Paper Menu >>

Journal Menu >>

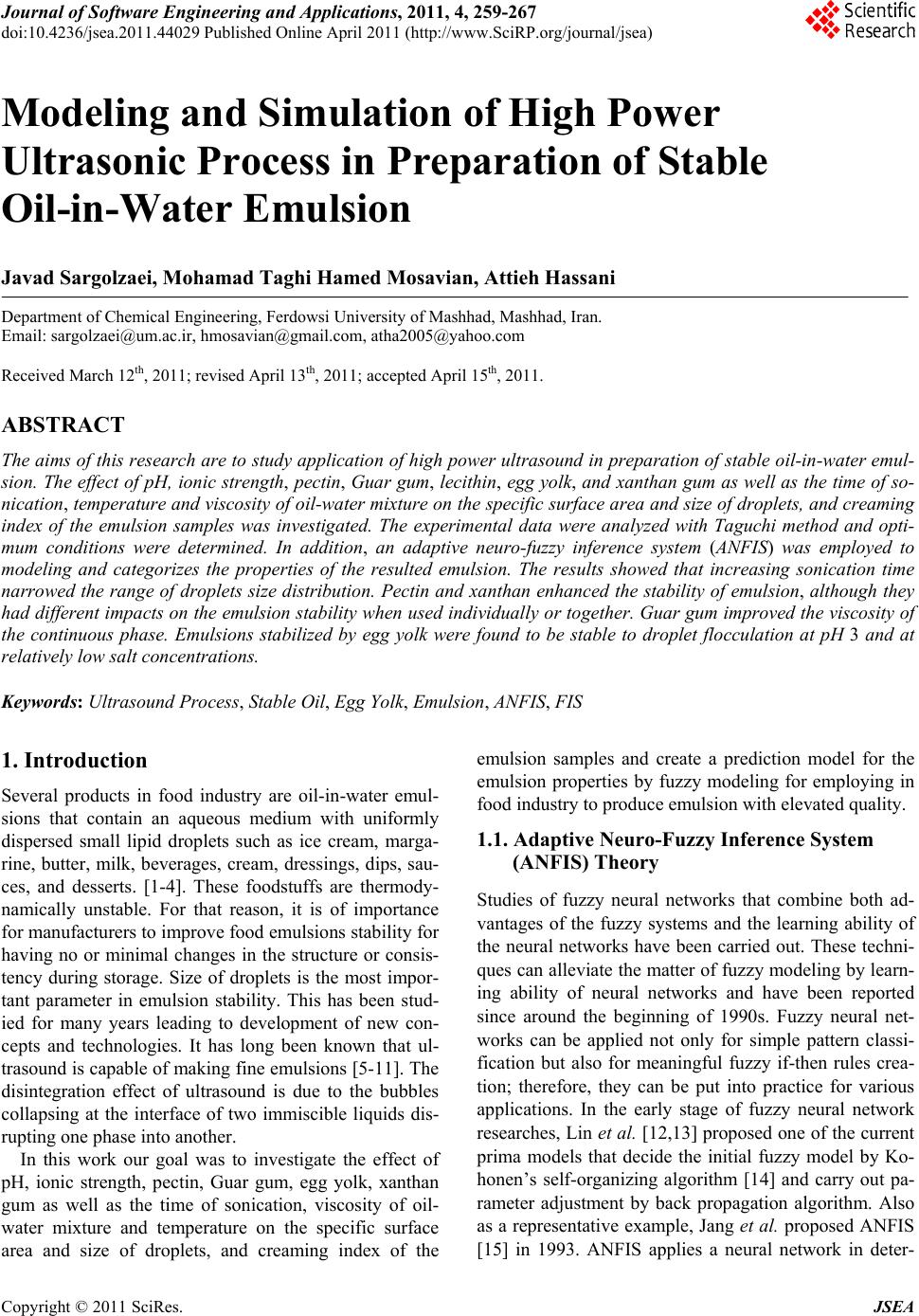

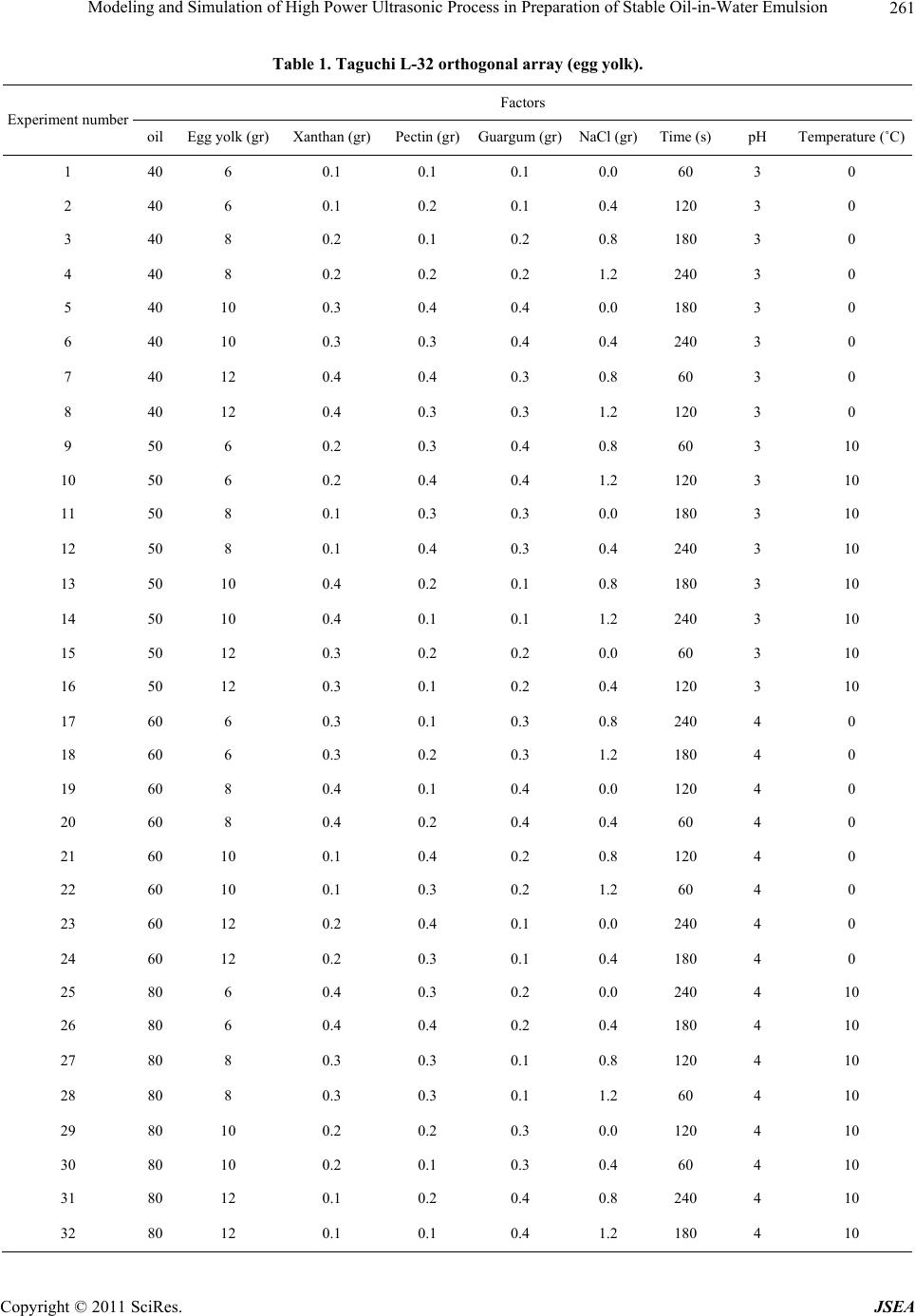

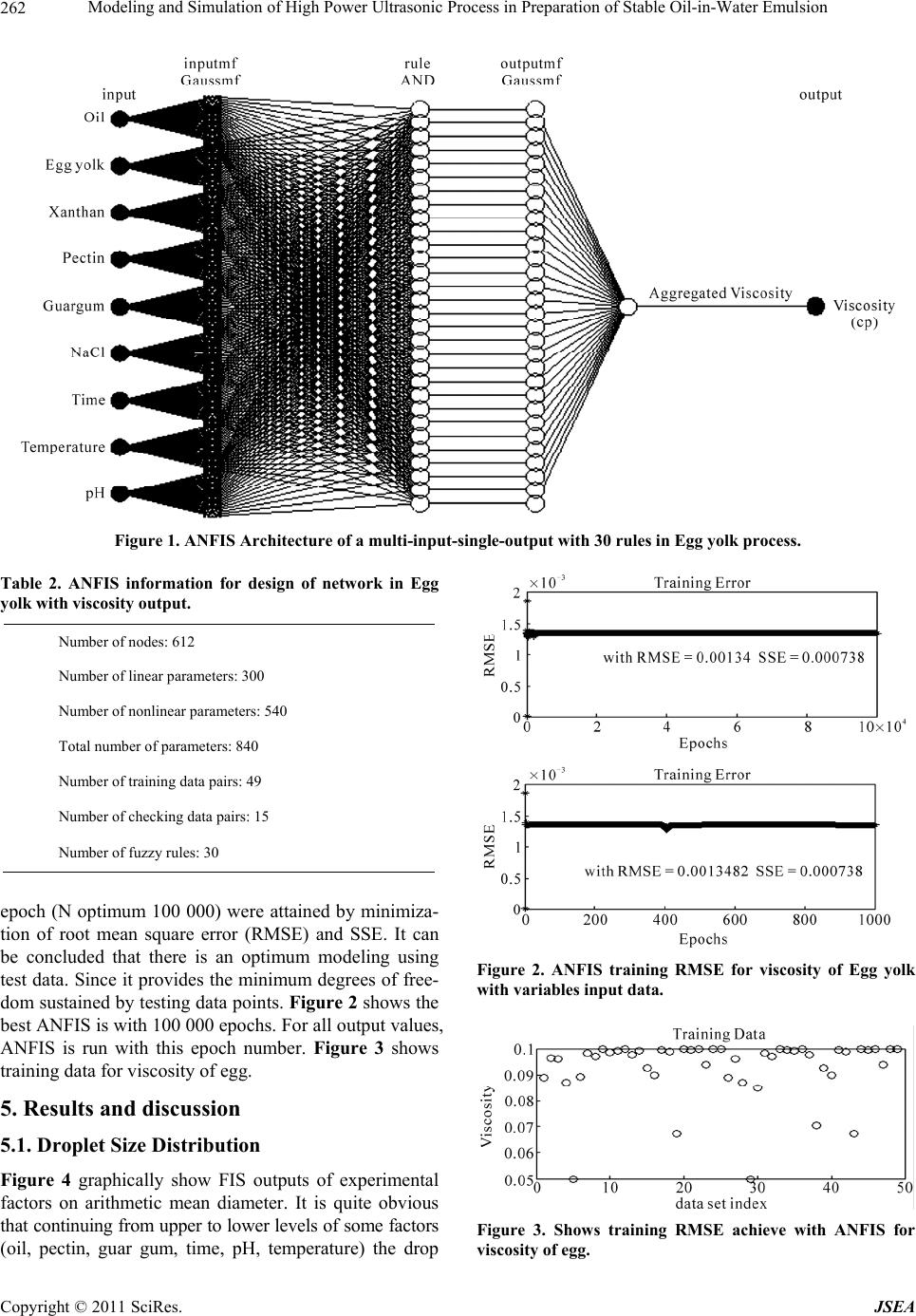

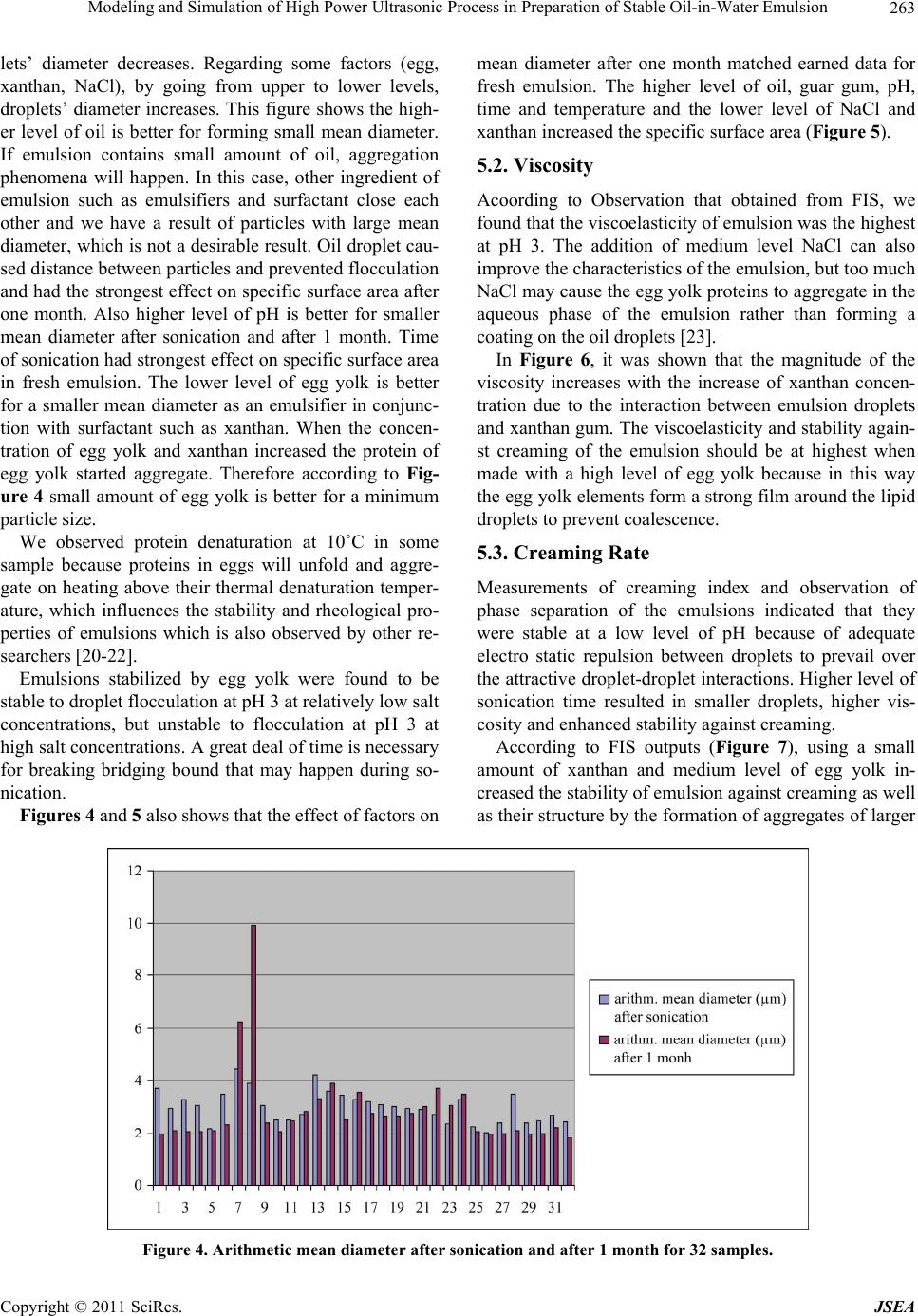

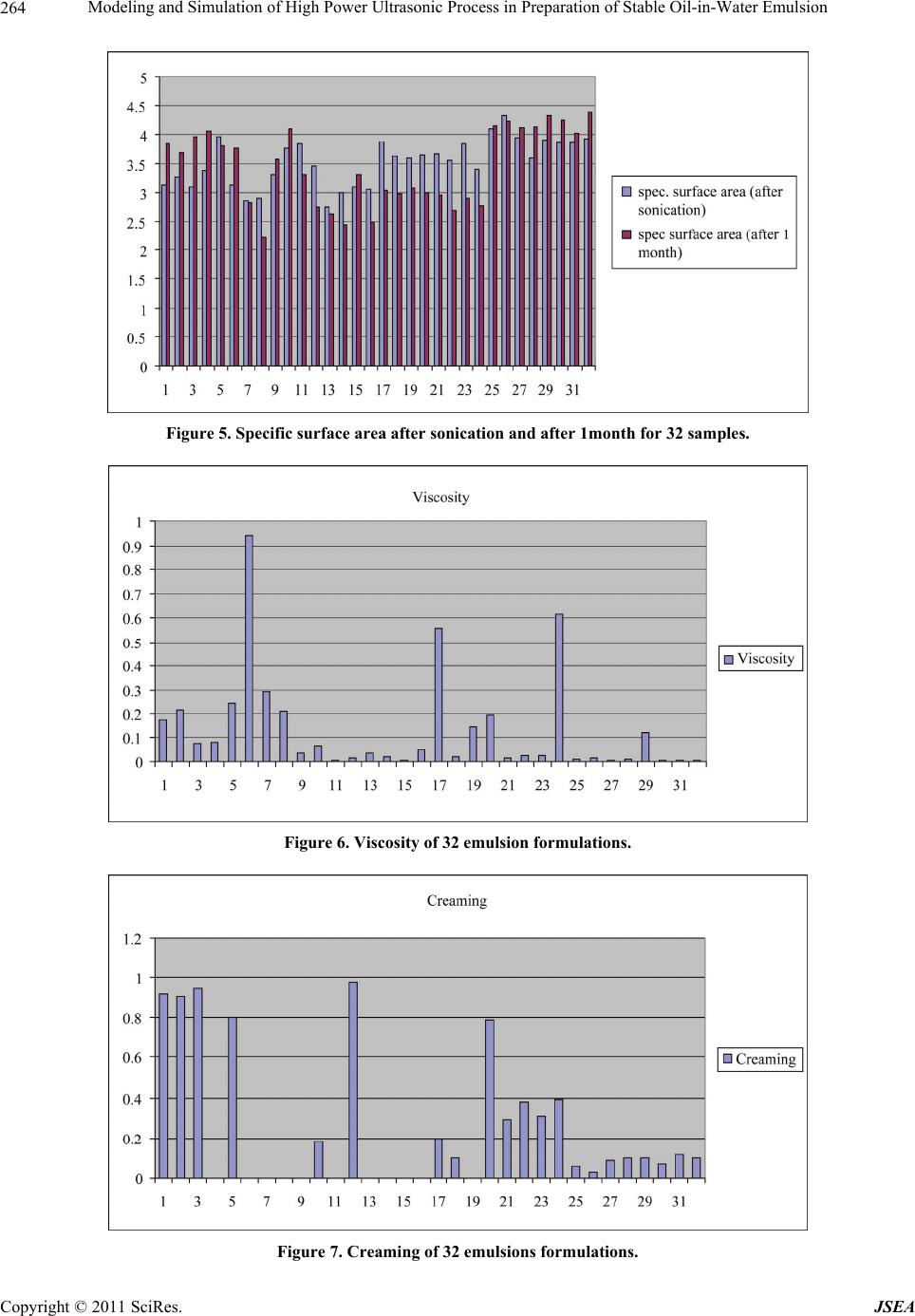

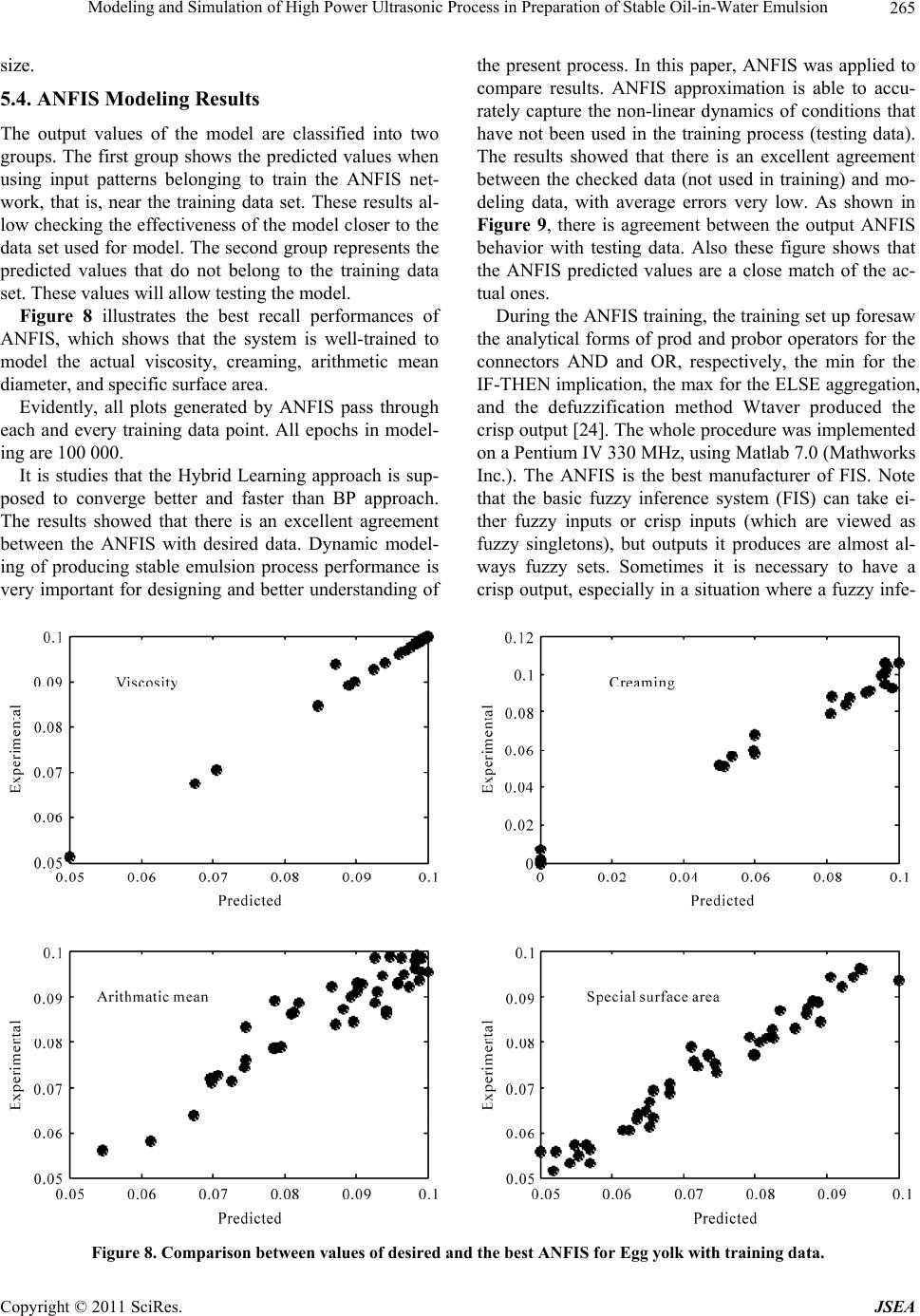

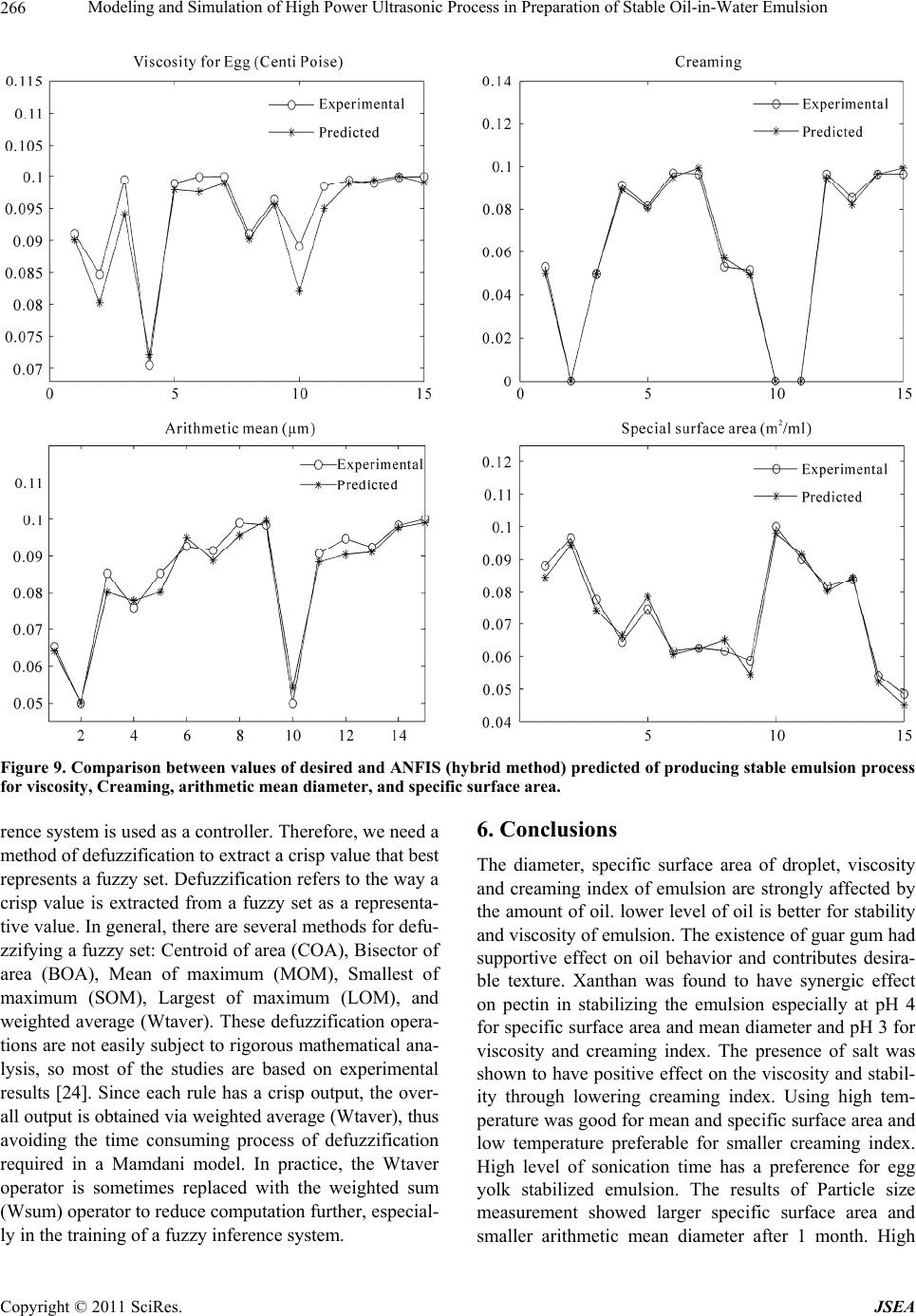

Journal of Software Engineering and Applications, 2011, 4, 259-267 doi:10.4236/jsea.2011.44029 Published Online April 2011 (http://www.SciRP.org/journal/jsea) Copyright © 2011 SciRes. JSEA 259 Modeling and Simulation of High Power Ultrasonic Process in Preparation of Stable Oil-in-Water Emulsion Javad Sargolzaei, Mohamad Taghi Hamed Mosavian, Attieh Hassani Department of Chemical Engineering, Ferdowsi University of Mashhad, Mashhad, Iran. Email: sargolzaei@um.ac.ir, hmosavian@gmail.com, atha2005@yahoo.com Received March 12th, 2011; revised April 13th, 2011; accepted April 15th, 2011. ABSTRACT The aims of this research are to study application of high power ultrasound in preparation of stable oil-in-water emul- sion. The effect of pH, ionic strength, pectin, Guar gum, lecithin, egg yolk, and xanthan gum as well as the time of so- nication, temperature and viscosity of oil-water mixture on the sp ecific surface area and size o f droplets, and creaming index of the emulsion samples was investigated. The experimental data were analyzed with Taguchi method and opti- mum conditions were determined. In addition, an adaptive neuro-fuzzy inference system (ANFIS) was employed to modeling and categorizes the properties of the resulted emulsion. The results showed that increasing sonication time narrowed the range of droplets size distribution. Pectin and xanthan enhanced the stability of emulsion, although they had different impacts on the emulsion stability when used individually or together. Guar gum improved the viscosity of the continuous phase. Emulsions stabilized by egg yolk were found to be stable to droplet flocculation at pH 3 and at relatively low salt concentrations. Keywords: Ul tr asound Process, Stable Oil, Egg Yolk, Emulsion, ANFIS, FIS 1. Introduction Several products in food industry are oil-in-water emul- sions that contain an aqueous medium with uniformly dispersed small lipid droplets such as ice cream, marga- rine, butter, milk, beverages, cream, dressings, dips, sau- ces, and desserts. [1-4]. These foodstuffs are thermody- namically unstable. For that reason, it is of importance for manufacturers to improve food emulsions stability for having no or minimal changes in the structure or consis- tency during storage. Size of droplets is the most impor- tant parameter in emulsion stability. This has been stud- ied for many years leading to development of new con- cepts and technologies. It has long been known that ul- trasound is capable of making fine emulsions [5-11]. The disintegration effect of ultrasound is due to the bubbles collapsing at the interface of two immiscible liquids dis- rupting one phase into another. In this work our goal was to investigate the effect of pH, ionic strength, pectin, Guar gum, egg yolk, xanthan gum as well as the time of sonication, viscosity of oil- water mixture and temperature on the specific surface area and size of droplets, and creaming index of the emulsion samples and create a prediction model for the emulsion properties by fuzzy modeling for employing in food industry to produce emulsion with elevated qu ality. 