Journal of Power and Energy Engineering, 2014, 2, 198-202 Published Online April 2014 in SciRes. http://www.scirp.org/journal/jpee http://dx.doi.org/10.4236/jpee.2014.24028 How to cite this paper: Dosaev, M.Z., Klimina, L.A., Lokshin, B.Ya., Selyutskiy, Y.D. and Hwang, S.-S. (2014) On Optimization of Power Coefficient of HAWT. Journal of Power and Energy Engineering, 2, 198-202. http://dx.doi.org/10.4236/jpee.2014.24028 On Optimization of Power Coefficient of HAWT Marat Z. Dosaev1, Lyubov A. Klimina1, Boris Ya. Lokshin1, Yury D. Selyutskiy1, Shih-Shin Hwang2 1Institute of Mechanics, Lomonosov Moscow State University, Moscow, Russia 2Mechanical Engineering Department, Chien Hsin University of Science and Technologies, Zhongli City, Taiwan Email: dosayev@imec.msu.ru Received December 2013 Abstract The horizontal axis wind turbine (HAWT) blades rotation in the steady wind flow is considered. We discuss the problem of determining the blade twist which could guarantee the maximum value of the power coefficient. We define the blade twist as the technological turn of sections of blade around its axis. This turn changes the effective pitch angle of turbine blade along its length. For description of aerodynamic load upon the blades we used the quasi-steady approach. Air veloci- ties of centers of pressure of blade sections are represented when taking into account components induced by flow and vortex. We reduced the functional maximization problem to find the maxi- mum of non-dimensional function. This function is given by Riemann integral depending on sec- tion pitch angle and tip speed ratio. We suggested the algorithm for solving the problem under consideration for a given blade shape. Keywords HAWT Blade; Tip Speed Ratio; Maximum of Power Coefficient 1. Introduction The problem of designing the new shape for wind turbine blade is very complicated. Along with taking into ac- count vibration and strength properties of blade, one must allow for necessity to utilize the maximum energy of wind. Wide spreading of different types of wind turbine enables to construct engineering techniques for blade design. For example, in [1,2] authors proposed the engineering method for choosing blades parameters, such as the aerodynamic profile, blade width, pitch angle, and etc for several sections along the flow. On the other hand the wind turbine aerodynamics is comprehensively studied [3]. Some authors use analytical approaches for power efficiency estimating of wind turbine. The method based on using Goldstein functions is proposed in [4] for ideal turbine with the finite number of blades. The simple enough algorithm of numerical estimation of the upper bound of the power coefficient is suggested. In present paper, we propose the analytical-computational approach for calculating the distribution of twist blade angle along the blade length, which guarantee the maximum value of power coefficient for given blade section profile and give distribution of blade width (Figure 1). We use the mechanical-mathematical model of  M. Z. Dosaev et al. Figure 1. Blade twist for several sections. aerodynamic load upon turbine blades developed in [5]. This model is based on quasi-steady approach. In order to advance this model we introduce the components that related with induced velocities (see for example, [5]). 2. Problem Formulation We consider the turbine with radius R (where R is a distance between axis of rotation and blade tip) that has n blades (usually n = 3 - 6) and rotates with angular speed in steady airflow. The wind speed W is directed along the turbine axis. The output power P of turbine looks as following: , where is TSR (tip speed ratio) of turbine, is the air density, is turbine swept area, is the power coefficient that characterizes the efficiency of wind turbine. We assume that the blade section, which is located at distance r (0 < r < R) from axis of rotation, represents the given airfoil. The shape of section is the same for all blade sections. We formulate the following problem: to determine the specified