Paper Menu >>

Journal Menu >>

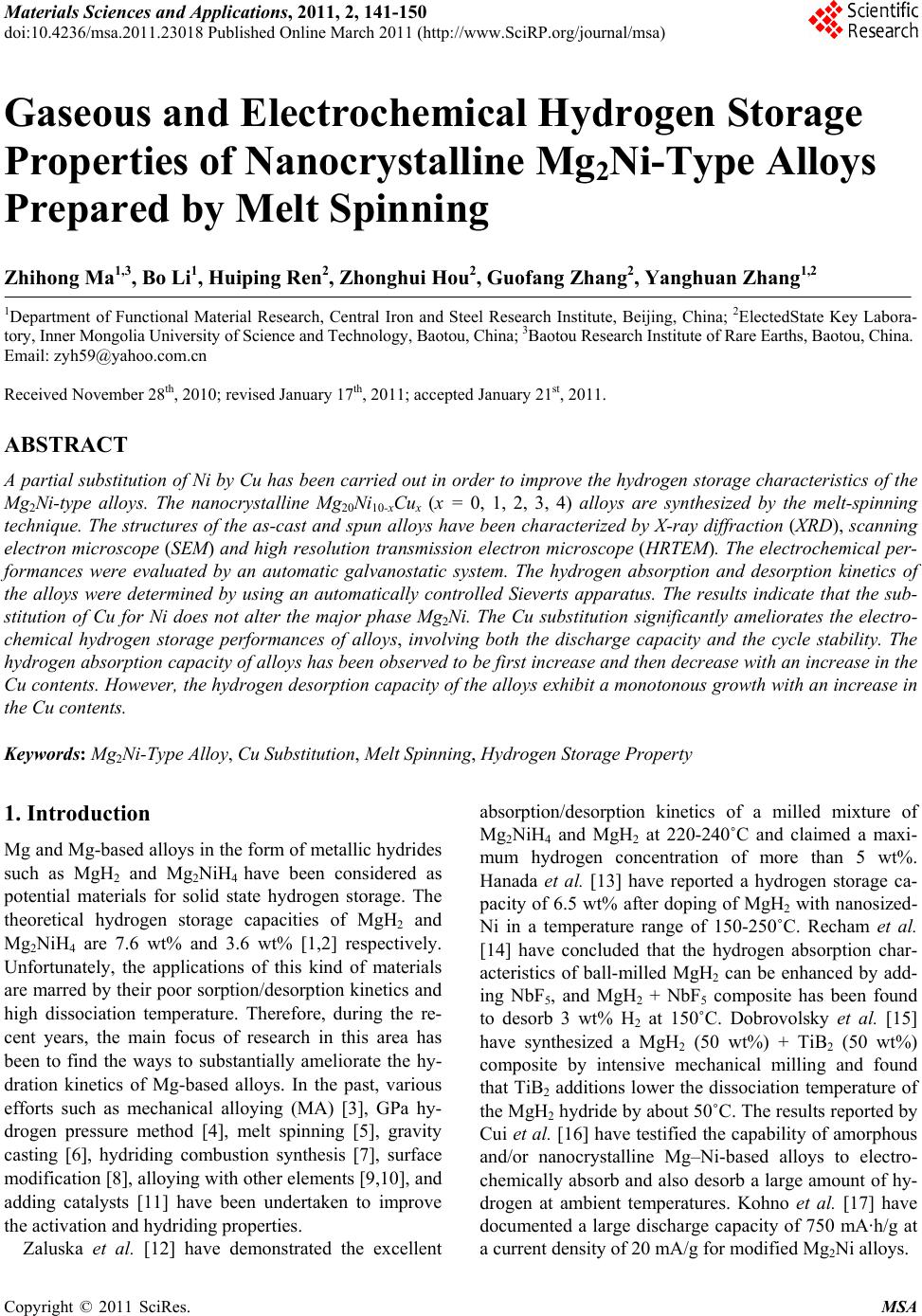

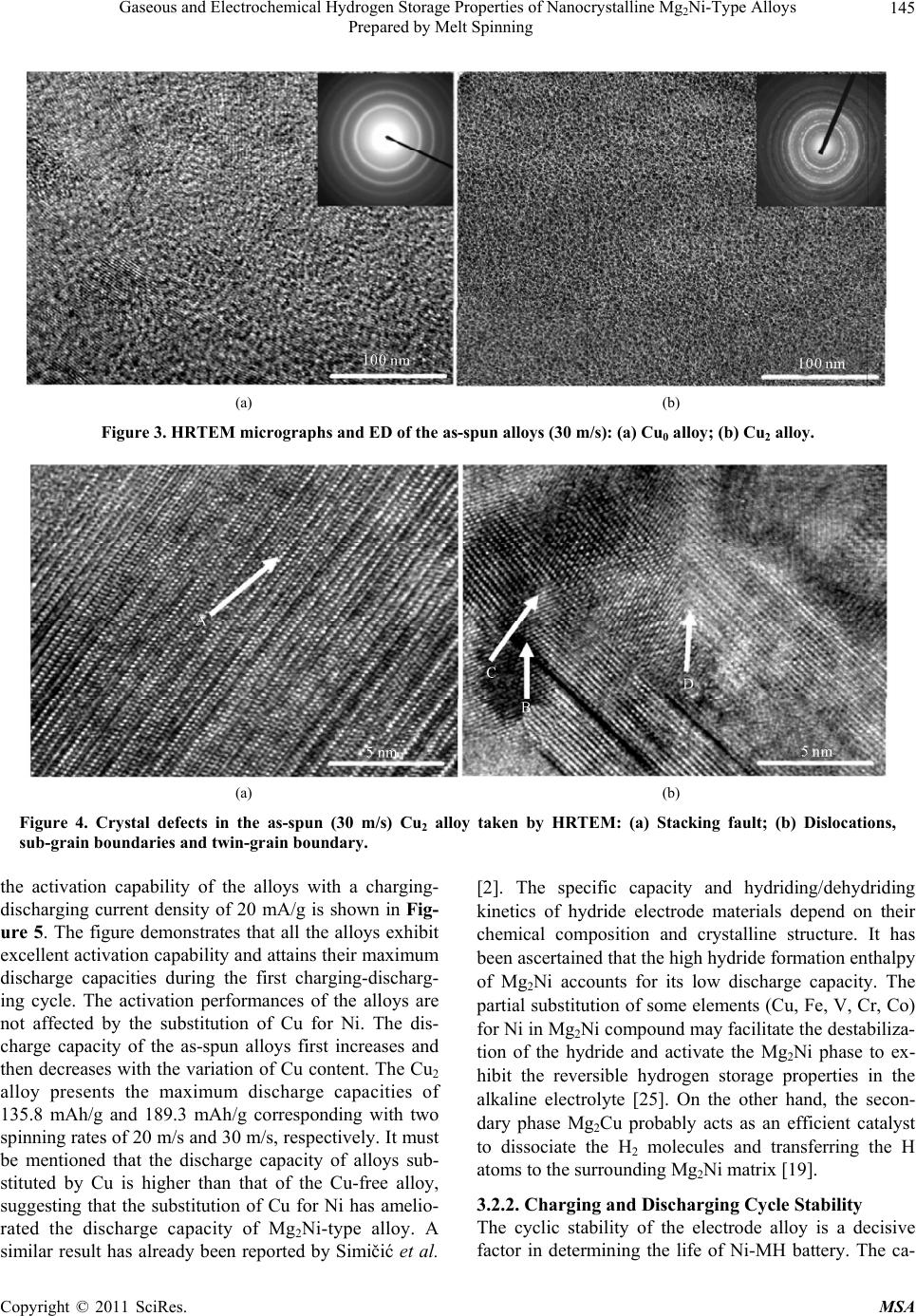

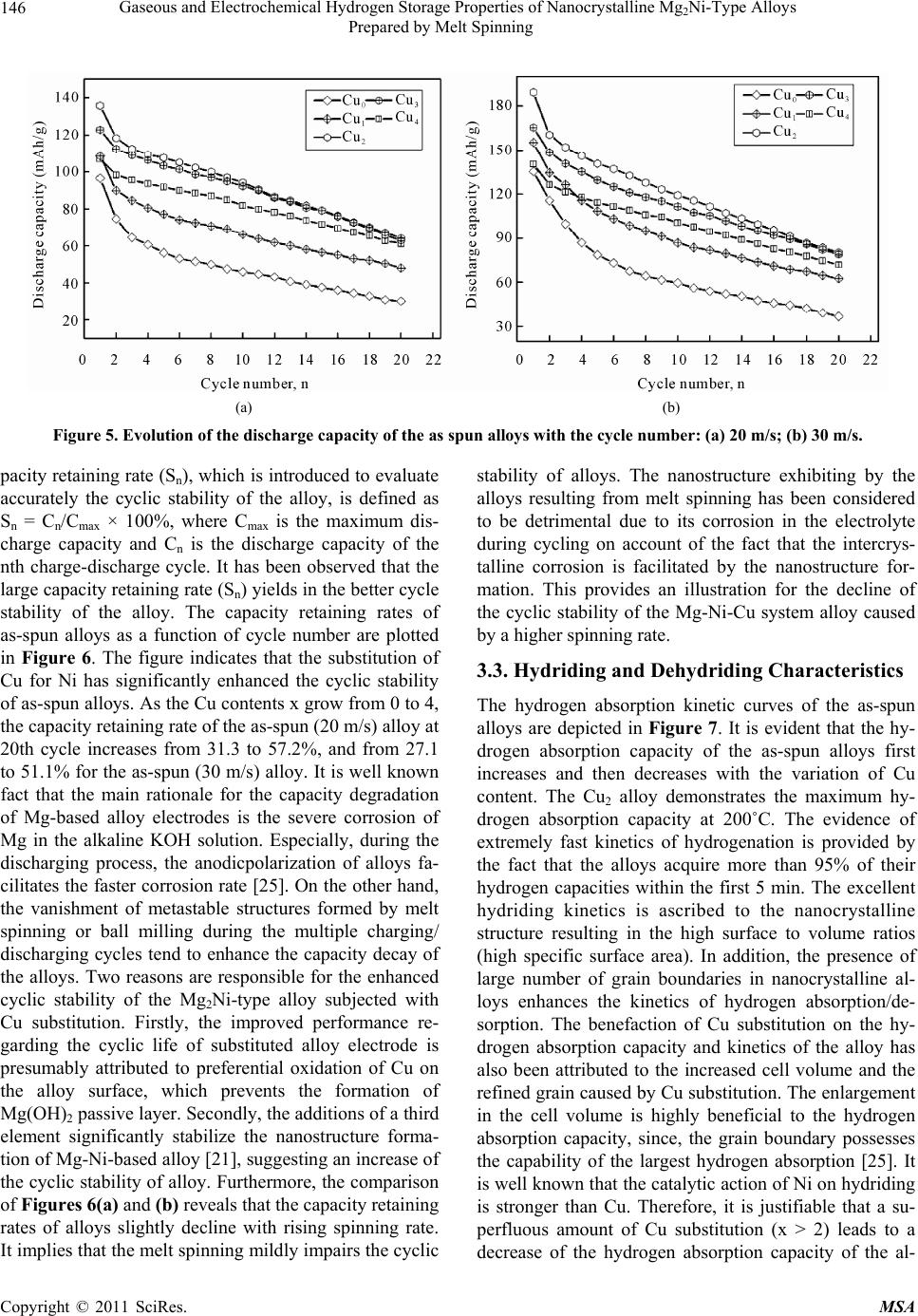

Materials Sciences and Applications, 2011, 2, 141-150 doi:10.4236/msa.2011.23018 Published Online March 2011 (http://www.SciRP.org/journal/msa) Copyright © 2011 SciRes. MSA Gaseous and Electrochemical Hydrogen Storage Properties of Nanocrystalline Mg2Ni-Type Alloys Prepared by Melt Spinning Zhihong Ma1,3, Bo Li1, Huiping Ren2, Zhonghu i Hou2, Guofang Zhang2, Yanghuan Zhang1,2 1Department of Functional Material Research, Central Iron and Steel Research Institute, Beijing, China; 2ElectedState Key Labora- tory, Inner Mongolia University of Science and Technology, Baotou, China; 3Baotou Research Institute of Rare Earths, Baotou, China. Email: zyh59@yahoo.com.cn Received November 28th, 2010; revised January 17th, 2011; accepted January 21st, 2011. ABSTRACT A partial substitution of Ni by Cu has been carried out in order to improve the hydrogen storage characteristics of the Mg2Ni-type alloys. The nanocrystalline Mg20Ni10-xCux (x = 0, 1, 2, 3, 4) alloys are synthesized by the melt-spinning technique. The stru ctures of the as-cast and spun allo ys have been chara cterized by X-ray diffraction (XRD), scanning electron microscope (SEM) and high resolution transmission electron microscope (HRTEM). The electrochemical per- formances were evaluated by an automatic galvanostatic system. The hydrogen absorption and desorption kinetics of the alloys were determined by using an automatically controlled Sieverts apparatus. The results indicate that the sub- stitution of Cu for Ni does not alter the major phase Mg2Ni. The Cu substitution significantly ameliorates the electro- chemical hydrogen storage performances of alloys, involving both the discharge capacity and the cycle stability. The hydrogen absorption capacity of alloys has been observed to be first increase and then decrease with an increase in the Cu contents. However, the hydrogen desorption capacity of the alloys exhibit a monotonous growth with an increase in the Cu contents. Keywords: Mg2Ni-Type Alloy, Cu Substitution, Melt Spinning, Hydr o gen Storage Prope rt y 1. Introduction Mg and Mg-based alloys in the form of metallic hydrides such as MgH2 and Mg2NiH4 have been considered as potential materials for solid state hydrogen storage. The theoretical hydrogen storage capacities of MgH2 and Mg2NiH4 are 7.6 wt% and 3.6 wt% [1,2] respectively. Unfortunately, the applications of this kind of materials are marred by their poor sorption/desorption kinetics and high dissociation temperature. Therefore, during the re- cent years, the main focus of research in this area has been to find the ways to substantially ameliorate the hy- dration kinetics of Mg-based alloys. In the past, various efforts such as mechanical alloying (MA) [3], GPa hy- drogen pressure method [4], melt spinning [5], gravity casting [6], hydriding combustion synthesis [7], surface modification [8], alloying with other elements [9,10], and adding catalysts [11] have been undertaken to improve the activation and hydriding properties. Zaluska et al. [12] have demonstrated the excellent absorption/desorption kinetics of a milled mixture of Mg2NiH4 and MgH2 at 220-240˚C and claimed a maxi- mum hydrogen concentration of more than 5 wt%. Hanada et al. [13] have reported a hydrogen storage ca- pacity of 6.5 wt% after doping of MgH2 with nanosized- Ni in a temperature range of 150-250˚C. Recham et al. [14] have concluded that the hydrogen absorption char- acteristics of ball-milled MgH2 can be enhanced by add- ing NbF5, and MgH2 + NbF5 composite has been found to desorb 3 wt% H2 at 150˚C. Dobrovolsky et al. [15] have synthesized a MgH2 (50 wt%) + TiB2 (50 wt%) composite by intensive mechanical milling and found that TiB2 additions lower the dissociation temperature of the MgH2 hydride by about 50˚C. The results reported by Cui et al. [16] have testified the capability of amorphous and/or nanocrystalline Mg–Ni-based alloys to electro- chemically absorb and also desorb a large amount of hy- drogen at ambient temperatures. Kohno et al. [17] have documented a large discharge capacity of 750 mA·h/g at a current density of 20 mA/g for modified Mg2Ni alloys.  