P. L. LENG ET AL.

Open Access ANP

382

na magnetic

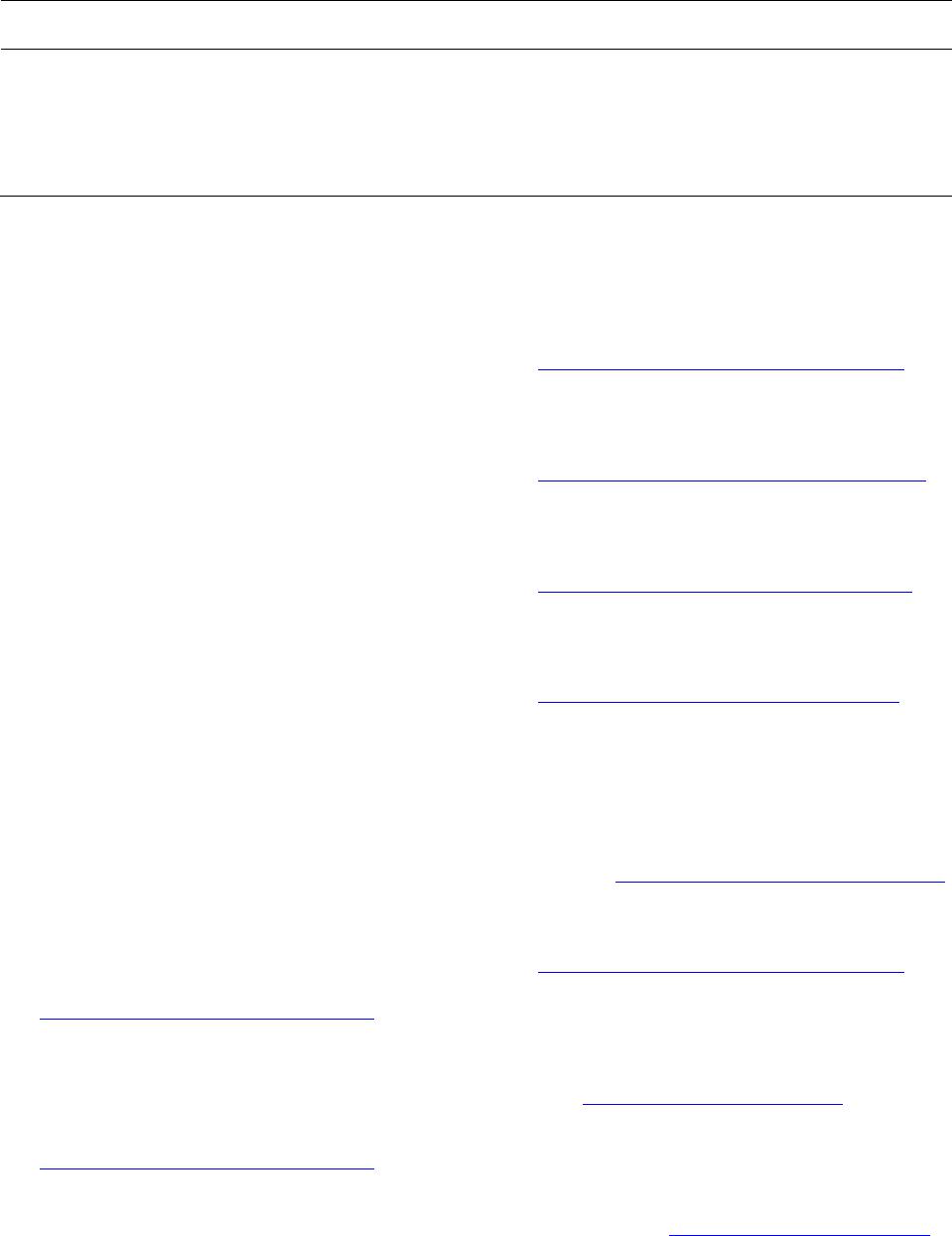

Ni0.25Zn0.75Fe2O4 Calcinations Average particle Average particle Saturation magnetization,Coercivity Peak to peak line factorResonance

Table 1. The average particle sizes (nm) of Ni0.25Zn0.75Fe2O4oparticles determined from XRD and TEM andn

properties observed from VSM and EPR at room temperature.

nanoparticles temperature (K) size XRD (nm) size TEM (nm)Ms (emu/g) field Hc (G)width ΔHpp (G) g- field, Hr (G)

Ni-2.0670Zn ferrite 1 723 9 7 11.414 7 758 3170

Ni-Zn ferrite 2 773 11 9 15.785 10 755 2.08853140

Ni-Zn ferrite 3 823 14 13 20.320 26 753 2.10503118

Ni-Zn ferrite 4 873 23 20 26.447 29 750 2.12203090

nthesis of Ni0.25Zn0.75Fe2O4 nanocrystals with grain

by the Ministry of Higher

[1] A. Goldman, “logy,” 2nd Edition,

6/j.jmmm.2006.02.031

sy

size ranging from 7 to 25 nm at the calcination tempera-

tures from 723 to 873 K as measured by XRD and TEM.

