Agricultural Sciences

Vol.4 No.3(2013), Article ID:28908,7 pages DOI:10.4236/as.2013.43020

Effect of drip irrigation method, Nitrogen source, and flushing schedule on emitter clogging

![]()

Water Relation and Field Irrigation Department, National Research Center, Giza, Egypt; *Corresponding Author: mansourhani2011@gmail.com

Received 24 December 2012; revised 4 February 2013; accepted 20 February 2013

Keywords: Irrigation Method; Nitrogen Source; Flushing Number; Water and Soil Analysis; Emitter Clogging

ABSTRACT

Field experiments were carried out at the National Research Center farm, Nubaria area, Behura Governorate, Egypt, to study the effect of nitrogen source, flushing schedule and irrigation method on emitter clogging. Peanut Giza 5 variety (Arachishy pogaea L.) was planted in sandy soil during two successive growing seasons (2010-2011) in the 1st week of May and harvested after 130 days. Treatments used are: 1) two irrigation methods: surface drip irrigation and sub-surface drip irrigation (SDI; SSDI), 2) nitrogen source (NS):NH4NO3, (NH4)2SO4 and Ca(NO3)2 (NS1, NS2 and NS3) and 3) flushing number (FL) 0, 1 and 4 (FL1, FL2; FL3). The experiments design was split-split plot and three replicates were used. Data obtained were subjected to statistical analysis. The main effects of treatments used on clogging per cent could be written the following ascending orders: SDI wang#Bracket## SSDI, FL3 wang#Bracket## FL2 < FL1, NS1 < NS2 < NS3. Concerning the 1st interaction the following ascend- ing orders denote their effects on clogging percent: SDI × FL3 wang#Bracket## SDI × FL2 wang#Bracket## SDI × FL1, SDI × NS1 wang#Bracket## SDI × NS2 wang#Bracket## SDI × NS3, SSDI × FL3 wang#Bracket## SSDI × FL2 wang#Bracket## SSDI × FL1, SSDI × NS1 < SSDI × NS2 < SSDI × NS3, FL1 × NS1

1. INTRODUCTION

Due to water shortages in many parts of the world today, drip irrigation is becoming quite popular [1]. According to [2] fertigation has increased dramatically in the past 15 years, particularly for sprinkler and drip irrigation systems. He add that it will continue to grow since such systems result in less water usage, better uniformity and lend themselves to the modern technology much more readily than other irrigation methods.

[3] stated that although drip irrigation has many advantages, it also has some limitations. Emitters clogging are the most common one. Emitter clogging will increase the maintenance cost of drip irrigation systems [4], and reduce the working life and the use efficiency [5]. Therefore, As a result, emitter clogging is one of the key factors that determine whether drip irrigation systems can succeed [6]. [7] found that complete or partial blocking of drippers reduces the application uniformity of both water and fertilizers and negatively affects plant growth. [8] mentioned that effective fertigation program requires knowledge of:

1) Plant characteristics such as optimum daily nutrient consumption rate and root distribution in the soil;

2) Nutrient characteristics such as solubility and mobility;

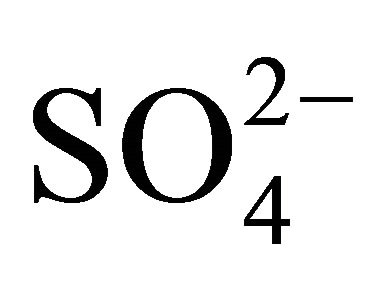

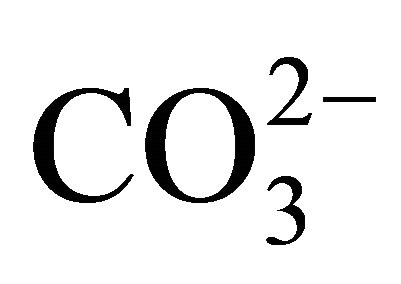

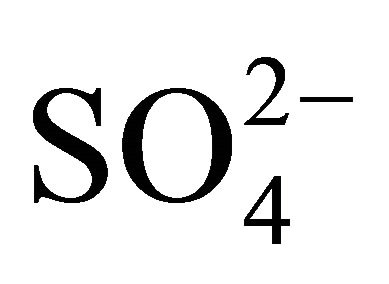

3) Irrigation water quality such as pH, total soluble ions of Ca2+, Mg2+, Na+, P, Fe2+, B,  ,

