Y. X. Sun et al. / Natural Science 3 (2011) 120-123

Copyright © 2011 SciRes. OPEN ACCESS

121

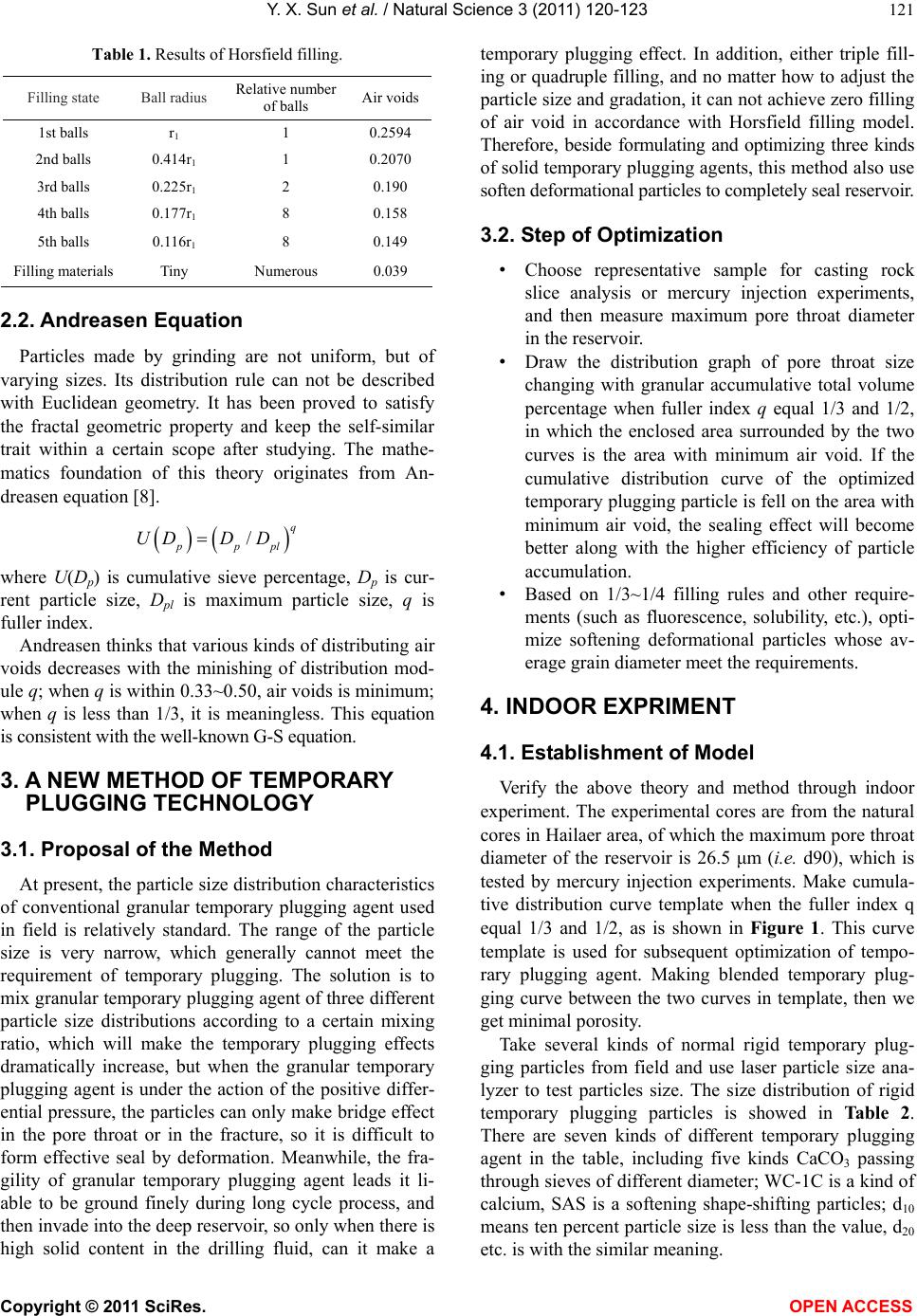

Table 1. Results of Horsfield filling.

