Journal of Geoscience and Environment Protection, 2014, 2, 60-65 Published Online June 2014 in SciRes. http://www.scirp.org/journal/gep http://dx.doi.org/10.4236/gep.2014.23008 How to cite this paper: Jiang, B.-C. et al. (2014). Research on Determination of the Main Factors Influencing the Gas Well Post-Frac Productivity Prediction for Tight Sandstone Reservoirs Based on Factors Analysis. Journal of Geoscience and Environment Protection, 2, 60-65. http://dx.doi.org/10.4236/gep.2014.23008 Research on Determination of the Main Factors Influencing the Gas Well Post-Frac Productivity Prediction for Tight Sandstone Reservoirs Based on Factors Analysis Bi-Ci Jiang1*, Bao-Zhi Pan1, Hai-Tao Zhang2, Xiao-Ming Yang2, Gang Chen3, Wen-Bin Liu4 1Jilin University, Changchun, China 2Research Institute of Exploration and Development, Petro Changqing Oilfield Company, Xi’an, China 3China Coal Research Institute Xi’an Science and Industry Group, Xi’an, China 4China University of Petroleum (East China), Qingdao, China Email: *jiangbici@163.com Received March 2014 Abstract With the characteristics such as low porosity, low permeability and low gas saturation, tight sand- stone reservoirs almost have no natural capacity and need to be fractured (or fracturing) for pro- ductivity. Therefore, fracturing capacity prediction is very necessary. However there we re so many factors, and the relations between the factor and the post-frac productivity are complex. In this study, first of all factors are concluded from the gas well stable productivity formula, then I used factor analysis to look for the main factors from the logging parameters and fracturing pa- rameters in SULIGE area. This study could provide basal references for the gas post-frac produc- tivity prediction in tight sandstone reservoirs. Keywords Factor Analysis, Tight Sandstone, SULIGE Region, Post-Frac Produ c ti vi ty 1. Introduction The fracturing is needed for tight reservoirs’ productivity, and the factors influencing the gas productivity pre- diction became complicated after fracturing. At present, there are two methods for tight sandstone gas post-frac productivity prediction that are formula method (Chen, 1998) and mathematical statistical method (Zhang, 2011; Zhang, 2007; Zhang, 2013; Zhang, 2008). For formula method, the accurately determined parameters involved in the equation are needed. However, for mathematical statistical method, the main factors were needed. The main factors come from the logging parameters and fracturing parameters. Zhang Jing (2011) used linear regres- sion analysis and Zhang Song-yan g (2007) used method of trial and error to look for the relationship between *Corresponding author.  B.-C. Jiang et al. the log parameters and the open-flow potential. Zhuang Hua (2013) used gray correlation method to search for the main factors in post-frac capacity in SULIGE region. Huang, He and Zhang (2010) integrated gray correla- tion, stepwise analysis, principal component analysis to analyze the main factors which had influence on ul- tra-low permeability reservoir oil production capacity. Factor analysis puts all of the information involved in original variables together, by exploring the internal structure of the correlation matrix and makes multivariate integrated into a small number of factors, which can reproduce the original relationship between the variables (Luo et al., 2005). Factor analysis is a good application in lithology identification (Luo et al., 2013). In this study, first it concluded the total factors from the gas well stable productivity formula, then it used factor analysis to analyze the main factors of tight sandstone gas Post-frac capacity forecast. This study could provide basal refer- ences for mathematical statistical method in the gas post-frac productivity. 2. Theoretical Formulas of Gas Reservoir Fracturing Capacity In the literature (Chen, 1998), gas well stable binomial deliverability equation is (1) Where is reservoir static pressure, (MPa); wf is the bottom hole flowing pressure (MPa); A and is binomial coefficients. 