Performance Characteristics of n-Butanol-Diesel Fuel Blend Fired in a Turbo-Charged Compression Ignition Engine

Copyright © 2013 SciRes. JPEE

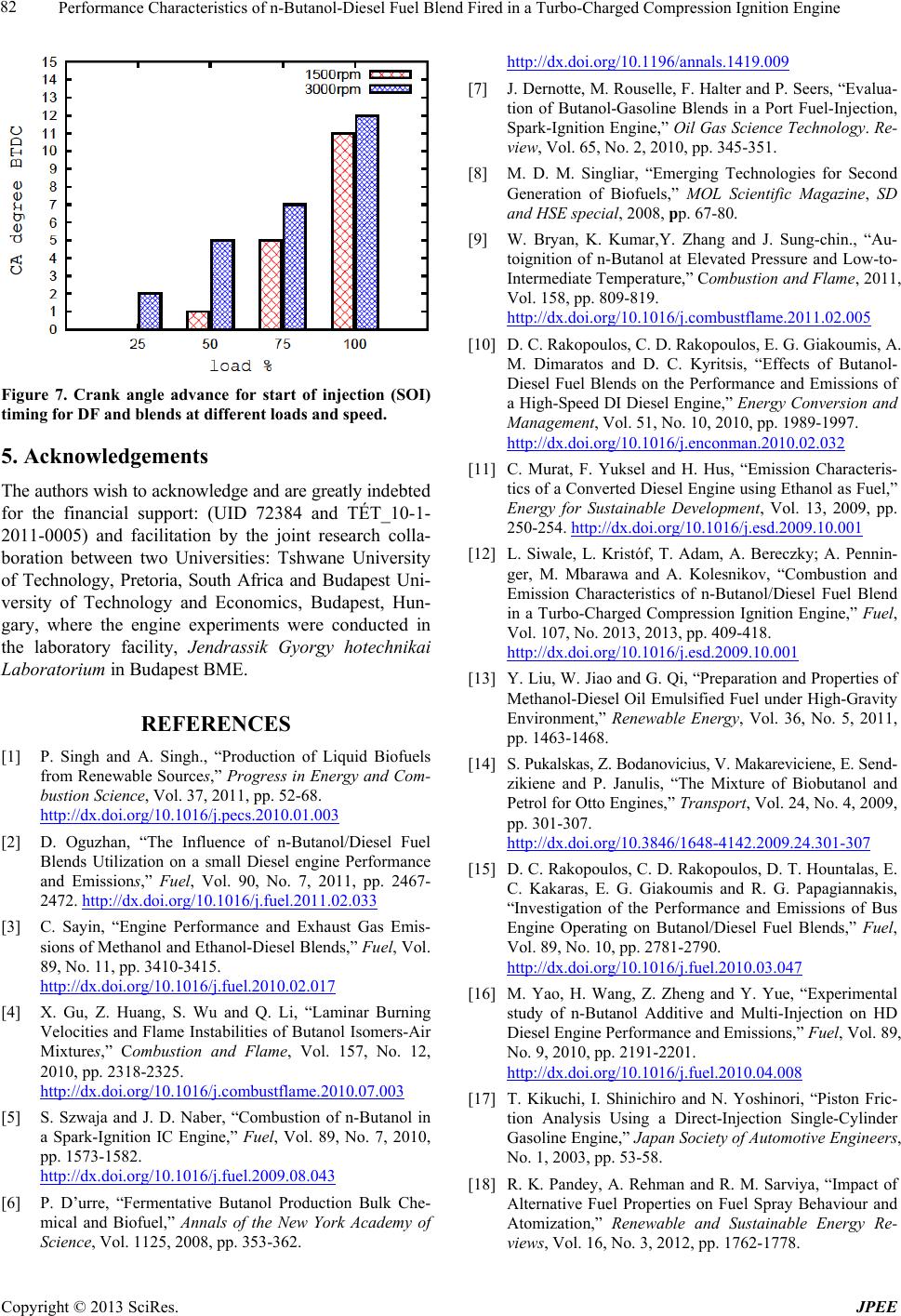

Figure 7. Crank angle advance for start of injection (SOI)

timing for DF and bl ends at different loads and speed.

5. Acknowledgements

The authors wish to acknowledge and are greatly indebted

for the financial support: (UID 72384 and TÉT_10-1-

2011-0005) and facilitation by the joint research colla-

boration between two Universities: Tshwane University

of Technology, Pretoria, South Africa and Budapest Uni-

versity of Technology and Economics, Budapest, Hun-

gary, where the engine experiments were conducted in

the laboratory facility, Jendrassik Gyorgy hotechnikai

Laboratorium in Budapest BME.

REFERENCES

[1] P. Singh and A. Singh., “Production of Liquid Biofuels

from Renewable Sources,” Progress in Energy and Com-

bustion Science , Vol. 37, 2011, pp. 52-68.

http://dx.doi.org/10.1016/j.pecs.2010.01.003

[2] D. Oguzhan, “The Influence of n-Butanol/Diesel Fuel

Blends Utilization on a small Diesel engine Performance

and Emissions,” Fuel, Vol. 90, No. 7, 2011, pp. 2467-

2472.