value and specified dependence for twist angle of blade along its length, which ensure the maximum value of power coefficient. We use the flat cross-section hypothesis for needed characteristics obtaining. We allocate the section element dr which is located at distance r from axis of rotation (Figure 2). Dependence b = b(r) is given. The air velocity of point of intersection of blade axis and blade section is a sum of flow speed W(1 - а) and speed of its rotation. Here coefficients to be determined are functions of r. In Figure 3, the side view of this element is shown. In this projection, it is convenient to introduce all re- quired values: pitch angle , angle of attack , velocity with respect to the flow, angle between the turbine plane and , and vectors , —components of the aerodynamic force (drag and lift, respectively) acting upon the selected element. By construction, we have: 222 2 ,tg(1) /(1) (1)sin ,(1)cos , (1)() (1) W ara WaVra V VWa ra θ φαφ φφ ′ =−= −Ω+ ′ − =Ω+= ′ =− +Ω + (2. 1) Aerodynamic forces are defined by the following conventional formulae: , (2.2) where is the element area, and aerodynamic coefficients are known functions for a given airfoil [6]. Note that such approach to describing the aerodynamics was used in [7]. The aerodynamic torque with respect to the rotation axis produced on this element is given by the ex- pression or, taking into account (2.1) and (2.2), ()( )( ) ( ) ()( )()()( )() ( ) 2 2 2 2 0.5cos sin 0.51( )111 LD LD dMrb rCCV dr rb rWa CaCrWaraWdr αφα φρ ρ αα = − ′′ =−−+Ω× − +Ω+  M. Z. Dosaev et al. Figure 2. Blade element. Figure 3. Side view of blade element. Denote: (2.3) Then the torque produced by all blades can be represented as an integral ()()() ()( )()() 22 22 0 0.5111 1 R LD MnWrb ra CaCaadr ρααωω ′′ =−−+− ++ ∫ The power looks as follows: ()()( )()( )()() 22 31 2 0 0.5111 1 R LD PnWrb rRa CaCaadr ρ λααωω − ′′ =−−+− ++ ∫ (2.4) Substituting r in (2.4) using the expression (2.3), we obtain (2 .5 ) Here the non-dimensional function is introduced ()()( )()( )()() 22 11 2 01 111 LD bRa CaCaad λ λ λωααωωω −− ′′ Φ=−−+− ++ ∫ (2 .6 ) Comparing (2.5) with the general formula for the power produced by the wind turbine, one can readily see that the following relation holds: , (2.7) and the initial optimization problem is reduced to the problem of maximum search for the function (2.6). 3. Solution of the Problem Before solving the problem of optimization of this coefficient (values to be varied are and , blade chord b is a given function of , values are also to be defined as functions of ), consider the process of calculation of the integrand in (2.6) for fixed . For that, following [3], we  M. Z. Dosaev et al. introduce the adjustment coefficient , taking into account losses at the blade tip, where , , ()cos ()sin NL D CC C αφαφ = + is the component of aerodynamic force along HAWT the axis, and ()sin ()cos TL D CC C αφ αφ = − is the component of aerodynamic force lying in the turbine plane. Then induced speeds coefficients can be represented as follows [3]: ( ) 21 1 ( )(4sin( )) , ()4sin cos() NN TT aC FC aC FC σα ϕσα σα ϕϕσα − − = + ′= − (3.1) Angles and can be expressed as follows (using (2.1) and (2.3)): , ( ) ( ) ( ) 11 arctg 11aa ϕω −− ′ =−+ (3.2) Relations (3.1)-(3.2) make a system of four equations with respect to . Contrarily to the iterative method of solving these equations proposed in [3,5], consider another way for determining the sought values. Substituting (3.1) into the second Equation (3.2), we obtain ( ) ( ) 2 4sinsin cos0 NT F CC ωϕϕϕ σω −++= (3.3 ) From here, is expressed via . In particular, for we have: [ ] arctg() / () LD DL CC CC ϕλλ =−−+ . After having solved (3.3), parameters are also expressed from (3.1) via , and then the angle is determined from the first Equation (3.2) as a function of the same parameters . Thus, the integrand in (2.6) represents an explicit function of . Such representa- tion is more preferable for solving the original problem of maximization of the coefficient . Now return to the problem of maximization