Paper Menu >>

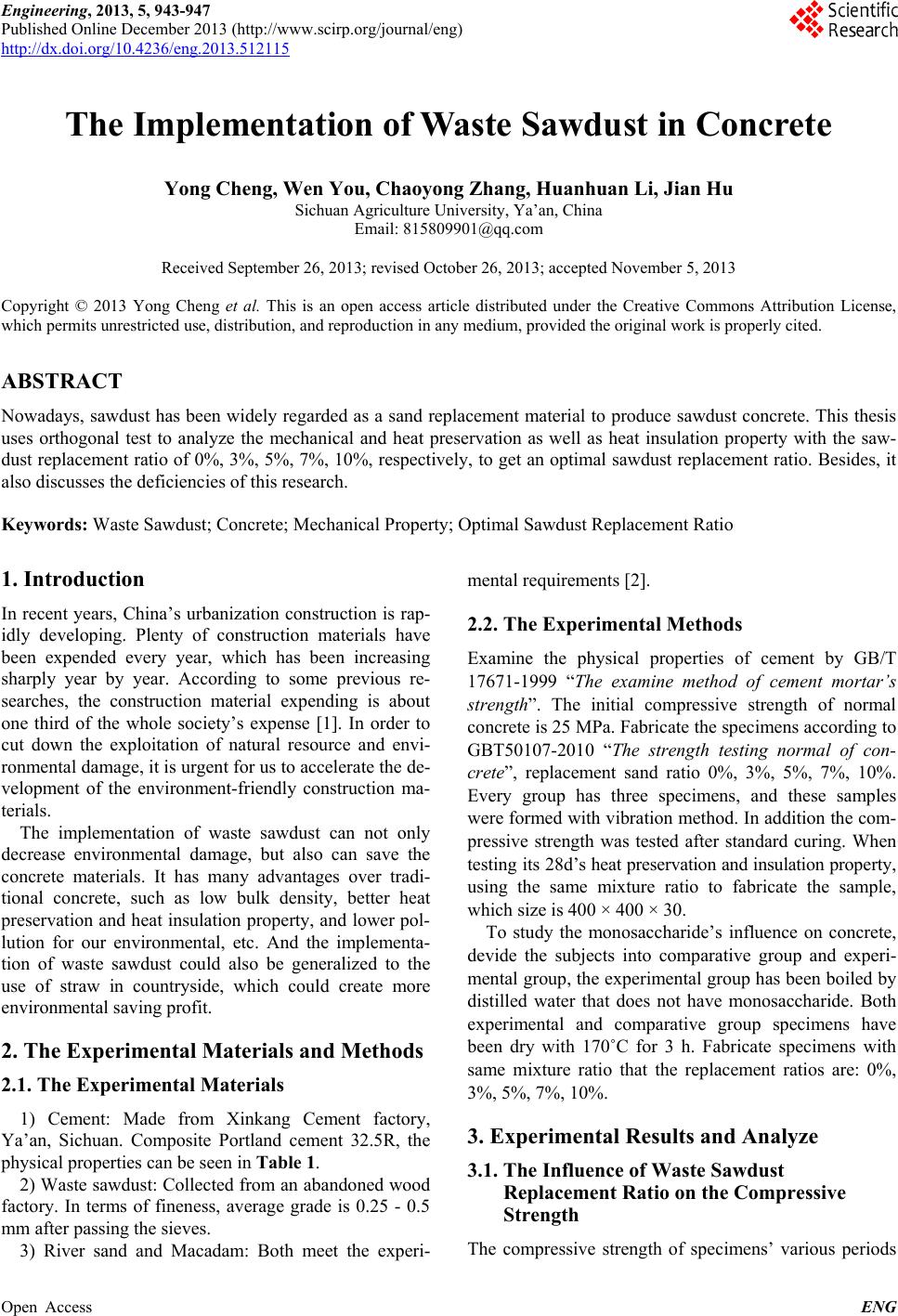

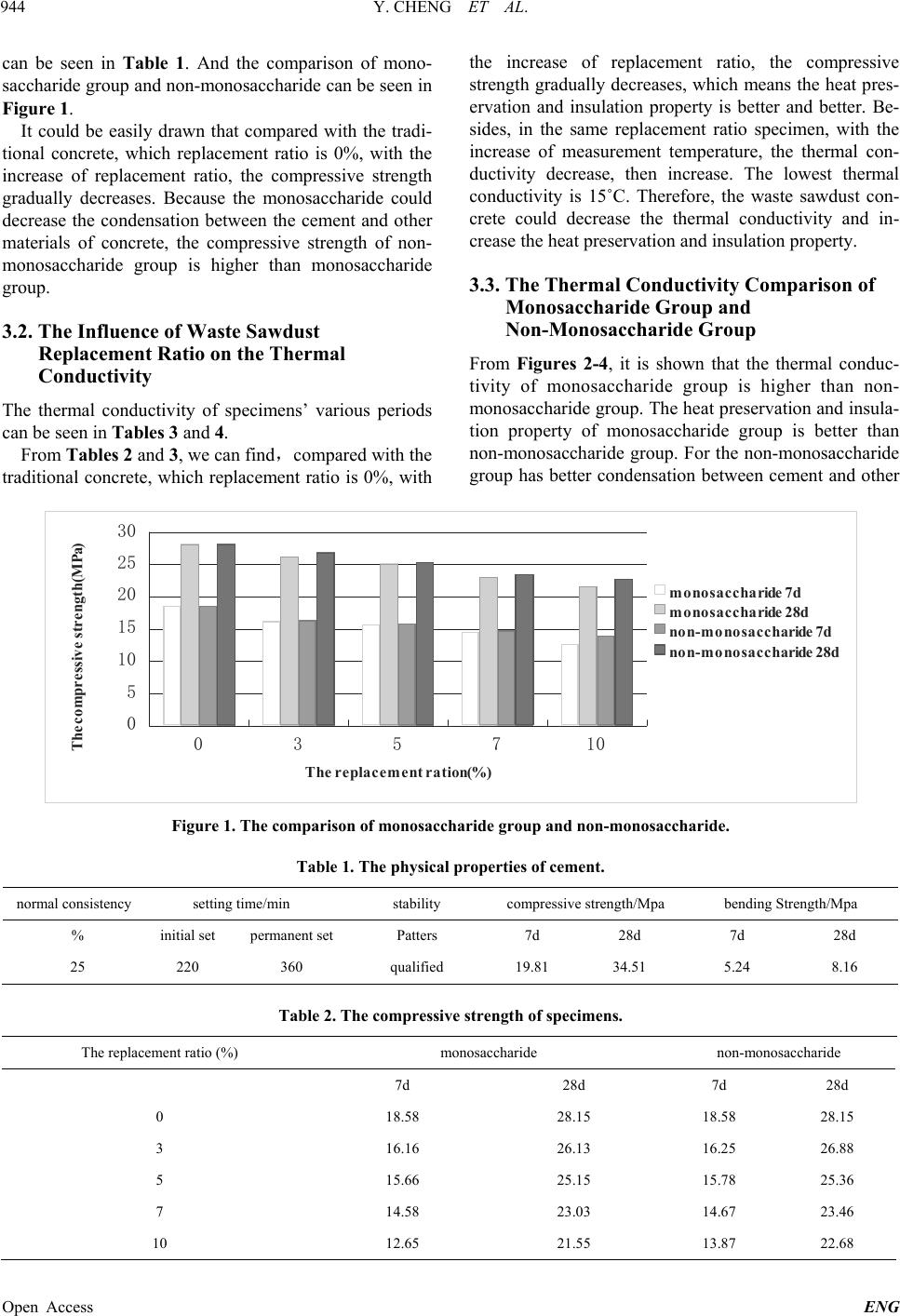

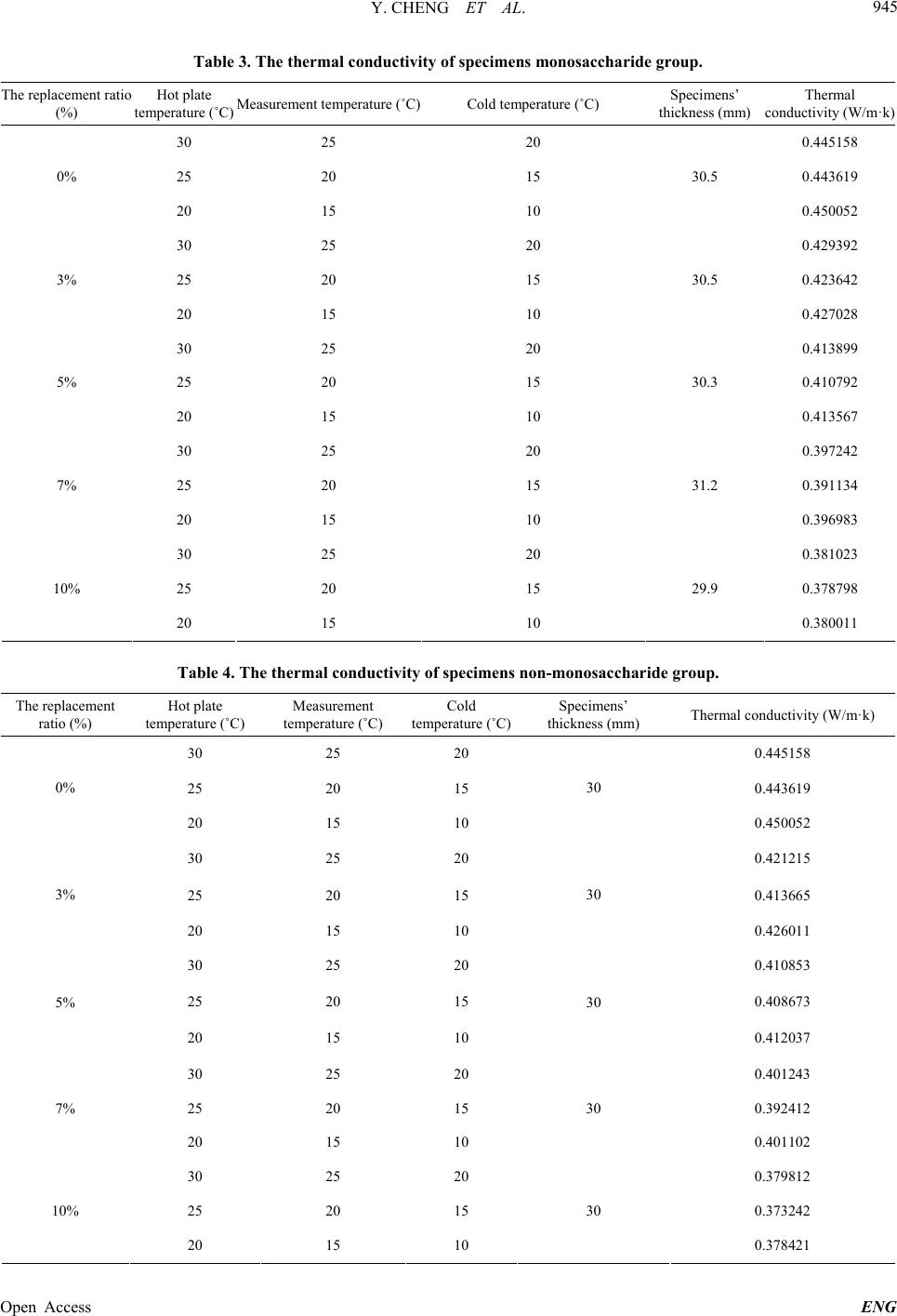

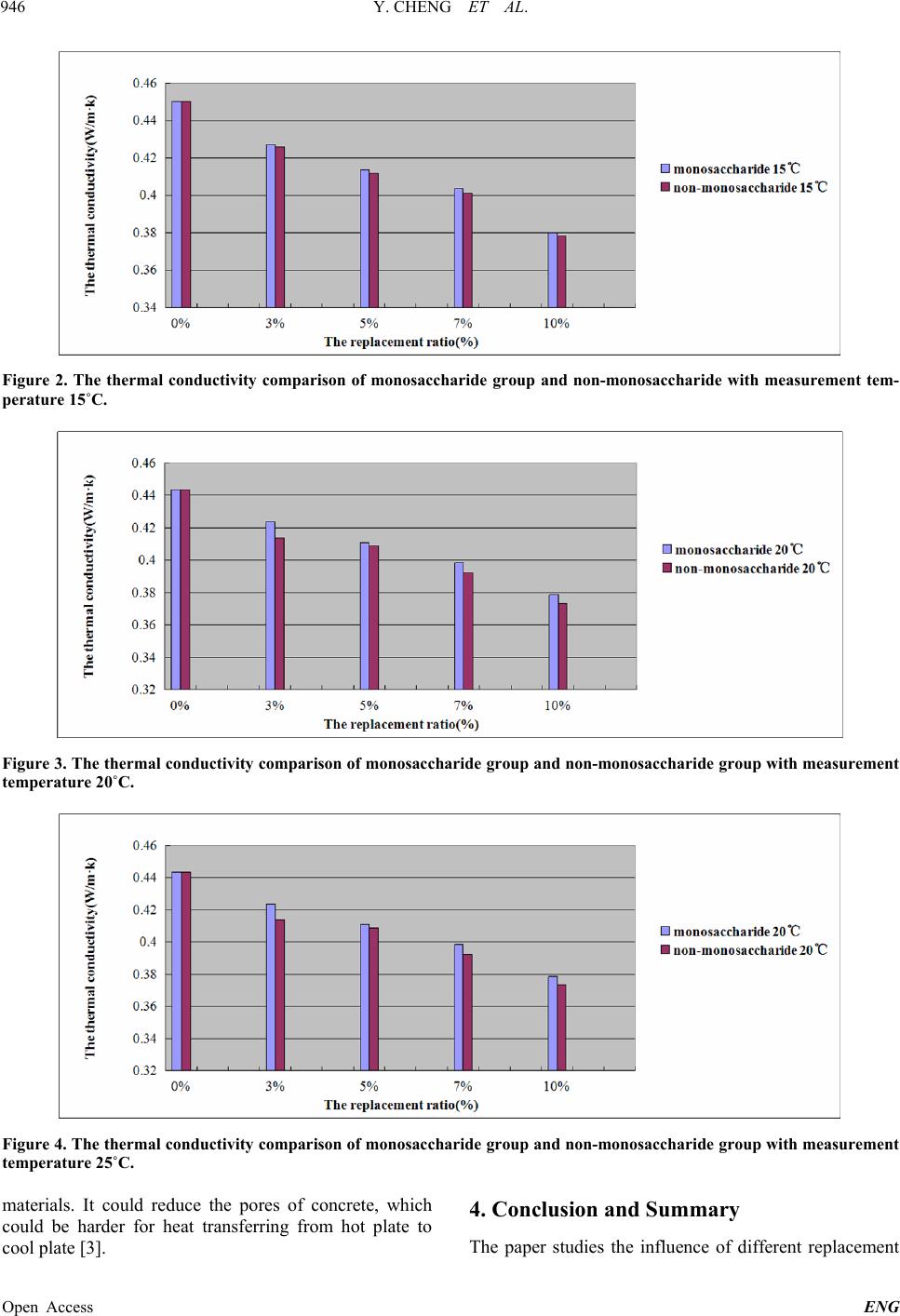

Journal Menu >>

Engineering, 2013, 5, 943-947 Published Online December 2013 (http://www.scirp.org/journal/eng) http://dx.doi.org/10.4236/eng.2013.512115 Open Access ENG The Implementation of Waste Sawdust in Concrete Yong Cheng, Wen You, Chaoyong Zhang, Huanhuan Li, Jian Hu Sichuan Agriculture University, Ya’an, China Email: 815809901@qq.com Received September 26, 2013; revised October 26, 2013; accepted November 5, 2013 Copyright © 2013 Yong Cheng et al. This is an open access article distributed under the Creative Commons Attribution License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited. ABSTRACT Nowadays, sawdust has been widely regarded as a sand replacement material to produce sawdust concrete. This thesis uses orthogonal test to analyze the mechanical and heat preservation as well as heat insulation property with the saw- dust replacement ratio of 0%, 3%, 5%, 7%, 10%, respectively, to get an optimal sawdust replacement ratio. Besides, it also discusses the deficiencies of this research. Keywords: Waste Sawdust; Concrete; Mechanical Property; Optimal Sawdust Replacement Ratio 1. Introduction In recent years, China’s urbanization construction is rap- idly developing. Plenty of construction materials have been expended every year, which has been increasing sharply year by year. According to some previous re- searches, the construction material expending