplace transform space read 1 1,,1, 0, rr Ts s s (26) while the regularity conditions are ,0,,0,atTrsursr . (27) Taking d, d ur where is the thermoelastic po- tential function and introducing it in Equations (24) and (25), we find 2 12 DD sT (28) 22 12 12 DDT DD (29) where 12 d2 , dd n DD rr d r Eliminating from Equations (28) and (29), we get T 22222 12 12 10DDs DDs (30) Introducing ,1,2 i mi into Equation (30) become 22 12 11220DD mDD m (31) where ,1,2 i mi are the positive solutions of the fol- lowing characteristic equation 222 22 10msm s (32) In order to transform Equation (31) into a normal Bessell equation, a new dependant variable r is in- troduced as 1/2n rr Then, Equation (31) is rewritten as 22 2 22 d1d0,1, 2, d di mi rr rr (33) where 1 2 n The solution of in will be the form 2 1/2 1 niiii i rr AKmrBImr (34) where i mr and i mr are the modified Bessell functions of order of first and second kind respectively. 1 and 2 are independent of but depend on r and are to be determined from the boundary conditions. In the case of spherical cavity the solution to be continuous every where, we take equal to zero. i B Copyright © 2011 SciRes. AM  A. E. ABOUELREGA629 Using the relations between ,urTr and r , and using the recurrence relations of modified Bessell functions, we obtain the solution for the displacement ur and temperature Tr as follows 1/2 2 1 1 12 2 2 n iii i ur r i nK mrmrKmr r (35) 2 1/2 22 1 nii i i TrrAms K mr (36) Substituting the above solutions for ur and Tr in the relations (22) and (23), we obtain the following solutions for rr and in the form 1/2 2 1 2 1 11 2 2 n rr iii i r 1 i LK mrmrKmr rC (37) 1/2 22 56 21 2 1 11 4 4 n iii ii i r LmL KmrmrLKmr rC (38) where 3 1 222 11 12 23422 242 L Cnnnrs Cn 211 1 22LCnC, 2 412222 22LCnCC, 22 312 22 23 43484 48 4 LC nnn CC n 22 2 511 1 1 44 b LrCCr b , 2 22 2 53 11 1 4b LL rCs b . In