1.1. Adaptive Neuro-Fuzzy Inference System (ANFIS) Theory Studies of fuzzy neural networks that combine both ad- vantages of the fuzzy systems and the learning ability of the neural networks have been carried out. These techni- ques can alleviate the matter of fuzzy modeling by learn- ing ability of neural networks and have been reported since around the beginning of 1990s. Fuzzy neural net- works can be applied not only for simple pattern classi- fication but also for meaningful fuzzy if-then rules crea- tion; therefore, they can be put into practice for various applications. In the early stage of fuzzy neural network researches, Lin et al. [12,13] proposed one of the current prima models that decide the initial fuzzy model by Ko- honen’s self-organizing algorithm [14] and carry out pa- rameter adjustment by back propagation algorithm. Also as a representative example, Jang et al. proposed ANFIS [15] in 1993. ANFIS applies a neural network in deter-  Modeling and Simulation of High Power Ultrasonic Process in Preparation of Stable Oil-in-Water Emulsion Copyright © 2011 SciRes. JSEA 260 mination of the shape of membership functions and rule extraction. However, since it needs to divide the input data space in advance, accuracy of the system depends much on the achievement of this pre-processing. Wang reported an approach to acquire fuzzy rules by dividing input space [16]. These techniques, however, do not con- sider the output data space, so the obtained rules should not be always reasonable. Since the architecture and be- havior of ANFIS are very applicable [17], it has been adopted as a basic component for interpretation resear- ches [17,18]. Normalization of inputs leads to avoidance of numeri- cal overflows due to very large or very small weights [2]. Therefore, data are normalized by the following rela- tionship: min max min 1 N UL L VV VVV (1) Where VN is the normalized value of V, the Vmax and Vmin are th e ma x i mu m a n d mi n i mu m v alues of V, respectively. From experience, the authors have found that a better fit will be achieved if U and L (small margins) are kept at a value of 0.05 [19]. 2. Materials and methods 2.1. Materials Pectin extracted from citrus peel, Xanthan Gum extracted from Xanthamonas campestris, Lecithin from soybean and Guar gum were purchased from Sigma Chemical Company, Germany. Analytical grade sodium chloride (NaCl) and acetic acid glacial (CH3COOH) was supplied from the Merck Chemical Company, Germany. Sunflower oil and egg were obtained from local mar- ket. Deionized water was used for the preparation of all solutions. 2.2. Preparation of Emulsion Mixture Oil phase was prepared by dispersing different propor- tions of lecithin or egg yolk, xanthan, pectin, guar gum and NaCl in different amount of sun flower oil and mix- ed for 30 minutes by a magnetic stirrer (Model VELP SCIENTIFICA s.r.l, Europe). The oil phase mixture was then mixed with distilled water adjusted to pH 3 or 4 by glacial acetic acid. Table 1 shows proportion of each constituent in emulsion mixture for various formulas used in the experiment. 