,  ,

,  and suspended solids;

and suspended solids;

4) No interaction will occur among fertilizers injected in the system and/or among fertilizers and irrigation water resulting in precipitates formation;

5) Fertigation is carried out properly and according to the regulation;

6) Good irrigation scheduling is used according to soil water holding capacity, profile depth, climate and grown crop;

7) Distribution uniformity of irrigation water is critical for uniform fertilizer application;

8) Over irrigation during fertigation not only wastes water but could leach fertilizers below the root zone and pollute ground water;

9) Be aware which injector type is used;

10) Under saline conditions, salinity problem can be intensified by fertigation and improper irrigation management;

11) Irrigation systems should be monitored more closely during fertigation process continuously if possible;

12) Be aware of cations-anions balance, selecting the correct nitrogen form used and fertilizer compatibility, and;

13) Be aware of flushing schedule of irrigation system components right away after fertigation.

[9] stated that successful fertigation requires precise calculation of injection rate, knowledge regarding solubility of different fertilizer components and basic know how of fertigation equipment’s. Emitter clogging may be due to physical, chemical and biological factors [10-14]. Two or more of these clogging reasons may occur at the same time [15,16]. Emitter clogging may be due their extreme small passages of water and low flow rate [7]. [17] stated that, more clogging emitters were found at the end of the drip laterals than at the beginning probably due pressure head loss. [18] found that normal fertilizers generally tend to clog the emitter. [19] carried a study on the effect of different fertigation practices on clogging of inline emitters using Samandag region well water in Turkey. Their data showed that different fertilizer treatments have significant effect on emitter clogging. Fertilizers containing both Ca2+ and  caused higher clogging compared with the others. [20] said that as water flow in irrigation system slows down and/ or the chemical background of the water changes, chemical precipitates and/or microbial flocks and slimes begin to form and grow, thus emitters clogging occurs. [21,22] studied the effect of injector types: by-bass pressurized tank (J1), venture injector (J2); positive displacement injector pump (J3), irrigation treatment: 50, 75; 100% Etc (I1, I2; I3) and nitrogen treatments 60, 90 and 120 kgN/fed (N1, N2; N3) and their interaction on emitter clogging percent. According to the values of emitter clogging percent, the treatments under investigation could be written in the following descending orders: J3 < J2 < J1, I3 < I2 < I1 and N1 < N2 < N3. They added that the interactions: J × I, J × N, I × N and J × I × N have significant effects at the 5% level on emitter clogging percent. The present research aimed to study the effect of nitrogen source, surface drip irrigation and subsurface drip irrigation systems and flushing schedule on emitter clogging.

caused higher clogging compared with the others. [20] said that as water flow in irrigation system slows down and/ or the chemical background of the water changes, chemical precipitates and/or microbial flocks and slimes begin to form and grow, thus emitters clogging occurs. [21,22] studied the effect of injector types: by-bass pressurized tank (J1), venture injector (J2); positive displacement injector pump (J3), irrigation treatment: 50, 75; 100% Etc (I1, I2; I3) and nitrogen treatments 60, 90 and 120 kgN/fed (N1, N2; N3) and their interaction on emitter clogging percent. According to the values of emitter clogging percent, the treatments under investigation could be written in the following descending orders: J3 < J2 < J1, I3 < I2 < I1 and N1 < N2 < N3. They added that the interactions: J × I, J × N, I × N and J × I × N have significant effects at the 5% level on emitter clogging percent. The present research aimed to study the effect of nitrogen source, surface drip irrigation and subsurface drip irrigation systems and flushing schedule on emitter clogging.