order to determine the parameters 1 and 2 , we need to consider the boundary conditions (26), we t ge 21 22 1 ii i i Ams K m , (39) (40) Solving (39) and (40), we obtain 2 11 1 20 iiii i ALK mmKm 1 and 2 as the following 11221 12ALKmmKm s 2 (41) 21111 12ALKmmKm s 22 111221 22 2211111 2 2 msKmLKm mKm msKmLKm mKm 2 Substituting the value of 1 and 2 from Equations (4 deduced from ou 1) and (42) yields the displacement, temperature and thermal stresses in the transformed space. The results for isotropic material can be r problem by simply replacing 11 2,C 12 ,C 22 23,CC 123bb 2t and r K win our calculation, here , are the Lame's constants, t is the coefficient of linear thermal expansion and the thermal conductivity for the isotropic material. Inversion of the Laplace Transforms K . o obtain a solution of the problem in physical domain, 4 T we adopt a numerical inversion method based on a Fourier series expansion [9]. In this method, the inverse gt of the Laplace transform gs is approximated by re- lation the 1 / 1 1 11 eRe e,0, 2 ct Nikt t k gc ik tgc tt tt (43) where is a sufficiently large inte o N ger representing the number f terms in the truncated infinite Fourier series. N must chosen such that 1 / 1 1 eRee ikt t ct ik gc t (44) where 1 is a persecuted small positive number that corresponds to the degree of accuracy to be achieved. The parameter c is a positive free parameter that must be greater than the real parts of all singularities of s. Two methods are used to reduce the total error. Firste Korrecktur method is used to reduce the discretization error. Next, the algorithm is used to reduce the truncation error and therefore to accelerate convergence. The details of these methods can be found in Honig and Hirdes [9]. The discretization error can be made arbitrarily small by choosing the constant c large enough. The values of c and 1 t are