2.3. Ultrasonic emulsification The aqueous and oil phase were premixed together in a beaker using a magnetic stirrer. 5 ml aliquot of the mix- ture was introduced into a round bottom glass. Sonication was carried out using a Dr. Hielscher ultrasonic proces- sor (Model UP 200 H, Germany), with the operating frequency of 24 KHz and power output of 460 W. A ta- pered titanium sonotrode of 3 mm in diameter was used for sonication. The tip of sonotrode was placed 1 cm be- low the surface of mixture. All samples were sonified in 0 and 10˚C for 60, 120, 180 and 240 seconds in thermos- tated water bath. All sonicated experiments were con- ducted in triplicates. One of the three samples was used to measure creaming and the other two were used for particle size measurement. 2.4. Particle Size Measurement Drop size distributions of samples were measured imme- diately after sonication and also after one month storage at 4˚C using Fritsch laser diffraction analyzer (Model Analysette 22, Germany). 2.5. Viscosity Measurement Viscosity was measured using Brooke Field DV-II (at 80 RPM) at 27˚C. The types of spindles used were S62, S63 and S64. 2.6. Creaming Measurement Ten ml of each emulsion were transferred into a test tube, and then stored for 1month at refrigerator temperature (4˚C). During storage a number of emulsions separated into an optically opaque ‘cream’ layer at the top and a transparent (or turbid) ‘serum’ layer at the bottom. Crea- ming index was calculated by dividing the total height of cream to the total height of the column of emulsion. 3. Statistical Analysis Taguchi L32 orthogonal array design was used to inves- tigate the effect of pH, sonication time, temperature and concentration of lecithin, egg yolk, guar gum, xanthan, pectin and sodium chloride on droplet size distribution, creaming and viscosity of samples. Table 1 shows the L32 orthogonal array design used in this study. 4. ANFIS Design The ANFIS information errors used for process are shown in Table 2. There are 0.5, 1.25, 0.5, 0.15 values for ranges of influence, squash factor, accept ratio, and reject ratio. Also the optimum method is back propaga- tion. The best threshold of the generation ANFIS is 0.05 for Egg yolk and Lecithin process simulations. ANFIS architecture for multi input and single output (for example, viscosity) data is shown in Figure 1. In this work, the applications of ANFIS for prediction of viscosity, creaming, arithmetic mean diameter, and specific surface area were tested at different operation conditions. For each variable, the optimum values of  Modeling and Simulation of High Power Ultrasonic Process in Preparation of Stable Oil-in-Water Emulsion Copyright © 2011 SciRes. JSEA 261 Table 1. Taguchi L-32 orthogonal array (egg yolk). Experiment number Factors oil Egg yolk (gr) Xanthan (gr)Pectin (gr)Guargum (gr)NaCl (gr)Time (s) pH Temperature (˚C) 1 40 6 0.1 0.1 0.1 0.0 60 3 0 2 40 6 0.1 0.2 0.1 0.4 120 3 0 3 40 8 0.2 0.1 0.2 0.8 180 3 0 4 40 8 0.2 0.2 0.2 1.2 240 3 0 5 40 10 0.3 0.4 0.4 0.0 180 3 0 6 40 10 0.3 0.3 0.4 0.4 240 3 0 7 40 12 0.4 0.4 0.3 0.8 60 3 0 8 40 12 0.4 0.3 0.3 1.2 120 3 0 9 50 6 0.2 0.3 0.4 0.8 60 3 10 10 50 6 0.2 0.4 0.4 1.2 120 3 10 11 50 8 0.1 0.3 0.3 0.0 180 3 10 12 50 8 0.1 0.4 0.3 0.4 240 3 10 13 50 10 0.4 0.2 0.1 0.8 180 3 10 14 50 10 0.4 0.1 0.1 1.2 240 3 10 15 50 12 0.3 0.2 0.2 0.0 