Gaseous and Electrochemical Hydrogen Storage Properties of Nanocrystalline Mg2Ni-Type Alloys Prepared by Melt Spinning Copyright © 2011 SciRes. MSA 142 Ball-milling indubitably is a very effective method for the fabrication of nanocrystalline and amorphous Mg and Mg-based alloys. Particularly, it is quite appropriate to solubilize the particular elements into MgH2 or Mg2NiH4 above the thermodynamic equilibrium limit. This may facilitate the destabilization of MgH2 or Mg2NiH4 [18]. However, the milled Mg and Mg-based alloys exhibit very poor hydrogen absorbing and desorbing stability on account of the evanishment of the metastable structures formed by ball milling during the multiple hydrogen ab- sorbing and desorbing cycles [19]. Alternatively, the melt-spun technique has not only overcome the afore- mentioned shortcoming but also prohibits the significant degradation of the hydrogen absorbing and desorbing cyclic characteristics of Mg and Mg-based compounds [20]. Furthermore, the melt-spinning technique is a bene- ficial method to yield a nanocrystalline structure and has been regarded to be the most appropriate for the mass- production of the nanocrystalline Mg-based alloys. It has also been testified that the nanocrystalline alloys pro- duced by melt-spinning method can exhibit excellent hydriding characteristics even at ambient temperatures, which is similar to that of the alloys fabricated by the MA process. Spassov et al. [21] have prepared Mg2 (Ni, Y) hydrogen storage alloy with possessing the composition of Mg63Ni30Y7 by rapid solidification process to yield a maximum hydrogen absorption capacity of about 3.0 wt%. In addition, the hydrogenation kinetics of the melt- spun Mg2 (Ni, Y) have been observed to exceed those of the conventionally prepared polycrystalline Mg2Ni alloys and also found to be comparable to that of the nanocrys- talline ball-milled Mg2Ni. Huang et al. [22] have con- cluded that the amorphous and the nanocrystalline Mg- based alloy (Mg60Ni25)90Nd10 prepared by melt-spinning technique displays the highest discharge capacity of 580 mAh/g and the maximum hydrogen capacity of 4.2 wt% H. Our previous work has confirmed that the substitution of Co for Ni significantly improves the hydriding and dehydriding kinetics of the Mg2Ni-type alloys [23]. Therefore, it is very desirable to investigate the influence of substituting the Ni with Cu on the hydrogen storage characteristics of Mg2Ni-type alloys prepared by melt- spinning. The objective of present work is to synthesize the Mg-Ni-based ternary nanocrystalline alloys by melt spinning and to examine their structures and hydrogen storage characteristics. 2. Experimental The nominal compositions of the experimental alloys were Mg20Ni10-xCux (x = 0, 1, 2, 3, 4). For convenience, the alloys were denoted with Cu content as Cu0, Cu1, Cu2, Cu3 and Cu4, respectively. The alloy ingots were pre- pared using a vacuum induction furnace in a helium at- mosphere at a pressure of 0.04 MPa. A part of the as-cast alloys was re-melted and spun by melt-spinning with a rotating copper roller. The spinning rate was approxi- mately expressed by the linear velocity of the copper roller because it was too difficult to measure a real spin- ning rate i.e. the cooling rate of the sample during spin- ning. The spinning rates used in the experiment were 15, 20, 25 and 30 m/s. The phase structures of the as-cast and spun alloys were determined by XRD (D/max/2400). The diffraction, with the experimental parameters of 160 mA, 40 kV and 10˚/min was performed with CuKα1 radiation filtered by graphite. The morphologies of the as-cast alloys were examined by SEM (Philips QUANTA 400). The thin film samples of the as-spun alloys were prepared by ion etching for observing the morphology with HRTEM (JEM-2100F, operated