Food and Nutrition Sciences

Vol.5 No.6(2014), Article ID:43599,9 pages DOI:10.4236/fns.2014.56060

Production of Traditional Sorghum Beer “Ikigage” Using Saccharomyces cerevisae, Lactobacillus fermentum and Issatckenkia orientalis as Starter Cultures

François Lyumugabe1,2*, Jeanne Primitive Uyisenga2, Emmanuel Bajyana Songa2, Philippe Thonart1

1Walloon Center of Industrial Biology (CWBI), Bio-Industry Unit, Gembloux Agro-Bio Tech, University of Liege, Liege, Belgium

2Biotechnology Unit, Faculty of Sciences, National University of Rwanda, Butare, Rwanda

Email: *flyumugabe@nur.ac.rw

Copyright © 2014 by authors and Scientific Research Publishing Inc.

This work is licensed under the Creative Commons Attribution International License (CC BY).

http://creativecommons.org/licenses/by/4.0/

Received 24 July 2013; revised 24 August 2013; accepted 31 August 2013

ABSTRACT

This study was carried out to evaluate the potential of the use of predominant yeast strains (Sacharomyces cerevisiae and Issatkenkia orientalis) and lactic acid bacteria (Lactobacillus fermentum) of Rwandese traditional sorghum beer “ikigage” as starter cultures to improve ikigage beer. The results show that L. fermentum has an influence on taste sour of ikigage beer and contributes also to generating ethyl acetate, ethyl lactate and higher alcohols such as 3-methylbutan-1-ol, 2-methylbutan-1-ol and 2-methylpropan-1-ol of this beer. I. orientalis contributed to the production of ethyl butyrate, ethyl caprylate, isobutyl butyrate and their corresponding acids, and to the generation of phenyl alcohols in ikigage beer. The association of S. cerevisiae with I. orientalis and L. fermentum produced ikigage beer with taste, aroma and mouth feel more similar to ikigage beers brewed locally by peasants. It is recommended to use S. cerevisiae in association with L. fermentum and I. orientalis as stater cultures to produce ikigage beer having the uniform organoleptic characteristics and a high ethanol content. This method also reduces the risk of contamination of the brew with food sanitary indicator and pathogenic microorganisms and will increase the chance of preservation of ikigage beer.

Keywords:Sorghum Beer; Ikigage; Saccharomyces cerevisiae; Issatckenkia orientalis; Lactobacillus fermentum

1. Introduction

Fermented foods make up an important contribution to the human diet in many countries because fermentation is an inexpensive technology which preserves food, improves its nutritional value and enhances its sensory properties [1] [2] . Fermentation has also the potential of enhancing food safety by controlling the growth and multiplication of a number of pathogens in foods. Its importance in modern-day life is underlined by the wide spectrum of fermented foods marketed both in developing and industrialized countries [3] .

In sub-Saharan African countries, traditional fermented beverages such as ikigage [4] , tchoukoutou [5] , dolo [6] , pito [7] , bili bili [8] and merissa [9] are prepared from sorghum and/or millet malts. The fermentation of these beverages is uncontrolled and the microorganisms that intervene come from the raw materials, equipment and local environments or from residues of previous fermentation batch. These microorganisms, by virtue of their metabolic activities, play an active role in physical, nutritional and organoleptic modification of starting material [10] . However, the wide variety of microorganisms present in a spontaneously fermented food gives a product with widely varying quality.

The use of starter cultures was proposed like a suitable approach to improving the African traditional fermented food [11] [12] . The use of suitable starter improves the fermentation process, facilitates the control over the initial phase of fermentation and the predictability of derivatives products [3] [12] . Similarly, the hygienic quality and the acceptability of African traditional food could be improved with the use of adequate starter [13] . The use of starter cultures also reduces the organoleptic variations and the microbiological instability of African fermented food [11] . The use of S. cerevisiae in combination with Lactobacillus plantarum as starter cultures was also used successfully for the production of “pito” sorghum beer having testa and aroma similar to that of the local pito beer [14] . Recently, N’Guessan et al. [15] used successfully S. cerevisiae and Candida tropicalis as starter cultures for the alcoholic fermentation of “tchapalo” sorghum beer.

