Partial Discharge Source Classification and De-noising in Rotating Machines 93

Using Discrete Wavelet Transform and Directional Coupling Capacitor

Copyright © 2009 SciRes JEMAA

these machines, there are different kinds of noise and

interference signals that make measurements unreliable.

Therefore, a method is needed to separate PD from these

signals. The method this paper follows is based on DWT

which is a time-frequency transform. As known, PD is a

non-stationary signal [9]. So, conventional transforms

such as Fourier Transform (FT) may not be used to ana-

lyze spectral specifications of PD as they do not distin-

guish short-term and long-term frequency components.

But DWT considers time events of the signal. Thus, it is

capable of interpreting short-time PD pulses. Next sec-

tion discusses PD de-noising using DWT.

3. PD De-Noising Using DWT

Wavelets have very attractive features which cause them

to be used in miscellaneous applications [10]. One of the

methods which works based on these features is decom-

posing and reconstructing signals using QMF2 filters.

Reference [2] is a good context to understand how DWT

decomposition using QMF filters works. But here the

focus is on applying this technique to develop the method.

In general, DWT decomposes a signal to its basic fre-

quency components as shown in Figure 1.

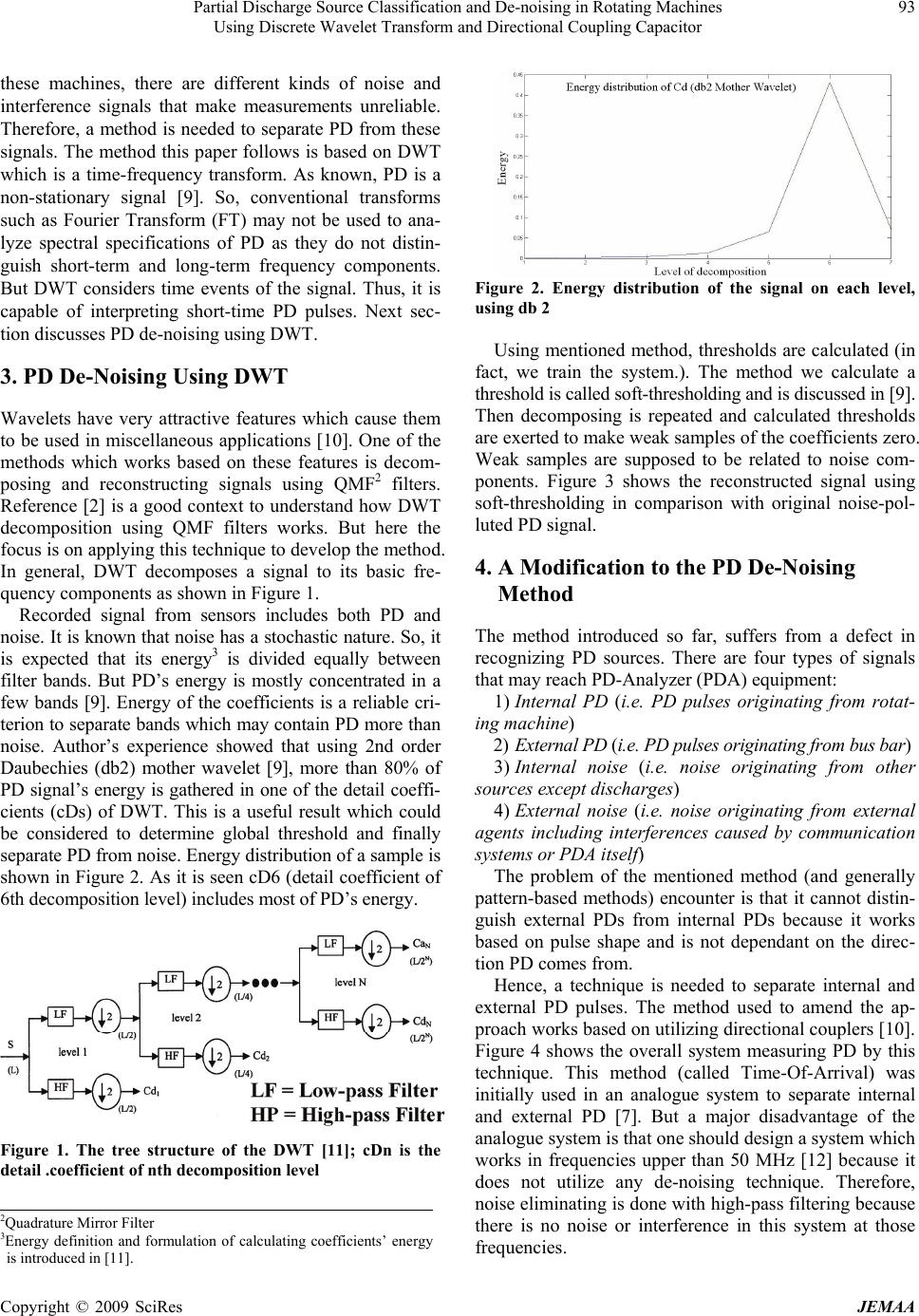

Recorded signal from sensors includes both PD and

noise. It is known that noise has a stochastic nature. So, it

is expected that its energy3 is divided equally between

filter bands. But PD’s energy is mostly concentrated in a

few bands [9]. Energy of the coefficients is a reliable cri-

terion to separate bands which may contain PD more than

noise. Author’s experience showed that using 2nd order

Daubechies (db2) mother wavelet [9], more than 80% of

PD signal’s energy is gathered in one of the detail coeffi-

cients (cDs) of DWT. This is a useful result which could

be considered to determine global threshold and finally

separate PD from noise. Energy distribution of a sample is

shown in Figure 2. As it is seen cD6 (detail coefficient of

6th decomposition level) includes most of PD’s energy.