at 200 kV), and for determining the crystalline state of the samples with electron diffrac- tion (ED). The alloy ribbons were pulverized and then mixed with carbonyl nickel powder in a weight ratio of 1:4. The mixture was cold pressed into round electrode pellets of 10 mm in diameter and total mass of about 1 g with a pressure of 35 MPa. A tri-electrode open cell, consisting of a metal hydride electrode, a sintered NiOOH/Ni(OH)2 counter electrode and a Hg/HgO reference electrode, was used for testing the electrochemical characteristics of the experimental alloy electrodes. A 6 M KOH solution was used as electrolyte. The voltage between the negative electrode and the reference electrode was defined as the discharge voltage. In every cycle, the alloy electrode was first charged at a current density of 20 mA/g, after resting for 15 min, it was discharged at the same current density to −0.500 V cut-off voltages. The environment tempera- ture of the measurement was kept at 30˚C. The hydrogen absorption and desorption kinetics of the alloys were monitored by an automatically controlled Sieverts apparatus. The hydrogen absorption was con- ducted at 1.5 MPa and the hydrogen desorption at a pressure of 1 × 10−4 MPa was performed at 200˚C. 3. Results and Discussion 3.1. Microstructure Characteristics The XRD profiles of the as-cast and spun Mg20Ni10-xCux (x = 0-4) alloys are presented in Figure 1. The results indicate that all the as-cast and spun alloys display a sin- gle phase structure. The substitution of Cu for Ni does not modify the phase structure. Table 1 lists the lattice parameters, cell volume and full width at half maximum  Gaseous and Electrochemical Hydrogen Storage Properties of Nanocrystalline Mg2Ni-Type Alloys Prepared by Melt Spinning Copyright © 2011 SciRes. MSA 143 Table 1. The lattice parameters, cell volume and the FWHM values of the major diffraction peaks of the alloys. FWHM values Lattice parameters and cell Volume 2θ (20.02°) 2θ (45.14°) a (nm) c (nm) V (nm3) Alloys As-cast 15 m/s As-cast 15 m/sAs-cast 15 m/s As-cast 15 m/s As-cast 15 m/s Cu0 0.122 0.125 0.169 0.171 0.5210 0.5210 1.3244 1.3251 0.3113 0.3115 Cu1 0.133 0.155 0.178 0.194 0.5210 0.5212. 1.3252 1.3259 0.3115 0.3120 Cu2 0.148 0.181 0.183 0.207 0.5214 0.5216 1.3283 1.3293 0.3127 0.3132 Cu3 0.151 0.197 0.192 0.215 0.5215 0.5217 1.3297 1.3305 0.3132 0.3135 Cu4 0.165 0.232 0.204 0.241 0.5217 0.5220 1.3302 1.3311 0.3135 0.3141 (a) (b) Figure 1. XRD profiles of the as-cast and spun alloys: (a) As-cast; (b) As-spun (15 m/s). (FWHM) values of the main diffraction peaks of the as-cast and spun (15 m/s) alloys, which are calculated by software Jade 6.0. It is evident in Table 1 that the sub- stitution of Cu for Ni intensifies the FWHM values of the main diffraction peaks exhibited by the as-cast and spun alloys. Furthermore, it leads to a sharp enlargement of the lattice parameter and cell volume of the alloys, justi- fies the successful alloying of Cu with Mg2Ni. Table 1 also demonstrates the enhancement in the FWHM values of the main diffraction peaks of the alloys caused by the melt spinning, which is ostensibly attributed to the re- finement of grains and the accumulated stress in grains rendered by the melt spinning. The crystallite size <Dhkl> (nm) of the as-spun alloy has been calculated by utilizing the FWHM values of the broad diffraction peak (203) in Figure 1(b) by employing the Scherer’s equation. The grain size of the as-spun alloys is found to be in the range of 15-30 nm, which is consistent with the results reported by Friedlmeier et al. [24]. It is noteworthy that for the comparison purposes, the <D> values have been calcu- lated by using the similar peak having the Miller indices (203). The SEM images of the as-cast Cu0 and Cu2 alloys are illustrated in Figure 2. It is quite evident that the as-cast  Gaseous and Electrochemical Hydrogen Storage Properties of Nanocrystalline Mg2Ni-Type Alloys Prepared by Melt Spinning Copyright © 2011 SciRes. MSA 144 alloys exhibit a typical dendritic