is about one third of the whole society’s expense [1]. In order to cut down the exploitation of natural resource and envi- ronmental damage, it is urgent for us to accelerate the de- velopment of the environment-friendly construction ma- terials. The implementation of waste sawdust can not only decrease environmental damage, but also can save the concrete materials. It has many advantages over tradi- tional concrete, such as low bulk density, better heat preservation and heat insulation property, and lower pol- lution for our environmental, etc. And the implementa- tion of waste sawdust could also be generalized to the use of straw in countryside, which could create more environmental saving profit. 2. The Experimental Materials and Methods 2.1. The Experimental Materials 1) Cement: Made from Xinkang Cement factory, Ya’an, Sichuan. Composite Portland cement 32.5R, the physical prope rt i e s can be see n in Table 1. 2) Waste sawdust: Collected from an abandoned wood factory. In terms of fineness, average grade is 0.25 - 0.5 mm after passing the sieves. 3) River sand and Macadam: Both meet the experi- mental requirements [2]. 2.2. The Experimental Methods Examine the physical properties of cement by GB/T 17671-1999 “The examine method of cement mortar’s strength”. The initial compressive strength of normal concrete is 25 MPa. Fabricate the specimens according to GBT50107-2010 “The strength testing normal of con- crete”, replacement sand ratio 0%, 3%, 5%, 7%, 10%. Every group has three specimens, and these samples were formed with vibration method. In