Paper Menu >>

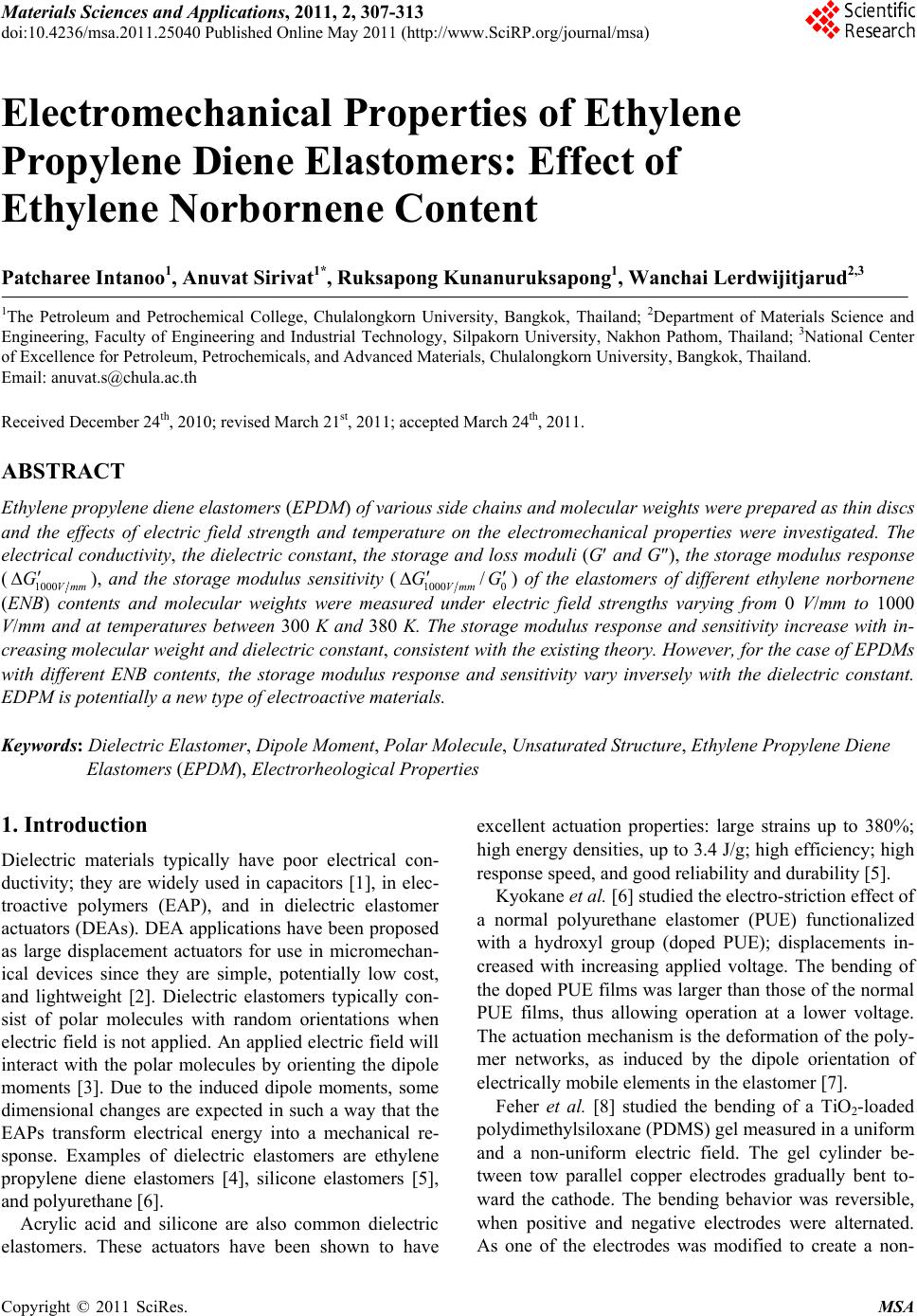

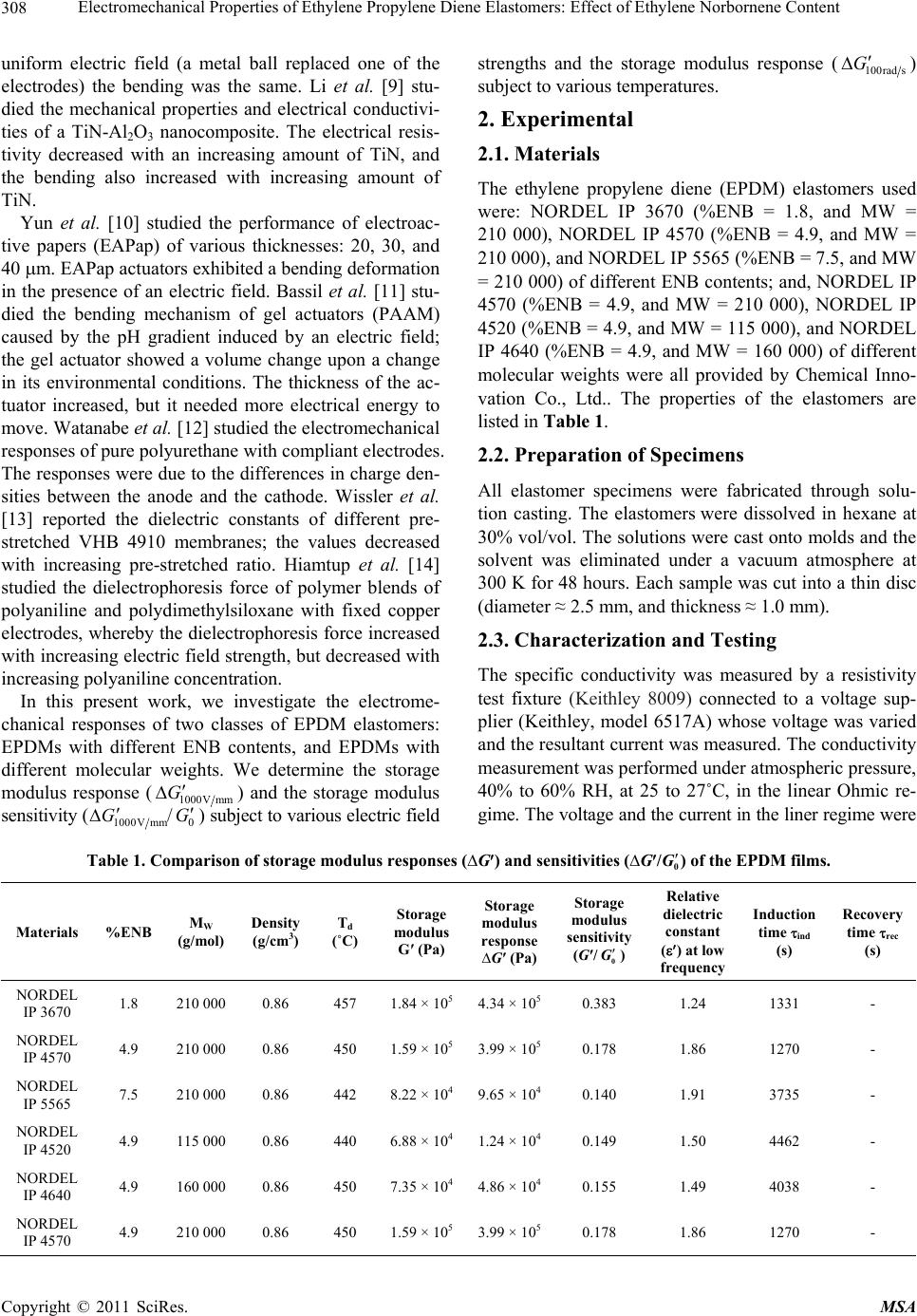

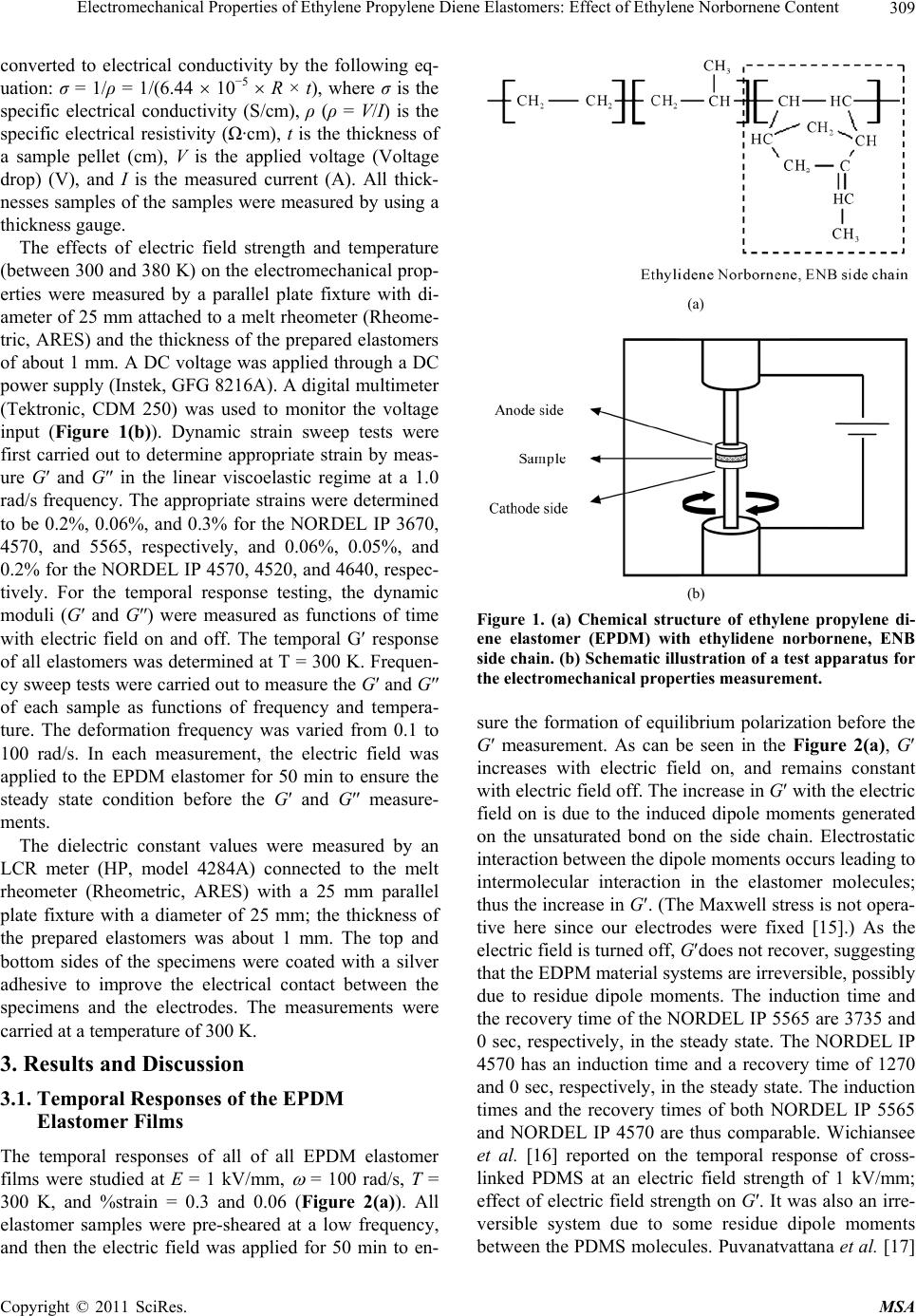

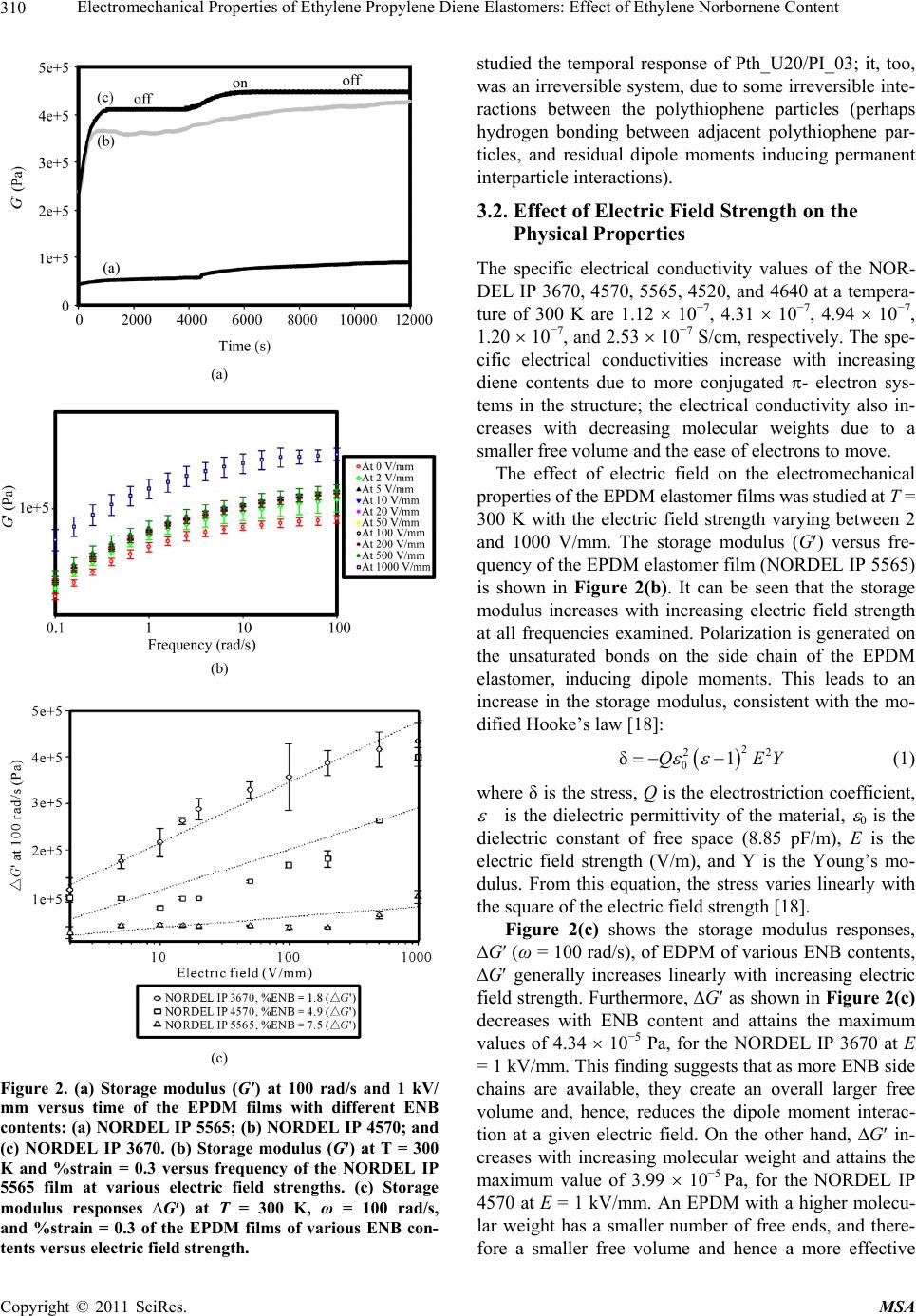

Journal Menu >>

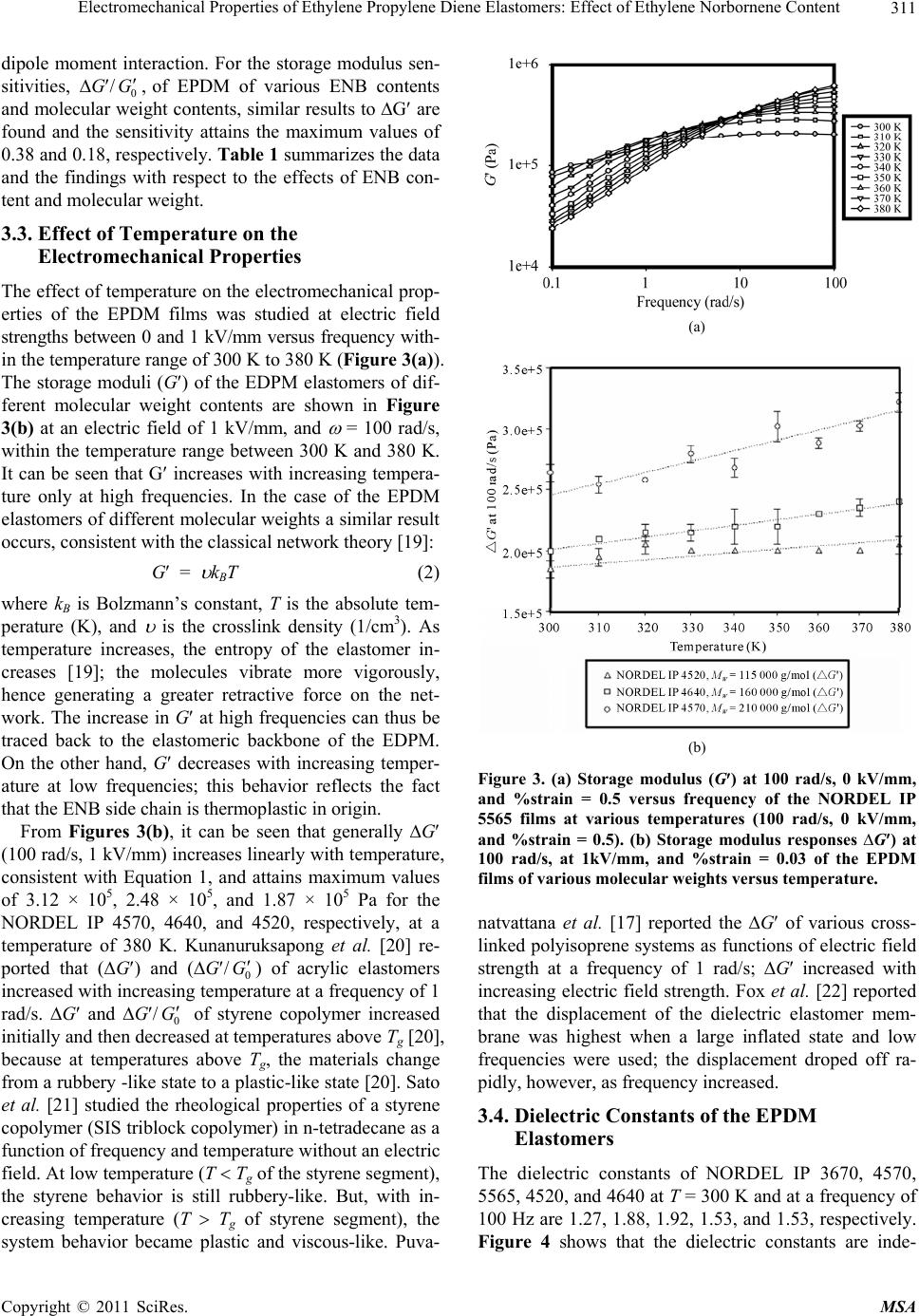

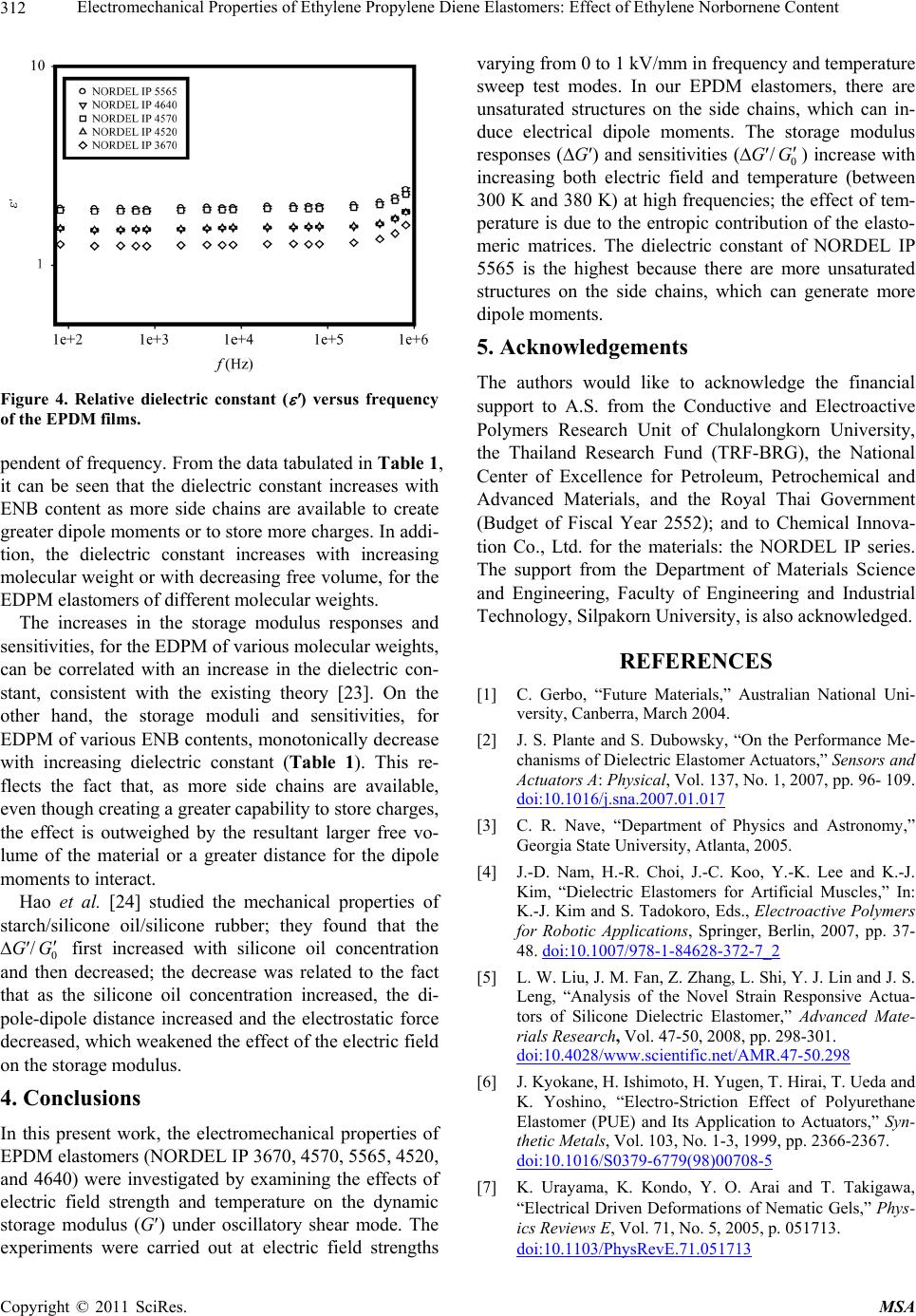

Materials Sciences and Applications, 2011, 2, 307-313 doi:10.4236/msa.2011.25040 Published Online May 2011 (http://www.SciRP.org/journal/msa) Copyright © 2011 SciRes. MSA 307 Electromechanical Properties of Ethylene Propylene Diene Elastomers: Effect of Ethylene Norbornene Content Patcharee Intanoo1, Anuvat Sirivat1*, Ruksapong Kunanuruksapong1, Wanchai Lerdwijitjarud2,3 1The Petroleum and Petrochemical College, Chulalongkorn University, Bangkok, Thailand; 2Department of Materials Science and Engineering, Faculty of Engineering and Industrial Technology, Silpakorn University, Nakhon Pathom, Thailand; 3National Center of Excellence for Petroleum, Petrochemicals, and Advanced Materials, Chulalongkorn University, Bangkok, Thailand. Email: anuvat.s@chula.ac.th Received December 24th, 2010; revised March 21st, 2011; accepted March 24th, 2011. ABSTRACT Ethylene propylene diene elastomers (EPDM) of various side chains and molecular weights were prepared as thin discs and the effects of electric field strength and temperature on the electromechanical properties were investigated. The electrical conductivity, the dielectric constant, the storage and loss moduli (G and G), the storage modulus response (1000Vmm G ), and the storage modulus sensitivity (1000Vmm G /0 G ) of the elastomers of different ethylene norbornene (ENB) contents and molecular weights were measured under electric field strengths varying from 0 V/mm to 1000 V/mm and at temperatures between 300 K and 380 K. The storage modulus response and sensitivity increase with in- creasing molecular weight and dielectric constant, consistent with the existing theory. However, for the case of EPDMs with different ENB contents, the storage modulus response and sensitivity vary inversely with the dielectric constant. EDPM is potentially a new type of electroactive materials. Keywords: Dielectric Elastomer, Dipole Moment, Polar Molecule, Unsaturated Structure, Ethylene Propylene Diene Elastomers (EPDM), Electrorheological Properties 1. Introduction Dielectric materials typically have poor electrical con- ductivity; they are widely used in capacitors [1], in elec- troactive polymers (EAP), and in dielectric elastomer actuators (DEAs). DEA applications have been proposed as large displacement actuators for use in micromechan- ical devices since they are simple, potentially low cost, and lightweight [2]. Dielectric elastomers typically con- sist of polar molecules with random orientations when electric field is not applied. An applied electric field will interact with the polar molecules by orienting the dipole moments [3]. Due to the induced dipole moments, some dimensional changes are expected in such a way that the EAPs transform electrical energy into a mechanical re- sponse. Examples of dielectric elastomers are ethylene propylene diene elastomers [4], silicone elastomers [5], and polyurethane [6]. Acrylic acid and silicone are also common dielectric elastomers. These actuators have been shown to have excellent actuation properties: large strains up to 380%; high energy densities, up to 3.4 J/g; high efficiency; high response speed, and good reliability and durability [5]. Kyokane et al. [6] studied the electro-striction effect of a normal polyurethane elastomer (PUE) functionalized with a