Ikigage is a popular traditional fermented beverage in Rwanda and specially appreciated in various festivals and ceremonies (e.g., marriage, birth, baptism, dowery, etc.). But ikigage beer is declining because of poor hygienic quality, organoleptic variations and unsatisfactory conservation [4] . The fermentation of this beer is started by a traditional leaven “umusemburo”, resulting from a previous spontaneous fermentation of sorghum wort. The dominant microorganisms involved in this fermentation have been identified as being yeasts (Saccharomyces cerevisiae and Issatckenkia orientalis) and lactic acid bacteria (Lactobacillus fermentum) [4] . The aim of the present study was to investigate the use of S. cerevisiae, I. orientalis and L. fermentum as starter cultures to produce ikigage beer of acceptable and consistent quality. Microbiological, physico-chemical, volatile compounds and organoleptic characteristics of pilot ikigage beers were compared to commercial ikigage beer from peasants.

2. Materials and Methods

2.1. Malting

The red sorghum grains (Kigufi variety) and Eleusine coracana “uburo” grains (Musama variety) were obtained from Rubona and Musanze stations of Rwanda Agriculture Board (RAB). The grains were sorted manually to remove broken kernels and debris and then used for malting. The grains selected for malting (5 kg) were steeped in distilled water (10 L) at 25˚C for 24 h. Before and after steeping, grains were sterilized by immersion in sodium hypoclorite solution (1% wt/v). After rinsing with sterile distilled water as described elsewhere [16] , the grains were germinated at 30˚C for 3 days and then kilned at 50˚C for 24 h. The shoots and rootlets were removed manually and the malt kernels were ground in a hammer mill to pass through a sieve of pore size 1.0 mm.

2.2. Wort Production

The wort was produced by decantation mashing procedure developed for sorghum [17] [18] . 3.5 kg of milled malt (70% sorghum and 30% Eleusine coracana) were mixed with 12 L distilled water at 45˚C and left in decantation during 30 min. Thereafter, 6 L of the clear “enzymatic supernatant” was removed while a mash residue was heated at 90˚C for 30 min to gelatinize malt starch. After cooling below 50˚C, the clear “enzymatic supernatant” was re-added and then the mixture was brewed according to the following mashing program: 1 h at 63˚C, 10 min at 75˚C and cooled to 30˚C. The filtration was very poor so the mash was centrifuged at 4000 × g for 5 min and then the filtrate was heated until boiling for 1 h. The leaves of Vernonia amygdalina (2 g/L) were added 10 min before the end of boiling.

2.3. Yeast and Lactic acid Bacteria Strains

Two yeast strains (Saccharomyces cerevisiae RV6 and Issatckenkia orientalis RG1) and lactic acid bacteria strain (Lactobacillius fermentum CWBI-B552) used as starter cultures in this work were obtained from culture collection of Walloon Center of Industrial Biology (CWBI-Gemboux, Belgium). These strains were isolated from Rwandese traditional leaven “Umusemburo”.

2.4. Preparation of Starter Culture

S. cerevisiae RV6 and I. orientalis RG1 strains were each sub-cultured on Yeast extract dextrose peptone (YEPD) agar at 30˚C for 48 h and then by successive sub-culturing on YEPD broth at 30˚C for 24 h and 18 h, respectively. L. fermentum CWBI-B552 strain culture was sub-cultured at 37˚C for 48 h on Man-RogosaSharpe (MRS) agar followed by two successive rounds of sub-culturing in MRS broth with incubation at 37˚C for 24 h and 16 h, respectively. Yeast and LAB strains were each harvested by centrifugation at 4000 × g for 20 min and pellets were added in 50 ml of sterile sorghum worts and then incubated at 30˚C for 24 h in order to initiate fermentation. The cell concentrations were checked using a Bürker counting cell.