structure. The substitu- tion of Cu for Ni, instead of changing the morphology of the alloys, causes a significant refinement of the grains. The result obtained by energy dispersive spectrometry (EDS) reveals that the major phase of the as-cast alloys is Mg2Ni phase (denoted by A). The Cu2 alloy clearly ex- hibits some small massive particulates. The EDS analysis confirms that these particulates are Mg2Cu phase (de- noted by B). This result is contrary to the XRD observa- tions depicted in Figure 1. This phenomenon may be attributed to the fact that the amount of the Mg2Cu phase is very little and therefore unable to be detected by the XRD observation. Figure 3 depicts the TEM micrographs and electron diffraction patterns of as-spun Cu0 and Cu2 alloys. A na- nocrystalline microstructure possessing an average crys- tal size of about 20 nm is evident. TEM observations clearly supplement the evidence of the presence of strongly disordered and nanostructured phase of as-spun alloys. This result agrees very well with the XRD obser- vations shown in Figure 1. The existence of crystal defects in the as-spun alloy such as stacking faults (denoted as A), dislocations (de- noted as B), sub-grain boundaries (denoted as C) and twin-grain boundaries (denoted as D) is clearly depicted in Figure 4. 3.2. Electrochemical Hydrogen Storage Performances 3.2.1. Activation Capability and Discharge Capacity Electrochemical galvanostatic charge/discharge is an effective and time-saving method for determining the hydrogen absorbing capacity as compared with a gaseous technique. The influence of substituting Ni with Cu on (a) (b) Figure 2. SEM images of the as-cast alloys together with typical EDS spectra of sections A and B in Figure 2(b): (a) Cu0 alloy; (b) Cu2 alloy.  Gaseous and Electrochemical Hydrogen Storage Properties of Nanocrystalline Mg2Ni-Type Alloys Prepared by Melt Spinning Copyright © 2011 SciRes. MSA 145 (a) (b) Figure 3. HRTEM micrographs and ED of the as-spun alloys (30 m/s): (a) Cu0 alloy; (b) Cu2 alloy. (a) (b) Figure 4. Crystal defects in the as-spun (30 m/s) Cu2 alloy taken by HRTEM: (a) Stacking fault; (b) Dislocations, sub-grain boundaries and twin-gr a in boundar y. the activation capability of the alloys with a charging- discharging current density of 20 mA/g is shown in Fig- ure 5. The figure demonstrates that all the alloys exhibit excellent activation capability and attains their maximum discharge capacities during the first charging-discharg- ing cycle. The activation performances of the alloys are not affected by the substitution of Cu for Ni. The dis- charge capacity of the as-spun alloys first increases and then decreases with the variation of Cu content. The Cu2 alloy presents the maximum discharge capacities of 135.8 mAh/g and 189.3 mAh/g corresponding with two spinning rates of 20 m/s and 30 m/s, respectively. It must be mentioned that the discharge capacity of alloys sub- stituted by Cu is higher than that of the Cu-free alloy, suggesting that the substitution of Cu for Ni has amelio- rated the discharge capacity of Mg2Ni-type alloy. A similar result has already been reported by Simičić et al. [2]. The specific capacity and hydriding/dehydriding kinetics of hydride electrode materials depend on their chemical composition and crystalline structure. It has been ascertained that the high hydride formation enthalpy of Mg2Ni accounts for its low discharge capacity. The partial substitution of some elements (Cu, Fe, V, Cr, Co) for Ni in Mg2Ni compound may facilitate the destabiliza- tion of the hydride and activate the Mg2Ni phase to ex- hibit the reversible hydrogen storage properties in the alkaline electrolyte [25]. On the other hand, the secon- dary phase Mg2Cu probably acts as an efficient catalyst to dissociate the H2 molecules and transferring the H atoms to the surrounding Mg2Ni matrix [19]. 