of , or of function . Taking into account that is a constant (though unknown), the integral (2.6) can be interpreted as a functional defined on the class of differen- tiable functions . Then the source problem is deduced to the problem of choice of a function that delivers maximum to the integral, and of subsequent choice of such a value that deliv- ers maximum value to the function . In order to find , we use the convenient method for solving variational problems, we obtain the fol- lowing necessary condition of the maximum of the integral (Euler-Lagrange equation): the full derivative of the integrand with respect to is zero (this equation is not written here due to its complexity). In [5], results of numerical solution of Equations (3.1)-(3.2) are given for several NACA airfoils, from which one can see that coefficients almost do not change for . Hence, we assume (as the first approxima- tion) that (3 .4 ) Then the mentioned Euler-Lagrange equation looks as follows (1 )(1)0 LD a dCdadCd αω α ′ − −+= (3.5 ) From (3.5) it is possible to find as a function of : . One of branches of this solution will contain the optimal dependence , and from (3.3) (or from (3.2)) it is possible to determine the in- termediate variable , and then from (3.2) it is possible to derive the expression for the desired blade twist containing the undetermined (so far) parameter : () ( ) ( ) 011 0 ( ,)arctg11( , )aa θ ωλωα ωλ −− ′ = −+− (3.6) Substituting the obtained expression for into the integrand in (2.6), we obtain the function of single argument , maximum value of which is determined analytically (if possible) or numerically. Thus, the desired optimal value will be found, after which the optimal blade twist is determined from (3.6) as a func- tion of . Note that . In principle, the problem is solved. Taking into account dependences (e.g., [6]), one can show that the solution of Equation (3.5) exists as a monotonically decaying function. If it delivers maximum to the functional (3.6), then upon having determined the optimal value of and returning back to the variable r, the optimal blade twist can also be decreasing function ( ) ( )() ( ) 1 0 000 ( )arctg11(/)rR raarR θ λαλ − ′ =−+ − .  M. Z. Dosaev et al. This monotony is qualitatively confirmed by the practice of HAWT design. 4. Conclusion In this paper we studied the problem of maximization of power coefficient for a HAWT by optimization of a blade twist and tip speed ratio. We obtained an algorithm for determining of the optimal solution of this problem in the frame of the quasi-steady model of aerodynamic action taking into account induced velocities. Each step of this algorithm depends on parameters of the model, so the final shape of the twist can be specified for each particular airfoil. Still qualitative features of the optimal solution remain for the general case: for instance, there exists the optimal pitch angle function that is monotone along the blade length. Acknowledgements The work is partially supported by RFBR, projects NN 11-08-92005, 12-01-00364, and 14-08-01130. References [1] Perli, S.B. (1938) Windpump and Windelectrical Units. ONTI, Kharkov. (in Russian) [2] Sabinin, G.H. (1931) Theory and Aerodynamic Calculation of Wind Engines. Trudi TsAGI, Moscow. (in Russian) [3] Hansen, M.O.L. (2000) Aerodynamics of Wind Turbines. James and James, London. [4] Okulov, V.L. and Sorensen, G. N. (2008) Ideal Wind Turbine with Finite Number of Blades. DAN, 420, 478-483. (in Russian) [5] Tenguria, N., Mittal, N.D. and Ahmed, S. (2011) Evaluation of Performance of Horizontal Axis Wind Turbine Blades Based on Optimal Rotor Theory. Journal of Urban and Environmental Engineering, 5, 15-23. http://dx.doi.org/10.4090/juee.2011.v5n1.015023 [6] Kashafutdinov, S.T. and Lushin, V.N. (1994) Atlas of Aerodyna mic Characteristics of Wing Airfoils. SO RASHN, Novosibirsk. (in Russian) [7] Dosaev, M.Z., Kobrin, A .I. , Lokshin, B.Ya., Samsonov, V.A. and Sely utsk iy, Yu.D. (2007) Constructive Theory of Small-Scale Power Generators. Part I, MSU Publishing, Moscow.

