Paper Menu >>

Journal Menu >>

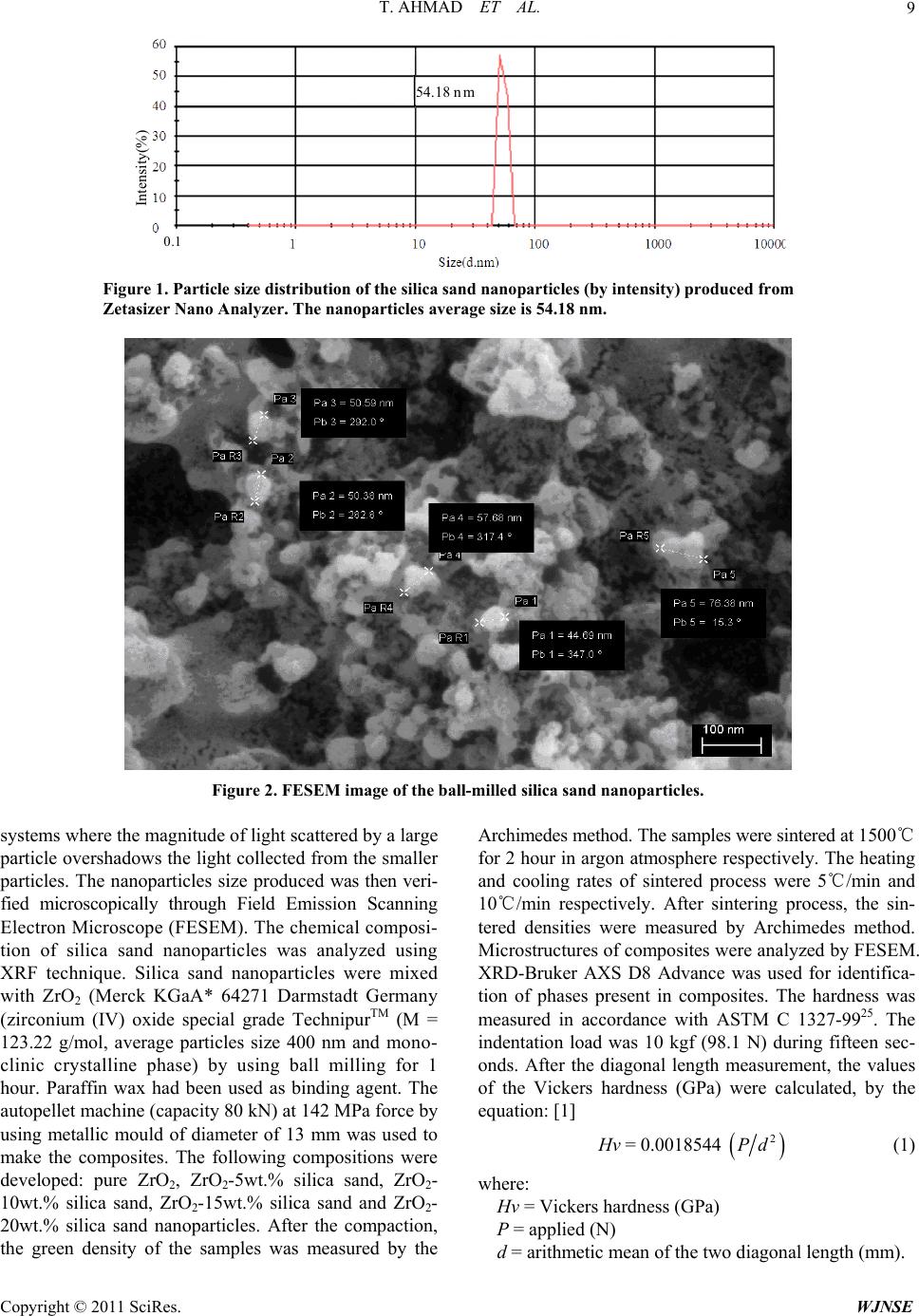

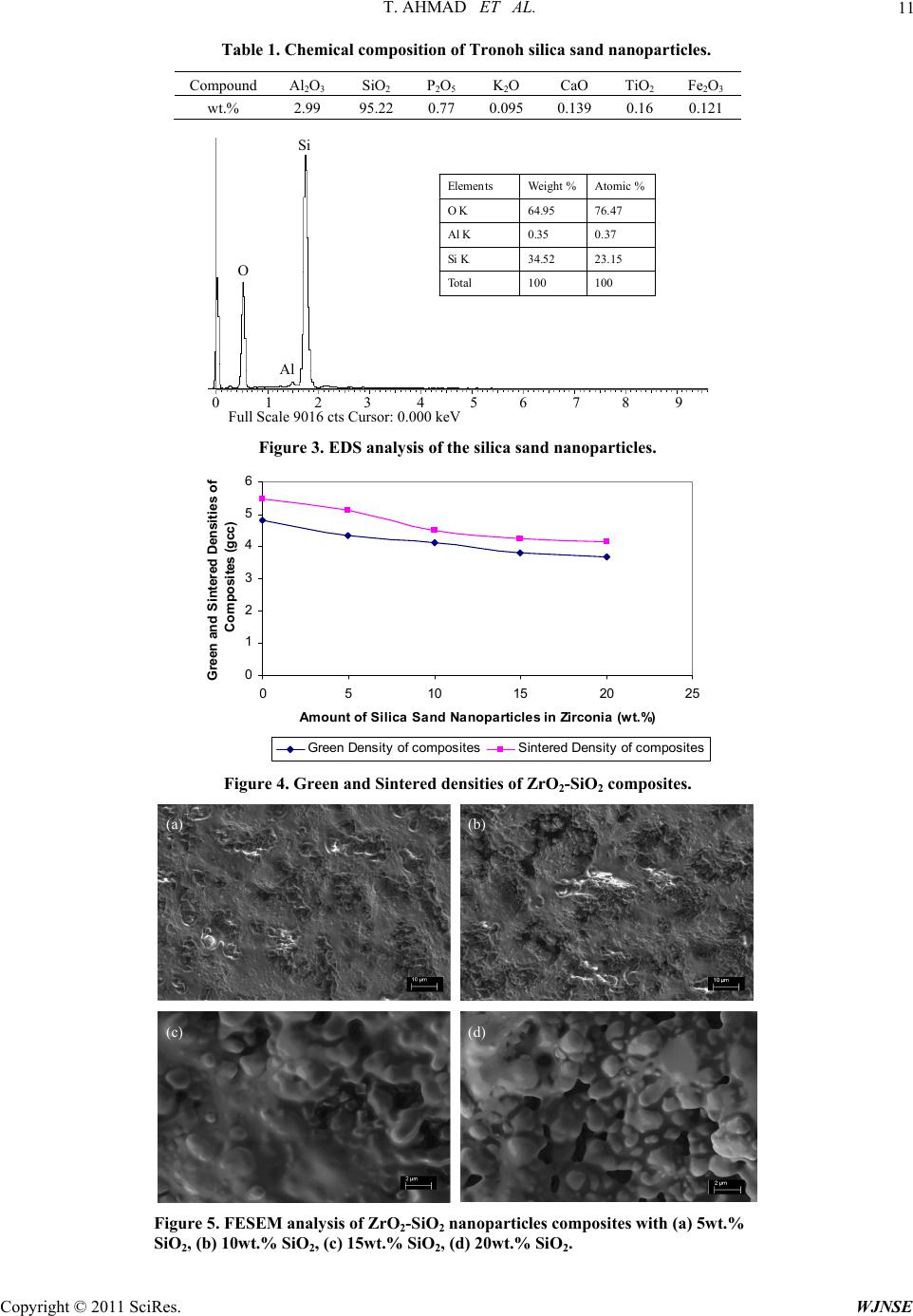

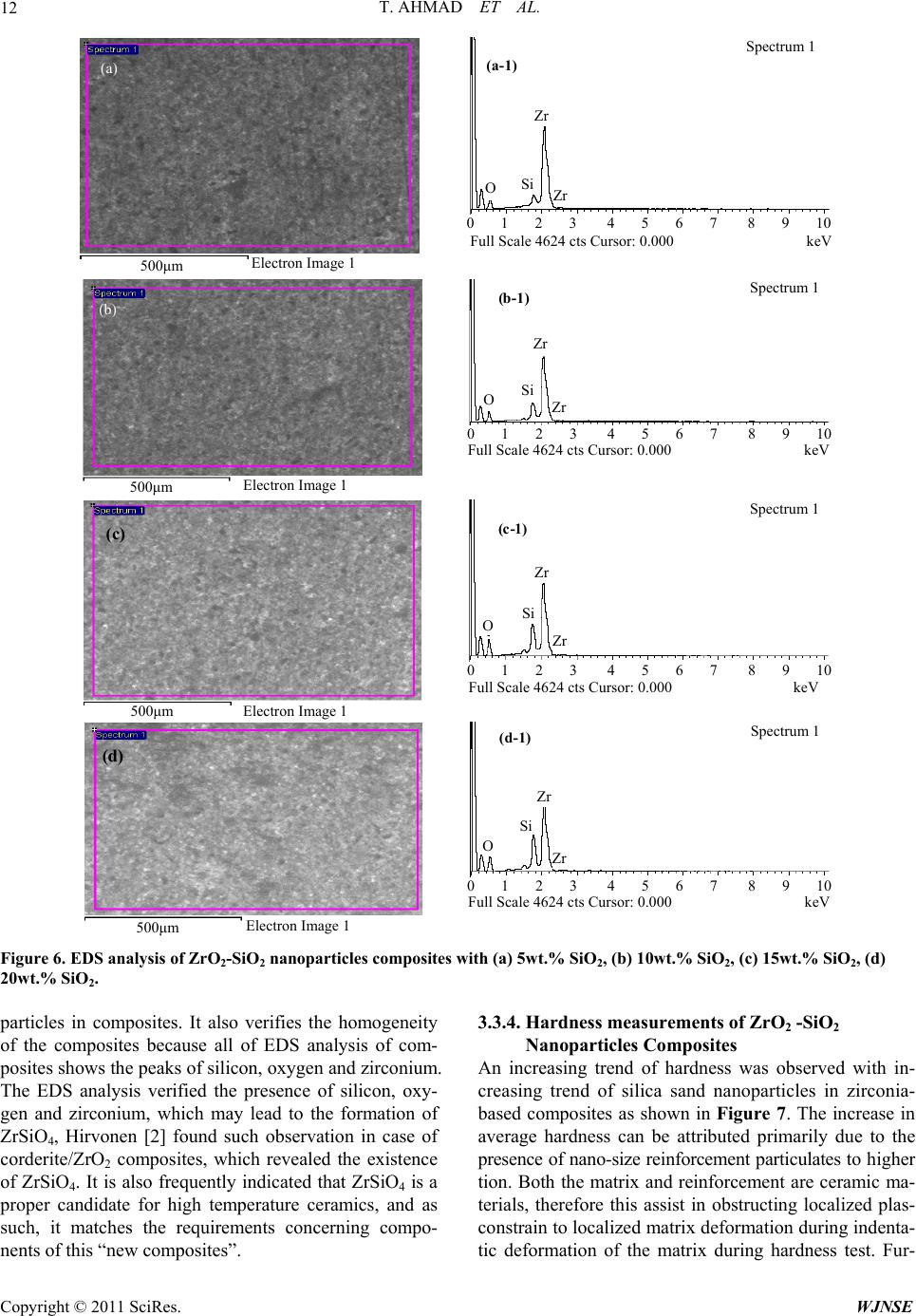

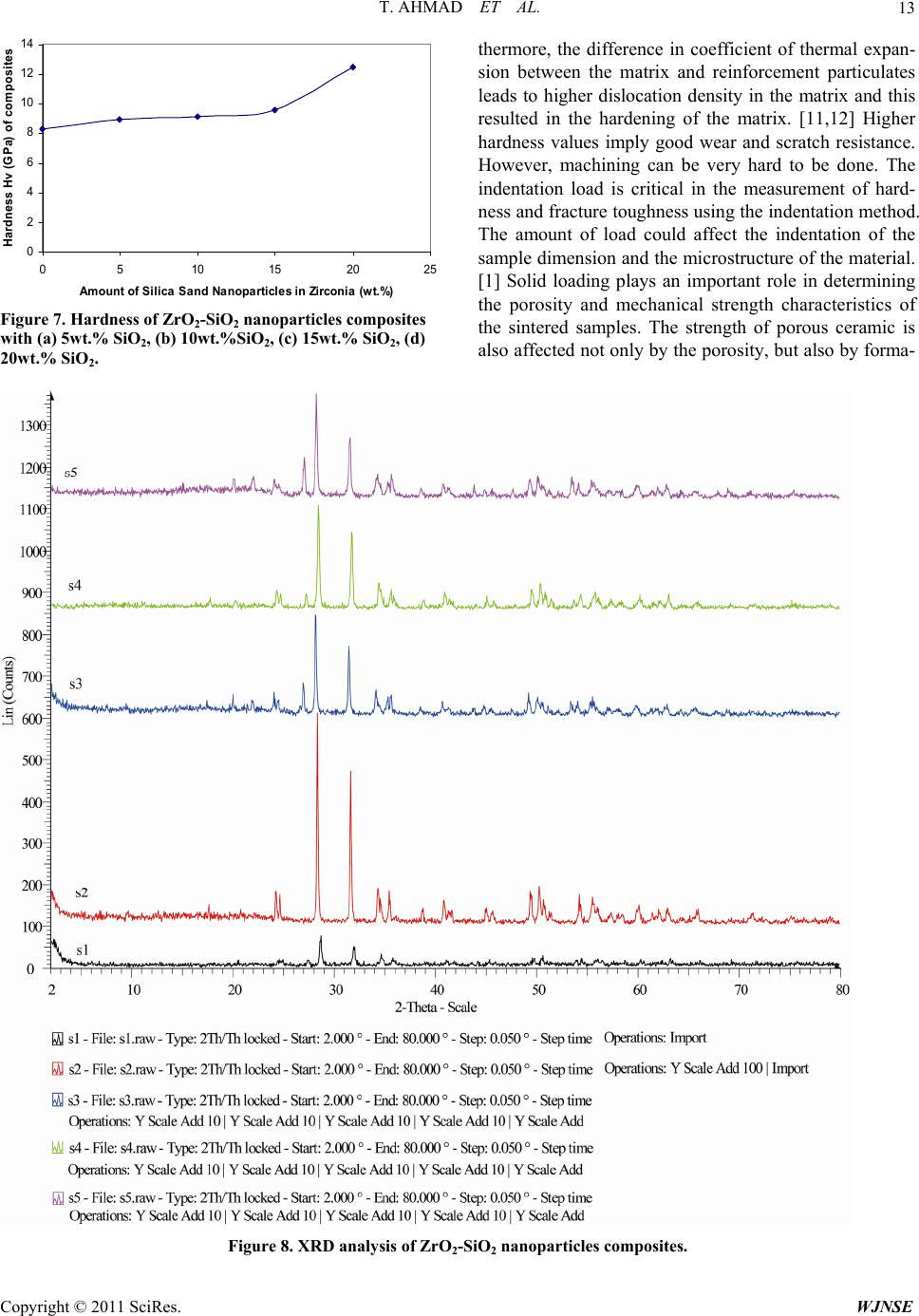

World Journal of Nano Science and Engineering, 2011, 1, 7-14 doi:10.4236/wjnse.2011.11002 Published Online March 2011 (http://www.scirp.org/journal/wjnse) Copyright © 2011 SciRes. WJNSE 7 The Development and Characterization of Zirconia-Silica Sand Nanoparticles Composites Tahir Ahmad, Othman Mamat Mechanical Engineering Department, Universiti Teknologi Petronas, Tronoh, Malaysia E-mail: tahirengg4051@yahoo.com Received February 7, 2011; revised March 14, 2011; accepted March 21, 2011 Abstract The present study aims to develop zirconia-Silica sand nanoparticles composites through powder processing route and to study the physical properties, mechanical properties and microstructure of the composites. Zir- conia based silica sand nanoparticles composite with 5, 10, 15 and 20 wt.% were developed through powder processing technique and sintered at 1500℃ for two hours. A decreasing trend of green density however an improvement in sintered density was observed. Also the addition of silica sand nanoparticles with 20 wt.% increased the hardness up to 12.45 GPa and microstructures indicated the diffusion mechanism of silica sand nanoparticles into pore sites of the composites. Keywords: Zirconia-Silica Sand Nanoparticles Composites, Physical Properties, Mechanical Properties, Mi- crostructures 1. Introduction A great progress in dental restoration technique has been established by the use of ceramic materials since the 70’s. Ceramics show some advantages like being the material that best mimic the bone tissue, although present low toughness when compared with the metallic materials. Alumina-zirconia composites are one of the relatively good and promising candidates for biomaterials appli- cation, due to biocompatibility and their mechanical pro- perties that combine high flexural strength with high toughness. [1] Hirvonen et al. [2] prepared nanocomposites by pres- sureless sintering method (PSM). The properties of the yttrium stabilized zirconia (Y-TZP)/zircon (ZrSiO4) com- posites obtained by PSM are discussed in terms of its structure and fabrication condition that include the con- tent of cordierite in initial mixture of cordierites and Y- TZP nanopowders and sintering temperature. The inter- esting finding of this study concerns the coefficient of thermal conductivity of Y-TZP based composites with zircon, fabricated from the powder with more than 15 vol.% content of cordierites, which appears to be lower than that of pure zirconia, despite the mixed materials exhibit high thermal conductivity. The DTA-TG examination confirmed excellent stability of the compo-site at ele- vated temperatures and proved the lack of the nanocom- posite oxidation. Wen-Cheng et al. [3] studied ZrO2/mullite composites with homogeneously dispersed ZrO2 grains from co- lloidal or sol-gel processes of the precursors, which were a mixture of colloidal pseudo-boehmite (γ- AlOOH), zirconia and silicic acid gel, or prepared from dissociated zircon with alumina powder. Experimental results in- dicated that heat treatment from 1300 to 1600 