hydroxyl group (doped PUE); displacements in- creased with increasing applied voltage. The bending of the doped PUE films was larger than those of the normal PUE films, thus allowing operation at a lower voltage. The actuation mechanism is the deformation of the poly- mer networks, as induced by the dipole orientation of electrically mobile elements in the elastomer [7]. Feher et al. [8] studied the bending of a TiO2-loaded polydimethylsiloxane (PDMS) gel measured in a uniform and a non-uniform electric field. The gel cylinder be- tween tow parallel copper electrodes gradually bent to- ward the cathode. The bending behavior was reversible, when positive and negative electrodes were alternated. As one of the electrodes was modified to create a non-  Electromechanical Properties of Ethylene Propylene Diene Elastomers: Effect of Ethylene Norbornene Content Copyright © 2011 SciRes. MSA 308 uniform electric field (a metal ball replaced one of the electrodes) the bending was the same. Li et al. [9] stu- died the mechanical properties and electrical conductivi- ties of a TiN-Al2O3 nanocomposite. The electrical resis- tivity decreased with an increasing amount of TiN, and the bending also increased with increasing amount of TiN. Yun et al. [10] studied the performance of electroac- tive papers (EAPap) of various thicknesses: 20, 30, and 40 m. EAPap actuators exhibited a bending deformation in the presence of an electric field. Bassil et al. [11] stu- died the bending mechanism of gel actuators (PAAM) caused by the pH gradient induced by an electric field; the gel actuator showed a volume change upon a change in its environmental conditions. The thickness of the ac- tuator increased, but it needed more electrical energy to move. Watanabe et al. [12] studied the electromechanical responses of pure polyurethane with compliant electrodes. The responses were due to the differences in charge den- sities between the anode and the cathode. Wissler et al. [13] reported the dielectric constants of different pre- stretched VHB 4910 membranes; the values decreased with increasing pre-stretched ratio. Hiamtup et al. [14] studied the dielectrophoresis force of polymer blends of polyaniline and polydimethylsiloxane with fixed copper electrodes, whereby the dielectrophoresis force increased with increasing electric field strength, but decreased with increasing polyaniline concentration. In this present work, we investigate the electrome- chanical responses of two classes of EPDM elastomers: EPDMs with different ENB contents, and EPDMs with different molecular weights. We determine the storage modulus response (1000V mm G ) and the storage modulus sensitivity (1000V m m G /0 G) subject to various electric field strengths and the storage modulus response (100rad s G ) subject to various temperatures. 2. Experimental 2.1. Materials The ethylene propylene diene (EPDM) elastomers used were: NORDEL IP 3670 (%ENB = 1.8, and MW = 210 000), NORDEL IP 4570 (%ENB = 4.9, and MW = 210 000), and NORDEL IP 5565 (%ENB = 7.5, and MW = 210 000) of different ENB contents; and, NORDEL IP 4570 (%ENB = 4.9, and MW = 210 000), NORDEL IP 4520 (%ENB = 4.9, and MW = 115 000), and NORDEL IP 4640 (%ENB = 4.9, and MW = 160 000) of different molecular weights were all provided by Chemical Inno- vation Co., Ltd.. The properties of the elastomers are listed in Table 1. 2.2. Preparation of Specimens All elastomer specimens were fabricated through solu- tion casting. The elastomers were dissolved in hexane at 30% vol/vol. The solutions were cast onto molds and the solvent was eliminated under a vacuum atmosphere at 300 K for 48 hours. Each sample was cut into a thin disc (diameter ≈ 2.5 mm, and thickness ≈ 1.0 mm). 