2. MATERIALS AND METHODS

Experiments were carried out at the Experimental Farm of the National Research Center at Nubaria, Behura Governorate, Egypt, in sandy soil.

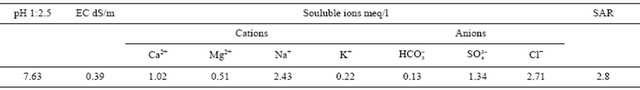

2.1. Irrigation Water Characteristics

The source of irrigation water at experimental site is well water (the total depth of wall: 45 m; water depth from ground surface: 4 - 5 m; and diameter of well: 6”). Screen filter (2”/2” inlet, outlet diam.; 35 m3/h discharge rate and filtration degree 120 mesh). Water sample was taken from the irrigation water to be analyzed. Table 1 shows the results of irrigation water analysis.

2.2. Fertilizer Injector (Venturi Injector)

A venturi injector is a tapered constriction which operates on the principle that a pressure drop accompanies the increase in velocity of the water as it passes through the constriction It was installed on a by-bass arrangement placed on an open container contained the fertilizer solution. The injector is constructed of a PE tube 1.5” in diameter. The venturi was devised by regulator valve which creates a differential pressure, thereby, allowing the injector to produce a vacuum. N and K2O fertilizers were injected in two doses. The irrigation and injection processes lasted 3 and 2 hours, respectively.

2.3. Experiment Layout and Treatments

Field experiments were conducted in growing seasons 2010/2011 in split plot design with three replications combined. Super phosphate (15.5% P2O5) was added at the rate of 200 kg/fed., using traditional method of fertilization application (broadcasting). This amount was divided into two doses (1st during soil preparation and 2nd after month from planting date). Giza 10 peanut seeds variety (Arachishy pogaea L.) were planted at the first week of May. The main plots were devoted to irrigation treatment. Two irrigation methods were used: surTable 1. Some chemical data of the irrigation water at Nubaria.

face drip irrigation and subsurface drip irrigation (SDI and SSDI). On the other hand, N fertilizer treatments occupied the sub-plots. Three sources of N-fertilizer namely:

NS1: NH4NO3, NS2: (NH4)2SO4 and NS3: Ca(NO3)2

The levels of nitrogen and potassium fertilizers (N and K2O) were 110 and 150 kg/fed., respectively as recommended by Ministry of Agriculture and Land Reclamation. Three methods of flushing: no flushing, one flushing, and a monthly flushing (FL1, FL2; FL3) during the irrigation period were used. Peanut crop was harvested at the second week of September (i.e. growing season lasted 130 days).

2.4. Emitters Clogging

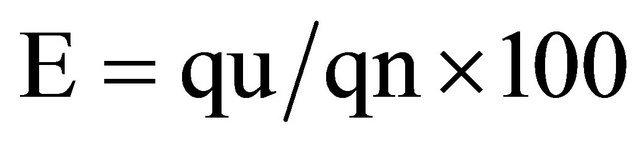

The flow cross section diameter of the long-path emitter was 0.7 mm; discharges 4 L/h lateral length was 30 m. Distance between emitter along the lateral was 50 cm. Subsurface drip irrigation laterals were put at the depth of 20 cm. The emitter is considered laminar-flow-type (Re < 2000) [23]. To estimate the emitter flow rate cans and a stopwatch were used. Nine emitters from each lateral had been chosen to be evaluated by calculating their clogging ratio at the beginning and at the end of the growing season for two seasons. Three emitters at the beginning, three at middle and threat the end of the lateral were tested for flow rate. Clogging ratio was calculated after [24] using the following equations:

(1)

(1)

(2)

(2)

where:

E = the emitter discharge efficiency (%)

qu = emitter discharge, at the end of the growing season (L/h)

qn = emitter discharge, at the beginning of the growing season (L/h)

CR = the emitter clogging ratio (%)

2.5. Statistical Analysis

All data collected were statistically analyzed as a splitsplit plot design with three replications using analysis of variance to evaluate main and interaction effects as described by [25]. Means among treatments were compared using Least Significant Difference (LSD) at P 0.05 probability.