in℃- fluence the growth of mullite and fine ZrO2 grains in ZMCs, especially for the composite prepared from sol- gel methods in which the ZrO2 grew from tens of nano- meters to micrometer size. The growth of fine ZrO2 grains in a mullite matrix belongs to a mechanism of coalescence. Pyda et al. [4] studied the reaction between carbon and titanium originated from zirconia-titania solid solution to produce TiC inclusions in situ in zirconia powders and dense materials. The co-precipitated powder composed of 1.5 mol% Y2O3, 18 mol% TiO2 and 80.5 mol% ZrO2 was mixed with phenol-formaldehyde resin in an amount giving 200% excess of carbon in terms of stoichiometry of the carbothermal reduction of TiO2. The mixture was heated for 2 h at 1500℃ in argon. The sintered bodies were composed mainly of tetragonal and monoclinic phase and contained nano-crystalline TiC inclusions which showed two different morphologies: oval and elongated. The role of oxygen vacancies in the in situ  T. AHMAD ET AL. Copyright © 2011 SciRes. WJNSE 8 formation of elongated TiC inclusions is discussed. Im- provement in the characteristics of the zirconia materials was obtained. Anne et al. [5] prepared Yttria-stabilised zirconia (Y- TZP) based composites with carbide (WC) content up to 50 vol.% from nanopowders by means of conventional hot pressing. The mechanical properties were investi- gated as a function of the WC content. The hardness in- creased from 12.3 GPa for pure Y-TZP up to 16.4 GPa for the composites with 50 vol.% WC, whereas the bend- ing strength reached a maximum of 1551 MPa for 20 vol.% WC composites. The toughness of the composites could be optimised by judicious adjustment of overall yttria content by mixing monoclinic and 3 mol% Y2O3 co- precipitated ZrO2 starting powders. An optimum fracture toughness of 9 MPa m1/2 was obtained for a 40 vol.% WC composites with an overall yttria content of 2 mol%. The hardness, strength as well as fracture toughness of the ultrafine grained composites with a nanosized WC source was significantly higher than with micron-sized WC. Liang et al. [6,7] prepared zirconia-mullite nano- composite ceramics by in-situ controlled crystallization of Si-Al-Zr-O amorphous bulk, which were first treated at 900-1000℃ for nucleation, then treated at higher tem- perature for crystallization to obtain ultra-fine zirconia- mullite composite ceramics. The effects of treating tem- perature and ZrO2 addition on mechanical properties and microstructure were analyzed. A unique structure in which there are a lot of near equated t-ZrO2 grains and fine yield-cracks has been developed in the samples with 15% zirconia addition treated at 1150℃. This specific microstructure is much more effective in toughening ceramics matrix and results in the best mechanical prop- erties. The flexural strength and fracture toughness are 520 MPa and 5.13 MPa.m1/2. Zhan et al. [8] prepared the Y-TZP ceramic containing up to 30 vol.% TiC particles. A physical mixture of 3 mol% Y2O3-ZrO2 powder with the TiC one was used. The cold isostatically pressed compacts were hot-pressed for 40 min at 1700℃ under 30 MPa in argon. Adding TiC particles to Y-TZP did not changed practically the bending strength and it improved the fracture toughness and hardness. With 20 vol.