2.3. Characterization and Testing The specific conductivity was measured by a resistivity test fixture (Keithley 8009) connected to a voltage sup- plier (Keithley, model 6517A) whose voltage was varied and the resultant current was measured. The conductivity measurement was performed under atmospheric pressure, 40% to 60% RH, at 25 to 27˚C, in the linear Ohmic re- gime. The voltage and the current in the liner regime were Table 1. Comparison of storage modulus responses (∆G) and sensitivities (∆G/ 0 G) of the EPDM films. Materials %ENB MW (g/mol) Density (g/cm3) Td (˚C) Storage modulus G′ (Pa) Storage modulus response ∆G′ (Pa) Storage modulus sensitivity (G′/ 0 G) Relative dielectric constant () at low frequency Induction time ind (s) Recovery time rec (s) NORDEL IP 3670 1.8 210 0000.86 457 1.84 × 1054.34 × 1050.383 1.24 1331 - NORDEL IP 4570 4.9 210 0000.86 450 1.59 × 1053.99 × 1050.178 1.86 1270 - NORDEL IP 5565 7.5 210 0000.86 442 8.22 × 1049.65 × 1040.140 1.91 3735 - NORDEL IP 4520 4.9 115 0000.86 440 6.88 × 1041.24 × 1040.149 1.50 4462 - NORDEL IP 4640 4.9 160 0000.86 450 7.35 × 1044.86 × 1040.155 1.49 4038 - NORDEL IP 4570 4.9 210 0000.86 450 1.59 × 1053.99 × 1050.178 1.86 1270 -  Electromechanical Properties of Ethylene Propylene Diene Elastomers: Effect of Ethylene Norbornene Content Copyright © 2011 SciRes. MSA 309 converted to electrical conductivity by the following eq- uation: σ = 1/ρ = 1/(6.44 10−5 R × t), where σ is the specific electrical conductivity (S/cm), ρ (ρ = V/I) is the specific electrical resistivity (Ω·cm), t is the thickness of a sample pellet (cm), V is the applied voltage (Voltage drop) (V), and I is the measured current (A). All thick- nesses samples of the samples were measured by using a thickness gauge. The effects of electric field strength and temperature (between 300 and 380 K) on the electromechanical prop- erties were measured by a parallel plate fixture with di- ameter of 25 mm attached to a melt rheometer (Rheome- tric, ARES) and the thickness of the prepared elastomers of about 1 mm. A DC voltage was applied through a DC power supply (Instek, GFG 8216A). A digital multimeter (Tektronic, CDM 250) was used to monitor the voltage input (Figure 1(b)). Dynamic strain sweep tests were first carried out to determine appropriate strain by meas- ure G′ and G″ in the linear viscoelastic regime at a 1.0 rad/s frequency. The appropriate strains were determined to be 0.2%, 0.06%, and 0.3% for the NORDEL IP 3670, 4570, and 5565, respectively, and 0.06%, 0.05%, and 0.2% for the NORDEL IP 4570, 4520, and 4640, respec- tively. For the temporal response testing, the dynamic moduli (G′ and G″) were measured as functions of time with electric field on and off. The temporal G response of all elastomers was determined at T = 300 K. Frequen- cy sweep tests were carried out to measure the G′ and G″ of each sample as functions of frequency and tempera- ture. The deformation frequency was varied from 0.1 to 100 rad/s. In each measurement, the electric field was applied to the EPDM elastomer for 50 min to ensure the steady state condition before the G′ and G″ measure- ments. The dielectric constant values were measured by an LCR meter (HP, model 4284A) connected to the melt rheometer (Rheometric, ARES) with a 25 mm parallel plate fixture with a diameter of 25 mm; the thickness of the prepared elastomers was about 1 mm. The top and bottom sides of the specimens were