Efficiency of Amphoteric Surfactants as Flow Improvers and Pour Point Depressants

Copyright © 2013 SciRes. JPEE

al fluids. They are characterized by good biodegradabili-

ty, low volatility, good lubr icity, good thermal stability

and low pour points. Action mechanism of sorbitan pal-

mitate as multifunction additive for pour, cloud points

depressant and viscosity improver with oxidation of oil.

The efficiency of this additive depend s on its critical mi-

celle concentration. The micelle core act as trap for hy-

drocarbon oxide radicals and terminate chain of hydro-

carbon oxidation. The micellar inhibition depend on in-

corporation of hydroperox ide or other polar oxygen con-

taining molecules to the reversed micelle, as the results

increase oxidation stability of oil [3]. The author studies

new antioxidant for lube oil. This antioxidant dibenzyl

s-phenyl thio glyconitrile and other derivatives were pre-

par ed phase transfere catalysts. These compounds were

added to oil in different concentrations. The antioxidants

activities of different dosages were evaluated and sug-

gested mechanism according to micelle and their ther-

modynamic [1].

The purpose of the present work study of prepared

amphoteric surfactants calcium salt of N-Decyl-N-ben-

zyl-N-methylglycine (AB) and N-Dodecyl-N-benzyl-N-

methylglycine (CD) which differs in hydrocarbon chain

length and apply as pour point and anti oxidant for the

paraffinic gas oil.

2. Experimental

Preparation the additive by phase transfer catalysts by

two techniques:

N-D ec y l -N-benzyl-N-me t hylgl y cine(AB) and N-Do-

decyl-N-benzyl-N-methylglycine(CD) were synthesized

by Omar [7]. 3 mol N methyl b enzylamine and 1 mol

calcium chloroacetate to react overnight in pure ethanol

at 50 C0 in the presence of 0.1 mol of benzyl triethanol

ammonium chloride as phase transfere catalyst. The re-

sulting solution was treat ed with sodium carbonate and

recrystallized by alcohol. The resulting prolcoduct cal-

cium salt of N-Decyl-N-benzyl-N-methylglycine (AB) and

N-Dodecyl-N-benzyl-N-methylglycine (CD).

Surface tension of different concentrations for 10−7 to

0.1 mol/L of the synthesized additives were measured by

using Kruss Model 8451 in petroleum ether at 30˚C ac-

cording to omar et al. [8].

The oxidation test was carried out at 120˚C according

to ASTM D 943 standard methods. The base stock sam-

ple was subjected to oxidation with pure oxygen at a

flow rate of 0.1 L/hour for maximum 70 hours. The in-

vestigated amphoteric surfactant was added in different

concentrations. Pour point depressants and viscosity ac-

cording to ASTM-D 97 and IP 71/80 respectively.

