Photonics from Al-Haitham to Optoelectronics of AMTEC

Open Access JCC

cation of optics more in practical aspect, and an analogy

to electronics.

The term quantum electronics was used for the area of

physics dealing with the effects of quantum mechanics

on the behavior of electrons in matter, and their interac-

tions with photons. It is today rarely considered a sub-

field in its own right, as it has been absorbed by other

fields. The term was mainly used between the 1950s and

the 1970s. Today, the research output of this field is

mainly used in quantum optics, especially for the part of

it that draws not from atomic physics but from solid-state

physics.

Electro-optics, not to be confused with optoelectronics,

involves components, devices and systems which operate

by modification of the optical properties of a material by

an electric field. This branch of technology deals with the

interaction between the electromagnetic and the electrical

or in modern terminology electronic and optical states of

material.

Optomechanics can be referred to as the study of the

interaction of photons (electromagnetic radiation) with

mechanical systems via radiation pressure, and also the

manufacture and maintenance of optical devic es and parts,

such as fiber aligners, mirror mounts, optical mounts,

translation stages, rotary and kinematic stages, pedestals

and posts, rails, micrometers, screws and screw sets. It

may also include optomechanical design and integration

with exterior package, manufacture and maintenance of

fiber optic materials, and design and packaging of rugged

optical trains in compact form.

The term optoelectronics connotes devices or circuits

comprise both electrical and optical functions, i.e., a thin-

film semiconductor device. The term electro-optics came

into earlier use and sp e c ifically encompasses nonlinear

electrical-optical interactions applied, e.g., as bulk crystal

modulators. It also includes advanced imaging sensors

used typically for surveillance. It is the design, manufac-

ture and working of AMTEC as a whole, which p er tains

to the device domain of optoelectronics.

AMTEC is an infrared regenerative electrochemical

device for the direct conversion of heat into electricity.

While AMTEC technology development is primarily fo-

cused for deep space missions because of its longevity

and high efficiency under static conversion, it is also

expected to have many terrestrial uses. Its simulated de-

sign has shown its longevity as much as fifteen years.