coated with a silver adhesive to improve the electrical contact between the specimens and the electrodes. The measurements were carried at a temperature of 300 K. 3. Results and Discussion 3.1. Temporal Responses of the EPDM Elastomer Films The temporal responses of all of all EPDM elastomer films were studied at E = 1 kV/mm, = 100 rad/s, T = 300 K, and %strain = 0.3 and 0.06 (Figure 2(a)). All elastomer samples were pre-sheared at a low frequency, and then the electric field was applied for 50 min to en- (a) (b) Figure 1. (a) Chemical structure of ethylene propylene di- ene elastomer (EPDM) with ethylidene norbornene, ENB side chain. (b) Schematic illustration of a test apparatus for the electromechanical properties measurement. sure the formation of equilibrium polarization before the G′ measurement. As can be seen in the Figure 2(a), G increases with electric field on, and remains constant with electric field off. The increase in G with the electric field on is due to the induced dipole moments generated on the unsaturated bond on the side chain. Electrostatic interaction between the dipole moments occurs leading to intermolecular interaction in the elastomer molecules; thus the increase in G. (The Maxwell stress is not opera- tive here since our electrodes were fixed [15].) As the electric field is turned off, Gdoes not recover, suggesting that the EDPM material systems are irreversible, possibly due to residue dipole moments. The induction time and the recovery time of the NORDEL IP 5565 are 3735 and 0 sec, respectively, in the steady state. The NORDEL IP 4570 has an induction time and a recovery time of 1270 and 0 sec, respectively, in the steady state. The induction times and the recovery times of both NORDEL IP 5565 and NORDEL IP 4570 are thus comparable. Wichiansee et al. [16] reported on the temporal response of cross- linked PDMS at an electric field strength of 1 kV/mm; effect of electric field strength on G′. It was also an irre- versible system due to some residue dipole moments between the PDMS molecules. Puvanatvattana et al. [17]  Electromechanical Properties of Ethylene Propylene Diene Elastomers: Effect of Ethylene Norbornene Content Copyright © 2011 SciRes. MSA 310 (a) (b) (c) Figure 2. (a) Storage modulus (G′) at 100 rad/s and 1 kV/ mm versus time of the EPDM films with different ENB contents: (a) NORDEL IP 5565; (b) NORDEL IP 4570; and (c) NORDEL IP 3670. (b) Storage modulus (G) at T = 300 K and %strain = 0.3 versus frequency of the NORDEL IP 5565 film at various electric field strengths. (c) Storage modulus responses ∆G) at T = 300 K, ω = 100 rad/s, and %strain = 0.3 of the EPDM films of various ENB con- tents versus electric field strength. studied the temporal response of Pth_U20/PI_03; it, too, was an irreversible system, due to some irreversible inte- ractions between the polythiophene particles (perhaps hydrogen bonding between adjacent polythiophene par- ticles, and residual dipole moments inducing permanent interparticle interactions). 3.2. Effect of Electric Field Strength on the Physical Properties The specific electrical conductivity values of the NOR- DEL IP 3670, 4570, 5565, 4520, and 4640 at a tempera- ture of 300 K are 1.12 10−7, 4.31 10−7, 4.94 10−7, 1.20 10−7, and 2.53 10−7 S/cm, respectively. The spe- cific electrical conductivities increase with increasing diene contents due to more conjugated - electron sys- tems in the structure; the electrical conductivity also in- creases with decreasing molecular weights due to a smaller free volume and the ease of electrons to move. The