3.2.2. Charging and Discharging Cycle Stability The cyclic stability of the electrode alloy is a decisive factor in determining the life of Ni-MH battery. The ca-  Gaseous and Electrochemical Hydrogen Storage Properties of Nanocrystalline Mg2Ni-Type Alloys Prepared by Melt Spinning Copyright © 2011 SciRes. MSA 146 (a) (b) Figure 5. Evolution of the discharge capacity of the as spun alloys with the cycle number: (a) 20 m/s; (b) 30 m/s. pacity retaining rate (Sn), which is introduced to evaluate accurately the cyclic stability of the alloy, is defined as Sn = Cn/Cmax × 100%, where Cmax is the maximum dis- charge capacity and Cn is the discharge capacity of the nth charge-discharge cycle. It has been observed that the large capacity retaining rate (Sn) yields in the better cycle stability of the alloy. The capacity retaining rates of as-spun alloys as a function of cycle number are plotted in Figure 6. The figure indicates that the substitution of Cu for Ni has significantly enhanced the cyclic stability of as-spun alloys. As the Cu contents x grow from 0 to 4, the capacity retaining rate of the as-spun (20 m/s) alloy at 20th cycle increases from 31.3 to 57.2%, and from 27.1 to 51.1% for the as-spun (30 m/s) alloy. It is well known fact that the main rationale for the capacity degradation of Mg-based alloy electrodes is the severe corrosion of Mg in the alkaline KOH solution. Especially, during the discharging process, the anodicpolarization of alloys fa- cilitates the faster corrosion rate [25]. On the other hand, the vanishment of metastable structures formed by melt spinning or ball milling during the multiple charging/ discharging cycles tend to enhance the capacity decay of the alloys. Two reasons are responsible for the enhanced cyclic stability of the Mg2Ni-type alloy subjected with Cu substitution. Firstly, the improved performance re- garding the cyclic life of substituted alloy electrode is presumably attributed to preferential oxidation of Cu on the alloy surface, which prevents the formation of Mg(OH)2 passive layer. Secondly, the additions of a third element significantly stabilize the nanostructure forma- tion of Mg-Ni-based alloy [21], suggesting an increase of the cyclic stability of alloy. Furthermore, the comparison of Figures 6(a) and (b) reveals that the capacity retaining rates of alloys slightly decline with rising spinning rate. It implies that the melt spinning mildly impairs the cyclic stability of alloys. The nanostructure exhibiting by the alloys resulting from melt spinning has been considered to be detrimental due to its corrosion in the electrolyte during cycling on account of the fact that the intercrys- talline corrosion is facilitated by the nanostructure for- mation. This provides an illustration for the decline of the cyclic stability of the Mg-Ni-Cu system alloy caused by a higher spinning rate. 3.3. Hydriding and Dehydriding Characteristics The hydrogen absorption kinetic curves of the as-spun alloys are depicted in Figure 7. It is evident that the hy- drogen absorption capacity of the as-spun alloys first increases and then decreases with the variation of Cu content. The Cu2 alloy demonstrates the maximum hy- drogen absorption capacity at 200˚C. The evidence of extremely fast kinetics of hydrogenation is provided by the fact that the alloys acquire more than 95% of their hydrogen capacities within the first 5 min. The excellent hydriding kinetics is ascribed to the nanocrystalline structure resulting in the high surface to volume ratios (high specific surface area). In addition, the presence of large number of grain boundaries in nanocrystalline al- loys enhances the kinetics of hydrogen absorption/de- sorption. The benefaction of Cu substitution on the hy- drogen absorption capacity and kinetics of the alloy has also been attributed to the increased cell volume and the refined grain caused by Cu substitution. The enlargement in the cell volume is highly beneficial to the hydrogen absorption capacity, since, the grain boundary possesses the capability of the largest hydrogen absorption [25]. It is well known that the catalytic action of Ni on hydriding is stronger than Cu. Therefore, it is justifiable that a