4 (8.484 10/)[ln(/)0.434] gscsce wa AZTpKhTr rS µ =×+ (2) ( ) 82 22 (1.96610/) 11 g scscwe BZTphTRrr βγ − =×− (3) when , the gas well absolute open flow is 222 (4(0.101)) / 2 AOF R QABpA B=+− − (4) where is effective thickness(m); is terrestrial standard pressure (MPa); is permeability (mD); is terrestrial standard temperature (K); is gas deviation factor; is apparent skin factor; is inertial re- sistance coefficient caused turbulence; is gas gravity; is gas viscosity(mPa·s); is gas control ra- dius, m; bottom radius, m; is universal gas constant ( ); formation tempera- ture(K). In the formula (4), it’s very difficult to accurately determine the various parameters. For these parameters h , , R, T, , it is easy to obtain obtained. However, for the others, exact values are difficult to be ob- tained. K suffered many influential factors, so it is usually established by the relationship of porosity. Sa is af- fected by many factors (Chen & Yan, 2004), so it is difficult to get an accurate value. β is related to Sa. Z is the function of formation temperature and formation pressure (Gao & Hao, 2001), so there were some discrepancies; is got based on the empirical formula proposed by Lee and Gonzalez (Gao & Hao, 2001), and there will be some deviation; is affected by permeability, reservoir pressure and other factors, there is some deviation too. Therefore, there is a big difficulty and a certain deviation when using the formula method to calculate gas well fracturing capacity, it’s necessary to predict gas well fracturing capacity by using statistical mathematical meth- ods. However there are too many parameters to response reservoir conditions and fracturing conditions. We need to filter out the main influencing parameters. In the formula (4) we could see that factors influencing gas well fracturing capacity besides the gas’s property, the thickness and the reservoir’s conditions, gas well fracturing capacity is also closely related to reservoir’s properties (permeability K),fracturing parameters (mainly effect Sa, and reservoir properties). In order to avoid the impact of reservoir thickness and the various parameters referred come from unit thickness. 2. Selecting Factors Influencing the Gas Well Post-Frac Productivity for Tight Sandstone Reservoir Nowadays, the forecast of productivity is building a model with an indicator which can reflect the gas produc- tivity. The indicator is built by the well deliver ability testing, the porosity, the absolute permeability and so on (Zhang, 2011; Zhang, 2007; Zhang, 2013; Zhang, 2008). Compared with conventional reservoir, tight gas res- ervoir has tight lithology, poor physical property, strong aeolotropism, low trap amplitude and low natural de- liverability. In the actual production process, fracturing has a great impact on tight gas productivity. So it is  B.-C. Jiang et al. needed to consider the reservoir property and the fracturing parameters in the post-frac productivity predicting. The formation P1-2sh in SULIGE area is a typical representative of tight sand stone reservoirs with the per- meability (0.1 - 1) * 10−3∙μm2. In this study, the data came from 52 wells in west of SULIGE region, ten pa- rameters from logging and fracturing parameters were picked up: natural gamma (GR, API), acoustic travel time (AC, us/m), resistance (RT, Ω∙m), density (DEN, g/cm3), neutron(CNL,%), the amount of sand per meter (SD, m3), the sand ratio (SR,%), the sand concentration (SC, kg/m3), delivery capacity per meter(VOE, m3/min) and total amount of fluid into the well per meter (FV, m3/min). 3. Analyzing the Impact of Various Factors on Fracturing Capacity by Factor Analysis Method Factor analysis method put all relevant information of the original variables together. It reduces the number of factors by exploring the internal structure of the correlation matrix, which can reflect the relationship among the original variables, and looks for the reason of the correlation additionally (Zhu et al., 2014). Factor analysis method that can determine the main factors for tight sandstone post-frac predicting, it could search out the in- ternal correlation among all of the factors, and afford a few general factors to explain the varieties of post-frac productivities in the tight sandstone. Then we could select the main effect factors of tight sand stone fracturing capacity forecast based on the contribution made by each factor in the common factors. The step of factor analysis method is just as following: First: importing the raw data Xn*p, then calculating the average values and variance of the sample, and stan- dardizing the data. Second: evaluating the sample’s correlation matrix R = (rij) p * p. Third: finding the eigen value of correlation coefficient matrix λi (λ1, λ2, ..., λp > 0) and the corresponding standard orthonormal eigen vectors (li). Forth: determining the number of common factors; Fifth: calculating the common variance of com- mon factors hi2. Last: calculating the score of the common factors component and then explaining the practical application. Depending on the method factor analysis, we analyze the data with SPSS software. The detail procedure