3. RESULTS AND DISCUSSION

3.1. Main Effect of the Treatments on Emitter Clogging

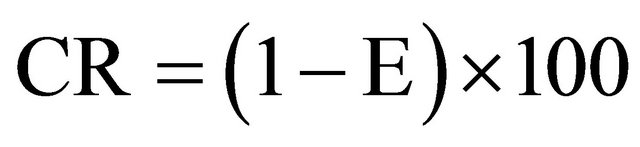

Table 2 showed the effect of treatments used:

Table 2. Main effect of irrigation system, flushing management and nitrogen source on clogging %.

1) Irrigation systems, surface drip irrigation and subsurface drip irrigation (SDI; SSDI)

2) Nitrogen source: NH4NO3, (NH4)2SO4 and Ca(NO3)2 (NS1, NS2 and NS3) and 3) Flushing number/season 0.1 and 4 (FL1, FL2; FL3).

According to the emitter clogging per cent values obtained, the treatments under investigation could be written the following ascending orders: SDI < SSDI, FL3 < FL2 < FL1, NS1 < NS2 < NS3. Differences in emitter clogging percent between any two treatments within the order were significant at the 5% level.

3.2. Effect of the Interactions on Emitter Clogging

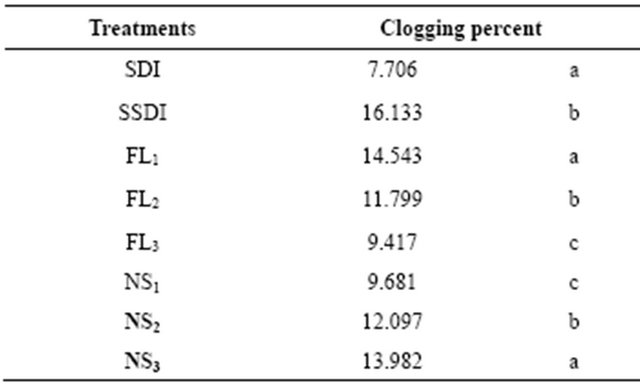

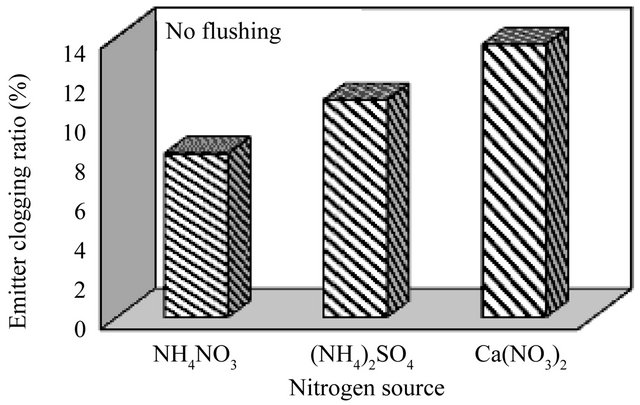

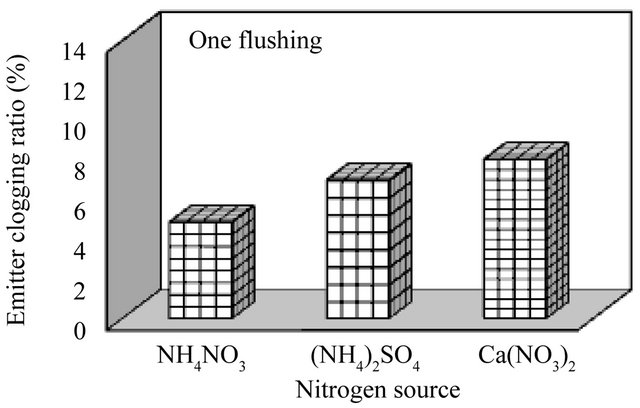

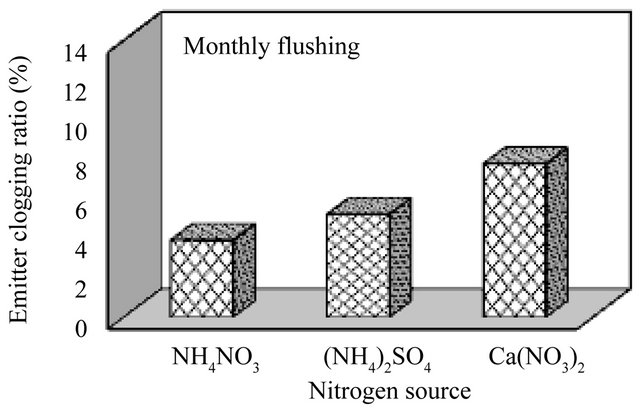

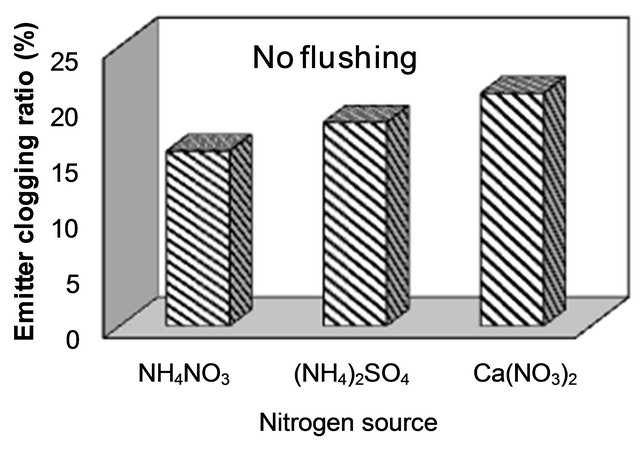

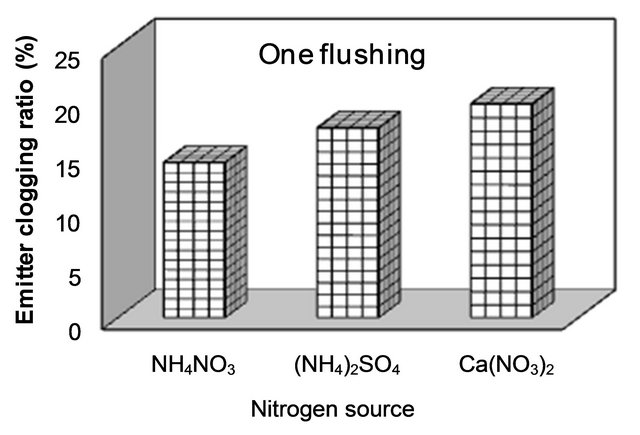

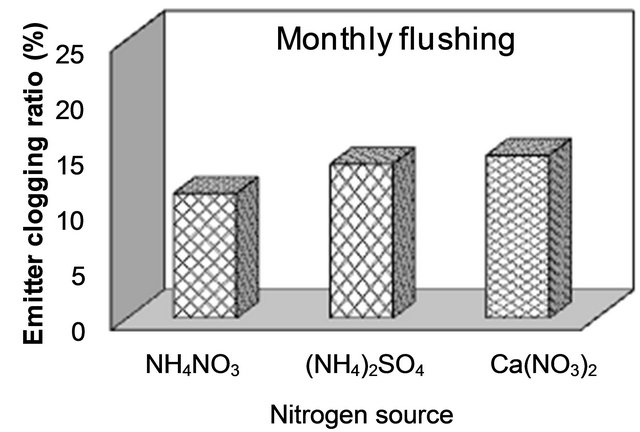

Table 3 and Figures 1 and 2 indicated the effect of the second interaction between and/or among treatments used on emitter clogging.

1) Under subsurface drip irrigation:

a) The effect of the SSDI × FL on emitter clogging percent is given in Table 3 and Figure 1. The following ascending orders: SSDI × FL3 < SSDI × FL2 < SSDI × FL1 illustrates the effect on emitter clogging regardless of NS usedb) The ascending order: SSDI × NS1 < SSDI × NS2 < SSDI × NS3 illustrated the effect on emitter clogging regardless of FL in Table 3 and Figure 2.