effect of electric field on the electromechanical properties of the EPDM elastomer films was studied at T = 300 K with the electric field strength varying between 2 and 1000 V/mm. The storage modulus (G) versus fre- quency of the EPDM elastomer film (NORDEL IP 5565) is shown in Figure 2(b). It can be seen that the storage modulus increases with increasing electric field strength at all frequencies examined. Polarization is generated on the unsaturated bonds on the side chain of the EPDM elastomer, inducing dipole moments. This leads to an increase in the storage modulus, consistent with the mo- dified Hooke’s law [18]: 2 22 0 δ1QEY (1) where δ is the stress, Q is the electrostriction coefficient, is the dielectric permittivity of the material, 0 is the dielectric constant of free space (8.85 pF/m), E is the electric field strength (V/m), and Y is the Young’s mo- dulus. From this equation, the stress varies linearly with the square of the electric field strength [18]. Figure 2(c) shows the storage modulus responses, ∆G′ (ω = 100 rad/s), of EDPM of various ENB contents, ∆G generally increases linearly with increasing electric field strength. Furthermore, ∆G as shown in Figure 2(c) decreases with ENB content and attains the maximum values of 4.34 10−5 Pa, for the NORDEL IP 3670 at E = 1 kV/mm. This finding suggests that as more ENB side chains are available, they create an overall larger free volume and, hence, reduces the dipole moment interac- tion at a given electric field. On the other hand, ∆G in- creases with increasing molecular weight and attains the maximum value of 3.99 10−5 Pa, for the NORDEL IP 4570 at E = 1 kV/mm. An EPDM with a higher molecu- lar weight has a smaller number of free ends, and there- fore a smaller free volume and hence a more effective  Electromechanical Properties of Ethylene Propylene Diene Elastomers: Effect of Ethylene Norbornene Content Copyright © 2011 SciRes. MSA 311 dipole moment interaction. For the storage modulus sen- sitivities, ∆G/0 G, of EPDM of various ENB contents and molecular weight contents, similar results to ∆G are found and the sensitivity attains the maximum values of 0.38 and 0.18, respectively. Table 1 summarizes the data and the findings with respect to the effects of ENB con- tent and molecular weight. 3.3. Effect of Temperature on the Electromechanical Properties The effect of temperature on the electromechanical prop- erties of the EPDM films was studied at electric field strengths between 0 and 1 kV/mm versus frequency with- in the temperature range of 300 K to 380 K (Figure 3(a)). The storage moduli (G) of the EDPM elastomers of dif- ferent molecular weight contents are shown in Figure 3(b) at an electric field of 1 kV/mm, and = 100 rad/s, within the temperature range between 300 K and 380 K. It can be seen that G increases with increasing tempera- ture only at high frequencies. In the case of the EPDM elastomers of different molecular weights a similar result occurs, consistent with the classical network theory [19]: G = kBT (2) where kB is Bolzmann’s constant, T is the absolute tem- perature (K), and is the crosslink density (1/cm3). As temperature increases, the entropy of the elastomer in- creases [19]; the molecules vibrate more vigorously, hence generating a greater retractive force on the net- work. The increase in G at high frequencies can thus be traced back to the elastomeric backbone of the EDPM. On the other hand, G decreases with increasing temper- ature at low frequencies; this behavior reflects the fact that the ENB side chain is thermoplastic