chosen according to the criteria outlined in [9]. Formla (43) was used to invert the Laplace transforms in Equations (35)-(38), given the temperature, stress, and displacement distribution numerically. . Numerical Example and Dis , th cussion tained in u 5 ith the view of illustrating theoretical results obW 1 (42) where the preceding sections, we now present some numerical results. The materials chosen for this purpose is single crystal of magnesium, the physical data for which is given Copyright © 2011 SciRes. AM  A. E. ABOUELREGA 630 2 Numerical calculation are carried out for the tempera- tu of a homoge mensionless va as 10 2102 11 12 10 2 23 =5.97410Nm, = 2.62410Nm = 2.1710Nm, CC C l0 233 33 0 0 =6.1710Nm, = 1.4710kgm, = 298 K, = 0.0202, C T 621 l2 0 3 E == 2.6810Nm deg = 1.710, = 1.0410 bb K C re, the displacement, and the stress components along the r-direction. The computations were performed for one value of time, namely for 0.2t. For all numerical calculations Mathematica proing Language has been used. The results of the numerical evaluation of the thermoelastic stresses variations, displacement and tem- perature distribution are illustrated in Figures 1-8. The computational work has been performed for a suffici- ently wide range of values of the nonhomogeneity index n, via 0,1,2,1nand –2. Moreover 0n leads to the caseneous medium. Figures 1-4 elucidate the variation of di gramm lues of displacement, temperature, and thermal stresses distributions with respect to radius r for different values of 0,1,2,1nand –2. Figure 1 give the variation of the with observation distance for different values of n, It is seen that displacement takes positive values andradually increases until it attains a peak val- ue at a particular location in close proximity to the cavity surface and then diminishes rapidly with increasing dis- tance. Figure 2 