% TiC particles the bending strength, fracture toughness and Vickers hardness of composites reached~1.1 GPa, 14.6 MPa.m0.5 and 16 GPa respectively. Haberko et al. [9] prepared a TiC-TZP composite starting from a solid solution powder of composition 3 mol % Y2O3, 18 mol % TiO2 and 79 mol% ZrO2. The material, hot-pressed at 1500℃ under 25 MPa in argon, showed a density of + 98%, a hardness of 17 GPa, a Young’s modulus of 221 GPa and a fracture toughness of 4.1 MPa.m0.5 in the presence of 8.3 vol.% TiC inclusions. From above cited literature, no researcher still had used silica sand nanoparticles as reinforcement in zirconia based composites, therefore the present study’s aim to develop zirconia based silica sand nanoparticles compos- ites through powder processing technique and to investi- gate the physical, mechanical properties, microstructure and XRD analysis of the composites. 2. Experimental Work The silica sand was originated naturally from Tronoh, Perak, Malaysia was washed with water to remove mud particles and dried in oven at 120℃ for 3 hours. The dried silica sand was meshed about 600 μm using sieve analysis. The 600 μm size of natural silica was ground to nanoparticles by using dry ball mill with zirconium ball (beads) as grinding media. This high energy milling was known as one of the “top-down” nanoparticles type ap- proach which generally relies on physical methods for their production.[10] In this work it was used to reduce the macro and micro-scale of silica sand to a nanoscale particle size (which is thereafter referred to “silica (SiO2) nanoparticles”). The high-energy milling processes in- volve the comminution of bulk materials. The principle of comminution is centred on applying physical forces to bulk material so as to affect breakage into smaller sizes. The forces required to effect breakage are usually a com- bination of either impact or shear. Material is introduced into a milling chamber in which grinding (milling) media are contained. Milling occurs when the media is made to move either by stirring (using a rotor) or by shak- ing/vibrating the chamber. These results in the milling media making contact the bulk material thus imparting, depending on the milling parameters, either impact or shear forces on it. Breakage can occur through a variety of mechanisms and are generally described as attrition, abrasion, fragmentation or chipping, and occur both at the macro and microscopic level. [10] The nanoparticles obtained were verified by ZetaSizer, Nano ZS (ZEN 3600) (MALVERN) analyser. The ZetaSizer analyser is based on Photon Correlation Spectroscopy (PCS) or Dy- namic Light Scattering (DLS) which is a process used to determine particle size by examining the diffusion rates (i.e. Brownian motion) of suspended particles. The tech- nique utilizes a light source to illuminate the samples and scattered light is collected at a detector typically posi- tioned at a fixed scattering angle. The latest generation of PCS/DLS instruments, such as the Zetasizer Nano, utilize a backscatter angle of 173 degrees. This optical configuration accommodates both high and low sample concentration, low sample volumes, and reduces the probability of in- tensity biasing, a phenomenon that