Filling state Ball radius Relative number

of balls Air voids

1st balls r1 1 0.2594

2nd balls 0.414r1 1 0.2070

3rd balls 0.225r1 2 0.190

4th balls 0.177r1 8 0.158

5th balls 0.116r1 8 0.149

Filling materials Tiny Numerous 0.039

2.2. Andreasen Equation

Particles made by grinding are not uniform, but of

varying sizes. Its distribution rule can not be described

with Euclidean geometry. It has been proved to satisfy

the fractal geometric property and keep the self-similar

trait within a certain scope after studying. The mathe-

matics foundation of this theory originates from An-

dreasen equation [8].

/q

pppl

UDD D

where U(Dp) is cumulative sieve percentage, Dp is cur-

rent particle size, Dpl is maximum particle size, q is

fuller index.

Andreasen thinks that various kinds of distributing air

voids decreases with the minishing of distribution mod-

ule q; when q is within 0.33~0.50, air voids is minimum;

when q is less than 1/3, it is meaningless. This equation

is consistent with the well-known G-S equation.

3. A NEW METHOD OF TEMPORARY

PLUGGING TECHNOLOGY

3.1. Proposal of the Method

At present, the particle size distribution characteristics

of conventional granular temporary plugging agent used

in field is relatively standard. The range of the particle

size is very narrow, which generally cannot meet the

requirement of temporary plugging. The solution is to

mix granular temporary plugging agent of three different

particle size distributions according to a certain mixing

ratio, which will make the temporary plugging effects

dramatically increase, but when the granular temporary

plugging agent is under the action of the positive differ-

ential pressure, the particles can only make bridge effect

in the pore throat or in the fracture, so it is difficult to

form effective seal by deformation. Meanwhile, the fra-

gility of granular temporary plugging agent leads it li-

able to be ground finely during long cycle process, and

then invade into the deep reservoir, so only when there is

high solid content in the drilling fluid, can it make a

temporary plugging effect. In addition, either triple fill-

ing or quadruple filling, and no matter how to adjust the

particle size and gradation, it can not achieve zero filling

of air void in accordance with Horsfield filling model.

Therefore, beside formulating and optimizing three kinds

of solid temporary plugging agents, this method also use

soften deformational particles to completely seal reservoir.

3.2. Step of Optimization

• Choose representative sample for casting rock

slice analysis or mercury injection experiments,

and then measure maximum pore throat diameter

in the reservoir.

• Draw the distribution graph of pore throat size

changing with granular accumulative total volume

percentage when fuller index q equal 1/3 and 1/2,

in which the enclosed area surrounded by the two

curves is the area with minimum air void. If the

cumulative distribution curve of the optimized

temporary plugging particle is fell on the area with

minimum air void, the sealing effect will become

better along with the higher efficiency of particle

accumulation.

• Based on 1/3~1/4 filling rules and other require-

ments (such as fluorescence, solubility, etc.), opti-

mize softening deformational particles whose av-

erage grain diameter meet the requirements.

4. INDOOR EXPRIMENT

4.1. Establishment of Model

Verify the above theory and method through indoor

experiment. The experimental cores are from the natural

cores in Hailaer area, of which the maximum pore throat

diameter of the reservoir is 26.5 μm (i.e. d90), which is

tested by mercury injection experiments. Make cumula-

tive distribution curve template when the fuller index q

equal 1/3 and 1/2, as is shown in Figure 1. This curve

template is used for subsequent optimization of tempo-

rary plugging agent. Making blended temporary plug-

ging curve between the two curves in template, then we

get minimal porosity.

Take several kinds of normal rigid temporary plug-

ging particles from field and use laser particle size ana-

lyzer to test particles size. The size distribution of rigid

temporary plugging particles is showed in Table 2.

There are seven kinds of different temporary plugging

agent in the table, including five kinds CaCO3 passing

through sieves of different diameter; WC-1C is a kind of

calcium, SAS is a softening shape-shifting particles; d10

means ten percent particle size is less than the value, d20

etc. is with the similar meaning.