[3] C. Sayin, “Engine Performance and Exhaust Gas Emis-

sions of Methanol and Ethanol-Diesel Blends,” Fuel, Vol.

89, No. 11, pp. 3410-3415.

http://dx.doi.org/10.1016/j.fuel.2011.02.033

http://dx.doi.org/10.1016/j.fuel.2010.02.017

[4] X. Gu, Z. Huang, S. Wu and Q. Li, “Laminar Burning

Velocities and Flame Instabilities of Butanol Isomers-Air

Mixtures,” Combustion and Flame, Vol. 157, No. 12,

2010, pp. 2318-2325.

http://dx.doi.org/10.1016/j.combustflame.2010.07.003

[5] S. Szwaja and J. D. Naber, “Combustion of n-Butanol in

a Spark-Ignition IC Engine,” Fuel, Vol. 89, No. 7, 2010,

pp. 1573-1582.

[6] P. D’urre, “Fermentative Butanol Production Bulk Che-

mical and Biofuel,” Annals of the New York Academy of

Science, Vol. 1125, 2008, pp. 353-362.

http://dx.doi.org/10.1016/j.fuel.2009.08.043

http://dx.doi.org/10.1196/annals.1419.009

[7] J. Dernotte, M. Rouselle, F. Halter and P. Seers, “Evalua-

tion of Butanol-Gasoline Blends in a Port Fuel-Injection,

Spark-Ignition Engine,” Oil Gas Science Technology. Re-

view, Vol. 65, No. 2, 2010, pp. 345-351.

[8] M. D. M. Singliar, “Emerging Technologies for Second

Generation of Biofuels,” MOL Scientific Magazine, SD

and HSE special, 2008, pp. 67-80.

[9] W. Bryan, K. Kumar,Y. Zhang and J. Sung-chin., “Au-

toignition of n-Butanol at Elevated Pressure and Low-to-

Intermediate Temperature,” Combustion and Flame, 2011,

Vol. 158, pp. 809-819.

http://dx.doi.org/10.1016/j.combustflame.2011.02.005

[10] D. C. Rakopoulos, C. D. Rakopoulos, E. G. Giakoumis, A.

M. Dimaratos and D. C. Kyritsis, “Effects of Butanol-

Diesel Fuel Blends on the Performance and Emissions of

a High-Speed DI Diesel Engine,” Energy Conversion and

Management, Vol. 51, No. 10, 2010, pp. 1989-1997.

http://dx.doi.org/10.1016/j.enconman.2010.02.032

[11] C. Murat, F. Yuksel and H. Hus, “Emission Characteris-

tics of a Converted Diesel Engine using Ethanol as Fuel,”

Energy for Sustainable Development, Vol. 13, 2009, pp.

250-254.

[12] L. Siwale, L. Kristóf, T. Adam, A. Bereczky; A. Pennin-

ger, M. Mbarawa and A. Kolesnikov, “Combustion and

Emission Characteristics of n-Butanol/Diesel Fuel Blend

in a Turbo-Charged Compression Ignition Engine,” Fuel,

Vol. 107, No. 2013, 2013, pp. 409-418.

http://dx.doi.org/10.1016/j.esd.2009.10.001

http://dx.doi.org/10.1016/j.esd.2009.10.001

[13] Y. Liu, W. Jiao and G. Qi, “Preparation and Properties of

Methanol-Diesel Oil Emulsified Fuel under High-Gravity

Environment,” Renewable Energy, Vol. 36, No. 5, 2011,

pp. 1463-1468.

[14] S. Pukalskas, Z. Bodanovicius, V. Makareviciene, E. Send-

zikiene and P. Janulis, “The Mixture of Biobutanol and

Petrol for Otto Engines,” Transport, Vol. 24, No. 4, 2009,

pp. 301-307.

http://dx.doi.org/10.3846/1648-4142.2009.24.301-307

[15] D. C. Rakopoulos, C. D. Rakopoulos, D. T. Hountalas, E.

C. Kakaras, E. G. Giakoumis and R. G. Papagiannakis,

“Investigation of the Performance and Emissions of Bus

Engine Operating on Butanol/Diesel Fuel Blends,” Fuel,

Vol. 89, No. 10, pp. 2781-2790.

http://dx.doi.org/10.1016/j.fuel.2010.03.047

[16] M. Yao, H. Wang, Z. Zheng and Y. Yue, “Experimental

study of n-Butanol Additive and Multi-Injection on HD

Diesel Engine Performance and Emissions,” Fuel, Vol. 89,

No. 9, 2010, pp. 2191-2201.

http://dx.doi.org/10.1016/j.fuel.2010.04.008

[17] T. Kikuchi, I. Shinichiro and N. Yoshinori, “Piston Fric-

tion Analysis Using a Direct-Injection Single-Cylinder

Gasoline Engine,” Japan Society of Automotive Engineers,

No. 1, 2003, pp. 53-58.

[18] R. K. Pandey, A. Rehman and R. M. Sarviya, “Impact of

Alternative Fuel Properties on Fuel Spray Behaviour and

Atomization,” Renewable and Sustainable Energy Re-

views, Vol. 16, No. 3, 2012, pp. 1762-1778.