occurs in 90 degree  T. AHMAD ET AL. Copyright © 2011 SciRes. WJNSE 9 Figure 1. Particle size distribution of the silica sand nanoparticles (by intensity) produce d fr om Zetasizer Nano Analyzer. The nanoparticles average size is 54.18 nm. Figure 2. FESEM image of the ball-milled silica sand nanoparticles. systems where the magnitude of light scattered by a large particle overshadows the light collected from the smaller particles. The nanoparticles size produced was then veri- fied microscopically through Field Emission Scanning Electron Microscope (FESEM). The chemical composi- tion of silica sand nanoparticles was analyzed using XRF technique. Silica sand nanoparticles were mixed with ZrO2 (Merck KGaA* 64271 Darmstadt Germany (zirconium (IV) oxide special grade TechnipurTM (M = 123.22 g/mol, average particles size 400 nm and mono- clinic crystalline phase) by using ball milling for 1 hour. Paraffin wax had been used as binding agent. The autopellet machine (capacity 80 kN) at 142 MPa force by using metallic mould of diameter of 13 mm was used to make the composites. The following compositions were developed: pure ZrO2, ZrO2-5wt.% silica sand, ZrO2- 10wt.% silica sand, ZrO2-15wt.% silica sand and ZrO2- 20wt.% silica sand nanoparticles. After the compaction, the green density of the samples was measured by the Archimedes method. The samples were sintered at 1500℃ for 2 hour in argon atmosphere respectively. The heating and cooling rates of sintered process were 5℃/min and 10℃/min respectively. After sintering process, the sin- tered densities were measured by Archimedes method. Microstructures of composites were analyzed by FESEM. XRD-Bruker AXS D8 Advance was used for identifica- tion of phases present in composites. The hardness was measured in accordance with ASTM C 1327-9925. The indentation load was 10 kgf (98.1 N) during fifteen sec- onds. After the diagonal length measurement, the values of the Vickers hardness (GPa) were calculated, by the equation: [1] Hv = 0.0018544 2 P d (1) where: Hv = Vickers hardness (GPa) P = applied (N) d = arithmetic mean of the two diagonal length (mm). 54.18 nm 0.1 In te n s i ty(%) Intensity(%)  T. AHMAD ET AL. Copyright © 2011 SciRes. WJNSE 10 3. Results and Discussion 3.1. Morphology, Size and Distribution Analysis of Silica Sand Nanoparticles In this work silica sand particles, the macro and micro- scale were reduced to a nanoscale particle size (which then called as “silica (SiO2) sand nanoparticles”). The high-energy milling processes involve the comminution of bulk materials. The principle of comminution is centred on applying physical forces to bulk material so as to af- fect breakage into smaller sizes. The forces required to effect breakage are usually a combination of either im- pact or shear. Material is introduced into a milling cham- ber, which contained grinding (milling) media are. Mill- ing occurs when the media is made to move either by stirring (using a rotor) or by shaking/vibrating the cham- ber and contacts the bulk material thus imparting, de- pending on the milling parameters, either impact or shear forces on it. Breakage can occur through a variety of mechanisms and are generally described as attrition, abrasion, fragmentation or chipping and occur