2.5. Fermentation

Seven or ten liters of sterile wort were transferred into fermenter kit (30 L, Brewferm, Belgium), equipped with airlock bubbler and tap, and pitched with starter cultures to obtain 106 cfu/mL followed by the incubation at 30˚C for 72 h. In parallel, 2 L sterile wort transferred into sterile Erlenmeyer flasks (5 L) were pitched with L. fermentum culture to obtain 107 cfu/mL, and then incubated at 30˚C for 22 h and again boiled (30 min) and cooled. Four fermentation systems were constituted as follows:

1) 10 L wort was inoculated with S. cerevisaie alone or I. orientalis alone;

2) 10 L wort was inoculated with S. cerevisaie (60%) in combination with L. fermentum (40%);

3) 10 L wort was inoculated with S. cerevisaie (60%) in combination with I. orientalis (40%).

2.6. Enumeration of Microorganisms

Duplicate aliquots of ikigage beer (10 mL) were diluted in 90 mL sterile peptone physiological saline solution (5 g peptone, 8.5 g NaCl, and 1000 mL distilled water, pH = 7.0) and homogenised. Decimal dilutions were plated. Total counts of aerobic mesophilic flora, yeasts, Lactic acid bacteria (LAB), coliform, Escherichia coli, fecal streptococci and Staphylococcus aureus were enumerated as described by Lyumugabe et al. [4] .

2.7. Physicochemical Analysis

The pH was measured using a pH meter 781 (Metrohm Herisau). Titratables acidity, expressed as a percentage lactic acid, was determined by titrating the samples with 0.1 N NaOH. Ethanol was determined by enzymatic method using the Boehringer Kit (R-Biopharm AG, D-64293 Darmastadt). The reducing sugars (glucose, maltose and maltotriose) were determined by High-Performance Liquid Chromatography (HPLC) on an Agilent 1100 series apparatus (Agilent Technologies, Massy, France) equipped with a refractometric detector. Sugars were separated on a C-610-H ion exchange column (300 mm × 7.8 mm, supelco, Bellefonte, PA) preceded by a pre-column H (5 cm × 4.6 mm, supelco, Bellefonte, PA).

2.8. Determination of Volatile Compounds

The analysis of the volatile compounds of ikigage beers was performed with Headspace solid phase microextraction (HS -SPME) and an Agilent 7890 GC system equipped with a 5975 C. inert XL EI/ CI. Mass Selective Detector (Agilent Technologies, Santa Clara, CA, USA). The samples analyzed were extracted using a 50/30 μm divinylbenzene/carboxen/polydimethylsiloxane (DVB/CAR/PDMS) fiber (Supelco, Inc., Bellefonte, PA). 10 ml of beer were enclosed in a 20 mL SPME glass vial together with 2.5 g of sodium chloride and 5 μL of the internal standard 3-octanol (100 mg/L in absolute ethanol). The samples were equilibrated at 40˚C for 10 min and then the fiber was exposed in the headspace of the vial for 30 min and the extracted analytes from fiber were automatically desorbed in injection port of the GC-MS system at 250˚C. A HP—5 ms column (30 m × 0.25 mm I.D) with a film thickness of 0.25 mm was applied to extract the volatile compounds from the headspace of above-prepared glass vial. The GC was equipped with a split—splitless injector which was held at 250˚C. After starting at 30˚C, the oven temperature was raised in 3 steps after 2 min: 30˚C - 70˚C at 10˚C/min followed by 1 min at 70˚C; 70˚C - 220˚C at 4˚C/min and 220˚C - 280˚C at 20˚C/min and was finally held at 280˚C for 6 min. During this program a constant flow rate (1.0 mL/min) of the carrier gas (Helium) was maintained. Mass spectra were obtained by electronic impact (E.I) scan mode (Low mass: 30.0; High mass: 500.0; Threshold: 150) and temperature source (230˚C) were generated. The identification was achieved by comparing mass spectra obtained from the sample with those from the NIST and Pal1600k.L. libraries Database and by comparing the kovats index estimated for each compounds on both chromatographic column with the values given in the literature [19] (www.pherobase.com/database/kovats). Selective ion monitoring was used for the integrations of all chromatogram peaks and the semi-quantitative concentrations of volatiles in ikigage beers were calculated according to the method proposed by Zhao et al. [20] .

