Journal of Applied Mathematics and Physics

Vol.04 No.10(2016), Article ID:71308,10 pages

10.4236/jamp.2016.410190

High Quality of Piezoelectric Response of Nano Ni Doped Pb1−xNixTiO3 Ceramic

A. Tawfik1, O. M. Hemeda1, D. M. Hemeda1, M. Barakat1, M. M. El-Shahawy1, R. Shady1,2*

1Department Physics, Faculty of Science, Tanta University, Tanta, Egypt

2Department Physics, Oklat Al-Skoor College of Science & Arts, Qassim University, Qassim, Kingdom of Saudi Arabia

Copyright © 2016 by authors and Scientific Research Publishing Inc.

This work is licensed under the Creative Commons Attribution International License (CC BY 4.0).

http://creativecommons.org/licenses/by/4.0/

Received: September 8, 2016; Accepted: October 15, 2016; Published: October 19, 2016

ABSTRACT

A series of Pb1−xNixTiO3 (x = 0, 0.1, 0.2, 0.3, 0.4 and 0.5) were prepared by the general ceramic and co-precipitation method. The grain size decreased with increasing Ni contents. The piezoelectric modulus d33 increased with increasing Ni contents. It was observed also the d33 of the nanocomposite Pb1−xNixTiO3 prepared by co-precipita- tion method is higher than those of the prepared by general ceramic method. The coupling factor kp increased by the more doping of Ni. The ultrasonic wave velocity decreased also with increasing Ni contents. The polarized nano-sample of composition Pb0.5Ni0.5TiO3 is suitable for improving application of useful piezoelectric technology.

Keywords:

Piezoelectric Ceramics, d33 Coefficient, Electromechanical Coupling Factor Kp

1. Introduction

Lead titanate PT ceramics modified by rare earth elements and alkaline earth elements have emerged as highly promising materials for several piezoelectric applications. This is due to existence of large electromechanical anisotropy in the coupling factors along and transfers direction of polarization [1] - [3] .

Samarium modified PT ceramics are reported to exhibit best electric feature [4] , [5] . In calcium, modified PT ceramics grain size and porosity is found to affect the behavior of permittivity and planar thickness frequency constant [6] . Additional of strontium in calcium modified PT ceramics increases piezoelectric anisotropy [7] , [8] . By substitution of isovalent (Ca2+, Ba2+, Cd2+ … etc.) ions into the Pb2+ sites, the lattice anisotropy is reduced [9] , [10] and the samples become more dense result in a relatively large thickness electromechanical coupling coefficient.

In the present work, a comparison between the piezoelectric modulus d33 and the electromechanical coupling factor kp for polarized tablets of Pb1−xNixTiO3 prepared by the usual ceramic method and those prepared by co-precipitation method. It is expected that the nano Pb1−xNixTiO3 ceramics will have a pronounced characteristic of d33 and kp than those of published data. This purpose can help in the improved technology.

2. Experimental

A series of Pb1−xNixTiO3 (x = 0, 0.1, 0.2, 0.3, 0.4 and 0.5) were prepared by the usual ceramic method. The raw materials were presenter at 800˚C for 2 hours. The samples were in the form of tablets and then to be cooled gradually to room temperature.

A second series of Pb1−xNixTiO3 (x = 0, 0.1, 0.2, 0.3, 0.4 and 0.5) were prepared using co-precipitation method. The chemical reagent were titanium chloride (TiCl3.15 H2O) nickel (II) chloride, (NiCl2.6 H2O), lead chloride (PbCl2) and sodium hydroxide (NaOH). All the chemical reagents were dissolve in to 200 ml of distilled water. After mixing and stirring solutions for 6 hours, chemical precipitation was achieved at room temperature vigorous stirring by adding of NaOH solution gradually the reaction system keep at 80˚C for 2 hours and PH solution ±12. After the system cooled to room temperature, the precipitates were washed with distilled water until PH-7. Finally the samples dried in oven at 200˚C for several hours and sintered at 1000˚C for 2 hours then left to be cooled gradually with the rate 50˚C/hr.