both at the macro and microscopic level. The silica (SiO2) sand par- ticle was quantitatively analysed by using the ZetaSizer, Nano ZS (ZEN 3600) (MALVERN) and its result is shown in (Figure 1). The average size for the silica par- ticles was found to be 54.18 nm, which qualified the product to be considered as SiO2 nanoparticles. Morphology, size and distribution of the SiO2 sand nanoparticles are shown in Figure 2. It can be seen that some of SiO2 particulates which have fused together re- sulted from squeezing action of the ball-milling process. Thereafter ball-milled SiO2 nanoparticles formed wide range of shape from irregular or rod-like aggregates and agglomerates to rounded nanoparticles. The high surface energy of nanoparticles SiO2 is responsible for the ag- gregation. The conglomeration of submicron SiO2 parti- cles is a spontaneous process because the Gibbs energy decreases during this process. The FESEM image shown in Figure 2 also illustrates various structures of the SiO2 particles including spherical particles and irregular shape particles as well as agglom- erates. This strong tendency for agglomeration which exists in the particles was induced by the Van-der-Waal forces acting between the individual particles. The mor- phology of such agglomerates may vary from chain-like (1-D) to heavily aggregated (3-D). This alone would not constitute a major problem since soft agglomerates held together by Van-der-Waal forces only are easily broken down in the next step of “dry” pressing that was incorpo- rated in the powder processing. Several primary particles seem to cluster or fuse at their faces, which is possibly due to growth and “sintering” of individual crystals dur- ing the ball-milling process. EDS analysis on the silica sand rich phase shown in Figure 3, revealed the presence of high Si with little amount of Al. 3.2. Chemical Composition of Tronoh Silica Sand Nanoparticles The chemical composition of the silica sand analyzed by XRF analysis gave the results shown in Table 1 . 3.3. Characterization of the Zirconia-Silica Sand Nanoparticles Composites 3.3.1. Zirconia Matrix Composites with Silica Sand Nanoparticles Property: Density A decrease in green density is shown in Figure 4, as increasing amount of silica sand nanoparticles, which indicates the presence of porosity in the green samples. Contrary to that, the rein-forcing of silica sand nanopar- ticles shows an improvement in densities after sintering. Also, after sintering, the porosity of the samples de- creased and the presence of silica sand nanoparticles in zirconia probably reduce the mobility of zirconia grain boundaries during sintering and shows full densification. It also shows a better adhesion between zirconia matrix and silica sand nanoparticles which improved the sin- tered densities. Hirvonen [2] also observed such results of decreasing green densities and improvement in sin- tered densities in case of corderite/ZrO2 composites. 3.3.2. FESEM Analysis of the ZrO2-SiO2 Nanoparticles Composites Good interfacial integrity has been observed between the matrix and the reinforcement and homogeneous distri- bution of reinforcement can be seen form microstructures regardless of the size difference between matrix and the reinforcement. This is due to diffusion of silica sand na- noparticles in the pores sites of the composites as shown in Figure 5. In case of 15 and 20 wt.