Some of its laboratory devices have achieved efficiencies

as high as 19%. Small system designs using AMTEC

have shown 27% cell and 23% system efficiencies. An

Optimized AMTEC can, however, potentially provide a

theoretical efficiency close to Carnot efficiency almost

up to 40% [2]. It has no moving part thus creating no

noise with the potential for low maintenance, high dura-

bility and reliability. As it has no moving parts it is not

subjected to any material wear and tear. There is no vi-

bration or uncompensated momentum present in AM-

TEC, which reduces the chances of corrosion. It has the

ability to use infrared energy as an input from high tem-

perature combustion, nuclear, radioisotope, solar or heat

rejected from other devices [3-6]. A number of research

programs on AMTEC have been focusing on improving

its performance characteristics and technology improve-

ment. Of course, these efforts have successfully resolved

many of the important technological issues pertaining to

its design and fabrication. The performance level, how-

ever, achieved until today is still below the expected po-

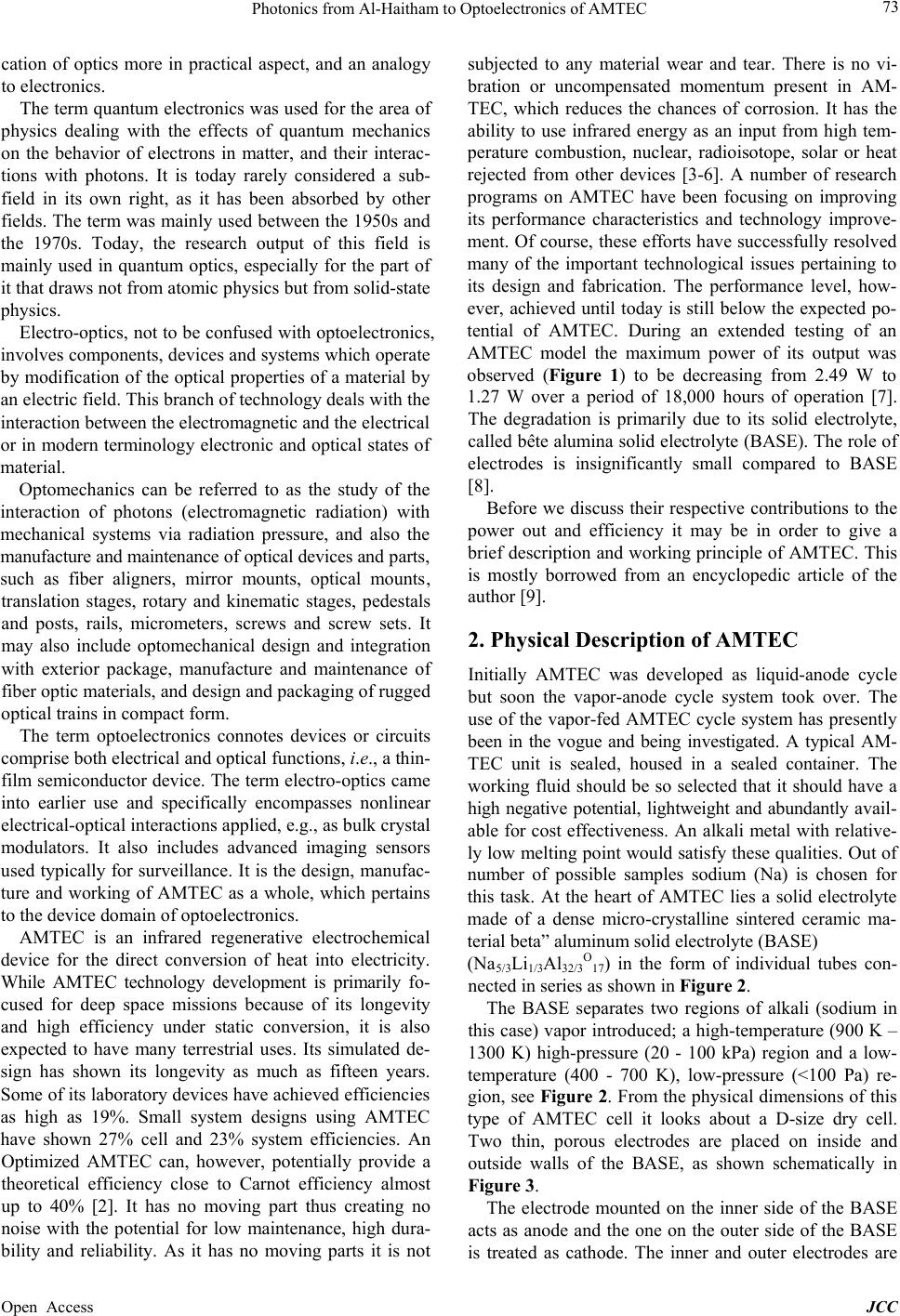

tential of AMTEC. During an extended testing of an

AMTEC model the maximum power of its output was

observed (Figure 1) to be decreasing from 2.49 W to

1.27 W over a period of 18,000 hours of operation [7].

The degradation is primarily due to its solid electrolyte,

called bête alumina solid electrolyte (BASE). The role of

electrodes is insignificantly small compared to BASE

[8].

Before we discuss their respective contributions to the

power out and efficiency it may be in order to give a

brief description and working princ iple of AMTEC. Th is

is mostly borrowed from an encyclopedic article of the

author [9].

2. Physical Description of AMTEC

Initially AMTEC was developed as liquid-anode cycle

but soon the vapor-anode cycle system took over. The

use of the vapor-fed AMTEC cycle system has presently

been in the vogue and being investigated. A typical AM-

TEC unit is sealed, housed in a sealed container. The

working fluid should be so selected that it should have a

high negative potential, lightweight and abundantly avail-

able for cost effectiveness. An alkali metal with relative-

ly low melting point would satisfy these qualities. Out of

number of possible samples sodium (Na) is chosen for

this task. At the heart of AMTEC lies a solid electrolyte

made of a dense micro-crystalline sintered ceramic ma-

terial beta” aluminum solid electrolyte (BASE)

(Na5/3Li1/3Al32/3O17) in the form of individual tubes con-

nected in series as shown in Figure 2.

The BASE separates two regions of alkali (sodium in

this case) vapor introduced; a high-temperature (900 K –

1300 K) high-pressure (20 - 100 kPa) region and a low-

temperature (400 - 700 K), low-pressure (<100 Pa) re-

gion, see Figure 2. From the physical dimensions of this

type of AMTEC cell it looks about a D-size dry cell.

Two thin, porous electrodes are placed on inside and

outside walls of the BASE, as shown schematically in

Figure 3.

The electrode mounted on the inner side of the BASE

acts as anode and the one on the outer side of the BASE

is treated as cathode. The inner and outer electrodes are