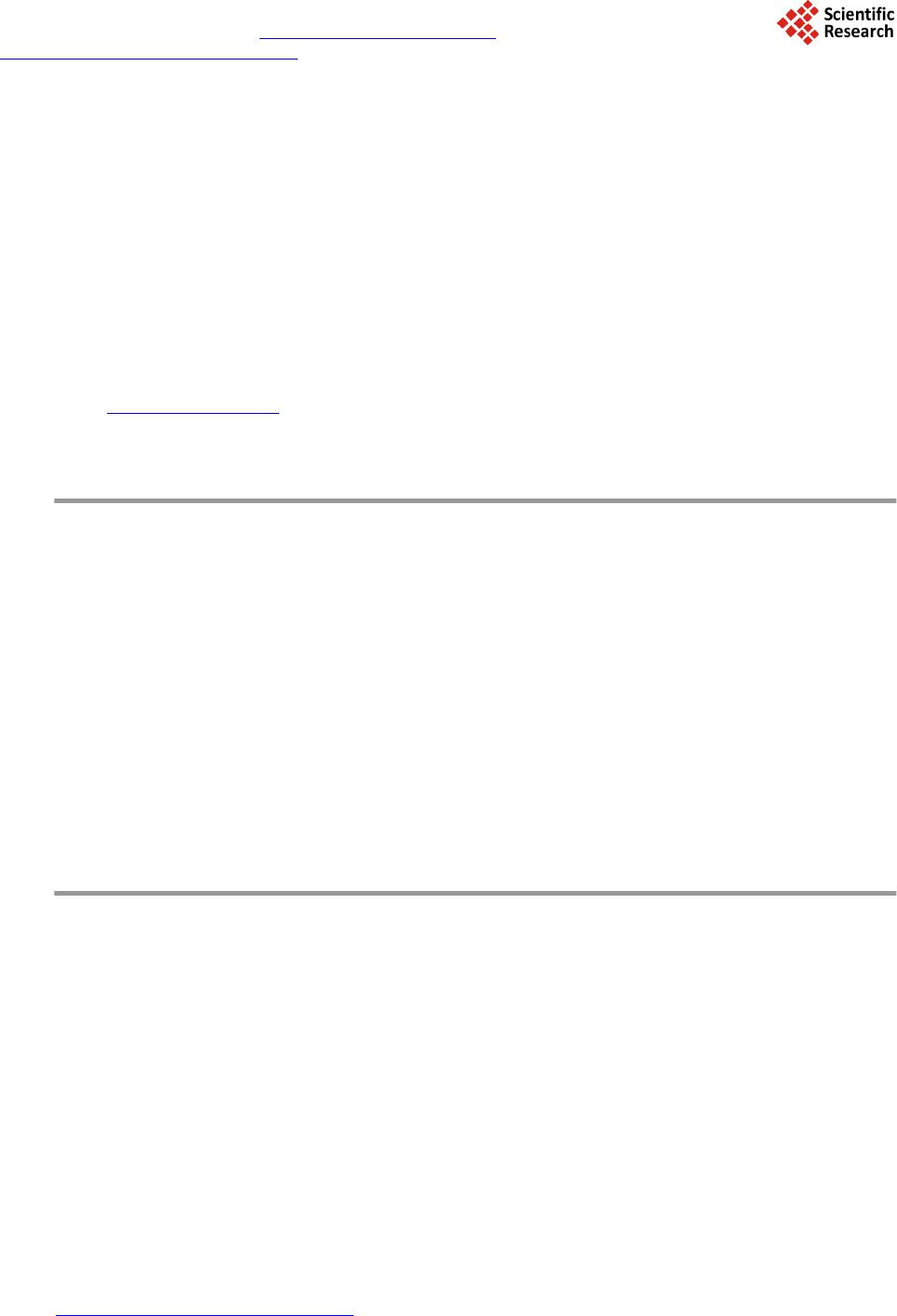