represents the graph of temperature T versus r. It is noted that near the region of the cavity, T is maximum and it decreases with the increase of r, as it should occur in the real situation. Figure 3 represents the graph of radial thermal stress rr displacement g versus radius r. Also stress in each of the all cases is found to vanish on the boundaries, which agrees with the theoretical boundary condition. It is clear that for fixed t it decreases with the increase of r, which is physically plausible. Figure 4 is plotted to show the variation of hoop stress versus r for different values of n, from the graph it lear that the maximum values o occur near the surface of the cavity and its magnitude decreases with the increase of r, keeping t fixed. Figures 5-8 sh is c f ow the displacement, temperature, radial stress and hoop stress distributions for three different values of the parameters q and . These computations were carried out in the coupled theory (q=0 ), in Lord-Shulman theory (0, q0 =0 t the generalized theory of theosed by Tzou (q0 ) and in prmoelasticity pro ). The numerical values of the temperature, dit components and stress components are obtained and represented graphically for these theories. splacemen 6. Conclusions he problem of investigating the thermoelastic stresses, T 0.16 0 0.04 0.08 0.12 11.21.41.61.8 0n 2n 1n 2n u r u 1n n = 0 Figure 1. Variation of displacement with respect to radus i for fifferent values of nonhomogeneity parameter n. 0 0.2 0.4 0.6 0.8 1 11.21.4 1.61.82 T r 0n n = 0 1n 2n 1n 2n Figure 2. Variation of temperature with respect to radiu s for different values of nonhomogeneity parameter n. -1. 6 -1. 2 -0. 8 -0. 4 0 11.2 1.41.6 1.8 rr r 0n –0.4 –0.8 n = 0 1n 2n 1n –1.2 2n Figure 3. Variation of radial stress with respect to radis –1.6 u for different values of nonhomogeneity parameter n. Copyright © 2011 SciRes. AM  A. E. ABOUELREGA631 -1. 