3. Results and Discussion

3.1. Physicochemical and Microbiological Characteristics of Sorghum Beer “Ikigage”

The pH, total acidity (expressed as lactic acid), reducing sugars and ethanol content of pilot ikigage beers produced with starter cultures are given in Table 1. Pilot ikigage beers produced with S. cerevisiae in combination with L. fermentum or S. cervisiae in combination with I. orientalis and L. fermentum have pH and total acidity more similar to commercial ikigage beer from peasants than those produced without association of L. fermentum. Higher ethanol content and lower reducing sugars were observed in ikigage produced with S. cerevisiae in combination with I. orientalis following by ikigage produced with S. cerevisiae alone and ikigage obtained by the association of S. cerevisiae with I. orientatilis and L. fermentum. Except I. orientalis, all starter cultures used produced higher ethanol content than that observed in local ikigage beers from peasants. Contrary to ikigage beers from peasants, S. aureus and the food sanitary microorganisms were absents in pilot ikigage beers made with starter cultures.

The production of lactic acid by LAB can explain the lower and higher total acidity values observed in ikigage beers produced by peasants and those produced with association of L. fermentum. The similar total acidity level and low pH value were also observed by Orji et al. [14] in Nigerian traditional sorghum pito beers produced by Lactobacillus plantarum in combination with S. cerevisiae. Light increase of ethanol content obtained with S. cerevisiae in combination with I. orientalis compared to S. cerevisiae alone shown that I. orientalis could have to play an influence, for example by facilitating the synthesis of α-glucosidase by the fast glucose consumption, on maltose and maltotriose fermentation by S. cerevisiae.

Lower ethanol content obtained with I. orientalis alone could be explained by the no maltose fermentation by this yeast strain. Similar studies on fermentation of grape wort [21] reported also that I. orientalis produced a low ethanol content compared to S. cerevisae, but when the co-fermentation of S. cerevisaie and I. orientalis

Table 1. Physicochemical and microbiological characteristics of sorghum beers “ikigage”.

*SC: S. cerevisiae alone; IO: I. orientalis alone; SCIO: S. cerevisiae in combination with I. orientalis; SCLF: S. cerevisiae in combination with L. fermentum; SCIOLF: S. cervisiae in association with I. orientalis and L. fermentum; Ikp: traditional ikigage beer from local peasants.

were used, the ethanol production and reducing sugars consumption were similar to those obtained by S. cerevisiae alone.

3.2. Volatile Compounds of Sorghum Beer “Ikigage”

The results of GC-MS analyses of the volatile compounds obtained from the pilot ikigage beers produced with starter cultures and traditional sorghum beers ikigage made by peasants are outlined in Table 2. Traditional sorghum beer ikigage made by peasants differs from those produced in laboratory with starter cultures by relatively high concentrations of certain alcohols (propan-1-ol, 2-methylpropan-1-ol and 2,3-butanediol), esters (ethyl acetate, isobutyl acetate, propyl acetate, ethyl lactate and ethyl valerate), acids (acetic acid and heptanoic acid) and carbonyls (acetaldehyde). These compounds were also found in great quantity in the ikigage beers produced with S. cerevisiae in association with L. fermentum and I. orientalis.