% of silica sand zirconia based high resolution microstructures reveal the shrinkage of big pores into shallow inter-connected pores, with evidence of diffusion mechanism. Formation of bigger grains, necking and bridging structures was due to pre-liquid phase sintering. 3.3.3. EDS Analysis of the ZrO2-SiO2 Nanoparticles Composites Figure 6 (a, b, c and d), shows the EDS analysis that reveals the presence of silica sand nanoparticles in 5, 10, 15 and 20 wt.% zirconia based composites. Increasing trend of silica sand nanoparticles are verified by the EDS analysis, as the curve of 20 wt.% silica sand is more pro- nounced as compared to 5 wt.% silica sand nano-  T. AHMAD ET AL. Copyright © 2011 SciRes. WJNSE 11 Table 1. Chemical composition of Tronoh silica sand nanoparticles. Compound Al2O3 SiO2 P 2O5 K 2O CaO TiO2 Fe2O3 wt.% 2.99 95.22 0.77 0.095 0.139 0.16 0.121 Figure 3. EDS analysis of the silica sand nanoparticles. 0 1 2 3 4 5 6 0510 1520 25 Amount of Silica Sa nd Nanoparticles in Zirconia (w t.%) Green an d S intered Densi ties of Com po sites (gcc) Green Densi ty of c om posit esS i ntered Den si ty of c om posit es Figure 4. Green and Sintered densities of ZrO2-SiO2 composites. Figure 5. FESEM analysis of ZrO2-SiO2 nanoparticles composites with (a) 5wt.% SiO2, (b) 10wt.% SiO2, (c) 15wt.% SiO2, (d) 20wt.% SiO2. Elements Weight %Atomic % O K 64.95 76.47 Al K 0.35 0.37 Si K 34.52 23.15 Total 100 100 Si O Al 0 1 2 3 4 5 6 7 8 9 Full Scale 9016 cts Cursor: 0.000 keV (a) (c) (d) (b)  T. AHMAD ET AL. Copyright © 2011 SciRes. WJNSE 12 Figure 6. EDS analysis of ZrO2-SiO2 nanoparticles composites with (a) 5wt.% SiO2, (b) 10wt.% SiO2, (c) 15wt.% SiO2, (d) 20wt.% SiO2. particles in composites. It also verifies the homogeneity of the composites because all of EDS analysis of com- posites shows the peaks of silicon, oxygen and zirconium. The EDS analysis verified the presence of silicon, oxy- gen and zirconium, which may lead to the formation of ZrSiO4, Hirvonen [2] found such observation in case of corderite/ZrO2 composites, which revealed the existence of ZrSiO4. It is also frequently indicated that ZrSiO4 is a proper candidate for high temperature ceramics, and as such, it matches the requirements concerning compo- nents of this “new composites”. 3.3.4. Hardness measurements of ZrO2 -SiO2 Nanoparticles Composites An increasing trend of hardness was observed with in- creasing trend of silica sand nanoparticles in zirconia- based composites as shown in Figure 7. The increase in average hardness can be attributed primarily due to the presence of nano-size reinforcement particulates to higher tion. Both the matrix and reinforcement are ceramic ma- terials, therefore this assist in obstructing localized plas- constrain to localized matrix deformation during indenta- tic deformation of the matrix during hardness test. Fur- (c) 500μm Electron Image 1 (b-1) 0 1 2 3 4 5 6 7 8 9 10 Full Scale 4624 cts Cursor: 0.000 keV Si Zr Zr O Spectrum 1 (b) 500μm Electron Image 1 (d) 500μm Electron Image 1 (d-1) 0 1 2 3 4 5 6 7 8 9 10 Full Scale 4624 cts Cursor: 0.000 keV Si Zr Zr O Spectrum 1 (c-1) 0 1 2 3 4 5 6 7 8 9 10 Full Scale 4624 cts Cursor: 0.000 keV Si Zr Zr O Spectrum 1 (a-1) 0 1 2 3 4 5 6 7 8 9 10 Full Scale 4624 cts Cursor: 0.000 keV Zr Zr Si O Spectrum 1 500μm Electron Image 1 (a)  T. AHMAD ET AL. Copyright © 2011 SciRes. WJNSE 13 0 2 4 6 8 10 12 14 0510 1520 25 Amount of Silica Sand Nano p articles in Zirconia ( wt.