X. Y. Han et al.

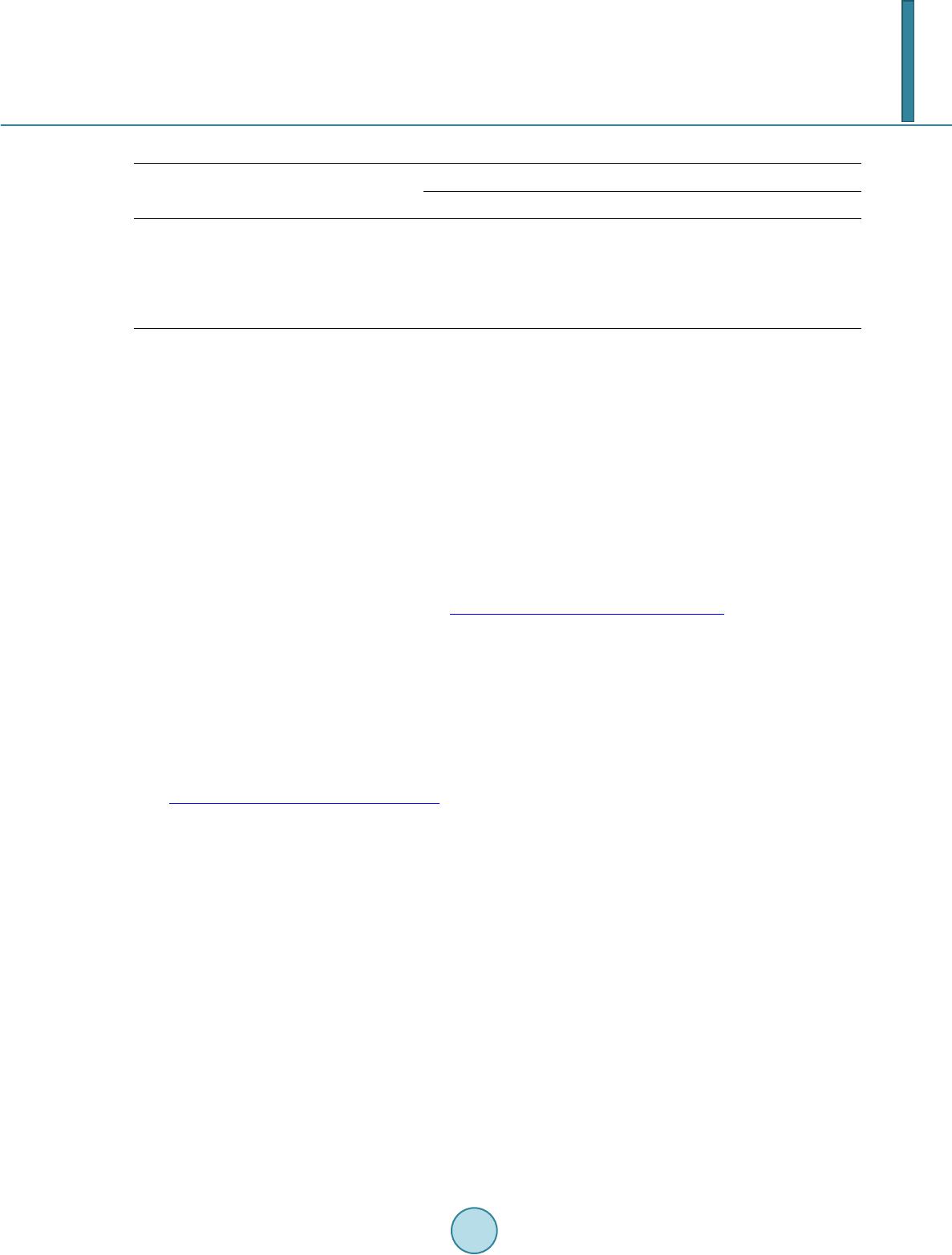

Table 1. Catalytic results of layered double hydroxides (LDHs) supported catalyst.

Catalyst T(K) CO conversion (%) STYROH Selectivity (wt.%) Alcohol distribution (wt.%)

(g/g/h) ROH CHn CO2 C1OH C2 + OH

CuFeMgAl

493 8.05 0.00 1.09 93.80 5.11 59.61 40.39

513 19.39 0.01 3.28 83.86 12.86 61.47 38.53

533 32.28 0.06 9.91 67.79 22.30 58.86 41.14

553 54.99 0.11 9.04 54.03 36.93 53.63 46.37

Reaction conditions: H2/CO = 2.0, GHSV = 5000 h−1, P = 4.0 MPa.

493 K to 9.91 w t.% at 533 K. And at 553 K the selectivity of alcohols slightly fell may be due to the sintering of

Cu.

4. Conclusion

In summary, this work confirmed that bimetallic highly dispersed Cu-base catalysts could be prepared via ther-

mal decomposition of layered double hydroxides precursors. This is attributed to the layered structure of hydro-

talcite which could efficiently inhibit the sintering of the Cu and Fe ions. Furthermore, at low temperature the

main products of the catalyst were alkanes and as temperature grows the selectivity of alcohols becomes higher.

References

[1] Lin, M., Fang, K., Li, D. and Sun, Y. (2008) CO Hydrogenation to Mixed Alcohols over Co-Precipitated Cu-Fe Cata-

lysts. Catalysis Communications, 9, 1869-1873. http://dx.doi.org/10.1016/j.catcom.2008.03.004

[2] Lin, M., Fang, K., Li, D. and Sun, Y. (2008) Phase Transformation in Cu-Fe Based Catalyst during CO Hydrogenation.

Chinese Journal of Catalysis, 29, 559-565.

[3] Fang, K., Li, D., Lin, M., Xiang, M., Wei, W. and Sun, Y. (2009) A Short Review of Heterogeneous Catalytic Process

for Mixed Alcohols Synthesis via Syn ga s . Catalysis Today, 147, 133-138.

[4] Gao, W., Zhao, Y.F., Liu, J.M., Huang, Q.W., He, S., L i, C.M., Zhao, J.W. and Wei, M. (2013) Catalytic Conversion

of Syngas to Mixed Alcohols over CuFe-Based Catalysts Derived from Layered Double Hydroxides. Catalysis Science

& Technology, 5, 1324-1332.

[5] Yuan, Z., Wang, L., Wang, J., Xia, S., Chen, P., Hou, Z. and Zheng, X. (2011) Hydrogenolysis of Glycerol over Ho-

mogenously Dispersed Copper on Solid Base Catalysts. Applied Catalysis B: Environmental, 101, 431-440.

http://dx.doi.org/10.1016/j.apcatb.2010.10.013