The samples were examined by X-ray diffraction using a Philips model (PW-1729) diffractometer with Cu-Kα radiation (l = 1.541 A˚).

The microstructure of the sintered samples examined using SEM and TEM model Quanta 250 FEG (Field Emission Gun) attached with EDX unit (Energy Dispersive X-ray Analyses), with accelerating voltage 30 K.V., magnification 14x up tp 100,000 and resolution for Gun. 1n. FEI company, Netherlands EMITECH K550X sputter coate England and (JOEL-100SX) and HRTEM model (High Resolution Transmission Electron Microscope JOEL EM 2-100) respectively. The prepared tablets with silver electrodes were polarized by exposing to 2 KV per min at 150˚C for 1 Hour and then the tablets were left to be cooled under applying the dc field.

The piezoelectric modulus d33 was determined by taking the slope of the charge depended of the applied stress.

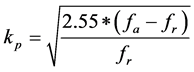

The coupling factor kp was estimated from the resonance frequency fr and antiresonance frequency fa for the radial mode of vibration [4] , [5] :

The ultrasonic wave velocity C was determined from the relation:

where a is radius of polarized tablets.

3. Results and Discussion

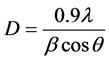

Room temperature XRD patterns of the sintered tablets of Pb1−xNixTiO3 for the two methods of preparation are shown in Figure 1. These have sharp and single diffraction peaks, indicating better homogeneity and crystallization of the samples. All the reflection peaks were indexed and correlated with JCPDS card file number 70 - 4057 showing the perovskite structure for all composites. The average particle size D was determined from the half width of the stronger reflections of X-ray using Scherer’s equation:

where l is the wavelength of the X-ray for Cu-Kα radiation (l = 1.541 A˚) and b is the full width at half maximum of the peak.

The particle size determined from X-ray diffraction for all samples using Scherer’s equation are found to be close nearly to be found from TEM micrographs as shown in Table 1, Figure 1 and Figure 2.

Figure 3 shows the scanning electron micrographs (SEM) of sintered and co-preci- pitation method of Pb1−xNixTiO3 indicate homogenous distribution of grain brought out the surface of material. The average grain size calculated from micrograph of PbTiO3 is 0.25 μm. As Ni2+ concentration increases the grain size decreases as given in Table 1. Figure 2 shows the transmission electron micrographs (TEM) of the usual

Figure 1. XRD pattern of “Pb1-xNixTiO3” system for different ratios of Ni content x, for (a) Ceramic method; (b) co-precipita- tion method.

Table 1. Indicates the value of particle size of Pb1−xNixTiO3 for 1) usual method and 2) co-pre- cipitation method.

Figure 2. (a) TEM of co-precipitation Pb1−xNixTiO3 samples; (b) TEM of ceramic Pb1−xNixTiO3 samples.

Figure 3. (a) SEM of co-precipitation Pb1−xNixTiO3 samples; (b) SEM of ceramic Pb1−xNixTiO3 samples.

ceramic samples and nano polycrystalline samples prepared by co-precipitation method. It is obvious that the increase of Ni content decrease the particle and grain size. This is due to the following: Ni2+ ions enter the lattice and replace some lead ions (Pb2+). These doped ions precipitate at grain boundaries and retard its motions. The increase of Ni2+ ions inhabit the grain growth keeping the grain size small. Our explanation in similar to previous work [10] , [11] .

3.1. Effect of Ni Content on the Piezoelectric Modulus d33

The effect of Ni content on the piezoelectric modulus d33 is shown in Figure 4. It is observed that d33 of the polarized samples prepared by co-precipitation method are higher than those prepared by ceramic method. Doping ions concentrate near the domain boundaries in which some dislocations might act as precipitating centers for migration

Figure 4. The piezoelectric coefficient d33 of “Pb1−xNixTiO3” for ceramic and co-pre- cipitation methods.

of these ions, which in turn act as pinning points causing further dislocations. Also the coulomb attraction between the doping ions and the induced vacancies leads to continuous formation of more lattice vacancies since many of them might act as sinks for these point defects.