5 -1. 1 -0. 7 -0. 3 11.21.41.61.8 r 0n 1n 2n 1n 2n Figure 4. Variation of hoop stress with respect to radius for different values of nonhomogeneity parameter n. -0.01 0.03 0.07 0.11 0.15 0.19 211.2 1.41.6 1.8 0.2, 0.15 q 0.2, 0.1 q 0.2, 0 q 0, 0 q 0.25, 0.1 q u r Figure 5. Variation of displacement with respect to radius for different values of phase-lags. -0.1 11.2 1.41.6 1.82 0.3 0.7 1.1 0.2, 0.1 q 0.25,0.1 q 0.2,0.15 q 0.2, 0 q 0, 0 q r T re 6. Variation of temperature with respect to radiu displacement and temperature distribution in a func- tio Figus for different values of phase-lags. nally graded orthotropic hollow sphere. Under thermal shock loading on the stress free boundaries of the hollow sphere the problem is studied using dual-phase-lag model -4 -3 -2 -1 0 11.2 1.4 1.6 1.82 0, 0 q 0.25, 0.1 q 0.2,0.1 q 0.2, 0 q 0.2, 0.15 q r rr Figure 7. Variation of radial stress with respect to radius for different values of phase-lags. -1. -1.4 -1 -0.6 -0.2 11.21.41.61.82 0.2, 0.1 q 0.25, 0.1 q 0.2, 0.15 q 0.2, 0 q 0, 0 q r F. Variation of hoop stress with respect to radius for f generalized thermoelasticity. The thermophysical pa- permits some concluding re be observed that the phase lags effect plays a sig d theory and dual- ph ement and tempe- ra eory (L-S), co phenomenon of finite speeds of propagation is manifested in all these figures. This is expected, since the thermal wave travels with a finite velocity. igure 8 different values of phase-lags. o rameters are assumed to vary as the power-law exponent of the radial coordinate. The analysis of the results marks: 1) It can nificant role on all distributions. 2) The difference between couple ase-lag (DPL) model is very clear. 3) The thermoelastic stresses, displac ture have a strong dependency on the nonhomogeneous parameter n, so to design an FGM, the importance of the parameter must be taken into consideration. 