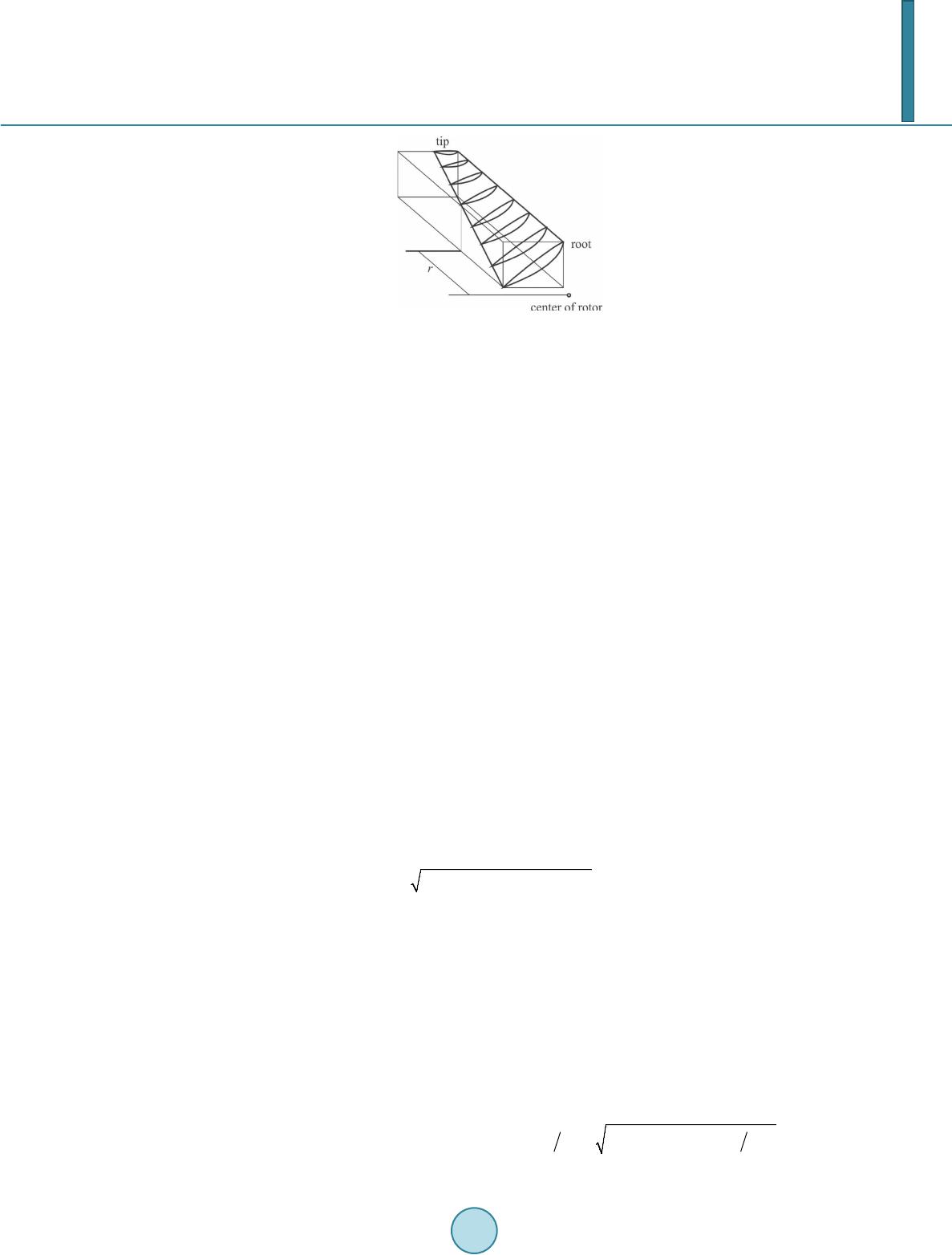

