K. YAMADA, S. THUMSORN

Open Access AMPC

331

[2] S. Thumsorn, K. Yamada, Y. W. Leong and H. Hamada,

“Thermal Decomposition Kinetic and Flame Retardancy

of CaCO3 Filled Recycled Polyethylene Terephtha-

late/Recycled Polypropylene Blend,” Journal of Applied

Polymer Science, Vol. 127, 2013, pp. 1245-1256.

http://dx.doi.org/10.1002/app.37673

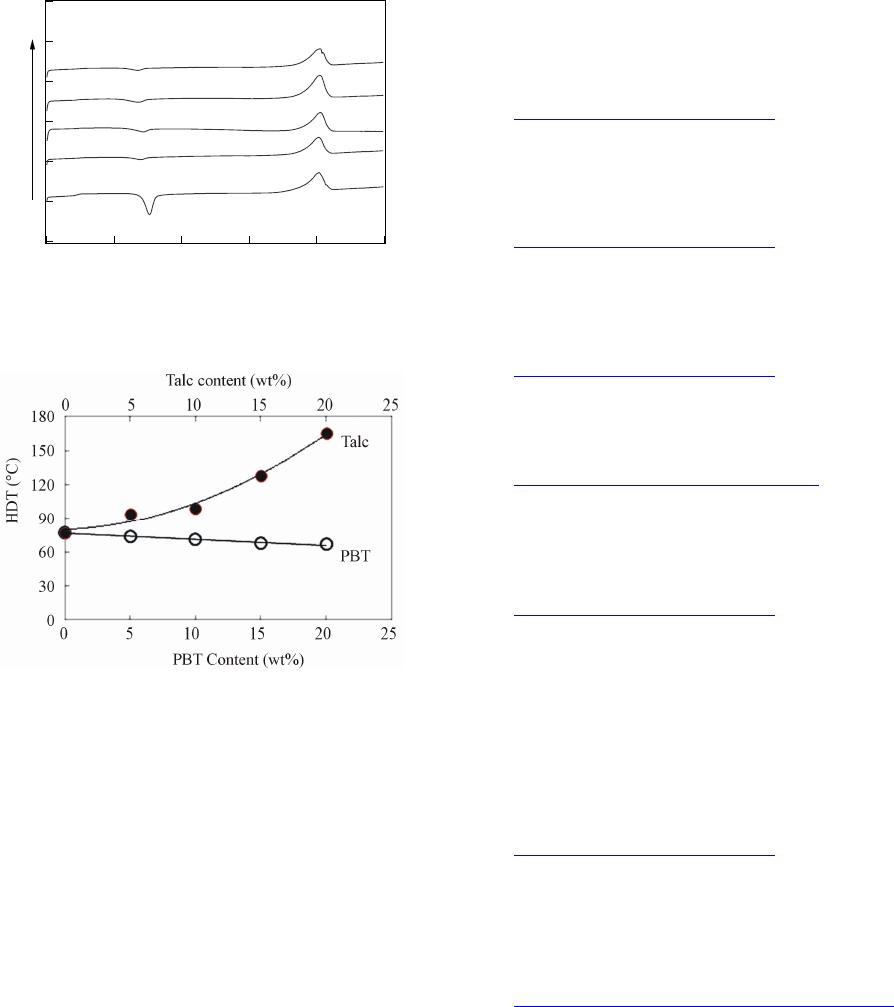

Endothermic Heat Flow

30025020015010050

Temperature [°C]

RPET/E-GMA

Talc 5 wt%

Talc 10 wt%

Talc 15 wt%

Talc 20 wt%

[3] M. Ogasahara, M. Shidou, S. Nagata, K. Yamada, Y. W.

Leong and H. Hamada, “Effectiveness of High Frequency

Heating on Drying and Intrinsic Viscosity Enhancement

of Recycled Poly (Ethylene Terephthalate),” Journal of

Applied Polymer Science, Vol. 126, 2012, pp. E166-E171.

http://dx.doi.org/10.1002/app.34368

[4] S. Thumsorn, K. Yamada, Y. W. Leong and H. Hamada,

“Effect of Pellet Size and Compatibilization on Thermal

Decomposition Kinetic of Recycled Polyethylene Ter-

ephthalate/Recycled Polypropylene Blend,” Journal of

Applied Polymer Science, Vol. 124, 2012, pp. 1605-1613.

http://dx.doi.org/10.1002/app.35166

Figure 8. DSC curves of RPET/E-GMA/talc blends at vari-

ous talc content.

[5] S. Thumsorn, K. Yamada, Y. W. Leong and H. Hamada,

“Development of Cockleshell-Derived CaCO3 for Flame

Retardancy of Recycled PET/Recycled PP Blend,” Mate-

rials Sciences and Applications, Vol. 2, 2011, pp. 59-69.

http://dx.doi.org/10.4236/msa.2011.22009

[6] N. Kunimune, K. Yamada, Y. W. Leong, S. Thumsorn

and H. Hamada, “Influence of the Reactive Processing of

Recycled Poly(Ethylene Terephthalate)/Poly (Ethylene-

Coglycidyl Methacrylate) Blends,” Journal of Applied

Polymer Science, Vol. 120, 2011, pp. 50-55.

http://dx.doi.org/10.1002/app.32836

[7] R. Konishi, K. Miyata, K. Yamada, Y. W. Leong, Y.

Hashimoto and H. Hamada, “Interface of Draw Ratio on

Adhesion of Heat-sealed Recycled-PET Films,” Journal

of Packaging Science and Technology, Vol. 20, No. 2,

2011, pp.107-115.

Figure 9. HDT properties for PBT or talc contents (wt%)

on RPET/E-GMA(3 wt%) blends.

[8] Y. Yand, C. G’Sell, J. Hiver and S. Bai, “Dynamic Me-

chanical Properties and Morphology of High-Density

Polyethylene/CaCO3 Blends with and without an Impact

Modifier,” Journal of Applied Polymer Science, Vol. 103,

2007, pp. 3907-3914.

http://dx.doi.org/10.1002/app.25619

5. Acknowledgements

This work was partly supported by Japan Science and

Technology Agency (JST), A-STEP feasibility study pro-

gram (#AS242Z01291K). We would like to express our

profound gratitude to them. [9] B. Alcock, N. O. Cabrera, N.-M. Barkoula, C. T. Rey-

nolds, L. E. Govaert and T. Peijs, “The Effect of Tempe-

rature and Strain Rate on the Mechanical Properties of

Highly Oriented Polypropylene Tapes and All-Polypropy-

lene Composites,” Composites Science and Technology,

Vol. 67, 2007, pp. 2061-2070.

http://dx.doi.org/10.1016/j.compscitech.2006.11.012

REFERENCES

[1] The Council for PET Bottle Recycling, “The Trend of

PET Bottle Resin Polymer in Japan,” 2009.

http://www.petbottle-rec.gr.jp/english/trend.html