% ) Hard ne ss Hv (G P a) o f composi tes Figure 7. Hardness of ZrO2-SiO2 nanoparticles composites with (a) 5wt.% SiO2, (b) 10wt.%SiO2, (c) 15wt.% SiO2, (d) 20wt.% SiO2. thermore, the difference in coefficient of thermal expan- sion between the matrix and reinforcement particulates leads to higher dislocation density in the matrix and this resulted in the hardening of the matrix. [11,12] Higher hardness values imply good wear and scratch resistance. However, machining can be very hard to be done. The indentation load is critical in the measurement of hard- ness and fracture toughness using the indentation method. The amount of load could affect the indentation of the sample dimension and the microstructure of the material. [1] Solid loading plays an important role in determining the porosity and mechanical strength characteristics of the sintered samples. The strength of porous ceramic is also affected not only by the porosity, but also by forma- Figure 8. XRD analysis of ZrO2-SiO2 nanoparticles composites.  T. AHMAD ET AL. Copyright © 2011 SciRes. WJNSE 14 tion of sintering neck on the wall as well as the smaller pore size. The loading of the solid materials and sintering temperature significantly contributes to change of ce- ramic struts and porosity. [13] 3.3.5. XRD Analysis of ZrO2-SiO2 Nanoparticles Composites XRD phase analysis of composites is shown in Figure 8. The peaks have been identified as belonging to phases of zirconia and silica. It was noted that as the weight per- centage of reinforcement increases, the intensity peaks becomes stronger. XRD results also reveals that almost all the composites show similar peaks which result proper mixing of the composites constituents. Originally the zirconia powder was monoclinic and when it is sin- tered at 1500℃ only a little bit phase trans-formation occur from monoclinic to tetragonal at this temperature. This quantity decreased with increasing temperature. This decrease could be due to grain growth of the ZrO2, lack of phase stabilizer, such as CaO or MgO and the thermal stress induced transformation and such behav- iour has also been discussed by Wen-Cheng et al. [3]. 4. Conclusions The outcomes of this research show that the addition of silica sand nanoparticles to zirconia decreased the green densities. However, an improvement in sintered densities is observed. The incorporation of silica sand nanoparti- cles enhanced the hardness of the composites up to 12.45 GPa. From FESEM and EDS analysis, it was ob- served that the silica sand nanoparticles diffused into the porous sites of composites causing an improvement in mechanical properties. The XRD results show almost similar peaks for all composites. These observations in- dicate that silica sand nanoparticles may be used to de- velop new zirconia based composites better properties. 5. Acknowledgements The authors would like to thank the Universiti Teknologi PETRONAS for providing necessary support in complet- ing this research. 