Thus, the domain walls are expected be quite free in smaller particle size and grain size considering that grain boundaries will give additional pinning points to the moving walls. The beneficial result of the reduction in grain boundary is the decrease in coupling effect between boundaries and the domain walls leading to increase in domain wall mobility.

This mechanism may affect domain wall motion towards the increase of polarization and hence the observed increase of d33 and generated piezoelectric charges under applied stress. More ever the d33 of nanoparticles of co-precipitation method is higher due to smaller area of grain boundaries compared to those in the samples prepared by ceramic method. This small area helpe the domain wall mobility to be increased giving rise to polarization under applied stresses. The behavior of our results are similar to those in previous work on lead titanate zirconate ceramics [12] , [13] .

3.2. Electromechanical Coupling Factor kp

The planer-coupling factor kp, as a function of Ni dopant is shown in Figure 5. for the prepared polarized tablets by usual ceramic and co-precipitation method. As Ni additions increases, kp increases. This can be explained as follows:

Ni3+ substituted pb2+ sites of the perovskite tetragonal structure. For each pb2+ cation replaced with Ni3+ that a vacancy is created to maintain the charge neutrality of the system. It is in the tetragonal polarized ferroelectric materials, two types of domains are

Figure 5. Effect of “Pb1−xNixTiO3” on the coupling factor kp for ceramic and co-pre- cipitation methods.

existed, 90˚ and 180˚ domains. The 180˚ domains remain entirely after poling process, and small percentage of 90˚ domains oriented in its position after poling. When ac field applied to the resonator (disc). The existence of lattice vacancies facilities to these domains to be vibrated at lower frequency [12] . This led to decrease the resonance frequency of the polarized tablets. The increase of Ni content increases the lattice vacancies caused the decrease of resonance frequency giving rise to kp.

The increase of kp in the nano Pb1−xNixTiO3 polarized discs than those prepared by usual ceramic method is due to the lower grain boundary area which facilitate the domain wall motion under applied ac field. This lead to increase kp of the nano disc of Pb1−xNixTiO3. From Table 2 it is noticed that the particle size of the co-precipitation method is smaller for the usual ceramic in all Ni contents. Ni3+ ions enter the lattice instead of pb2+ ions. The small area of grain boundary of the nanoparticle of the co-pre- cipitation method helped the domains wall mobility to be increased. This led to increase the piezoelectric characteristic properties in the nano crystallite of the co-pre- cipitation method than those prepared by usual ceramic method.

3.3. Effect of Ni Contents on the Ultrasonic Velocity

Figure 6 illustrates the effect of Ni content on the velocity of ultrasonic wave for the radial mode of vibrating polarized tablets. It is obvious that the velocity decreases with increasing x. This could be explained as following:

The velocity of sound wave for poled Pb1−xNixTiO3 of the two method of preparation can be evaluated in the radial mode may be due to the following:

The decrease in sound wave velocity with doping may be due to the creation of lead vacancies. These vacancies help the domain wall to vibrate early leading to decreases the ultrasonic wave velocity. Our explain is in close to previous work on PZT [11] .

Table 2. kp and d33 of the published data and our present data.

Figure 6.Effect of x on ultrasonic velocity for ceramic and co-precipitation methods.

4. Conclusions

In this paper, the piezoelectric d33 for the Pb1−xNixTiO3 ceramics prepared by co-pre- cipitation method were found to be higher than those prepared by ceramic method. This caused by inhibition of grain wall volume.

The increase of kp for samples prepared by co-precipitation method was due to entering Ni ions the lattice and substitute Pb2+ ions. This caused creation of vacancies. These vacancies helped the dipoles to vibrate at lower frequency.

The decrease of ultrasonic waves with enhancing Ni contents was due to creation of vacancies, which scattered the propagation of the waves.