is as below: Step one: Judging the parameters selected whether are suitable for factor analysis The precondition of using factor analysis method is that there is a linear relationship between the variables. Then the factors could be reduced and the purpose could be achieved. The result of analyzing of correlation ma- trix shows that the correlation coefficients were greater than 0.3. So there is a strong correlation between the factors which has an impact on tight sand gas reservoir fracturing capacity forecast. The correlation matrix of various factors was below (Table 1): Meanwhile calculating KMO and BaetlettSphere degree of the above table, results were as follows (Table 2): Table 2 shows: the statistic observation of BaetlettSphericity testing was 477.417, and the corresponding probabilities P (Sig) was close to zero. If the significance level was 0.05, due to the probability P was less than the significance level 0.05, you could pull off the null hypothesis. So obviously there were differences between correlation matrix and unit matrix, meanwhile KMO value was 0.715, that fit the criteria well. In short the method of factor analysis was available in this study. Step two: Extracting factors According to the correlation coefficient matrix of the original variants, eigen values over1were selected by PCA. Then calculating the explained variance of each parameters. The initial common factor variance is esti- mators of eachvariant’s explained variance. It is always equal to 1 in PCA. Because the number of components equals to the original parameters’ number, the common value is equal to 1. The common factor variance extract- ed was used to predict factors’ multiple correlation square value. The low value shows that the variant is not suitable as a factor, so it will be abandoned in the analysis. Now calculate the communality of the chosen factors. The results are as following in Table 3: The third column in table 3(extracted) is the final solution of common variable degree according to the factor analysis. What can be obtained is that most of the information has been analyzed with factor analysis, just a few information was lost. The overall effect of factor extraction is well. The number of the analyzed factors is ten, so there are ten ingredients. Now calculating characteristic values for each component (the total characteristic values). The proportion of each component’s explained variance in the total variance is just the proportion of the factors’ characteristic value in the total eigen value. Now calculat-  B.-C. Jiang et al. Table 1. Correlation coefficient matrix. Factors SD SR SC VOE FV RT GR AC CNL DEN SD 1 0.623 0.612 0.652 0.641 0.02 −0.04 0.107 0.074 0.104 SR 0.623 1 0.991 0.879 0.706 −0.2 0.24 0.079 0.063 0.14 SC 0.612 0.991 1 0.883 0.7 −0.1 0.246 0.075 0.083 0.135 VOE 0.652 0.879 0.883 1 0.764 −0 0.187 0.093 0.09 0.22 FV 0.641 0.706 0.7 0.764 1 0.19 −0.08 −0.08 −0.13 0.129 RT 0.022 −0.154 −0.145 −0.03 0.189 1 −0.37 −0.53 −0.44 0.249 GR −0.039 0.24 0.246 0.187 −0.076 −0.4 1 −0.08 0.339 0.472 AC 0.107 0.079 0.075 0.093 −0.08 −0.5 −0.08 1 0.557 −0.62 CNL 0.074 0.063 0.083 0.09 −0.126 −0.4 0.339 0.557 1 −0.26 DEN 0.104 0.14 0.135 0.22 0.129 0.25 0.472 −0.62 −0.26 1 Table 2. KMO and Bartlett’s test results. Sphericity test of Bartlett Similar chisquare 477.417 df 45 Sig. 0 Table 3. Common factor variance table. 1 0.731 1 0.861 SR 1 0.949 GR 1 0.908 SC 1 0.94 AC 1 0.849 VOE 1 0.893 CNL 1 0.922 FV 1 0.813 DEN 1 0.872 ing the summation percentage of the proportion of each component’s explained variance in the total variance. Then extract the components whose total variance is greater than 0.5. The results are shown in Table 4. The section 2 (total) of Table 4, there are four values greater than 0.5 in the variant correlation matrix as 4.079, 2.402, 1.625, 0.63. These four factors integrated 87.368 percentage information of the ten variants. In other words, the four factors which are in front reflect most information of the original data. Therefore extracting four common factors is appropriate, and it can also represent a comprehensive condition. Step three: According to the common factor component scores, finding the main influencing factors of tight sand gas deliverability Now we build equations for four general factors according to calculated scores coefficient of general factor. Then we select the previous two of the absolute values of the coefficient as the main factors of the impact of tight sandstone gas reservoir fracturing capacity. Coefficient matrix of component score is shown in Table 5: F1=0.198SD+0.233SR+0.232SC+0.229VOE+0.22 9FV+0.009RT 0.039GR +0.031AC0.029CNL 0.009DEN − −− (5) F2= 0.026SD 0.011SR 0.005SC+0.029VOE 0.079FV+0.053RT+0.484GR 0.289AC+0.134CNL+0.503DEN −−− − − (6) F3=0.335SD-0.182SR0.161SC+0.035VOE 0.028FV+0.216RT+0.171GR +0.263AC+0.836CNL+0.067DEN −− (7) F4= 0.378SD+0.242SR+0.227SC 0.009VOE 0.166FV0.716RT+0.24GR +0.115AC 0.311CNL 0.159DEN −− −− −− (8) In Table 5, each of the largest two of absolute value of the coefficient expressions of various common factors  B.