su- perfluous amount of Cu substitution (x > 2) leads to a decrease of the hydrogen absorption capacity of the al-  Gaseous and Electrochemical Hydrogen Storage Properties of Nanocrystalline Mg2Ni-Type Alloys Prepared by Melt Spinning Copyright © 2011 SciRes. MSA 147 (a) (b) Figure 6. Evolution of the capacity retaining rate of the alloys with cycle number: (a) 20 m/s; (b) 30 m/s. (a) (b) Figure 7. Hydrogen absorption kine tic curv e s of the as-spun alloys: (a) 20 m/s; (b) 30 m/s. loys. The hydrogenation kinetics and storage capacity of all the as-spun nanocrystalline Mg2Ni-type alloys have been found to be superior to those of conventional polycrystal- line materials possessing the similar composition. The enhanced hydrogenation property generated by melt spinning is doubtlessly associated with the refinement of grains produced by melt spinning [26]. Upon refining the microstructure, a lot of new crystallites and grain bounda- ries evolve, which may act as fast diffusion paths for hydrogen absorption. The hydrogen desorption kinetic curves of the as-spun alloys are plotted in Figure 8. An essential characteristic of the dehydrogenation process in the alloys is very fast hydrogen desorption at the initial stages, followed by a slack increase in the amount of hydrogen absorbed. The specific capacity and hydriding/dehydriding kinetics of hydride materials depend on their chemical composition and crystalline structure [27]. The observed differences from the previous documented results about the hydrid- ing/dehydriding kinetics of the melt-spun nanocrystalline Mg2Ni type alloys may be associated with the composi- tion of alloys, whereas, the differences in their micro- structure may be ascribed to the various spinning rates. It has been already reported that the high surface to volume ratios (high specific surface area) and the existence of large number of grain boundaries in nanocrystalline al- loys enhance the kinetics of hydrogen absorption/de- sorption [21]. Zaluski et al. [28] and Orimo et al. [29] have confirmed the exhibition of low temperatures (lower than 200˚C) hydriding/dehydriding characteristics of na- nocrystalline Mg2Ni alloys prepared by mechanical al-  Gaseous and Electrochemical Hydrogen Storage Properties of Nanocrystalline Mg2Ni-Type Alloys Prepared by Melt Spinning Copyright © 2011 SciRes. MSA 148 (a) (b) Figure 8. Hydrogen desorption curves of the as-spun alloys: (a) 20 m/s; (b) 30 m/s. loying. They have testified that a reduction in the grain size (20-30 nm) enhances the hydriding/dehydriding cha- racteristics owing to the hydrogen occupation in the dis- ordered interface phase. Two reasons are chiefly respon- sible for the impact action of Cu substitution on the de- hydriding kinetics of the alloys. Firstly, the partial sub- stitution of element Cu for Ni in Mg2Ni compound weakens the stability of hydride and renders the desorp- tion reaction easier [30]. Secondly, the presence of Mg2Cu phase apparently presents the catalytic effects for the hydriding and dehydriding reactions of Mg and Mg-based alloys [19]. 4. Conclusions 1) All the as-spun Mg20Ni10-xCux (x = 0, 1, 2, 3, 4) alloys exhibit the nanocrystalline structures without showing any presence of amorphous phase. The substitution of Cu for Ni does not vary the major phase of Mg2Ni-type in the alloy. On the contrary, the substitution leads to a sig- nificant refinement of grains in the as-cast alloys. 2) The Cu substitution has significantly enhanced the electrochemical hydrogen storage performances of alloy. It ameliorates the discharge capacity and the cycle stabil- ity by lowering the stability of hydride. This improve- ment is mainly attributed to the enlargement in the cell volume and the refinement of grains caused by the Cu substitution. 3) Furthermore, the substitution of Cu for Ni renders the hydrogen absorption capacity of the alloys first in- creased and then decreased. But overall it enhances the hydrogen desorption capacity and dehydriding rate of the alloys. 