W. H. KIM, T. S. PARK

Open Access JAMP

jet. These are driven by the anisotropy of turbulent

stresses. From these results, we can expect that the flow

evolution of the square jet is more three dimensional and

the square jet has a better mixing, because it has many

vortical structures. However, the streamwise velocity of

the triangular jet evo lves much faster. This represents the

weak dependency of the turbulence driven secondary

flows on the enhanced mixing. Also, it is supposed that

the jet mixing strongly depends on the roll-up vortices.

The vortex evolutions are coupled the nozzle configura-

tion, because the inflow has the radial and azimuthal

variati ons due to t he n on -circular cross-section.

As can be seen in the figure, the positive radial mo-

tions are observed in the center region, while the ambient

fluid moves to the center region. As a result, two motions

form a line. The line indicates the interface of secondary

flows between the central jet and ambient coflow. Ac-

cordingly, the interface can be used as a parameter

representing the evolution of jet flows. Near the injection

plane, the interface line nearly coincides with the nozzle

cross-section. As the flow develops down-stream, the

interface line becomes a circle. It is because the vortical

structures are declined gradually and the axial flow

spreads out radially.

On the other hand, the changes of the second ary flows

for the square and triangular jet are faster than that of the

circular jet. From a closer inspection of the figure, we

found that the interface lines nearly correspond to the

location of U/Uc = 0.3 regardless of the nozzle shapes. It

is very interesting to explain the development of jet

flows.

