The Comparative Study of Fatigue Crack Propagation Experiment and Computer Simulation on the

24

Component Materials for the Crane Life Remained

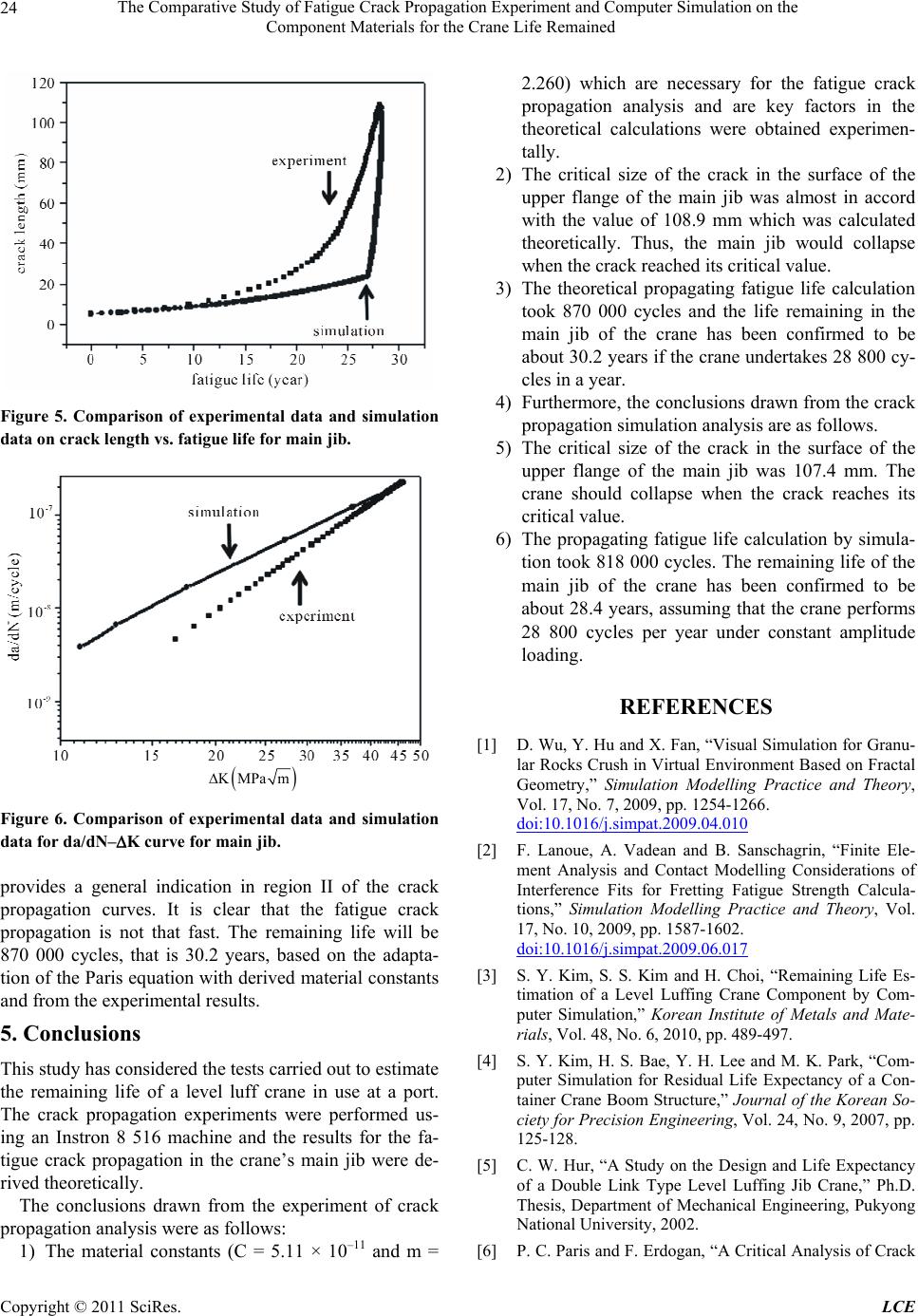

Figure 5. Comparison of experimental data and simulation

data on crack length vs. fatigue life for main jib.

KMPa m

Figure 6. Comparison of experimental data and simulation

data for da/dN–K curve for main jib.

provides a general indication in region II of the crack

propagation curves. It is clear that the fatigue crack

propagation is not that fast. The remaining life will be

870 000 cycles, that is 30.2 years, based on the adapta-

tion of the Paris equation with derived material constants

and from the experimental results.

5. Conclusions

This study has considered the tests carried out to estimate

the remaining life of a level luff crane in use at a port.

The crack propagation experiments were performed us-

ing an Instron 8 516 machine and the results for the fa-

tigue crack propagation in the crane’s main jib were de-

rived theoretically.

The conclusions drawn from the experiment of crack

propagation analysis were as follows:

1) The material constants (C = 5.11 × 10–11 and m =

2.260) which are necessary for the fatigue crack

propagation analysis and are key factors in the

theoretical calculations were obtained experimen-

tally.

2) The critical size of the crack in the surface of the

upper flange of the main jib was almost in accord

with the value of 108.9 mm which was calculated

theoretically. Thus, the main jib would collapse

when the crack reached its critical value.

3) The theoretical propagating fatigue life calculation

took 870 000 cycles and the life remaining in the

main jib of the crane has been confirmed to be

about 30.2 years if the crane undertakes 28 800 cy-

cles in a year.

4) Furthermore, the conclusions drawn from the crack

propagation simulation analysis are as follows.

5) The critical size of the crack in the surface of the

upper flange of the main jib was 107.4 mm. The

crane should collapse when the crack reaches its

critical value.

6) The propagating fatigue life calculation by simula-

tion took 818 000 cycles. The remaining life of the

main jib of the crane has been confirmed to be

about 28.4 years, assuming that the crane performs

28 800 cycles per year under constant amplitude

loading.

REFERENCES

[1] D. Wu, Y. Hu and X. Fan, “Visual Simulation for Granu-

lar Rocks Crush in Virtual Environment Based on Fractal

Geometry,” Simulation Modelling Practice and Theory,

Vol. 17, No. 7, 2009, pp. 1254-1266.

doi:10.1016/j.simpat.2009.04.010

[2] F. Lanoue, A. Vadean and B. Sanschagrin, “Finite Ele-

ment Analysis and Contact Modelling Considerations of

Interference Fits for Fretting Fatigue Strength Calcula-

tions,” Simulation Modelling Practice and Theory, Vol.

17, No. 10, 2009, pp. 1587-1602.

doi:10.1016/j.simpat.2009.06.017

[3] S. Y. Kim, S. S. Kim and H. Choi, “Remaining Life Es-

timation of a Level Luffing Crane Component by Com-

puter Simulation,” Korean Institute of Metals and Mate-

rials, Vol. 48, No. 6, 2010, pp. 489-497.

[4] S. Y. Kim, H. S. Bae, Y. H. Lee and M. K. Park, “Com-

puter Simulation for Residual Life Expectancy of a Con-

tainer Crane Boom Structure,” Journal of the Korean So-

ciety for Precision Engineering, Vol. 24, No. 9, 2007, pp.

125-128.

[5] C. W. Hur, “A Study on the Design and Life Expectancy

of a Double Link Type Level Luffing Jib Crane,” Ph.D.

Thesis, Department of Mechanical Engineering, Pukyong

National University, 2002.

[6] P. C. Paris and F. Erdogan, “A Critical Analysis of Crack

Copyright © 2011 SciRes. LCE