addition the com- pressive strength was tested after standard curing. When tes ting it s 28 d’s heat preservation and insulation propert y, using the same mixture ratio to fabricate the sample, which size is 400 × 400 × 30. To study the monosaccharide’s influence on concrete, devide the subjects into comparative group and experi- mental group, the experimental group has been boiled by distilled water that does not have monosaccharide. Both experimental and comparative group specimens have been dry with 170˚C for 3 h. Fabricate specimens with same mixture ratio that the replacement ratios are: 0%, 3%, 5%, 7%, 10%. 3. Experimental Results and Analyze 3.1. The Influence of Waste Sawdust Replacement Ratio on the Compressive Strength The compressive strength of specimens’ various periods  Y. CHENG ET AL. 944 can be seen in Table 1. And the comparison of mono- saccharide group and non-monosaccharide can be seen in Figure 1. It could be easily drawn that compared with the tradi- tional concrete, which replacement ratio is 0%, with the increase of replacement ratio, the compressive strength gradually decreases. Because the monosaccharide could decrease the condensation between the cement and other materials of concrete, the compressive strength of non- monosaccharide group is higher than monosaccharide group. 3.2. The Influence of Waste Sawdust Replacement Ratio on the Thermal Conductivity The thermal conductivity of specimens’ various periods can be seen in Tables 3 and 4. From Tables 2 and 3, we can find,compared with the traditional concrete, which