in origin. From Figures 3(b), it can be seen that generally ∆G (100 rad/s, 1 kV/mm) increases linearly with temperature, consistent with Equation 1, and attains maximum values of 3.12 × 105, 2.48 × 105, and 1.87 × 105 Pa for the NORDEL IP 4570, 4640, and 4520, respectively, at a temperature of 380 K. Kunanuruksapong et al. [20] re- ported that (∆G) and (∆G/0 G) of acrylic elastomers increased with increasing temperature at a frequency of 1 rad/s. ∆G and ∆G/0 G of styrene copolymer increased initially and then decreased at temperatures above Tg [20], because at temperatures above Tg, the materials change from a rubbery -like state to a plastic-like state [20]. Sato et al. [21] studied the rheological properties of a styrene copolymer (SIS triblock copolymer) in n-tetradecane as a function of frequency and temperature without an electric field. At low temperature (T Tg of the styrene segment), the styrene behavior is still rubbery-like. But, with in- creasing temperature (T Tg of styrene segment), the system behavior became plastic and viscous-like. Puva- (a) (b) Figure 3. (a) Storage modulus (G) at 100 rad/s, 0 kV/mm, and %strain = 0.5 versus frequency of the NORDEL IP 5565 films at various temperatures (100 rad/s, 0 kV/mm, and %strain = 0.5). (b) Storage modulus responses ∆G) at 100 rad/s, at 1kV/mm, and %strain = 0.03 of the EPDM films of various molecular weights versus temperature. natvattana et al. [17] reported the ∆G of various cross- linked polyisoprene systems as functions of electric field strength at a frequency of 1 rad/s; ∆G increased with increasing electric field strength. Fox et al. [22] reported that the displacement of the dielectric elastomer mem- brane was highest when a large inflated state and low frequencies were used; the displacement droped off ra- pidly, however, as frequency increased. 3.4. Dielectric Constants of the EPDM Elastomers The dielectric constants of NORDEL IP 3670, 4570, 5565, 4520, and 4640 at T = 300 K and at a frequency of 100 Hz are 1.27, 1.88, 1.92, 1.53, and 1.53, respectively. Figure 4 shows that the dielectric constants are inde-  Electromechanical Properties of Ethylene Propylene Diene Elastomers: Effect of Ethylene Norbornene Content Copyright © 2011 SciRes. MSA 312 Figure 4. Relative dielectric constant ( ') versus frequency of the EPDM films. pendent of frequency. From the data tabulated in Table 1, it can be seen that the dielectric constant increases with ENB content as more side chains are available to create greater dipole moments or to store more charges. In addi- tion, the dielectric constant increases with increasing molecular weight or with decreasing free volume, for the EDPM elastomers of different molecular weights. The increases in the storage modulus responses and sensitivities, for the EDPM of various molecular weights, can be correlated with an increase in the dielectric con- stant, consistent with the existing theory [23]. On the other hand, the storage moduli and sensitivities, for EDPM of various ENB contents, monotonically decrease with increasing dielectric constant (Table 1). This re- flects the fact that, as more side chains are available, even though creating a greater capability to store charges, the effect is outweighed by the resultant larger free vo- lume of the material or a greater distance for the dipole moments to interact. Hao et al. [24] studied the mechanical properties of starch/silicone oil/silicone rubber; they found that the ∆G′/0 G first increased with silicone oil concentration and then decreased; the decrease was related to the fact that as the silicone oil concentration increased, the di- pole-dipole distance increased and the electrostatic force decreased, which weakened the effect of the electric field on the storage modulus. 