3. Results and Discussions

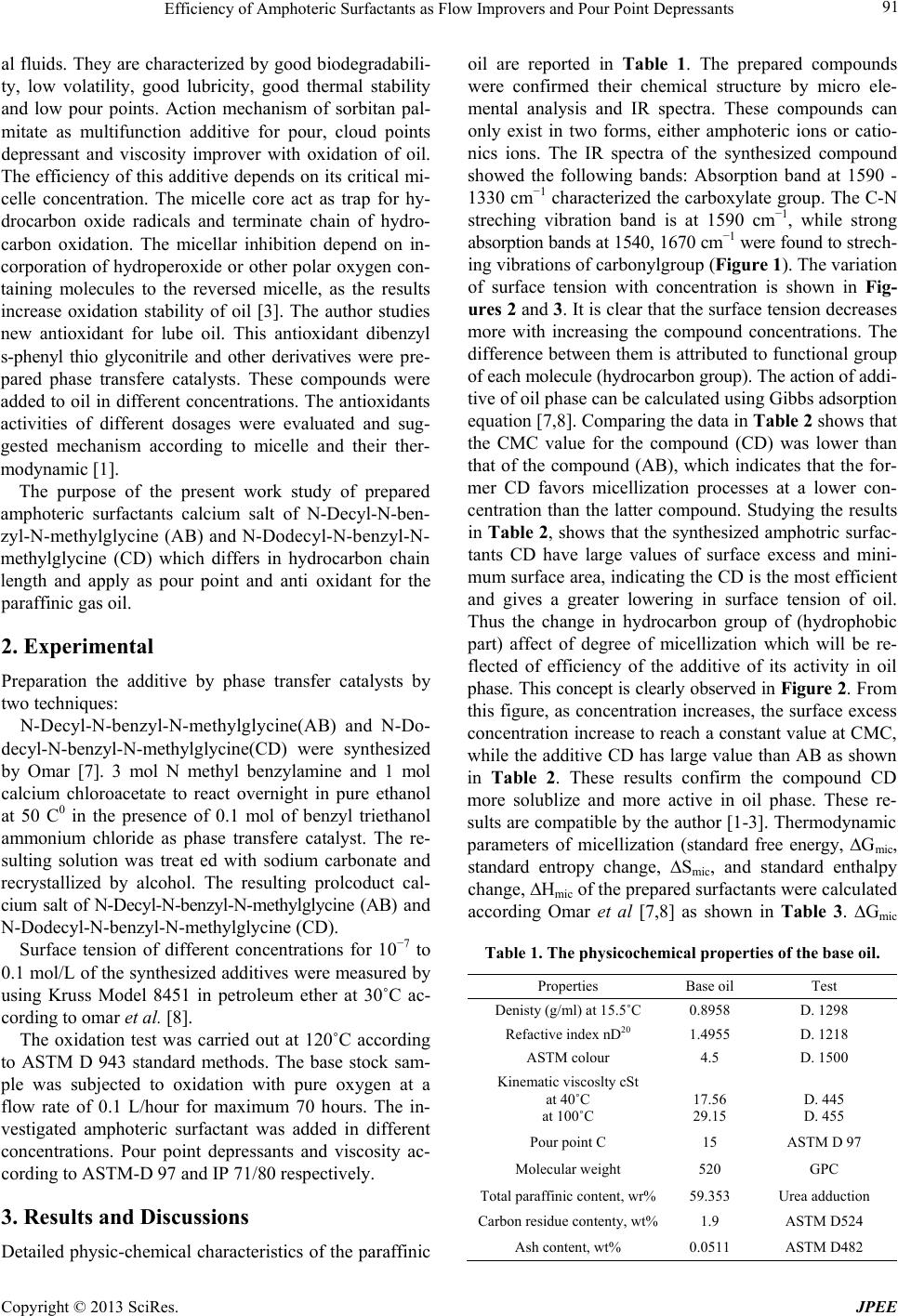

Detailed physic-ch emical characteristics of the paraffinic

oil are reported in Table 1. The prep ared compounds

were confirmed their chemical structure by micro ele-

mental analysis and IR spectra. These compounds can

only exist in two forms, either amphoteric ions or catio-

nics ions. The IR spectra of the synthesized compound

showed the following bands: Absorption band at 1590 -

1330 cm−1 characterized the carboxyla te group. The C-N

streching vibration band is at 1590 cm−1, while strong

absorption bands at 1540, 1670 cm−1 were found to strech-

ing vibrations of carbonylgroup (Figure 1). The variation

of surface tension with concentration is shown in Fig-

ures 2 and 3. It is clear that the surface tension decreases

more with increasing the compound concentrations. The

difference between them is attributed to f unctional group

of each molecule (hydrocarbon group). The action of addi-

tive of oil phase can be calculated using Gibbs adsorption

equation [7, 8]. Comparing the data in Table 2 shows that

the CMC value for the compound (CD) was lower than

that of the compound (AB), which indicates that the for-

mer CD favors micellization pr ocesses at a lower con-

centration than the latter compound. Studying the results

in Table 2, shows that the synth esized amphotric surfac-

tants CD have large values of surface excess and mini-

mum surface area, indicating the CD is the most efficient

and gives a greater lowering in surface tension of oil.

Thus the change in hydrocarbon group of (hydrophobic

part) affect of degree of micellization which will be re-

flected of efficiency of the additive of its activity in oil

phase. This concept is clearly observed in Figure 2. From

this figure, as concentration increases, the surface excess

concentration increase to reach a constant value at CMC,

while the additive CD has large value than AB as shown

in Table 2. These results c onfirm the compound CD

more solublize and more active in oil phase. These re-

sults are compatible by the author [1-3]. Thermodynamic

parameters of micellization (standard free energy, ∆Gmic,

standard entropy change, ∆Smic, and standard enthalpy

change, ∆Hmic of the prepared surfactants were calculated

according Omar et al [7,8] as shown in Table 3. ∆Gmic

Table 1. The physicochemical properties of the base oil.

Properties Base oil Test

Denisty (g/ml) at 15.5˚C 0.8958 D. 1298

Refactive index nD20 1.4955 D. 1218

ASTM colour 4.5 D. 1500

Kinematic viscoslty cSt

at 40˚C

at 100˚C

17.56

29.15

D. 445

D. 455

Pour point C 15 ASTM D 97

Molecular weight 520 GPC

Total paraffinic content, wr% 59.353 Urea adduction

Carbon residue contenty, wt% 1.9 ASTM D524

Ash content, wt% 0.0511 ASTM D482