4) The difference between Lord-Shulman th upled theory and dual-phase-lag (DPL) model is rather small. 5) The –0.3 1 –0.7 2 3 –1.1 4 –1.5 u –0.2 –0.6 –1 –1.4 –0.01 –1.8 –0.1 Copyright © 2011 SciRes. AM  A. E. ABOUELREGA Copyright © 2011 SciRes. AM 632 6. rsible Thermo- urnal of Applied Physics, Vol. 27, No. 3, 53. doi:10.1063/1.1722351 pp. 299-309. ol. 31, 995, pp. 8-16. doi:10.1115/1.2822329 Mathematics, Vol. 10, No. 1, 1984, [11] al, “Ther- hout Study of General- l Thermoelastic ction- ang, “The Use of Function- eneralized Thermoe- References [1] M. A. Biot, “Thermoelasticity and Irreve dynamic s, ” Jo 1956, pp. 240-2 [2] H. Lord and Y. Shulman, “A Generalized Dynamical Theory of Thermoelasticity,” Journal of the Mechanics and Physics of Solids, Vol. 15, No. 5, 1967, doi:10.1016/0022-5096(67)90024-5 [3] A. E. Green and K. A. Lindsay, “Thermoelasticity,” Journal of Elasticity, Vol. 2, No. 1, 1972, pp. 1-7. doi:10.1007/BF00045689 [4] A. E. Green and P. M. Naghdi, “Thermoelasticity With- out Energy Dissipation,” Journal of Elasticity, V No. 3, 1993, pp. 189-208. doi:10.1007/BF00044969 [5] D. Y. Tzou, “Macro- to Microscale Heat Transfer: The Lagging Behavior,” 1st Edition, Taylor & Francis, Wa- shington, 1996. [6] D. Y. Tzou, “A Unified Approach for Heat Conduction from Macro- to Microscales,” Journal of Heat Transfer, Vol. 117, No. 1, 1 [7] D. Y. Tzou, “Experimental Support for the Lagging Be- havior in Heat Propagation,” Journal of Thermophysics and Heat Transfer, Vol. 9, No. 4, 1995, pp. 686-693. doi:10.2514/3.725 [8] D. S. Chandrasekharaiah, “Thermoelasticity with Second Sound,” Applied Mechanics Reviews, Vol. 39, No 1986, pp. 354-376. . 