60 3 10 16 50 12 0.3 0.1 0.2 0.4 120 3 10 17 60 6 0.3 0.1 0.3 0.8 240 4 0 18 60 6 0.3 0.2 0.3 1.2 180 4 0 19 60 8 0.4 0.1 0.4 0.0 120 4 0 20 60 8 0.4 0.2 0.4 0.4 60 4 0 21 60 10 0.1 0.4 0.2 0.8 120 4 0 22 60 10 0.1 0.3 0.2 1.2 60 4 0 23 60 12 0.2 0.4 0.1 0.0 240 4 0 24 60 12 0.2 0.3 0.1 0.4 180 4 0 25 80 6 0.4 0.3 0.2 0.0 240 4 10 26 80 6 0.4 0.4 0.2 0.4 180 4 10 27 80 8 0.3 0.3 0.1 0.8 120 4 10 28 80 8 0.3 0.3 0.1 1.2 60 4 10 29 80 10 0.2 0.2 0.3 0.0 120 4 10 30 80 10 0.2 0.1 0.3 0.4 60 4 10 31 80 12 0.1 0.2 0.4 0.8 240 4 10 32 80 12 0.1 0.1 0.4 1.2 180 4 10  Modeling and Simulation of High Power Ultrasonic Process in Preparation of Stable Oil-in-Water Emulsion Copyright © 2011 SciRes. JSEA 262 Figure 1. ANFIS Architecture of a multi-input-single-output with 30 rules in Egg yolk process. Table 2. ANFIS information for design of network in Egg yolk with viscosity output. Number of nodes: 612 Number of linear parameters: 300 Number of nonlinear par am eters: 540 Total number of parameter s : 84 0 Number of training data pairs: 49 Number of checking data pairs : 15 Number of f uzzy rules: 30 epoch (N optimum 100 000) were attained by minimiza- tion of root mean square error (RMSE) and SSE. It can be concluded that there is an optimum modeling using test data. Since it provides the minimum degrees of free- dom sustained by testing data points. Figure 2 shows the best ANFIS is with 100 000 epochs. For all output values, ANFIS is run with this epoch number. Figure 3 shows training data for viscosity of egg. 5. Results and discussion 5.1. Droplet Size Distribution Figure 4 graphically show FIS outputs of experimental factors on arithmetic mean diameter. It is quite obvious that continuing from upper to lower levels of some factors (oil, pectin, guar gum, time, pH, temperature) the drop Figure 2. ANFIS training RMSE for viscosity of Egg yolk with variables input data. Figure 3. Shows training RMSE achieve with ANFIS for viscosity of egg.  Modeling and Simulation of High Power Ultrasonic Process in Preparation of Stable Oil-in-Water Emulsion Copyright © 2011 SciRes. JSEA 263 lets’ diameter decreases. Regarding some factors (egg, xanthan, NaCl), by going from upper to lower levels, droplets’ diameter increases. This figu re shows the high- er level of oil is better for forming small mean diameter. If emulsion contains small amount of oil, aggregation phenomena will happen. In this case, other ingredient of emulsion such as emulsifiers and surfactant close each other and we have a result of particles with large mean diameter, which is not a desirable result. Oil droplet cau- sed distance between particles and prevented flocculation and had the strongest effect on specific surface area after one month. Also higher level of pH is better for smaller mean diameter after sonication and after 1 month. Time of sonication had strongest effect on specific surface area in fresh emulsion. The lower level of egg yolk is better for a smaller mean diameter as an emulsifier in conjunc- tion with surfactant such as xanthan. When the concen- tration of egg yolk and xanthan increased the protein of egg yolk started aggregate. Therefore according to Fig- ure 4 small amount of egg yolk is better for a minimum particle size. We observed protein denaturation at 10˚C in some