High concentrations of 3-methylbutan-1-ol, 2-methylbutan-1-ol, ethyl acetate, acetic acid and ethyl lactate were also observed in the ikigage beers produced with S. cerevisiae in combination of L. fermentum without association of I. orientalis. However, ikigage beers produced with I. orientalis alone or in combination with S. cerevisiae were characterized by high concentration of ethyl butyrate, ethyl caprylate, isobutyl butyrate, ethyl nonanoate, ethyl dec-9-enoate, 3-methylbutyl decanoate, capric acid, butyric acid and 2-phenyl alcohols. These compounds were also found in great quantity in the ikigage beers produced with S. cerevisiae in association with L. fermentum and I. orientalis. High concentrations of 3-methylbutan-1-ol, 2-methylbutan-1-ol, ethyl acetate, acetic acid and ethyl lactate were also observed in the ikigage beers produced with S. cerevisiae in combination of L. fermentum without association of I. orientalis. However, ikigage beers produced with I. orientalis alone or in combination with S. cerevisiae were characterized by high concentration of ethyl butyrate, ethyl caprylate, isobutyl butyrate, ethyl nonanoate, ethyl dec-9-enoate, 3-methylbutyl decanoate, capric acid, butyric acid and 2- phenyl alcohols. Ethyl acetate (and its corresponding acid) and ethyl lactate were also considered as some of the main bacterial volatile compounds [22] , and the high concentrations were found in the ikigage beers produced by association of triple strains (S. cerevisiae, I. orientalis and L. fermentum). As Belgian Lambic and gueuze beers [23] , ethyl acetate, ethyl lactate and ethyl caprylate can be the characteristic compounds of ikigage beer. Important amounts of ethyl butyrate (and its corresponding acid) found when I. orientalis is used, were also observed in a Bavarian pilsner-type beer, where this odorant was suggested one of the key contributors to the overall aroma [24] .

The high concentration of 3-methylbutan-1-ol, 2-methylbutan-1-ol and 2-methylpropan-1-ol, observed in ikigage beers from peasants and those produced when L. fermentum was associated, were also found in fermented dough with mixed culture of L. fermentum and S. cerevisiae [25] . This observation can be explained by the amino acids released by the proteolytic activity of lactic acid bacteria and their use by S. cerevisiae [26] . Phenethyl alcohol, known to have intense odour of roses and a burning taste, is produced by enzymatic conversion of phenylalanine by yeast cells, particularly by S. cerevisiae [27] , but in this work, I. orientalis seems to produce high concentration of this compound more than S. cerevisiae.