3, ally Graded Materials to Eliminate or Control Thermal Deformation,” Composites Science and Technology, Vol. 56, No. 9, 1996, pp. 1099-1104. [9] G. Honig and V. Hirdes, “A Method for the Numerical Inversion of the Laplace Transform,” Journal of Compu- tational and Applied pp. 113-132. doi:10.1016/0377-0427(84)90075-X [10] S. B. Sinha and K. A. Elsibai, “Thermal Stresses for an Infinite Body with Spherical Cavity with Tow Relaxation Times,” Journal of Thermal Stresses, Vol. 19, No. 5, 1996, pp. 745-759. doi:10.1080/01495739608946190 M. N. Allam, K. A. Elsibai and A. E. Abouelerg mal Stresses in a Harmonic Field for an Infinite Body with a Circular Cylindrical Hole Without Energy Dissi- pation,” Journal of Thermal Stresses, Vol. 25, No. 1, 2002, pp. 57-68. doi:10.1080/014957302753305871 [12] S. Mukhopadhyay, “Thermoelastic Interactions wit Energy Dissipation in an Unbounded Body with a Spher- ical Cavity Subjected to Harmonically Varying Tem- perature,” Mechanics Research Communications, Vol. 31, No. 1, 2004, pp. 81-89. doi:10.1016/S0093-6413(03)00082-X [13] S. Mukhopadhyay and R. Kumar, “A ized Thermoelastic Interactions in an Unbounded Me- dium with a Spherical Cavity,” Computers and Mathe- matics with Applications, Vol. 56, No. 9, 2008, pp. 2329- 2339.doi:10.1016/j.camwa.2008.05.031 [14] S. K. Roychoudhuri, “One-Dimensiona Waves in Elastic Half-Space with Dual-Phase-Lag Ef- fects,” Materials and Structures Journal, Vol. 2, No. 1, 2007, pp. 489-503. doi:10.2140/jomms.2007.2.489 [15] S. Suresh and A. Mortensen, “Fundamentals of Fun ally Graded Materials,” Institute of Materials Communi- cations Ltd., London, 1998. [16] R. C. Wetherhold and S. S. W doi:10.1016/0266-3538(96)00075-9 [17] R. B. Hetnarski and J. Ignaczak, “G lasticity,” Journal of Thermal Stresses, Vol. 22, No. 4, 1999, pp. 451-476. doi:10.1080/014957399280832

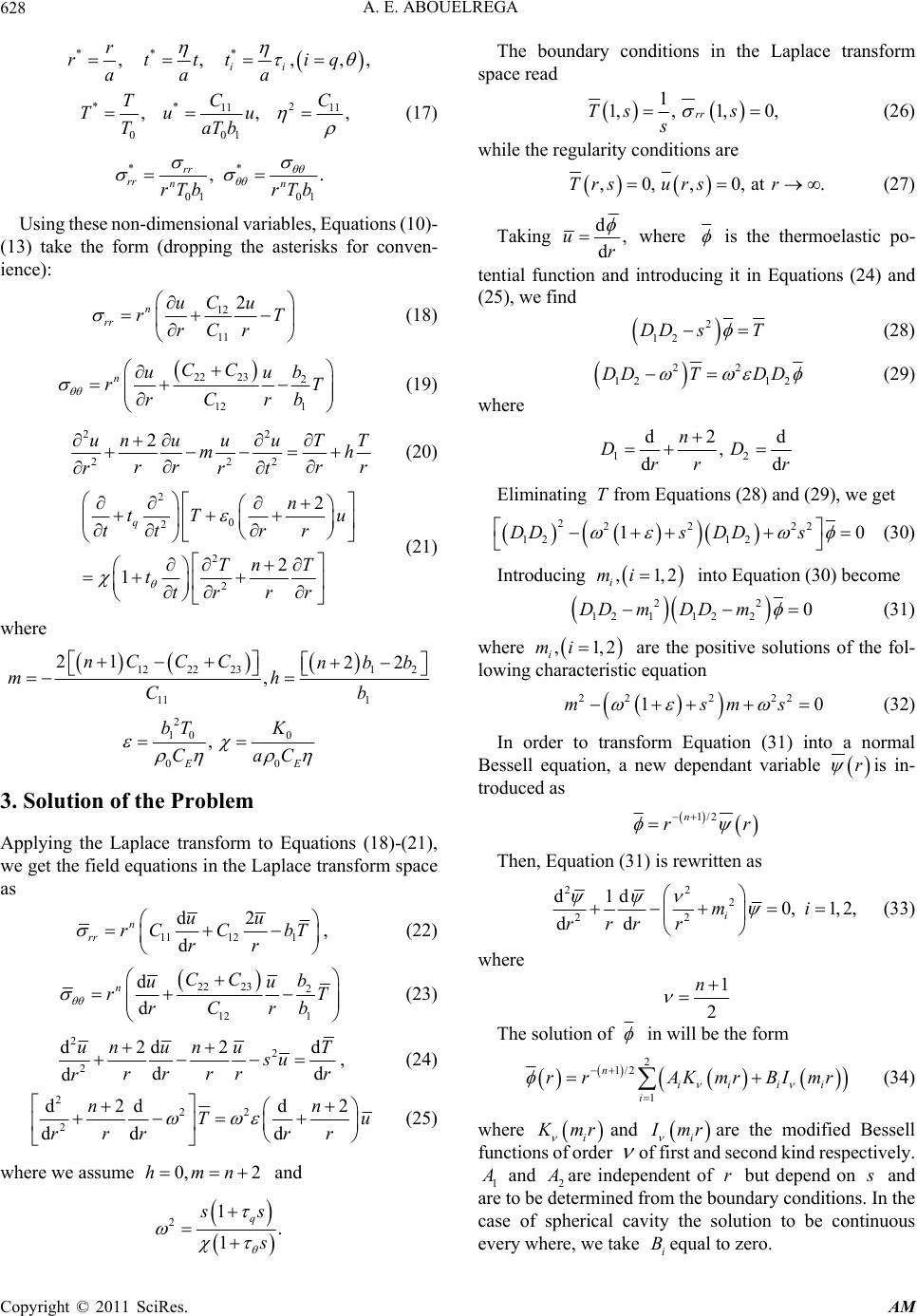

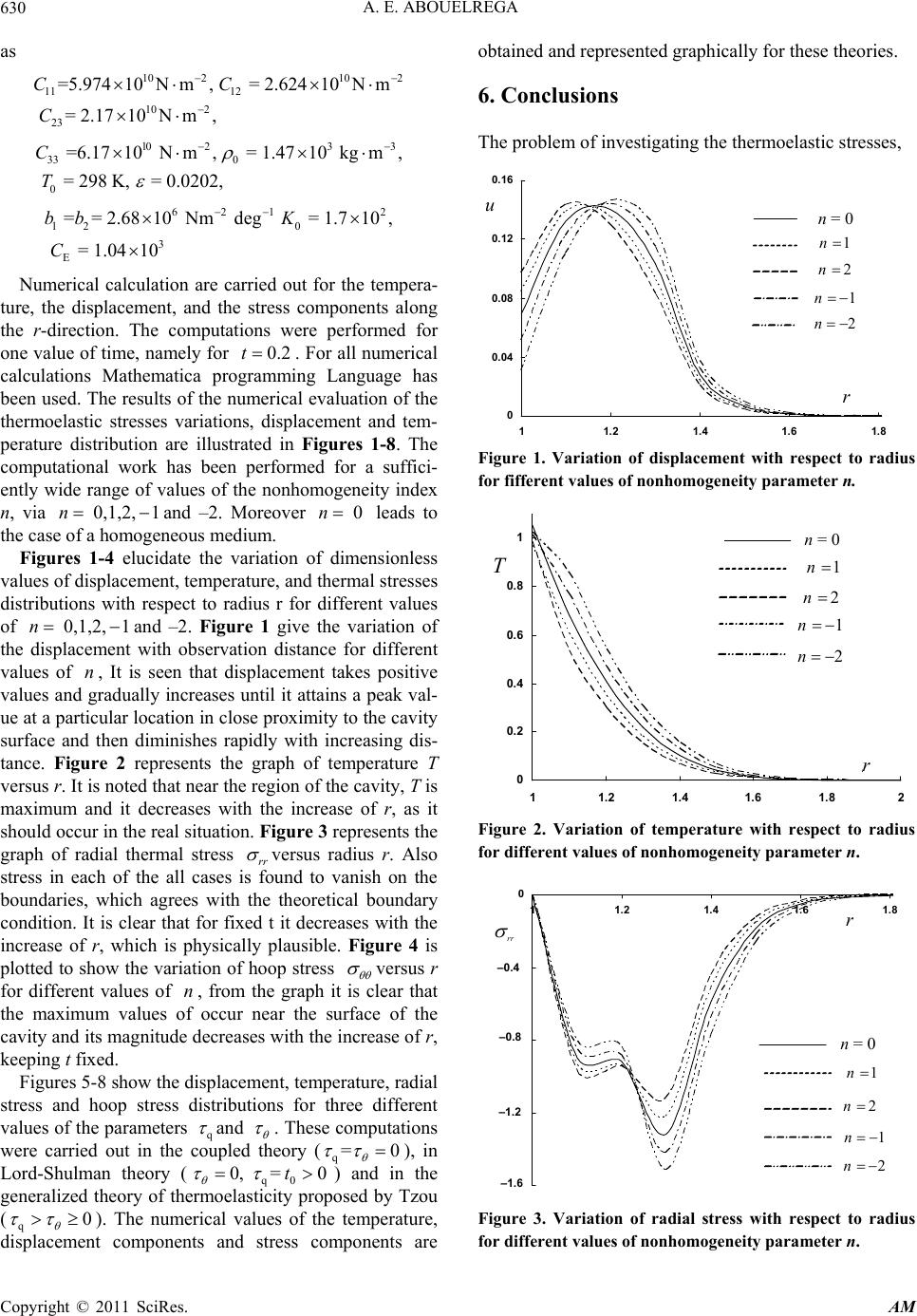

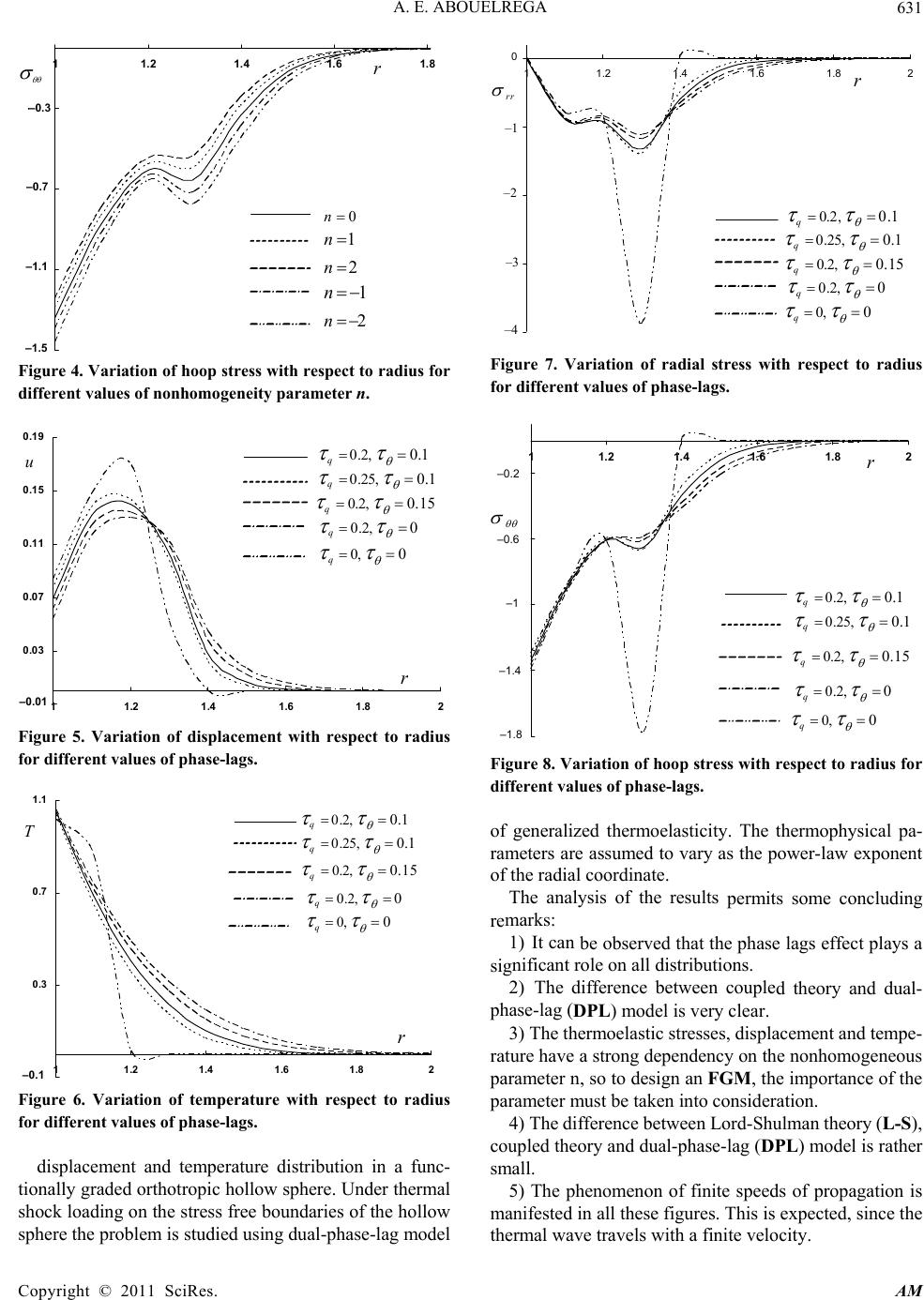

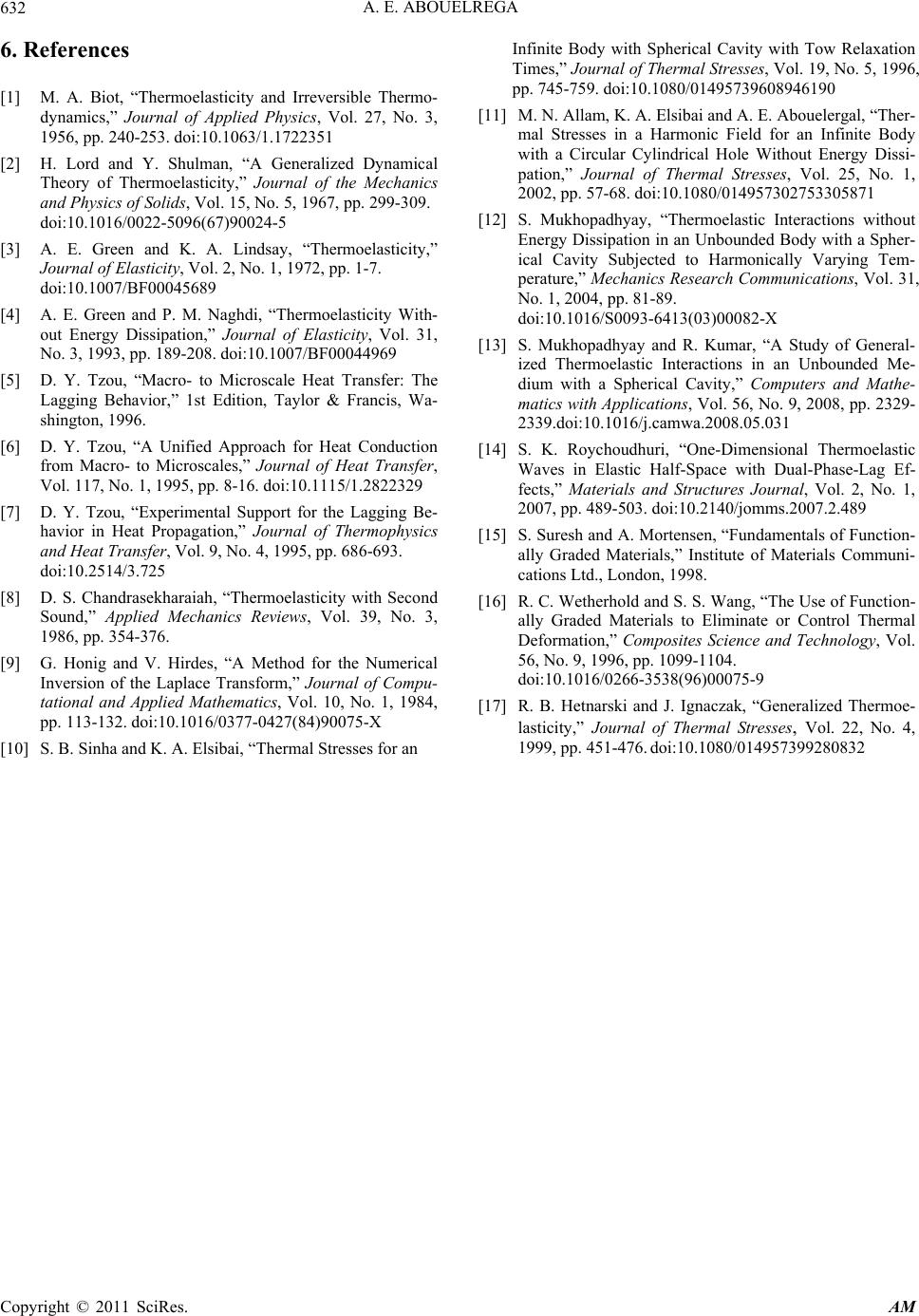

|