The PVP stabilized the particles and prevented them

from agglomerating. The FTIR measurement confirmed

the removal of all organic matters and leaving pure metal

oxides at 873 K. The VSM results showed that the satu-

ration magnetization increased from 11 emu/g to 26 emu/

g and the coercivity value increased from 7 to 29 G at

calcination temperatures from 723 K to 873 K due to the

increasing of the volume of single domain grains. The

values of g-factor increases with increase of calcination

temperature and particle size were increased. This simple

method, which is cost-effective and environmentally

friendly, produces no toxic byproduct effluents and can

be used to fabricate pure, crystalline spinel ferrite nano-

crystals.

5. Acknowledgements

This work was supported

Education of Malaysia under the FRGS grant. The au-

thors would also like to thank staff of the Faculty of Sci-

ence and the Bioscience Institute of University Putra

Malaysia, who had contributed to this work.

REFERENCES

Modern Ferrite Techno

Springer Science Business Media, Inc., New York, 2006.

[2] S. W. Lee and C. S. Kim, “Superparamagnetic Properties

Ni-Zn Ferrite for Nano-Bio Fusion Applications,” Jour-

nal of Magnetism and Magnetic Materials, Vol. 304, No.

1, 2006, pp. 418-420.

http://dx.doi.org/10.101

assa[3] G. R. Amiri, M. H. Yousefi, M. R. Abolhni, S.

Manouchehri, M. H. Keshavarz and S. Fatahian, “Mag-

netic Properties and Microwave Absorption in Ni-Zn and

Mn-Zn Ferrite Nanoparticles Synthesized by Low-Tem-

perature Solid-State Reaction,” Journal of Magnetism and

Magnetic Materials, Vol. 323, No. 6, 2011, pp. 730-734.

http://dx.doi.org/10.1016/j.jmmm.2010.10.034

[4] M. Mohapatra and S. Anand, “Synthesis and Applications

nology, Vol. 2, No. 8, 2010, pp. 127-146.

anodimensional

of Nano-Structured Iron Oxides/Hydroxides—A Review,”

International Journal of Engineering, Science and Tech-

[5] E. Manova, D. Paneva, B. Kunev, E. Rivière, C. Estour-

nès and I. Mitov, “Characterization of N

Ni-Zn Ferrite Prepared by Mechanochemical and Thermal

Methods,” Journal of Physics: Conference Series, Vol.

217, No. 1, 2010, Article ID: 012102.

http://dx.doi.org/10.1088/1742-6596/217/1/012102

[6] K. Velmurugan, V. S. K. Venkatachalapathy and S.

hilnathan, “Synthesis of Nickel Zinc Iron Nanopar

Send-

ticles

by Coprecipitation Technique,” Materials Research, Vol.

13, No. 3, 2010, pp. 299-303.

http://dx.doi.org/10.1590/S1516-14392010000300005

[7] B. T. Naughton, P. Majewski and D. R. Clarke, “Mag-

netic Properties of Nickel-Zinc Ferrite Toroids Prepar

ed

from Nanoparticles,” Journal of the American Ceramic

Society, Vol. 90, No. 11, 2007, pp. 3547-3553.

http://dx.doi.org/10.1111/j.1551-2916.2007.01981.x

[8] E. E. Sileo, R. Rotelo and S. E. Jacobo, “Nickel

Ferrites Prepared by the Citrate Precursor Method,”

Zinc

Phy-

sica B: Condensed Matter, Vol. 320, No. 1-4, 2002, pp.

257-260.

http://dx.doi.org/10.1016/S0921-4526(02)00705-6

[9] R. K. Singh, C. Upadhyay, S. Layek and A. Yadav

“Cation Distribution of NiZnFe O Nanopart

,

icles,”

ed Nickel Zinc

0.50.524

International Journal of Engineering, Science and Tech-

nology, Vol. 2, No. 8, 2010, pp. 104-109.

[10] A. Kumar, Annveer, M. Arora, M. S. Yadav and R. P.

Panta, “Induced Size Effect on Ni Dop

Ferrite Nanoparticles,” Physics Procedia, Vol. 9, 2010,

pp. 20-23. http://dx.doi.org/10.1016/j.phpro.2010.11.006

[11] M. Shigeta and A. B. Murphy, “Thermal Plasmas for

Nanofabrication,” Journal of Physics D: Applied Physics,

Vol. 44, No. 17, 2011, Article ID: 174025.

http://dx.doi.org/10.1088/0022-3727/44/17/174025

[12] S. A. Morrison, C. L. Cahill, E. E. Carpenter, S. Calvin

Swaminathan, M. E. McHenry and V. G. Harris, “

, R.

Mag-

netic and Structural Properties of Nickel Zinc Ferrite

Nanoparticles Synthesized at Room Temperature,” Jour-

nal of Applied Physics, Vol. 95, No. 11, 2004, Article ID:

6392. http://dx.doi.org/10.1063/1.1715132

[13] S. Thakur, S. C. Katyal, A. Gupta, V. R. Reddy, S. K.

Sharma, M. Knobel and M. Singh, “Nickel-Zinc Ferrite

from Reverse Micelle Process: Structural and Magnetic

Properties, Mössbauer Spectroscopy Characterization,”

Journal of Physical Chemistry C, Vol. 113, No. 49, 2009,

pp. 20785-20794. http://dx.doi.org/10.1021/jp9050287