3.3. Sensory Characteristics of Sorghum Beer “Ikigage”

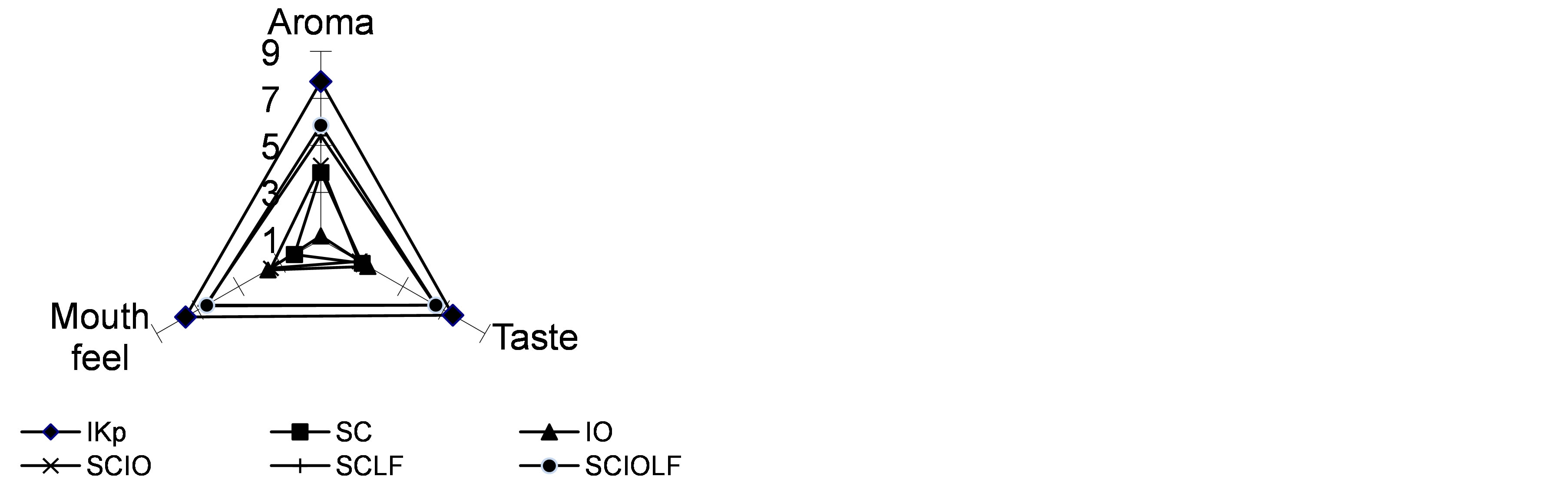

The results of sensory evaluation of ikigage beers produced with starter cultures are indicated in Figure 1. These results shown that ikigage beers produced with S. cerevisiae in association with I. orientalis and L. fermentum, following those produced with S. cerevisia in co-cultures with L. fermutum, have the taste, aroma and mouth feel much more similar to that the ikigage beer brewed locally by peasants. S. cervisiae in co-cultures with I. orientalis produced ikigage beers with aroma is also more comparable to local ikigage beers than S. cerevisiae or I. orientalis alone.

The lack of sour taste in the ikigage produced without L. fermentum may explain their unacceptability by the consumer panelists. The ikigage beers are characterized by the sour taste due to acidity produced during fermentation, mainly by L. fermentum. However, the acidity produced by I. orientalis may have contributed also to the taste and mouth feel of ikigage beers. By comparing the aroma scores with the volatile compounds observed in this work, it is obvious that esters and alcohols have contributed to the similarity between aroma of ikigage beers produced with the mixture cultures and those produced locally by peasants. Other studies reported also that the sour taste of Nigerian sorghum pito beers [7] [14] and kaffir sorghum beer of South Africa [28] was due to the lactic acid produced by the lactic acid bacteria during the fermentation.

Table 2. Volatile compounds of traditional sorghum beer ikigage.

Continued

IKp: traditional sorghum beer ikigage made by Rwandese peasants. SC: pilot ikigage beer made with S. cerevisiae alone; IO: pilot ikigage beer made with I. orientalis alone; SCIO: pilot ikigage beer made with S. cerevisiae in combination with I. orientalis. SCLF: pilot ikigage beer made with S. cerevisiae in combination with L. fermentum. SCIOLF: pilot ikigage beer made with S. cervisaie in association with I. orientalis and L. fermentum. aID: Identified by mass spectra (MS) and by comparison of retention index (RI on HP—5 ms) calculated and retention index from literature (RIL); bIdentification confirmed by pure standard injection.

Figure 1. Sensory evaluation of sorghum beers “ikigage”. 1: extremely different. 9: not different. IKp: traditional sorghum beer ikigage made by Rwandese peasants. SC: pilot ikigage beer made with S. cerevisiae alone; IO: pilot ikigage beer made with I. orientalis alone; SCIO: pilot ikigage beer made with S. cerevisiae in combination with I. orientalis. SCLF: pilot ikigage beer made with S. cerevisiae in combination with L. fermentum. SCIOLF: pilot ikigage beer made with S. cervisaie in association with I. orientalis and L. fermentum.

4. Conclusion

The present study has provided information on the use of S. cerevisiae, I. orientalis and L. fermentum as starter cultures for the production of Rwandese traditional sorghum beers “ikigage”. L. fermentum has an influence on sour taste of ikigage beer and contributes also to generating ethyl acetate, ethyl lactate and higher alcohols such as 3-methylbutan-1-ol, 2-methylbutan-1-ol and 2-methylpropan-1-ol of this beer. I. orientalis contributed to the production of ethyl butyrate, ethyl caprylate, isobutyl butyrate and their corresponding acids, and to generation of phenyl alcohols in ikigage beers. S. cerevisiae in co-culture with I. orientalis produced higher ethanol than S. cerevisiae alone or I. orientalis alone. The association of S. cerevisiae with I. orientalis and L. fermentum produced ikigage beer with taste, aroma and mouth feel much more similar to that of ikigage beer brewed locally by peasants. It is recommended to use S. cerevisiae in association with I. orientalis and L. fermentum as starter cultures to produce ikigage beer having the uniform organoleptic characteristics and a high ethanol content. This method also reduces the risk of contamination of the brew with food sanitary indicator and pathogenic microorganisms and will increase the chance of the conservation of ikigage beer. However, complementary studies on ikigage beer conservation are needed.