2) Under surface drip irrigation:

a) Due to the emitter clogging values, the interactions: SDI × FL. could be stated in the following ascending orders: SDI × FL3 < SDI × FL2 < SDI × FL1, regardless of NS used.

b) The effect of the interaction of SDI × NS on emitter clogging percent regardless of FL could be written in the following ascending orders: SDI × NS1 < SDI × NS2 < SDI × NS3.

c) Regardless of the irrigation method, the effect of the interactions FL × NS could be arranged in the follow ascending orders:

FL1 × NS1 < FL1 × NS2 < FL1 × NS3, FL2 × NS1 < FL2

Table 3. First and second interaction between irrigation system, flushing management and nitrogen source on clogging %.

Means with different letters within each column are significant at 5% level.

Figure 1. Effect of flushing management and nitrogen source on emitter clogging ratio (%) under surface drip irrigation.

Figure 2. Effect of flushing management and nitrogen source on emitter clogging ratio (%) under subsurface drip irrigation.

× NS2 < FL2 × NS3 and FL3 × NS1 < FL3 × NS2 < FL3 × NS3.

Differences in emitter clogging percent between any two interactions from those mentioned under the item were significant at the 5% level. This can be attributed to the presence of the ions: Ca2+, Mg2+,  ,

,  either in irrigation water or in injected fertilizer or in both leads to precipitates formation in the different irrigation system components in the following sequence: CaCO3, CaSO4 and MgSO4. Also increasing flushing numbers increases precipitates removal physically out of the irrigation system.

either in irrigation water or in injected fertilizer or in both leads to precipitates formation in the different irrigation system components in the following sequence: CaCO3, CaSO4 and MgSO4. Also increasing flushing numbers increases precipitates removal physically out of the irrigation system.

It is obvious that emitter clogging percent under SSDI exceeds that under the SDI (Figures 1 and 2).

This could be due to one or more of the following reasons:

1) Flushing processes are active under SDI relative to SSDI;

2) The ions Ca2+, Mg2+,  ,

,  and

and  in soil take part in precipitates formation on emitter outlets;

in soil take part in precipitates formation on emitter outlets;

3) The overburden pressure of soil layer on the lateral line under SSDI may cause partially deformation in the shape of their cross sections area increasing friction loss and subsequently decrease both pressure and water flow velocity [26] and [27];

4) Emitter discharge under SSDI can also decrease as a result of positive pressure in the soil water matrix creating a back pressure at the emitter orifice;

5) Also, biofilm formation is a primary problem in emitter clogging under SDI this problem is exacerbated under SSDI because external soil particles stocked to the biofilm at the emitter outlets increase clogging percent. It is expected that these soil particles would be siphoned back to the emitter inside when the irrigation system is shutdown for different reasons since the emitters used are non-pressure compensating ones [28];

6) Flushing process is less effective in biofilm remove without acidification and/or chlorination due to its low specific gravity and high adhesive characteristics [17] and [28];

7) Root intrusion of the crop and some weeds [29];

8) Water dissipation by emitter is negatively affected to some extent by soil resistance under SSDI;

9) More salts accumulated on the emitter outlets under SSDI due to both water loss via evaporation and water uptake by plant roots;

10) The micro changes in lateral level (up or down) decreases water flow in the laterals under SSDI and;

11) Many fine soil particles may find their way to the laterals inside due to digging, laying and covering processes.

3.3. Effect of the Second Interaction on Emitter Clogging

Table 3 indicates the effect of the second interaction I× NS × FL on emitter clogging. Differences in clogging percent between any two interactions were significant at the 5% level. According to the interaction under study, emitter clogging percent varied from 3.9 - 20.18. The maximum value of emitter clogging percent (20.18) and the minimum one (3.9) ware archived in the interactions SSDI × FL1 × NS3 and SDI × FL3 × NS1, respectively.