It is clearer the present sample Pb0.5Ni0.5TiO3 possessed higher d33 and kp than those in previous work [12] which is useful in technology.

Cite this paper

Tawfik, A., Hemeda, O.M., Hemeda, D.M., Barakat, M., El-Shahawy, M.M. and Shady, R. (2016) High Quality of Piezoelectric Response of Nano Ni Doped Pb1−xNixTiO3 Ceramic. Journal of Applied Mathematics and Physics, 4, 1879-1888. http://dx.doi.org/10.4236/jamp.2016.410190

References

- 1. Yamashita, Y., Yokoyama, K., Honda, H. and Takahashi, T. (1981) (Pb, Ca) ((Co1/2W1/2), Ti)O3 Piezoelectric Ceramics and Their Applications. Japanese Journal of Applied Physics, 20, 183-187.

http://dx.doi.org/10.7567/JJAPS.20S4.183 - 2. Takahashi, T. (1990) Lead Titanate Ceramics with Large Piezoelectric Anisotropy and Their Application. American Ceramic Society Bulletin, 69, 691-695.

- 3. Hashimoto, K., Tsuruta, T., Morinaka, K. and Yoshiike, N. (2000) High Performance Human Information Sensor. Sensors and Actuators A: Physical, 79, 46-52.

http://dx.doi.org/10.1016/S0924-4247(99)00247-2 - 4. Suwannasiri, T. and Safari, A. (1993) Modified Lead Titanate Ceramics. Journal of the American Ceramic Society, 76, 3155-3158.

http://dx.doi.org/10.1111/j.1151-2916.1993.tb06623.x - 5. Chu, S.Y. and Chen, C.H. (2001) Effect of Calcium on the Piezoelectric and Dielectric Properties of Sm-Modified PbTiO3 Ceramics. Sensors and Actuators A: Physical, 89, 210-214. http://dx.doi.org/10.1016/S0924-4247(00)00536-7

- 6. Ricote, J., Alemany, C. and Pardo, L. (1995) Microstructural Effects on Dielectric and Piezoelectric Behavior of Calcium-Modified Lead Titanate Ceramics. Journal of Materials Research, 10, 3194-3203.

http://dx.doi.org/10.1557/JMR.1995.3194 - 7. Troilo, L.M., Damjanovic, D. and Newnham, R.E. (1994) Modified Lead Calcium Titanate Ceramics with a Relatively Large Dielectric Constant for Hydrophone Applications. Journal of the American Ceramic Society, 77, 857-859.

http://dx.doi.org/10.1111/j.1151-2916.1994.tb05380.x - 8. Kellati, M., Sayouri, S., El-Moudden, N., Elaatmani, M., Kaal, A. and Taibi, M. (2004) Structural and Dielectric Properties of La-Doped Lead Titanate Ceramics. Materials Research Bulletin, 39, 867-872.

http://dx.doi.org/10.1016/j.materresbull.2004.01.003 - 9. Jiang, S.L., Zhang, X.L., Wang, X.Z. and Wang, X.H. (1995) Investigation on Anisotropy in Piezoelectric Properties of Modified PbTiO3 Ceramics. Piezoelect. Acoust., 17, 26-29.

- 10. Kumari1, N., Singh, A. and Mandal, J. (2013) Lead Zirconate Titanate Piezoelectric Ceramics with Nickel Oxide Additions. International Refereed Journal of Engineering and Science, 2, 51-55.