replacement ratio is 0%, with the increase of replacement ratio, the compressive strength gradually decreases, which means the heat pres- ervation and insulation property is better and better. Be- sides, in the same replacement ratio specimen, with the increase of measurement temperature, the thermal con- ductivity decrease, then increase. The lowest thermal conductivity is 15˚C. Therefore, the waste sawdust con- crete could decrease the thermal conductivity and in- crease the heat preservation and insulation property. 3.3. The Thermal Conductivity Comparison of Monosaccharide Group and Non-Monosaccharide Group From Figures 2-4, it is shown that the thermal conduc- tivity of monosaccharide group is higher than non- monosaccharide group. The heat preservation and insula- tion property of monosaccharide group is better than non-monosaccharide group. For the non-monosaccharide group has better condensation between cement and other 0 5 10 15 20 25 30 035710 The replacement ratio n ( %) The com pressive strength(MP a) monosacchari de 7d monosacchari de 28d non-monosacchari de 7d non-monosacchari de 28d Figure 1. The comparison of monosaccharide group and non-monosaccharide. Table 1. The physical properties of ceme nt. normal consistency setting time/min stability compressive strength/Mpa bending Strength/Mpa % initial set permanent set Patters 7d 28d 7d 28d 25 220 360 qualified 19.81 34.51 5.24 8.16 Table 2. The compressive strength of specimens. The replacement ratio (%) monosaccharide non-monosaccharide 7d 28d 7d 28d 0 18.58 28.15 18.58 28.15 3 