sample because proteins in eggs will unfold and aggre- gate on heating above th eir thermal denaturation temper- ature, which influences the stability and rheological pro- perties of emulsions which is also observed by other re- searchers [20-22]. Emulsions stabilized by egg yolk were found to be stable to droplet flocculation at pH 3 at relatively low salt concentrations, but unstable to flocculation at pH 3 at high salt concentration s. A great d eal of time is n ecessary for breaking bridging bound that may happen during so- nication. Figures 4 and 5 also shows that the effect of factors on mean diameter after one month matched earned data for fresh emulsion. The higher level of oil, guar gum, pH, time and temperature and the lower level of NaCl and xanthan increased the specific surface area (Figure 5). 5.2. Viscosity Acoording to Observation that obtained from FIS, we found that the viscoelasticity of emulsion was the highest at pH 3. The addition of medium level NaCl can also improve the characteristics of the emulsion, but too much NaCl may cause the egg yolk proteins to aggregate in the aqueous phase of the emulsion rather than forming a coating on the oil droplets [23]. In Figure 6, it was shown that the magnitude of the viscosity increases with the increase of xanthan concen- tration due to the interaction between emulsion droplets and xanthan gum. The viscoelasticity an d stability again- st creaming of the emulsion should be at highest when made with a high level of egg yolk because in this way the egg yolk elements form a strong film around the lipid droplets to prevent coalescence. 5.3. Creaming Rate Measurements of creaming index and observation of phase separation of the emulsions indicated that they were stable at a low level of pH because of adequate electro static repulsion between droplets to prevail over the attractive droplet-droplet interactions. Higher level of sonication time resulted in smaller droplets, higher vis- cosity and enhanced stability against creaming. According to FIS outputs (Figure 7), using a small amount of xanthan and medium level of egg yolk in- creased the stability of emulsion against creamin g as well as their structure by the formation of aggregates of larger Figure 4. Arithmetic mean diameter after sonication and after 1 month for 32 samples.  Modeling and Simulation of High Power Ultrasonic Process in Preparation of Stable Oil-in-Water Emulsion Copyright © 2011 SciRes. JSEA 264 Figure 5. Specific surface area after sonication and after 1month for 32 samples. Figure 6. Viscosity of 32 emulsion formulations. Figure 7. Creaming of 32 emulsions formulations.  Modeling and Simulation of High Power Ultrasonic Process in Preparation of Stable Oil-in-Water Emulsion Copyright © 2011 SciRes. JSEA 265 size. 5.4. ANFIS Modeling Results The output values of the model are classified into two groups. The first group shows the predicted values when using input patterns belonging to train the ANFIS net- work, that is, near the training data set. These results al- low checking the effectiveness of the model closer to th e data set used for model. The second group represents the predicted values that do not belong to the training data set. These values will allow testing the model. Figure 8 illustrates the best