5. Acknowledgements This work is supported by National Natural Science Foundations of China (50871050 and 50961009), Natural Science Foundation of Inner Mongolia, China (2010ZD05) and Higher Education Science Research Project of Inner Mongolia, China (NJzy08071). REFERENCES [1] L. Schlapbach and A. Züttel, “Hydogen-Storage Matcrials for Mobile Application,” Journal of Nature, Vol. 414, 2001, pp. 353-358. doi:10.1038/35104634 [2] M. V. Simičić, M. Zdujić, R. Dimitrijević, L. Niko- lić-Bujanović and N. H. Popović, “Hydrogen Absorption and Electrochemical Properties of Mg2Ni-Type Alloys Synthesized by Mechanical Alloying,” Journal of Power Sources, Vol. 158, No. 1, 2006, pp. 730-734. doi:10.1016/j.jpowsour.2005.09.030 [3] A. Ebrahimi-Purkani and S. F. Kashani-Bozorg, “Nano- crystalline Mg2Ni-Based Powders Produced by High- Energy Ball Milling and Subsequent Annealing,” Journal of Alloys and Compounds, Vol. 456, No. 1-2, 2008, pp. 211-215. doi:10.1016/j.jallcom.2007.02.003 [4] D. Kyoi, T. Sakai, N. Kitamura, A. Ueda and S. Tanase, “Synthesis of FCC Mg–Ta Hydrides Using GPa Hydro- gen Pressure Method and Their Hydrogen-Desorption Properties,” Journal of Alloys and Compounds, Vol. 463, No. 1-2, 2008, pp. 306-310. doi:10.1016/j.jallcom.2007.09.003 [5] P. Palade, S. Sartori, A. Maddalena, G. Principi, S. Lo Russo, M. Lazarescu, G. Schinteie, V. Kuncser and G. Filoti, “Hydrogen Storage in Mg-Ni-Fe Compounds Pre- pared by Melt Spinning and Ball Milling,” Journal of Al- loys and Compounds, Vol. 415, No. 1-2, 2006, pp. 170- 176. doi:10.1016/j.jallcom.2005.08.017 [6] M. Y. Song, C. D. Yim, J. S. Bae, D. R. Mummd and S. H. Hong, “Preparation by Gravity Casting and Hydro- gen-Storage Properties of Mg–23.5 wt%Ni–(5, 10 and 15 wt%)La,” Journal of Alloys and Compounds, Vol. 463, No. 1-2, 2008, pp. 143-147.  Gaseous and Electrochemical Hydrogen Storage Properties of Nanocrystalline Mg2Ni-Type Alloys Prepared by Melt Spinning Copyright © 2011 SciRes. MSA 149 doi:10.1016/j.jallcom.2007.08.079 [7] X. F. Liu, Y. F. Zhu and L. Q. Li, “Structure and Hydro- genation Properties of Nanocrystalline Mg2Ni Prepared by Hydriding Combustion Synthesis and Mechanical Milling,” Journal of Alloys Compounds, Vol. 455, No. 1-2, 2008, pp. 197-202. doi:10.1016/j.jallcom.2007.01.073 [8] F. J. Liu and S. Suda, “A Method for Improving the Long-Term Storability of Hydriding Alloys by Air Water Exposure,” Journal of Alloys and Compounds, Vol. 231, No. 1-2, 1995, pp. 742-750. doi:10.1016/0925-8388(95)01711-9 [9] T. Czujko, R. A. Varin, C. Chiu and Z. Wronski, “Inves- tigation of the Hydrogen Desorption Properties of Mg + 10 wt% X (X = V, Y, Zr) Submicrocrystalline Compos- ites,” Journal of Alloys and Compounds, Vol. 414, No. 1-2, 2006, pp. 240-247. doi:10.1016/j.jallcom.2005.07.009 [10] C. X. Shang, M. Bououdina, Y. Song and Z. X. Guo, “Mechanical Alloying and Electronic Simulations of (MgH2 + M) Systems (M = Al, Ti, Fe, Ni, Cu and Nb) for Hydrogen Storage,” Internation Journal of Hydrogen Energy, Vol. 29, No. 1, 2004, pp. 73-80. doi:10.1016/S0360-3199(03)00045-4 [11] B. Sakintuna, F. Lamari-Darkrim and M. Hirscher, “Metal Hydride Materials for Solid Hydrogen Storage: A Re- view,” International Journal of Hydrogen Energy, Vol. 32, No. 9, 2007, pp. 1121-1140. doi:10.1016/j.ijhydene.2006.11.022 [12] A. Zaluska, L. Zaluski and J. O. Stroem-Olsen, ”Synergy of Hydrogen Sorption in Ball-Milled Hydrides of Mg and Mg2Ni,” Journal of Alloys and Compounds, Vol. 289, No. 1-2, 1999, pp. 197-206. doi:10.1016/S0166-0462(99)00013-7 [13] N. Hanada, T. Ichikawa and H. Fujii, “Catalytic Effect of Nanoparticle 3d-Transition Metals on Hydrogen Storage Properties in Magnesium Hydride MgH2 Prepared by Mechanical Milling,” Journal of Physical Chemistry B, Vol. 109, No. 15, 2005, pp. 7188-7194. doi:10.1021/jp044576c [14] N. Recham, V. V. Bhat, M. Kandavel, L. Aymard, J.