4. CONCLUSIONS

Field experiments were conducted on peanut Giza 5 crop grown in sandy soil at the National Research Center farm, Nubaria, Behura Governorate, Egypt, during two successive growing seasons 2010-2011 to study the effect nitrogen source, method of irrigation and number of irrigation system flushing/season on emitter clogging percent. Treatments used were: 110 kgN/fed. in the form of NH4NO3, (NH4)2SO4 and Ca(NO3)2 (NS1, NS2 and NS3), two irrigation methods: surface drip irrigation and subsurface drip irrigation (SDI; SSDI) and irrigation system flushing number per growing season 0, 1 and 4 (Fl1, Fl2; Fl3). Results obtained could be abbreviated in the following:

1) Concerning the main effect of the treatments used on emitter clogging percent, the following ascending orders indicate their roll SDI < SSDI, Fl3 < Fl2 < Fl1 and NS1 < NS2 < NS3. The differences in emitter clogging percent between any two treatments within the same order: were significant at the 5% level.

2) The effects of both the 1st and 2nd interactions on emitter clogging percent between and/or among treatments were significant at the 5% level.

3) Regardless of the source of the ions: Ca2+, Mg2+,  ,

,  and

and  (irrigation water, soil; fertilizers) we have to avoid their existence together within the irrigation system to prevent participates formation especially under arid and semi-arid climate.

(irrigation water, soil; fertilizers) we have to avoid their existence together within the irrigation system to prevent participates formation especially under arid and semi-arid climate.

4) The maximum value of emitter clogging (20.19%) and the minimum one (3.9%) were obtained in the following interactions: SSDI × Fl1 × NS3 and SDI × Fl3 × NS1, respectively.

5) Analysis of (soil, irrigation water; fertilizers) and injector type used are essential to deal with clogging problem.

6) Since emitter clogging under SSDI surpassed that under SDI, the SSDI have to be equipped with pressure compensating emitters and vacuum relieve valve.

![]()

![]()

REFERENCES

- Sahin, U., Anapal, O., Donmez, M.F. and Sahin, F. (2005) Biological treatment of clogged emitters in a drip irrigation system. Journal of Environmental Management, 76, 338-341. doi:10.1016/j.jenvman.2005.02.003

- Segars, B. (2010) Fertigation. Efficient Fertilizer Use Manual-Fertigation, 1-8.

- Bucks, D.A., Nakayama, F.S. and Gilbert, R.G. (1977) Clogging research on drip irrigation. Proceedings of the 4th Annual International Drip Irrigation Associate Meeting, Phoenix, October 1976, 25-31.

- Oron, G., Demalach, J., Hoffman, Z. and Cibotaru, R. (1991) Subsurface micro irrigation with effluent. Journal of Irrigation and Drainage Engineering (ASCE), 117, 25- 36. doi:10.1061/(ASCE)0733-9437(1991)117:1(25)

- Zhai, G.L., Lv, M.C., Wang, H. and Xiang, H.A. (1999) Plugging of micro irrigation system and its prevention. Transactions of the Chinese Society of Agricultural Engineering, 15, 144-147.

- Zhu, L.Y. and Cui, C.L. (2005) Discussion on problem of block-up in drip irrigation underground and its treatment. Research of Soil and Water Conservation, 12, 111-112.

- Dasberg, S. and Bresler, E. (1986) Drip irrigation manual. International Irrigation Information Center, Bet Dagan, 61 p.

- Charles, M. and Burt, P.E. (1997) Fertigation chemicals. Irrigation Training and Research Center (ITRC), California Polytechnic State University. www.itrc.org.P 97-001

- Fares, A. and Abbas, F. (2009) Injection rates and components of a fertigation system. College of Tropical Agriculture and Human Resources, University of Hawai at Manoa, Engineer’s Notebook, 1-4.

- Pillsbury, A.F. and Degan, A. (1975) Sprinkler irrigation. FAO, Agricultural Development Paper No. 88, Rome.

- Hills, D.J., Nawar, F.M. and Waller, P.M. (1989) Effect of chemical clogging on drip-tap irrigation uniformity. Transactions of the ASAE, 32, 1202-1206.