recall performances of ANFIS, which shows that the system is well-trained to model the actual viscosity, creaming, arithmetic mean diameter, and specific surface area. Evidently, all plots generated by ANFIS pass through each and every training data point. All epochs in model- ing are 100 000 . It is studies that the Hybrid Learning approach is sup- posed to converge better and faster than BP approach. The results showed that there is an excellent agreement between the ANFIS with desired data. Dynamic model- ing of producing stable emulsion process performance is very important for designing and better understanding of the present process. In this paper, ANFIS was applied to compare results. ANFIS approximation is able to accu- rately capture the non-linear dynamics of conditions that have not been used in the training process (testing data). The results showed that there is an excellent agreement between the checked data (not used in training) and mo- deling data, with average errors very low. As shown in Figure 9, there is agreement between the output ANFIS behavior with testing data. Also these figure shows that the ANFIS predicted values are a close match of the ac- tual ones. During the ANFIS training, the training set up foresaw the analytical forms of prod and probor operators for the connectors AND and OR, respectively, the min for the IF-THEN implication, the max for the ELSE aggr egation, and the defuzzification method Wtaver produced the crisp output [24]. The whole procedure was implemented on a Pentium IV 330 MHz, using Matlab 7.0 (Mathworks Inc.). The ANFIS is the best manufacturer of FIS. Note that the basic fuzzy inference system (FIS) can take ei- ther fuzzy inputs or crisp inputs (which are viewed as fuzzy singletons), but outputs it produces are almost al- ways fuzzy sets. Sometimes it is necessary to have a crisp output, especially in a situatio n where a fuzzy infe- Figure 8. Comparison between values of desired and the best ANFIS for Egg yolk with training data.  Modeling and Simulation of High Power Ultrasonic Process in Preparation of Stable Oil-in-Water Emulsion Copyright © 2011 SciRes. JSEA 266 Figure 9. Comparison between values of desired and ANFIS (hybrid method) pr edicted of producing stable emulsion pr ocess for viscosity, Creaming, arithmetic mean diameter, and specific surface area. rence s ys te m is u s ed a s a c on tr o ller . Th e r efor e, we n e ed a method of defuzzification to extract a crisp value that best represents a fuzzy set. Defuzzification refers to the way a crisp value is extracted from a fuzzy set as a representa- tive value. In general, there are several methods for defu- zzifying a fuzzy set: Centroid of area (COA), Bisector of area (BOA), Mean of maximum (MOM), Smallest of maximum (SOM), Largest of maximum (LOM), and weighted average (Wtaver). These defuzzification opera- tions are not easily subject to rigorous mathematical ana- lysis, so most of the studies are based on experimental results [24]. Since each rule has a crisp output, the over- all output is obtained via weighted average (Wtaver), thus avoiding the time consuming process of defuzzification required in a Mamdani model. In practice, the Wtaver operator is sometimes replaced with the weighted sum (Wsum) operator to reduce computation further, especial- ly in the training of a fuzzy inference system. 