6. References [1] M. C. C. de S. e B. de Moraes and C. Elias, “Mechanical Properties of Alumina-Zirconia Composites for Ceramic Abutments,” Journal of Materials Research, Vol. 7, No. 4, 2004, pp. 643-649. [2] A. Hirvonen, R. Nowak, Y. Yamamoto, T. Sekino, “Fab- rication, Structure, Mechanical and Thermal Properties of Zirconia-Based Ceramic Nanocomposites,” Journal of the European Ceramic Society, Vol. 26, No. 3, 2006, pp. 1497-1505. doi:10.1016/j.jeurceramsoc.2005.03.232 [3] J. W.-C. Wei, H. C. Kao and M. H. Lo, “Phase Transfor- mation and Grain Coarsening of Zirconia/Mullite Com- posites,” Journal of the European Ceramic Society, Vol. 16, No. 2, 1996, pp. 239-247. doi:10.1016/0955-2219(95)00157-3 [4] W. Pyda, “Microstructure and Properties of Zirconia- Based Nanocomposites Derived from a Powder Contain- ing TiC Crystallised in Situ and Carbon,” Ceramics In- ternational, Vol. 30, No. 3, 2004, pp. 333-342. doi:10.1016/S0272-8842(03)00105-6 [5] G. Anne, S. Put, K. Vanmeensel and D. T. Jiang, “Hard- ness, Tough and Strong ZrO2-WC Composites from Nanosized Powders,” Journal of the European. Ceramic Society, Vol. 25, No. 1, 2005, pp. 55-63. doi:10.1016/j.jeurceramsoc.2004.01.015 [6] S.-Q. Liang, J. Zhong, X.-P. Tan and Y. Tang, “Mechani- cal Properties and Structure of Zirconia-Mullite Ceramics Prepared by In-situ Controlled Crystallization of Si-Al- Zr-O Amorphous Bulk,” Transaction of Nonferrous Met- als Society of China, Vol. 18, No. 4, 2008, pp. 799-803. doi:10.1016/S1003-6326(08)60138-7 [7] S.-Q. Liang, J. Zhong, X.-P. Tan and Y. Tang, “Prepara- tion of Mullite-Zirconia Composites with Ultra Fine Grains Ceramics by In-situ Controlled Crystallization from Si-Al-Zr-O Amorphous Bulk,” Nanoscience, Vol. 11, No. 1, 2006, pp. 32-37. [8] G. D. Zhan, T. R. Lai., J. L. Shi, T. S. Yen, Y. Zhou and Y. Z. Zhang, “Microstructure and Mechanical Properties of Yttria Stabilized Tetragonal Zirconia Polycrystal Con- taining Dispersed TiC Particles,” Journal of Materials Science, Vol. 31, No. 11, 1996, pp. 2903-2907. doi:10.1007/BF00356000 [9] K. Haberko, W. Pyda, Z. Pedzich and M. M. Bucko, “A TZP Matrix Composite with in Situ Grown TiC Inclu- sions,” Journal of the European. Ceramic Society, Vol. 20, No. 14-15, 2000, pp. 2649-2654. doi:10.1016/S0955-2219(00)00159-X [10] R. H. J. Hannink, “Nanostructure Control of Materials,” CRC Press, Boca Raton, 2006. doi:10.1533/9781845691189 [11] W. Acchar, “Microstructure of Alumina Reinforced with Tungsten Carbide,” Journal of Materials Science, Vol. 41, No. 11, 2006, pp. 3299-3302. doi:10.1007/s10853-005-5457-z [12] S. M. L. Nai, J. V. M. Kuma, M. E. Alam, X. L. Zhong, P. Babaghorbani and M. Gupta, “Using Microwave-Assisted Powder Metallurgy Route and Nano-Sized Reinforcement to Develop High-Strength Solder Composites,” Journal of Materials Engineering and Performance, Vol. 19, No. 3, 2009, pp. 335-341. doi:10.1007/s11665-009-9481-z [13] J. C. Han, C. Q. Hong, X. H. Zhang, J. Du, W. Zhang, “Highly Porous ZrO2 Ceramics Fabricated by a Cam- phene-Based Freeze-Casting Route: Microstructure and Properties,” Journal of the European Ceramic Society, Vol. 30, No. 1, 2010, pp. 53-60. doi:10.1016/j.jeurceramsoc.2009.08.018 |