- 11. Atikin, R.B. and Fulrath, R.M. (1971) Point Defects and Sintering of Lead Zirconate-Titanate. Journal of the American Ceramic Society, 54, 265-270.

http://dx.doi.org/10.1111/j.1151-2916.1971.tb12286.x - 12. Tawfik, A. (1985) Elastic Properties and Sound Wave Velocity of PZT Transducers Doped with Ta and La. Journal of the American Ceramic Society, 68, 317-319.

http://dx.doi.org/10.1111/j.1151-2916.1985.tb10132.x - 13. Ahd El-Salam, F., Tawfik, A. and Eatah, A.I. (1983) Effect of Li Loss on Some Physical Properties of Al-Li Alloy. Physica Status Solidi A, 75, 379-384.

http://onlinelibrary.wiley.com/doi/10.1002/pssa.2210750205/abstract - 14. Ikegami, S., Ueda, I. and Nagata, T. (1971) Electromechanical Properties of PbTiO3 Ceramics Containing La and Mn. The Journal of the Acoustical Society of America, 50, 1060-1066.

http://dx.doi.org/10.1121/1.1912729 - 15. Damjanovic, D., Gururaja, T.R. and Cross, L.E. (1987) Anisotropy in Piezoelectric Properties of Modified lead Titanate Ceramics. American Ceramic Society Bulletin, 66, 699-703.

- 16. Jaffe, B., Cook, W.R. and Jaffe, H. (1971) Piezoelectric Ceramics, Vol. 3. Non-Metallic Solids. Academic Press, London.

- 17. Kulcsa, F. (1959) Electromechanical Properties of Lead Titanate Zirconate Ceramics Modified with Certain Three-or Five-Valent Additions. Journal of the American Ceramic Society, 42, 343-349.

http://dx.doi.org/10.1111/j.1151-2916.1959.tb14321.x - 18. Flynn, A.M. (1997) MIT Artificial Intelligence Laboratory, Cambridge, 25.

- 19. Chu, S.Y., Chen, T.Y., Ta Tsai, I. and Water, W. (2004) Doping Effects of Nb Additives on the Piezoelectric and Dielectric Properties of PZT Ceramics and Its Application on SAW Device.. Sensors and Actuators A, 113.

- 20. Chen, X.M. and Yang, J.S. (1998) Toughening of PZT Piezoelectric Ceramics by In-Situ Complex Structures. Journal of the European Ceramic Society, 18, 1059-1062.

http://dx.doi.org/10.1016/S0955-2219(97)00199-4 - 21. Tung, V.T., Tinh, N.T., Yen, N.H. and Tuan, D.A. (2013) Evaluation of Electromechanical Coupling Factor for Piezoelectric Materials Using Finite Element Modeling Title. International Journal of Materials and Chemistry, 3, 59-63.

- 22. Tajima, K., Hwang, H.J., Sando, M. and Niihara, K. (1999) PZT Nanocomposites Reinforced by Small Amount of Oxides. Journal of the European Ceramic Society, 19, 1179-1182. http://dx.doi.org/10.1016/S0955-2219(98)00399-9

- 23. Nadoliisky, M.M. and Vasileva, T.K. (2007) Dielectric and Piezoelectric Properties of a Triple Ferroceramics System PbTiO3-PbZrO3-Pb(Mn1/3Nb2/3)O3. Bulgarian Journal of Physics, 34, 71-76.

- 24. Shi, L., Liao, Q., Zhang, B., Zhang, J. and Guo, D. (2014) Structure and Electrical Properties of (1-x)(0.1BiYbO3–0.9PbTiO3)–xPb(Zn1/3Nb2/3)O3 High-Temperature Ternary Piezoelectric Ceramics. Materials Letters, 114, 100-102.

http://dx.doi.org/10.1016/j.matlet.2013.09.061 - 25. Kumar, A. and Mishra, S.K. (2014) Structural and Dielectric Properties of Nb and Fe Co-Doped PZT Ceramic Prepared by a Semi-Wet Route. Advanced Materials Letters, 5, 479-484.

http://dx.doi.org/10.5185/amlett.2014.564 - 26. Miclea, C., Tanasoiu, C., Miclea, C.F., Gheorghiu1, A. and Sima, F.N. (2005) Effect of Iron and Nickel Substitution on the Piezoelectric Properties of PZT Type Ceramics. Journal of the European Ceramic Society, 25, 2397-2400.

http://dx.doi.org/10.1016/j.jeurceramsoc.2005.03.069