6. Conclusions The diameter, specific surface area of droplet, viscosity and creaming index of emulsion are strongly affected by the amount of oil. lower level of oil is better for stability and viscosity of emulsion. The existence of guar gum had supportive effect on oil behavior and contributes desira- ble texture. Xanthan was found to have synergic effect on pectin in stabilizing the emulsion especially at pH 4 for specific surface area and mean diameter and pH 3 for viscosity and creaming index. The presence of salt was shown to have positive effect on the viscosity and stabil- ity through lowering creaming index. Using high tem- perature was good for mean and specific surface area and low temperature preferable for smaller creaming index. High level of sonication time has a preference for egg yolk stabilized emulsion. The results of Particle size measurement showed larger specific surface area and smaller arithmetic mean diameter after 1 month. High  Modeling and Simulation of High Power Ultrasonic Process in Preparation of Stable Oil-in-Water Emulsion Copyright © 2011 SciRes. JSEA 267 level of sonication time has a preference for egg yolk stabilized emulsion. The current study proves that ANFIS is a technique that can be used capably to predict the food properties. It is consider that this technique can be useful to predict many other peroperties and parameters in food industry. 7. Acknowledgments The authors would like to thank the Ferdowsi University of Mashhad for supporting this research (P. No. 9085, 15 November 200 9) . REFERENCES [1] E. Dickinson, “Hydrocolloids as Emulsifiers and Emul- sion Stabilizers,” Food Hydrocolloids, Vol. 23, No. 6, 2009, pp. 1473-1482. doi:10.1016/j.foodhyd.2008.08.005 [2] B. Abismaïl, J. P. Canselier, A. M. Wilhelm, H. Delmas and C. Gourdon, “Emulsification by Ultrasound: Drop Size Distribution and Stability,” Ultrasonics Sonochemi- stry, Vol. 6, No. 1-2, 1999, pp. 75-83. [3] S. O. Agboola, H. Singh, P. A. Munro, D. G. Dalgleish and A. M. Singh, “Stability of Emulsions Formed Using Whey Protein Hydrolysate: Effects of Lecithin Addition and Retorting,” Journal of Agricultural and Food Chemi- stry, Vol. 46, No. 5, 1998, pp. 1814-1819. doi:10.1021/jf970913l [4] J. M. Aguilera and H. G. Kessler, “Properties of Mixed and Filled-Type Dairy Gels,” Journal of Food Science, Vol. 54, 1989, pp. 1213-1221. [5] A. Koocheki, R. Kadkhodaee, S. A. Mortazavi, F. Shahidi and A. R. Taherian, “Influence of Alyssum Homolocar- pum Seed Gum on the Stability and Flow Properties of O/W Emulsion Prepared by High Intensity Ultrasound,” Food Hydrocolloids, Vol. 23, No. 8, 2009, pp. 2416- 2424. doi:10.1016/j.foodhyd.2009.06.021 [6] A. E. Alegria, Y. Lion, T. Kondo and P. Riesz, “Sonoly- sis of Aqueous Surfactant Solutions. Probing the Interfa- cial Region of Cavitation Bubbles by Spin Trapping,” Journal of Physical Chemistry, Vol. 93, No. 12, 1989, pp. 4908-4913. doi:10.1021/j100349a046 [7] D. M. W. Anderson, “Gums and Stabilisers for the Food Industry 3,” Elsevier Applied Sciences, London, 1986. [8] M. Anton and G. Gandemer, “Effect of pH on Interface Composition and on Quality of Oil-in-Water Emulsions Made with Hen Egg Yolk,” Colloids and Surfaces B: Biointerfaces, Vol. 12, No. 3-6, 1999, pp. 351-358. doi:10.1016/S0927-7765(98)00089-7 [9] I. Aroutiounov, B. Toumanian, V. Melikian, D. Kova- lenko and V. Zubov, “Polymerisation in Miniemulsion,” 2e Congre’s Mondial de l’Emulsion, Bordeaux, 23-26 September 1997, pp. 102-106. [10] M. O. J. Azzam and R. M. Omari, “Stability of Egg White-Stabilized Edible Oil Emulsions Using Conductiv- ity Technique,” Food Hydrocolloids, Vol. 16, No. 2, 2002, pp. 105-110. doi:10.1016/S0268-005X(01)00068-6 [11] A. A. Baram, “Soviet Physics,” Acoustics, Vol. 10, No. 4, 1965, pp. 343-346. [12] C. T. Lin and C. S. G. Lee, “Neural-Network-Based Fuzzy Logic Control and Decision System,” IEEE Tran- sactions on Computers, Vol. 40, No. 12, 1991, pp. 1320- 1336. doi:10.1109/12.106218 [13] A. Amano and T. Arisuka, “On the Use of Neural Net- works and Fuzzy Logic in Speech Recognition,” Pro- ceedings of the International Joint Conference on Neural Networks, Washington, 1989, pp. 301-305. doi:10.1109/IJCNN.1989.118595 [14] T. Kohonen, “The Self-Organizing Map,” Proceedings of the IEEE, Vol. 78, No. 9, 1990, pp. 1464-1480. doi:10.1109/5.58325 [15] J. S. R. Jang, “ANFIS: Adaptive-Network-Based Fuzzy Inference System,” IEEE Transactions on Systems, Man and Cybernetics, Vol. 23, No. 3, 1993, pp. 665-685. doi:10.1109/21.256541 [16] L. X. Wang, “Training of Fuzzy Logic Systems Using Nearest Neighborhood Clustering,” Proceedings of the 2nd IEEE International Conference on Fuzzy Systems 1, San Francisco, 1993, pp. 93-100. [17] Anon, “Adaptive Fuzzy Inference Neural Network,” 2010. http://www.elsevier.com/locate/patcog [18] H. Iyatomi and M. Hagiwara, “Knowledge Extraction from Scenery Images and the Recognition Using Fuzzy Inference neural Networks,” Pattern Recognition, Vol. 35, No. 8, 2002, pp. 1793-1806. [19] J. Sargolzaei and A. Kianifar, “Modeling and Simulation of Wind Turbine Savonius Rotors Using Artificial Neural Networks for Estimation of the Power Ratio and Torque,” Simulation Modelling Practice and Theory, Vol. 17, No. 7, 2009, pp. 1290-1298. doi:10.1016/j.simpat.2009.05.003 [20] M. L. Denmat, M. Anton and G. Gandemer, “Protein Denaturation and Emulsifying Properties of Plasma and Granules of Egg Yolk as Related to Heat Treatment,” Journal of Food Science, Vol. 64, No. 2, 1999, pp. 194- 197. doi:10.1111/j.1365-2621.1999.tb15863.x [21] J. E Moros, J. M. Franco and C. Gallegos, “Rheological Properties of Cholesterol-Reduced, Yolk-Stabilized Ma- yonnaise,” Journal of the American Oil Chemists’ Society, Vol. 79, No. 8, 2002, pp. 837-843. [22] J. E. Moros, J. M. Franco and C. Gallegos, “Rheology of Spray-Dried Egg Yolk-Stabilized Emulsions,” Interna- tional Journal of Food Science and Technology, Vol. 37, No. 3, 2002, pp. 297-307. doi:10.1046/j.1365-2621.2002.00570.x [23] V. D. Kiosseoglou and P. Sherman, “Influence of Egg Yolk Lipoproteins on the Rheology and Stability of Oil/ Water Emulsions and Mayonnaise 1. Viscoelasticity of Groundnut Oil-in-Water Emulsions and Mayonnaise,” Journal of Texture Studies, Vol. 14, No. 4, 1983, pp. 397- 417. [24] J. Sargolzaei, M. Khoshnoodi, N. Saghatoleslami and M. Mousavi, “Fuzzy Inference System to Modeling of Crossflow Milk Ultrafiltration,” Applied Soft Computing Journal, Vol. 8, No. 1, 2008, pp. 456-465. doi:10.1016/j.asoc.2007.02.007 |