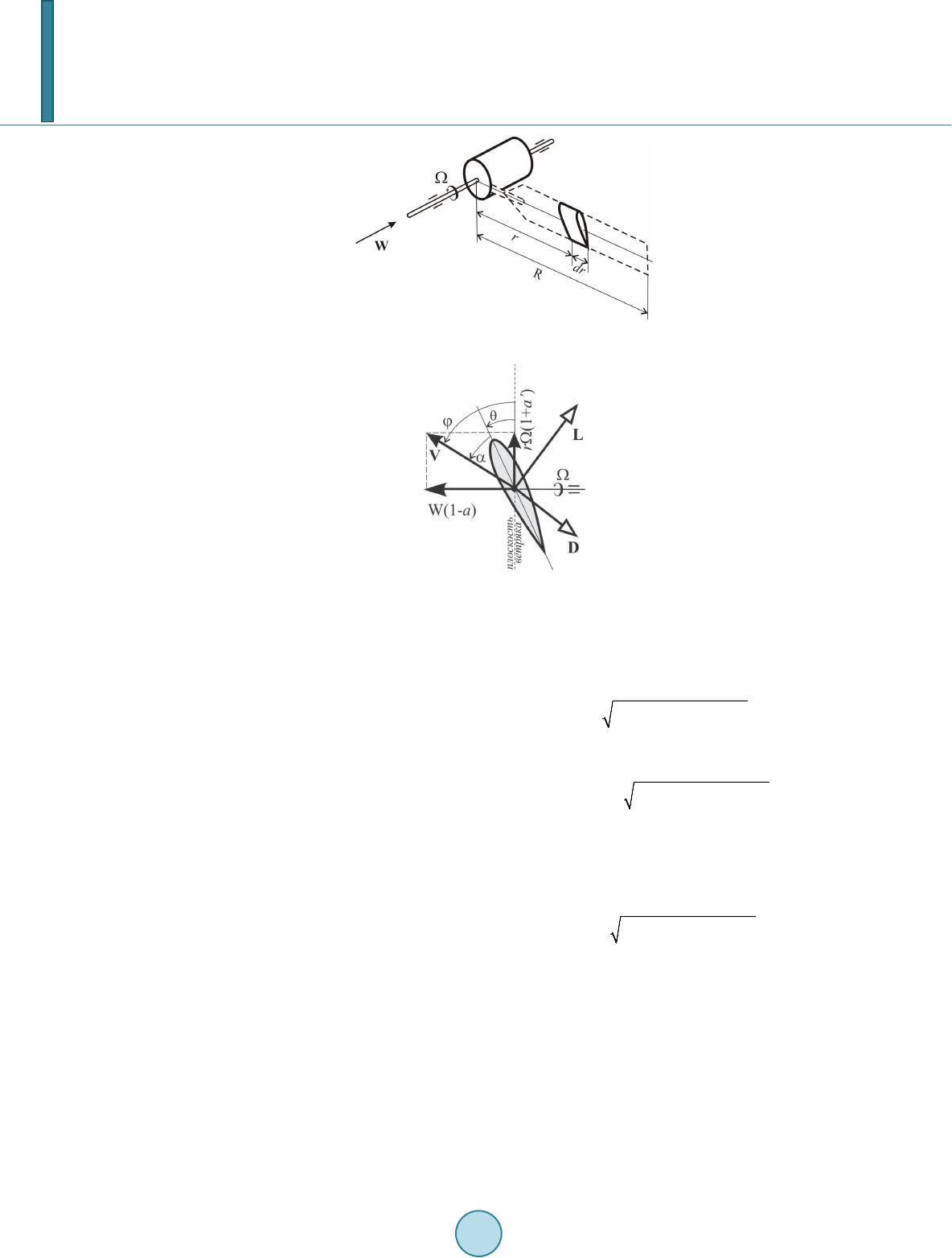

|