16.16 26.13 16.25 26.88 5 15.66 25.15 15.78 25.36 7 14.58 23.03 14.67 23.46 10 12.65 21.55 13.87 22.68 Open Access ENG  Y. CHENG ET AL. 945 Table 3. The thermal conductivity of specimens monosacc haride group. The replacement ratio (%) Hot plate temperature (˚C)Measurement temperature (˚C)Cold temperature (˚C) Specimens’ thickness (mm) Thermal conductivity (W/m·k) 30 25 20 0.445158 25 20 15 0.443619 0% 20 15 10 30.5 0.450052 30 25 20 0.429392 25 20 15 0.423642 3% 20 15 10 30.5 0.427028 30 25 20 0.413899 25 20 15 0.410792 5% 20 15 10 30.3 0.413567 30 25 20 0.397242 25 20 15 0.391134 7% 20 15 10 31.2 0.396983 30 25 20 0.381023 25 20 15 0.378798 10% 20 15 10 29.9 0.380011 Table 4. The thermal conductivity of specimens non-mono saccharide group. The replacement ratio (%) Hot plate temperature (˚C) Measurement temperature (˚C) Cold temperature (˚C) Specimens’ thickness (mm) Thermal conductiv ity (W/m·k) 30 25 20 0.445158 25 20 15 0.443619 0% 20 15 10 30 0.450052 30 25 20 0.421215 25 20 15 0.413665 3% 20 15 10 30 0.426011 30 25 20 0.410853 25 20 15 0.408673 5% 20 15 10 30 0.412037 30 25 20 0.401243 25 20 15 0.392412 7% 20 15 10 30 0.401102 30 25 20 0.379812 25 20 15 0.373242 10% 20 15 10 30 0.378421 Open Access ENG  Y. CHENG ET AL. Open Access ENG 946 Figure 2. The thermal conductivity comparison of monosaccharide group and non-monosaccharide with measurement tem- perature 15˚C. Figure 3. The thermal c onductivity comparison of monosacc haride group and non-monosacchar ide group with measur ement temperature 20˚C. Figure 4. The thermal c onductivity comparison of monosacc haride group and non-monosacchar ide group with measur ement temperature 25˚C. materials. It could reduce the pores of concrete, which could be harder for heat transferring from hot plate to cool plate [3]. 