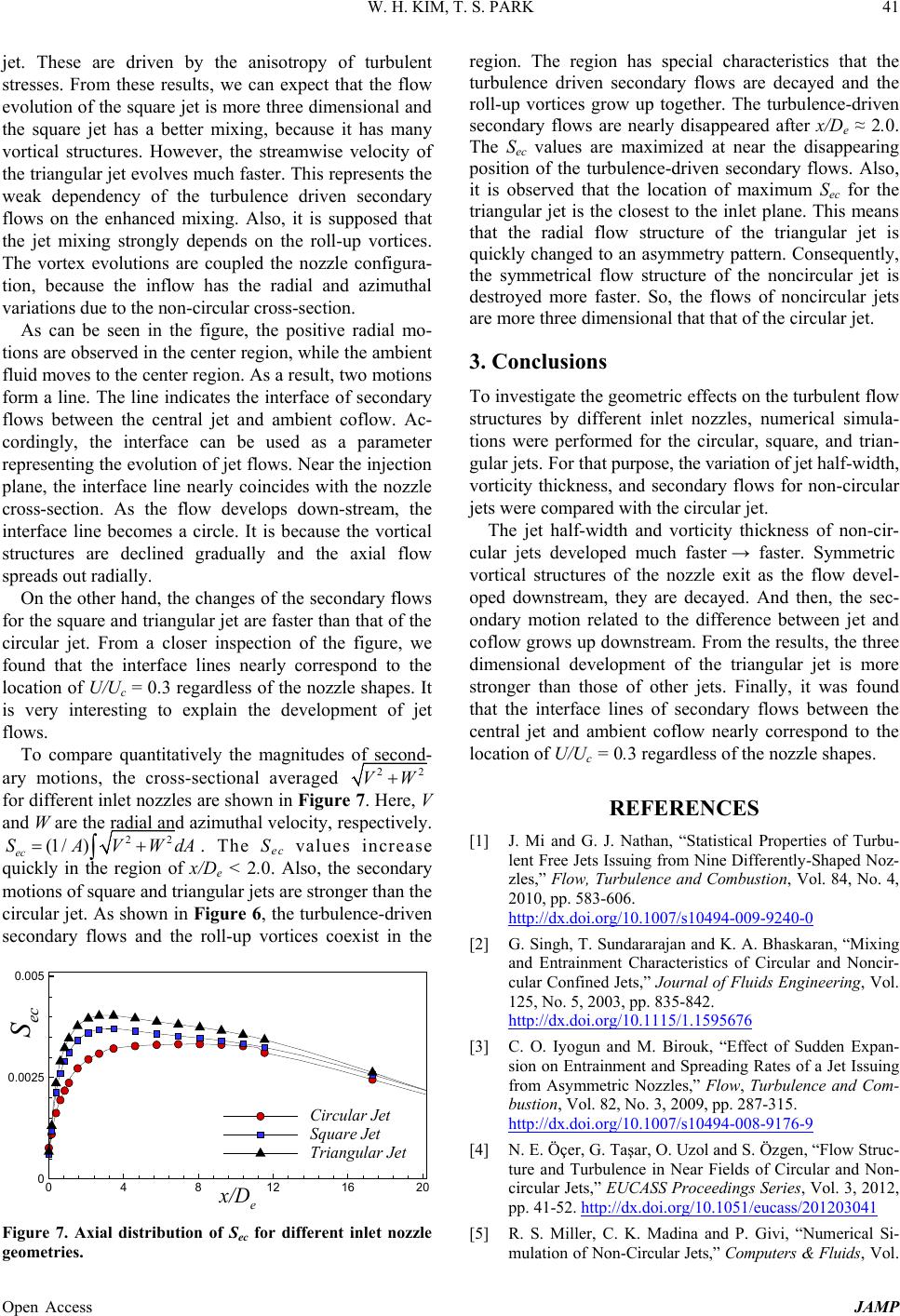

To compare quantitatively the magnitudes of second-

ary motions, the cross-sectional averaged

for different inlet no zzles are shown in Figure 7. Here, V

and W are the radial and azimuthal velocity, respectively.

. The Sec values increase

quickly in the region of x/De < 2.0. Also, the secondary

motions of square and triangular jets are stronger than the

circular jet. As show n in Figure 6, the turbulenc e-driven

secondary flows and the roll-up vortices coexist in the

Figure 7. Axial distribution of Sec for different inlet nozzle

geometries.

region. The region has special characteristics that the

turbulence driven secondary flows are decayed and the

roll-up vortices grow up together. The turbulence-driven

secondary flows are nearly disappeared after x/De ≈ 2.0.

The Sec values are maximized at near the disappearing

position of the turbulence-driven secondary flows. Also,

it is observed that the location of maximum Sec for the

triangular jet is the closest to the inlet plane. This means

that the radial flow structure of the triangular jet is

quickly changed to an asymmetry pattern. Consequently,

the symmetrical flow structure of the noncircular jet is

destroyed more faster. So, the flows of noncircular jets

are more three dimensional that that of the circular jet.

3. Conclusions

To investigate the geometric eff ects on the turbulent flow

structures by different inlet nozzles, numerical simula-

tions were performed for the circular, square, and trian-

gular jets. For th at purpose, the variation of jet half-width,

vorticity thickness, and secondary flows for non-circular

jets were compared with the circular jet.

The jet half-width and vorticity thickness of non-cir-

cular jets developed much faster → faster. Symmetric

vortical structures of the nozzle exit as the flow devel-

oped downstream, they are decayed. And then, the sec-

ondary motion related to the difference between jet and

coflow grows up downstream. From the results, the thr ee

dimensional development of the triangular jet is more

stronger than those of other jets. Finally, it was found

that the interface lines of secondary flows between the

central jet and ambient coflow nearly correspond to the

location of U/Uc = 0.3 regardless of the nozzle shapes.

REFERENCES

[1] J. Mi and G. J. Nathan, “Statistical Properties of Turbu-

lent Free Jets Issuing from Nine Differently-Shaped Noz-

zles,” Flow, Turbulence and Combustion, Vol. 84, No. 4,

2010, pp. 583-606.

http://dx.doi.org/10.1007/s10494-009-9240-0

[2] G. Singh, T. Sundararajan and K. A. Bhaskaran, “Mixing

and Entrainment Characteristics of Circular and Noncir-

cular Confined Jets,” Journal of Fluids Engineering, Vol.

125, No. 5, 2003, pp. 835-842.

http://dx.doi.org/10.1115/1.1595676

[3] C. O. Iyogun and M. Birouk, “Effect of Sudden Expan-

sion on Entrainment and Spreading Rates of a Jet Issui ng

from Asymmetric Nozzles,” Flow, Turbulence and Com-

bustion, Vol. 82, No. 3, 2009, pp. 287-315.

[4] N. E. Öçer, G. Taşar, O. Uzol and S . Özgen, “Flow Struc-

ture and Turbulence in Near Fields of Circular and Non-

circular Jets,” EUCASS Proceedings Series, Vol. 3, 2012,

pp. 41-52.

http://dx.doi.org/10.1007/s10494-008-9176-9

http://dx.doi.org/10.1051/eucass/201203041

[5] R. S. Miller, C. K. Madina and P. Givi, “Numerical Si-

mulation of Non-Circular Jets,” Com puters & Fluids, Vol.

x/D

e

S

ec

04812 16 20

0

0.0025

0.005

CircularJet

Square Jet

Triangular Jet