- Gilbert, R.G. and Ford, H.W. (1986) Operational principles emitters clogging. In: Nakayama, F.S. and Bucks, D.A. Eds., Trickle Irrigation for Crop Production, Elsevier Science, New York, 42-163.

- Ford, H.W. (1984) The problem of emitter clogging and methods for control. Citrus Ind., 46-52.

- Adin, A. (1987) Clogging in irrigation system reusing pond effluent and its prevention. Water Science and Technology, 19, 323-328.

- Bucks, D.A. and Nakayama, F.S. (1984) Problems to avoid with drip/trickle irrigation systems. Proceedings of the American Society of Civil Engineers Specially Conference on Irritation and Drainage Division, 24-84.

- De Troch, F. (1988) Irrigation and drainage. Ghent University, Ghent.

- Ravina, I., Paz, E., Sofer, Z., Marcu, A., Shisha, A., Sagi, G., Yechialy, Z. and Lev, Y. (1997) Control of clogging in drip irrigation with stored treated municipal sewage effluent. Agricultural Water Management, 33, 127-137. doi:10.1016/S0378-3774(96)01286-3

- Hebbar, S.S., Ramachandrappa, B.K., Nanjappa, H.V. and Prabhakar, M. (2004) Studies on NPK drip fertigation in field grown tomato (Lycopersiconesulentum Mill.) European Journal of Agronomy, 21, 117-127. doi:10.1016/S1161-0301(03)00091-1

- Ozekici, B. (1998) Clogging factors in drip irrigation systems. Final Report, University of Cukurova, Faculty of Agriculture, Department Research Project and C.U. Rectorate Research Fond BAP-TYS-95-06, Adana.

- Chang, C.A. (2008) Drip lines and emitters: Chlorination for disinfection and prevention of clogging. http://www.informaworld.com/smpp/content~content=a792065664~db=all~jumptype

- Tayel, M.Y., El-Gindy, A.M., El-Bagoury, K.F. and Sabreen, Kh. A. (2009) Effect of injector types, irrigation and nitrogen treatments on emitters clogging. Misr Journal of Agricultural Engineering, 23, 1263-1276.

- Sabreen, Kh. P. (2009) Fertigation technologies for improving the productivity of some vegetable crops. Ph.D. Thesis, Faculty of Agriculture, Ain Shams University.

- James, L.G. (1988) Principles of farm irrigation system design. Johan Wiley and Sons, Hoboken, 264-268.

- El-Berry, A.M., Bakeer, G.A. and Al-Weshali, A.M. (2003) The effect of water quality and aperture size on clogging of emitters. http://afeid.montpellier.cemagref.fr/Mpl2003/AtelierTechno/AtelierTechno/Papier%20Etier/N%C2%BO48%20-%20EGYPTE_BM.pdf

- Snedcor, G.W. and Cochran, W.G. (1982) Statistical methods. 7th Edition, The Iowa State University Press, Iowa.

- Tayel, M.Y., Mansour, H.A. and Lightfoot, D.A. (2012) Effect of different closed circuits and lateral lines length on: 1-pressure head and friction loss. Agricultural Sciences, 3, 392-399. doi:10.4236/as.2012.33046

- Tayel, M.Y., Mansour, H.A. and Lightfoot, D.A. (2012) Effect of different closed circuits and lateral lines length on: 2-flow velocity and velocity head. Agricultural Sciences, 3, 531-537. doi:10.4236/as.2012.34063

- Lamm, F.R. and Camp, R.C. (2007) Subsurface drip irrigation. In: Lamm, F.R., Ayars, J.E. and Nakayama, F.S., Eds., Microirrigation for Crop Production, Design, Operation, and Management, Elsevier, Amsterdam, 473-551. doi:10.1016/S0167-4137(07)80016-3

- Choi, C.Y. and Suarez-Rey, E.M. (2004) Subsurface drip irrigation for Bermuda grass with reclaimed water. Transactions of the ASAE, 47, 1943-1951.