4. Conclusions In this present work, the electromechanical properties of EPDM elastomers (NORDEL IP 3670, 4570, 5565, 4520, and 4640) were investigated by examining the effects of electric field strength and temperature on the dynamic storage modulus (G) under oscillatory shear mode. The experiments were carried out at electric field strengths varying from 0 to 1 kV/mm in frequency and temperature sweep test modes. In our EPDM elastomers, there are unsaturated structures on the side chains, which can in- duce electrical dipole moments. The storage modulus responses (∆G′) and sensitivities (∆G/0 G) increase with increasing both electric field and temperature (between 300 K and 380 K) at high frequencies; the effect of tem- perature is due to the entropic contribution of the elasto- meric matrices. The dielectric constant of NORDEL IP 5565 is the highest because there are more unsaturated structures on the side chains, which can generate more dipole moments. 5. Acknowledgements The authors would like to acknowledge the financial support to A.S. from the Conductive and Electroactive Polymers Research Unit of Chulalongkorn University, the Thailand Research Fund (TRF-BRG), the National Center of Excellence for Petroleum, Petrochemical and Advanced Materials, and the Royal Thai Government (Budget of Fiscal Year 2552); and to Chemical Innova- tion Co., Ltd. for the materials: the NORDEL IP series. The support from the Department of Materials Science and Engineering, Faculty of Engineering and Industrial Technology, Silpakorn University, is also acknowledged. REFERENCES [1] C. Gerbo, “Future Materials,” Australian National Uni- versity, Canberra, March 2004. [2] J. S. Plante and S. Dubowsky, “On the Performance Me- chanisms of Dielectric Elastomer Actuators,” Sensors and Actuators A: Physical, Vol. 137, No. 1, 2007, pp. 96- 109. doi:10.1016/j.sna.2007.01.017 [3] C. R. Nave, “Department of Physics and Astronomy,” Georgia State University, Atlanta, 2005. [4] J.-D. Nam, H.-R. Choi, J.-C. Koo, Y.-K. Lee and K.-J. Kim, “Dielectric Elastomers for Artificial Muscles,” In: K.-J. Kim and S. Tadokoro, Eds., Electroactive Polymers for Robotic Applications, Springer, Berlin, 2007, pp. 37- 48. doi:10.1007/978-1-84628-372-7_2 [5] L. W. Liu, J. M. Fan, Z. Zhang, L. Shi, Y. J. Lin and J. S. Leng, “Analysis of the Novel Strain Responsive Actua- tors of Silicone Dielectric Elastomer,” Advanced Mate- rials Research, Vol. 47-50, 2008, pp. 298-301. doi:10.4028/www.scientific.net/AMR.47-50.298 [6] J. Kyokane, H. Ishimoto, H. Yugen, T. Hirai, T. Ueda and K. Yoshino, “Electro-Striction Effect of Polyurethane Elastomer (PUE) and Its Application to Actuators,” Syn- thetic Metals, Vol. 103, No. 1-3, 1999, pp. 2366-2367. doi:10.1016/S0379-6779(98)00708-5 [7] K. Urayama, K. Kondo, Y. O. Arai and T. Takigawa, “Electrical Driven Deformations of Nematic Gels,” Phys- ics Reviews E, Vol. 71, No. 5, 2005, p. 051713. doi:10.1103/PhysRevE.71.051713  Electromechanical Properties of Ethylene Propylene Diene Elastomers: Effect of Ethylene Norbornene Content Copyright © 2011 SciRes. MSA 313 [8] J. Feher, G. Filipcsei, J. Szalma and M. Zrinyi, “Bending Deformation of Neutral Polymer Gels Induced by Electric Fields,” Colloid and Surface A: Physicochemical and En- gineering Aspects, Vol. 183-185, No. 15, 2001, pp. 505- 515. [9] J. Li, L. Gao and J. K. Guo, “Mechanical