Acknowledgements

The authors thank the Walloon Center of Industrial Biology (CWBI) and Research Commission of National University of Rwanda (NUR) for their financial support.

References

- Murty, D.S. and Kumar, K.A. (1995) Traditional Uses of Sorghum and Millets. In: Dendy, D.A.V., Ed., Sorghum and millets: Chemistry and Technology, American Association of Cereal Chemists, St. Paul, 185-221.

- Steinkraus, K.H. (1996) Handbook of Indigenous Fermented Foods. 2nd Edition, Marcel Dekker, Inc., New York.

- Holzapfel, W. (1997) Use of Starter Cultures in Fermentation on a Household Scale. Food Control, 8, 241-258. http://dx.doi.org/10.1016/S0956-7135(97)00017-0

- Lyumugabe, F., Kamaliza, G., Bajyana, E. and Thonart, P.H. (2010) Microbiological and Physico-Chemical Characteristic of Rwandese Traditional Beer Ikigage. African Journal of. Biotechnology, 9, 4241-4246.

- Kayodé, A.P.P., Aégbidi, A., Linnemenn, A.R., Nout, M.J.R. and Hounhouigana, J.D. (2005) Quality of Farmer’s Varieties of Sorghum and Derived Foods as Perceived by Consumers in Benin. Ecology and Food Nutrition, 44, 271-294. http://dx.doi.org/10.1080/03670240500187302

- Dicko, M.H., Gruppen, H., Traoré1, A.S., Voragen, A.G.J. and Van Berkel, W.J.H. (2006) Sorghum Grain as Human Food in Africa: Relevance of Content of Starch and Amylase Activities. African Journal of Biotechnology, 5, 384-395.

- Ekundayo, J.A. (1969) The Production of Pito, a Nigerian Fermented Beverage. Journal of Food Technology, 4, 217- 225. http://dx.doi.org/10.1111/j.1365-2621.1969.tb01517.x

- Maoura, N., Mbaiguinam, M., Nguyen, H.V., Gaillardin, C. and Pourquie, J. (2005) Identification and Typing of the Yeast Strains Isolated from Bili, a Traditional Sorghum Beer of Chad. African Journal of Biotechnology, 4, 646-656.

- Dirar, H.A. (1978) A Microbiological Study of Sudanese Merissa Brewing. Journal of Food Sciences, 43, 163-168. http://dx.doi.org/10.1111/j.1365-2621.1978.tb07388.x

- Aido, K.E. (1994) Application of Biotechnology to Indigenous Fermented Foods. Proc. Tehnol. Dev. Countries, 12, 83-94.

- Kirmaryo, V.M., Massawe, G.A., Olasupo, N.A. and Hololzpfel, W.H. (2000) The Use of a Starter Culture in the Fermentation of Cassava for the Production of “Kivunde”, a Traditional Tanzanian Food Product. International Journal of Food Microbiology, 56, 179-190. http://dx.doi.org/10.1016/S0168-1605(00)00159-8

- Holzapfel, W.H. (2002) Appropriate Starter Culture Technologies for Small-Scale Fermentation in Developing Countries. International Journal of Food Microbiology, 75, 197-212. http://dx.doi.org/10.1016/S0168-1605(01)00707-3

- Gran, H.M., Gadaga, H.T. and Narbhus, J.A. (2003) Utilization of Various Starter Cultures in the Product of Amasi, a Zimbabwean Naturally Fermented Raw Milk Product. International Journal of Food Microbiology, 88, 19-28. http://dx.doi.org/10.1016/S0168-1605(03)00078-3

- Orji, M.U., Mbata, T.I., Anich, G.N. and Ahonkhai, I. (2003) The Use of Starter Cultures to Produce “pito”, a Nigerian Fermented Alcoholic Beverage. World Journal of Microbiology and Biotechnology, 19, 733-736. http://dx.doi.org/10.1023/A:1025172506965