4. Conclusion and Summary The paper studies the influence of different replacement  Y. CHENG ET AL. 947 rations on the compressive strength and thermal conduc- tivity to get the change rule of compressive and thermal conductivity with the change of sawdust replacement ratio. And it also studies the influence of monosaccharide on the condensation property. With the increase of re- placement ratio, the compressive strength gradually de- creases [4]. When the replacement ratio is 5%, the com- pressive strength could meet the C25, and the heat pres- ervation and insulation property are also highly better than those of traditional concrete. The 5% could be seen as an optimal replacement ratio. If the replacement ratio is much higher, it could also be used as non-bearing com- ponent. REFERENCES [1] W. Zhao, “The Implementation of New Building Materi- als in Our Country,” The Word Garden, Vol. 4, 2013, p. 20. [2] H. Z. Zhu, “The Development of Regeneration of Saw- dust Concrete Blocks,” Building Technique Development, Vol. 12, 2003, pp. 46-48. [3] Z. F. Liu, “The Innovation and Development of Thermal Insulation Material,” Heilongjiang Science and Technol- ogy Information, Vol. 28, 2009, p. 317. [4] F. L. Yang, Y. S. Li and Y. Jian, “The Implementation of Waste Glass in Concrete,” Concrete, Vol. 263, 2011, pp. 81-86. Open Access ENG |