-C. Jiang et al. Table 4. The total explained variance. Ingredient Initialeigenvalue Squareextracted and loading Total Variance’s percentage Summation percentage Total Variance’s percentage Summation percentage 2 2.402 24.017 64.811 2.402 24.017 64.811 3 1.625 16.254 81.065 1.625 16.254 81.065 4 0.63 6.303 87.368 0.63 6.303 87.368 5 0.446 4.458 91.826 6 0.268 2.678 94.504 7 0.255 2.548 97.052 8 0.194 1.939 98.991 9 0.092 0.924 99.915 10 0.008 0.085 100 Table 5. Component score coefficient matrix. Factors Components 1 2 3 4 SD 0.198 −0.026 0.335 −0.378 SR 0.233 −0.011 −0.182 0.242 SC 0.232 −0.005 −0.161 0.227 VOE 0.229 0.029 0.035 −0.009 FV 0.229 −0.079 −0.028 −0.166 RT 0.009 0.053 0.216 −0.716 GR −0.039 0.484 0.171 0.24 AC 0.031 −0.289 0.263 0.115 CNL −0.029 0.134 0.836 −0.311 DEN −0.009 0.503 0.067 −0.159 is: the first common factor (F1) is the sand ratio(SR), sand concentration (SC); the second common factor (F2) is the natural gamma ray (GR), density (DEN); the third common factor (F3) is the neutron (CNL), the amount of sand per meter(SD); the fourth common factors (F4) resistivity (RT), the amount of sand per meter(SD). In the first common factor (F1) (Table 4 that, F1 information reflects 40.794%) expression, the five parameter coeffi- cients represent fracturing construction accounted for a large proportion than the five logging parameters, so we can see that fracturing construction parameter have a great impact on tight sand gas fracturing capacity. 4. Conclusions and Understanding For tight sand reservoirs, the relationship between individual factors and gas reservoir fracturing production is complicated, so we cannot determine the impact factors of tight sandstone gas fracturing capacity by a simple linear correlation analysis. In factor analysis, correlation of each factor which has an impact on tight sand gas fracturing capacity is greater than 0.3. There must be a certain relationship among the various factors. From factor analysis we can see that fracturing parameters is important in tight gas reservoir post-fract pro- ductivity prediction, therefore we must consider fracturing parameter into tight sand gas fracturing capacity forecast. The main factors determined by factor analysis are sand ratio (SR), sand concentration (SC), natural gamma ray (GR), density (DEN), neutron (CNL), the amount of sand per meter (SD), resistivity (RT). References Bureau Chen Y.-Q. (1998). Practical Reservoir Engineering Methods. Petroleum University Press.  B.-C. Jiang et al. Chen, Y.-Q., & Yan, W.-G. (2004). Decomposition of Skin Factor. Fault Block Oil & Gas Field, 10, 32-35. Gao, S.-H., & Hao, Y.-H. (2001). A Simple Method for Determination of Gas Well’s Non-Resistivity Flow During Different Producing Stages—An Example from Well Shan 7 in Changqinggasfield. XJPG, 22, 441-443. Huang, L., He, S.-L., Zhang, X.-X. et al. (2010). Research on Determination of the Main Factors Influencing the Oil Well- Productivity of Ultra Low Permeability Reservoir. Science Technology and Engineering, 030, 7408-7413. Liu, Q.-R., Xue, L.-F., Pan, B.-Z. et al. (2013). Study on Glutenite Reservoir Lithology Identification in Lishu Fau lt. Well Logging Technology, 37, 269-273. Luo, T.-Y., Guo, J.-C., Zhao, J.-Z. et al. (2005). New Method for Absolute Open Flow of Gas Wells after Fracturing. XJPG, 26, 554-556. Zhang, J. (2011). The Evaluation of Gas Characteristics of Tight Sandstone and Productivity Prediction of SULIGE Gas Field. Qingdao: China University of Petroleum (East China). Zhang, S.-Y. (2007). A Method for Extracting Log Characteristic Parameters and Evaluation Tenique of Tight Sandstone Gas Reservoir. QingDao: China University of Petroleum (East China). Zhang, S.-Z. (2008). Productivity Study of Ultra—Low Permeability Reservoir. Beijing: China University of Petroleum. Zhu, Z.-P.,Wan g, L.-J., Pei, F. et al. (2014). Study on Corrosion Evaluation of substation Ground Grid Soil by Factor Analy- sis. Journal of Chinese Society for Corrosion and Protection. Zhuang, H. (2013). Research on Gas Productivity Prediction Based on Logs for Post-Frac Tight Sandstone Reservoirs in SSULIGE Area. Changchun: Jilin University.