- N’guessan, F.K., N’diri, D.Y., Camara, F. and Djè, M.K. (2010) Saccharomyces cerevisiae and Candida tropicalis as Starter Cultures for the Alcoholic Fermentation of Tchapalo, a Traditional Sorghum Beer. World Journal Microbiology and Biotechnelogy, 26, 693-699. http://dx.doi.org/10.1007/s11274-009-0224-y

- Ezeogu, L.I. and Okolo, B.N. (1995) Effects of Air Rest Periods on Malting Sorghum Response to Final Warm Water Steep. Journal of Institute and Brewing, 101, 39-45. http://dx.doi.org/10.1002/j.2050-0416.1995.tb00848.x

- Palmer, G.H. (1989) Cereals in Malting and Brewing. In: Palmer G. H., Ed., Cereal Science and Technology, Aberdeen University Press, Aberdeen, 61-242.

- Igyor, M.A., Ogbonna, A.C. and Palmer, G.H. (2001) Effect of Malting Temperature and Mashing Methods on Sorghum Wort Composition and Beer Flavor. Process Biochemistry, 36, 1039-1044. http://dx.doi.org/10.1016/S0032-9592(00)00267-3

- Pino, J.A., Marquez, E., Quijano, C.E. and Castro, D. (2010) Volatile Compounds in Noni (Morinda citrifolia L.) at Two Ripening Stages. Ciência e Tecnologia de Alimentos, Campinas, 3, 183-187.

- Zhao, Y.P., Xu, Y., Li, J.M., Fan, W.L., and Jiang, W.G. (2009) Profile of Volatile Compounds in 11 Brandies by Headspace Solid-Phase Microextraction Followed by Gas Chromatography-Mass Spectrometry. Journal of Food Sciences, 74, 90-99. http://dx.doi.org/10.1111/j.1750-3841.2008.01029.x

- Kim, D., Hong, Y. and Park, H. (2008) Co-Fermentation of Grape Must by Issatchenkia orientalis and Saccharomyces cerevisiae Reduces the Malic Acid Content in Wine. Biotechnology Letter, 30, 1633-1638. http://dx.doi.org/10.1007/s10529-008-9726-1

- Damiani, P., Gobbetti, M., Cossignani, L., Corsetti, A., Simonetti, M.S. and Rossi, J. (1996) The Sourdough Microflora. Characterization of Heteroand Homofermentative Lactic Acid Bacteria, Yeasts and Their Interactions on the Basis of the Volatile Compounds Produced. Lebensmittel-Wissenschaft & Technologie, 29, 63-70.

- Spaepen, M., Vanoevelen, D. and Verachtert, H. (1978) Fatty-Acids and Esters Produced during Spontaneous Fermentation of Lambic and Gueuze. Journal of Institute of Brewing, 84, 278-282. http://dx.doi.org/10.1002/j.2050-0416.1978.tb03888.x

- Fritsch, H.T. and Schieberle, P. (2005) Identification Based on Quantitative Measurements and Aroma Recombination of the Character Impact Odorants in a Bavarian Pilsner—Type Beer. Journal of Agriculture and Foods Chemistry, 53, 7544-7551.

- Annan, N.T., Poll, L. and Sefa-Dedeh, S. (2003) Influence of Starter Culture Combinations of Lactobacillus fermentum, Saccharomyces cerevisiae and Candida krusei on Aroma in Ghanaian Maize Dough Fermentation. European Food Research and Technology, 216, 3377-3384.

- Spicher, G. and Nierle, W. (1988) Proteolytic Activity of Sourdough Bacteria. Applied Microbiology and Biotechnology, 28, 487-492. http://dx.doi.org/10.1007/BF00268220

- Stam, H., Hoogland, M. and Laane, C. (1997) Food Flavours from Yeast. In: Wood, B.J.B., Microbiology of Fermented Foods (2nd Ed.), Blackie Academic & Professional, London, 505-542.

NOTES

*Corresponding author.