Properties and Electrical Conductivity of TiN-Al2O3 Nanocomposites,” Journal of European Ceramic Society, Vol. 23, No. 1, 2003, pp. 69-74. doi:10.1016/S0955-2219(02)00089-4 [10] S. Yun, J. Kim and C. Song, “Performance of Electro- Active Paper Actuators with Thickness Variation,” Sen- sors and Actuators A: Physics, Vol. 133, No. 1, 2007, pp. 225-230. [11] M. Bassil, J. Davena and M. Tahchi, “Electrochemical Properties and Actuation Mechanisms of Polyacrylamide Hydrogel for Artificial Muscle Application,” Sensors and Actuators B: Chemistry, Vol. 134, No. 2, 2008, pp. 496- 501. [12] M. Watanabe and T. Hirai, “Space Charge Distribution in Bending-Electrostrictive Polyurethane Films Doped with Salts,” Journal of Polymer Science Part B: Polymer Physics, Vol. 42, No. 3, 2004, pp. 523-531. doi:10.1002/polb.10728 [13] M. Wissler and E. Mazza, “Electromechanical Coupling in Dielectric Elastomer Actuators,” Sensors and Actua- tors A: Physics, Vol. 138, No. 2, 2007, pp. 384-393. [14] P. Hiamtup, A. Sirivat and A. M. Jamieson, “Electrome- chanical Response of a Soft and Flexible Actuator Based on Polyaniline Particles Embedded in a Cross-Linked Poly (Dimethyl Siloxane) Network,” Materials Science and Engineering C, Vol. 28, No. 11, 2007, pp. 1044- 1051. [15] R. Pelrine, R. Kornbluh, J. Joseph, R. Heydt, Q. Pei and S. Chiba, “High-Field Deformation of Elastomeric Dielec- trics for Actuators,” Materials Science and Engineering C, Vol. 11, No. 2, 2000, pp. 89-100. doi:10.1016/S0928-4931(00)00128-4 [16] W. Wichiansee and A. Sirivat, “Electrorheological Prop- erties of Poly(Dimethylsiloxane) and Poly (3,4-Ethylene- dioxy Thiophene)/Poly(Stylene Sulfonic acid)/Ethylene Glycol Blends,” Materials Science and Engineering C, Vol. 29, No. 1, 2009, pp. 78-84. doi:10.1016/j.msec.2008.05.018 [17] T. Puvanatvattana, D. Chotpattananont, P. Hiamtup, S. Niamlang, A. Sirivat and A. M. Jamieson, “Electric Field Induced Stress Moduli in Polythiophene/Polyisoprene Elastomer Blends,” Reactive and Functional Polymers, Vol. 66, No. 12, 2006, pp. 1575-1588. doi:10.1016/j.reactfunctpolym.2006.06.001 [18] D. O. Diaconu, F. Dorohoi and T. Topoliceanu, “Electro- striction of a Polyurethane Elastomer-Based Polyester,” IEEE Sensors Journal, Vol. 6, No. 4, 2006, pp. 876-880. doi:10.1109/JSEN.2006.877978 [19] M. Rubinstein and R. H. Colby, “Polymer Physics,” Ox- ford University Press, New York, 2003. [20] R. Kunanuruksapong and A. Sirivat, “Electrical Proper- ties and Electromechanical Responses of Acrylic Elasto- mers and Styrene Copolymers: Effect of Temperature,” Applied Physics A, Vol. 92, No. 2, 2008, pp. 313-320. doi:10.1007/s00339-008-4513-3 [21] T. Sato, H. Watanabe and K. Osaki, “Rheological and Dielectric Behavior of a Styrene-Isoprene-Styrene Trib- lock Copolymer in n-Tetradecane. 1. Rubbery-Plastic- Viscous Transition,” Macromolecules, Vol. 29, No. 19, 1996, pp. 6231-6239. doi:10.1021/ma960060i [22] J. W. Fox and N. C. Goulbourne, “On the Dynamic Elec- tromechanical Loading of Dielectric Elastomer Mem- branes,” Journal of Mechanic and Physics of Solids, Vol. 56, No. 8, 2008, pp. 2669-2686. doi:10.1016/j.jmps.2008.03.007 [23] T. Shiga and T. Kurauchi, “Deformation of Polyelectro- lyte Gels under Influence of Electric Field,” Journal of Applied Polymer Science, Vol. 39, 1990, pp. 2305-2330. doi:10.1002/app.1990.070391110 [24] L. Hao, Z. Shi and X. Zhao, “Mechanical Behavior of Starch/Silicone Oil/Silicone Rubber Hybrid Electric Elastomer,” Reactive and Functional Polymers, Vol. 69, No. 3, 2009, pp. 165-169. doi:10.1016/j.reactfunctpolym.2008.12.014 |