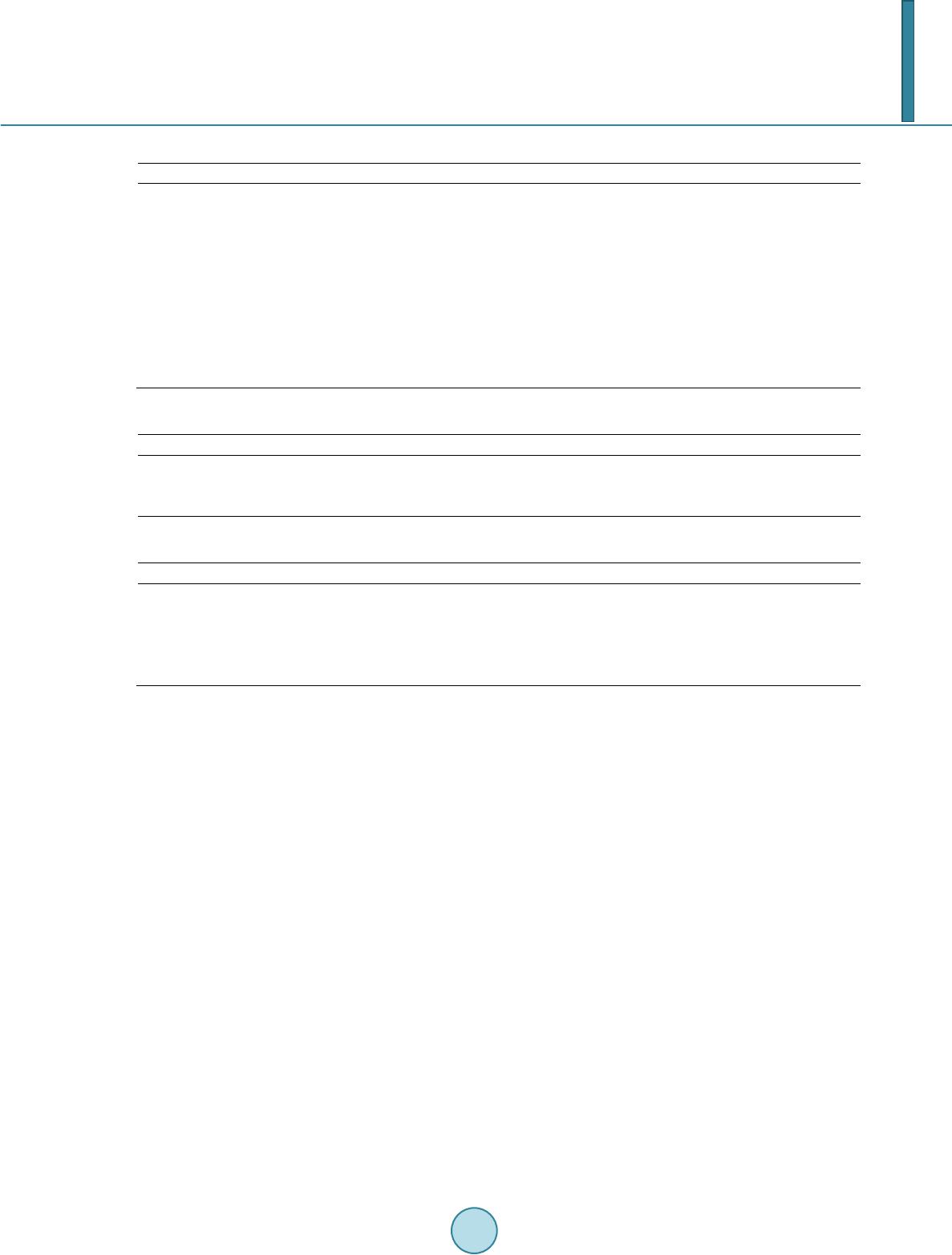