-M. Tarascon and A. Rougier, “Reduction of Hydrogen De- sorption Temperature of Ball-Milled MgH2 by NbF5 Ad- dition,” Journal of Alloys and Compounds, Vol. 464, No. 1-2, 2008, pp. 377-382. doi:10.1016/j.jallcom.2007.09.130 [15] V. D. Dobrovolsky, O. G. Ershova, Y. M. Solonin, O. Y. Khyzhuna and V. Paul-Boncour, “Influence of TiB2 Ad- dition upon Thermal Stability and Decomposition Tem- perature of the MgH2 Hydride of a Mg-Based Mechanical Alloy,” Journal of Alloys and Compounds, Vol. 465, No. 1-2, 2008, pp. 177-182. doi:10.1016/j.jallcom.2007.10.125 [16] N. Cui, B. Luan, H. J. Zhao, H. K. Liu and S. X. Dou, “Effects of Yttrium Additions on the Electrode Perform- ance of Magnesium-Based Hydrogen Storage Alloys,” Journal of Alloys and Compounds, Vol. 233, No. 1-2, 1996, pp. 236-240. doi:10.1016/0925-8388(95)02061-6 [17] T. Kohno and M. Kanda, “Effect of Partial Substitution on Hydrogen Storage Properties of Mg2Ni Alloy,” Jour- nal Electrochemical Society, Vol. 144, 1997, pp. 2384- 2388. doi:10.1149/1.1837823 [18] G. Y. Liang, “Synthesis and Hydrogen Storage Properties of Mg-Based Alloys,” Journal of Alloys and Compounds, Vol. 370, No. 1-2, 2004, pp. 123-128. doi:10.1016/j.jallcom.2003.09.031 [19] M. Y. Song, S. N. Kwon, J. S. Bae and S. H. Hong, “Hy- drogen-Storage Properties of Mg–23.5Ni–(0 and 5) Cu Prepared by Melt Spinning and Crystallization Heat Treatment,” International Journal of Hydrogen Energy, Vol. 33, No. 6, 2008, pp. 1711-1718. doi:10.1016/j.ijhydene.2008.01.006 [20] M. Savyak, S. Hirnyj, H.-D. Bauer, M. Uhlemann, J. Eckert, L. Schultz and A. Gebert, “Electrochemical Hy- drogenation of Mg65Cu25Y10 Metallic Glass,” Journal of Alloys and Compounds, Vol. 364, No. 1-2, 2004, pp. 229-237. doi:10.1016/S0925-8388(03)00529-2 [21] T. Spassov and U. Köster, “Thermal Stability and Hydrid- ing Properties of Nanocrystalline Melt-Spun Mg63Ni30Y7 Alloy,” Journal of Alloys and Compounds, Vol. 279, No. 2, 1998, pp. 279-286. doi:10.1016/S0925-8388(98)00680-X [22] L. J. Huang, G. Y. Liang, Z. B. Sun and D. C. Wu, “Elec- trode Properties of Melt-Spun Mg-Ni-Nd Amorphous Alloys,” Journal of Power Sources, Vol. 160, No. 1, 2006, pp. 684-687. doi:10.1016/j.jpowsour.2005.12.072 [23] Y. H. Zhang, B. W. Li, H. P. Ren, S. H. Guo, Z. W. Wu and X. L. Wang, “Hydriding and Dehydriding Character- istics of Nanocrystalline and Amorphous Mg20Ni10-xCox (x = 0-4) Alloys Prepared by Melt-Spinning,” Interna- tional Journal Hydrogen Energy, Vol. 34, No. 6, 2009, pp. 2684-2691. doi:10.1016/j.ijhydene.2009.01.031 [24] G. Friedlmeier, M. Arakawa, T. Hiraia and E. Akiba, “Preparation and Structural, Thermal and Hydriding Characteristics of Melt-Spun Mg–Ni Alloys,” Journal of Alloys and Compounds, Vol. 292, No. 1-2, 1999, pp. 107-117. doi:10.1016/S0925-8388(99)00285-6 [25] S. Orimo and H. Fujii, “Materials Science of Mg-Ni-Based New Hydrides,” Applied Physics A, Vol. 72, No. 2, 2001, pp. 167-186. doi:10.1007/s003390100771 [26] K. Tanaka, Y. Kanda, M. Furuhashi, K. Saito, K. Kuroda and H. Saka, “Improvement of Hydrogen Storage Proper- ties of Melt-Spun Mg–Ni–Re Alloys by Nanocrystalliza- tion,” Journal of Alloys and Compounds, Vol. 295, 1999, pp. 521-525. doi:10.1016/S0925-8388(99)00477-6 [27] G. Mulas, L. Schiffini and G. Cocco, “Mechanochemical Study of the Hydriding Properties of Nanostructured Mg2Ni–Ni Composites,” Journal of Materials Research, Vol. 19, 2004, pp. 3279-3289. doi:10.1557/JMR.2004.0417 [28] L. Zaluski, A. Zaluska and J. O. Ström-Olsen, “Nanocry- stalline Metal Hydrides,” Journal of Alloys and Com- pounds, Vol. 253-254, 1997, pp. 70-79.  Gaseous and Electrochemical Hydrogen Storage Properties of Nanocrystalline Mg2Ni-Type Alloys Prepared by Melt Spinning Copyright © 2011 SciRes. MSA 150 doi:10.1016/S0925-8388(96)02985-4 [29] S. Orimo, H. Fujii and K. Ikeda, “Notable Hydriding Properties of A Nanostructured Composite Material of the Mg2Ni-H System Synthesized by Reactive Mechanical Grinding,” Acta Materialia, Vol. 45, No. 1, 1997, pp. 331-341. doi:10.1016/S1359-6454(96)00158-9 [30] J.-H. Woo and K.-S. Lee, “Electrode Characteristics of Nanostructured MgNi-Type Alloys Prepared by Me- chanical Alloying,” Journal Electrochemical Society, Vol. 146, No. 3, 1999, pp. 819-823. doi:10.1149/1.1391687 |