Figure 1. The tree structure of the DWT [11]; cDn is the

detail .coefficient of nth decomposition level

Figure 2. Energy distribution of the signal on each level,

using db 2

Using mentioned method, thresholds are calculated (in

fact, we train the system.). The method we calculate a

threshold is called soft-thresholding and is discussed in [9].

Then decomposing is repeated and calculated thresholds

are exerted to make weak samples of the coefficients zero.

Weak samples are supposed to be related to noise com-

ponents. Figure 3 shows the reconstructed signal using

soft-thresholding in comparison with original noise-pol-

luted PD signal.

4. A Modification to the PD De-Noising

Method

The method introduced so far, suffers from a defect in

recognizing PD sources. There are four types of signals

that may reach PD-Analyzer (PDA) equipment:

1) Internal PD (i.e. PD pulses originating from rotat-

ing machine)

2) External PD (i.e. PD pulses originating from bus bar)

3) Internal noise (i.e. noise originating from other

sources except discharges)

4) External noise (i.e. noise originating from external

agents including interferences caused by communication

systems or PDA itself)

The problem of the mentioned method (and generally

pattern-based methods) encounter is that it cannot distin-

guish external PDs from internal PDs because it works

based on pulse shape and is not dependant on the direc-

tion PD comes from.

Hence, a technique is needed to separate internal and

external PD pulses. The method used to amend the ap-

proach works based on utilizing directional couplers [10].

Figure 4 shows the overall system measuring PD by this

technique. This method (called Time-Of-Arrival) was

initially used in an analogue system to separate internal

and external PD [7]. But a major disadvantage of the

analogue system is that one should design a system which

works in frequencies upper than 50 MHz [12] because it

does not utilize any de-noising technique. Therefore,

noise eliminating is done with high-pass filtering because

there is no noise or interference in this system at those

frequencies.

2Quadrature Mirror Filter

3Energy definition and formulation of calculating coefficients’ energy

is introduced in [11].