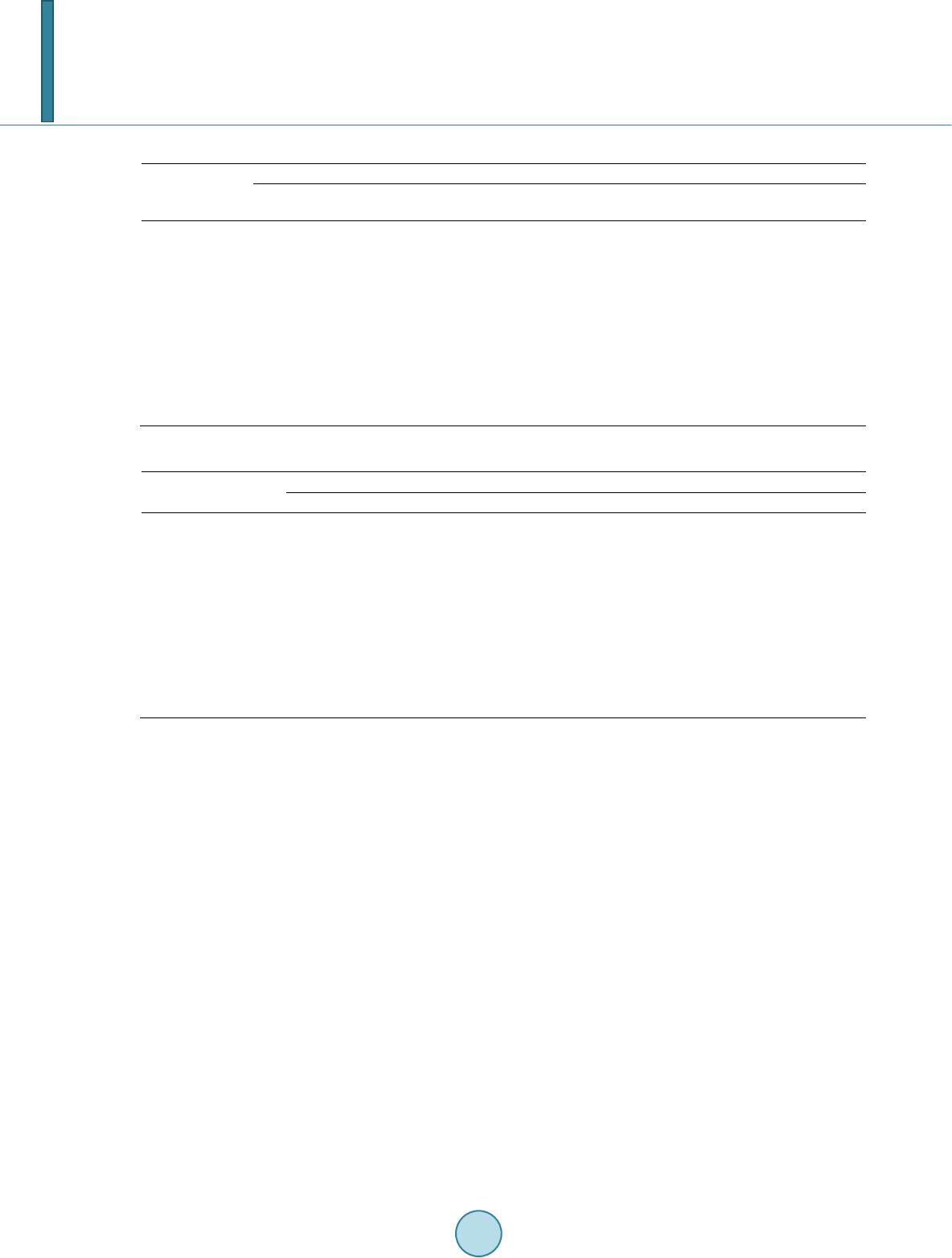

|