A. A. A. EL-RADY ET AL.

376

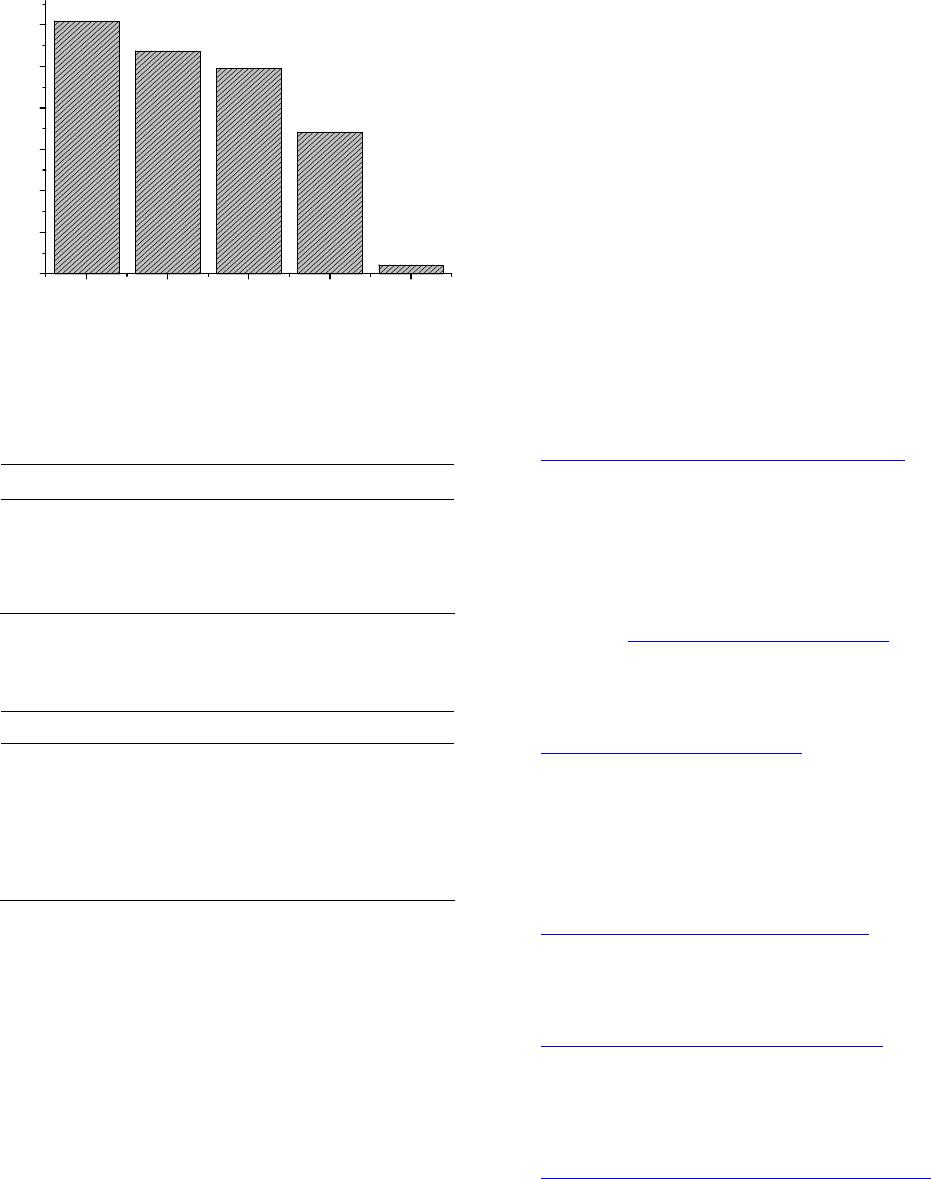

initial TOCundoped TiO 20.05 % pd doped T iO20.1 % pd doped TiO20.3% pd doped TiO2

0

10

20

30

40

50

60

TOC (ppm)

Figure 9. Removal of formic acid by the undoped TiO2,

0.05%, 0.1% and 0.3% Pd/TiO2. Catalyst wt 150 mg under

sun light irradiation.

Table 3. TOC and pH values for formic acid solution

treated by doped and undoped TiO2 nanoparticles prepared

by calcinations at 400˚C under UV irradiation for 6 hrs.

Sample Name pH TOC Degradation Rate (%)

Formic acid Solution 3.06 52.2 -

Undoped TiO2 3.3 23.6 54.8

0.05% Pd Doped TiO2 3.17 35 33

Table 4. TOC results for doped and undoped TiO2 nano-

particles annealed at 400˚C under sun light irradiation for 4

hrs.

Sample Name pH TOC Degradation Rate (%)

Formic Acid Solution 2.98 61 -

Undoped TiO2 2.99 53.8 11.8

0.05% Pd Doped TiO2 3.08 49.6 18.69

0.1% Pd Doped TiO2 3.02 34.2 43.93

0.3% Pd Doped TiO2 3.58 2.19 96.4

53.8 mg/L for 0.05%, 0.1%, 0.3% Pd doped TiO2 and

undoped TiO2, respectively under sun light irradiation

within the same time (see Table 4). The pH of the

solution also was changed from 2.98 to 3.08, 3.02, 3.58

and 2.98 for 0.05%, 0.1%, and 0.3% Pd doped TiO2 and

undoped TiO2 photocatalysts, respectively, within the

same time.

4. Conclusion

The pure and palladium doped TiO2 (Pd/TiO2) nano-

particles were prepared by the sol gel method. Samples

prepared by calcinations at 380˚C contain anatase phase

only. A mixture of anatase and rutile was obtained at

higher calcination temperatures. Doping TiO2 with

palladium in the concentration range of 0.05 to 0.3 has

no significant effect on the particle sizes and did not

result in the formation of a new crystalline phase. It was

confirmed that the incorporation of Pd in TiO2 matrix

shifts the onset wave length of absorption to higher

values (red shift). Under UV irradiation, the pure TiO2

exhibited higher efficiency than the palladium doped

TiO2 for formic acid removal from water. However,

when sun light was used as the radiation source, the

palladium doped photocatalyst exhibited higher effi-

ciency than the pure TiO2 and the photocatalytic ef-

ficiency increases with increasing palladium content up

to a concentration of 0.3% (0.3% Pd/TiO2).

REFERENCES

[1] D. A. Tryk, A. Fujishima and K. Honda, “Recent Topics

in Photoelectrochemistry: Achievements and Future Pros-

pects,” Electrochimica Acta, Vol. 45, No. 15-16, 2000, pp.

2363-2376.

http://dx.doi.org/10.1016/S0013-4686(00)00337-6

[2] M. Kunst, T. Moehl, F. Wunsch and H. Tributsch, “Opto-

electronic Properties of SnO2/TiO2 Junctions,” Super Lat-

tice Microst., Vol. 39, No. 1-4, 2006, pp. 376-380.

[3] S. M. Karvinen, “The Effects of Trace Element Doping

on the Optical Properties and Photocatalytic Activity of

Nanostructured Titanium Dioxide,” Industrial & Engi-

neering Chemistry Research, Vol. 42, No. 5, 2003, pp.

1035-1043. http://dx.doi.org/10.1021/ie020358z

[4] J. Chen, S. L. Li, Z. L. Tao, Y. T. Shen and C. X. Cui,

“Titanium Disulfide Nanotubes as Hydrogen-Storage

Materials,” Journal of the American Chemical Society,

Vol. 125, No. 18, 2003, pp. 5284-5285.

http://dx.doi.org/10.1021/ja034601c

[5] A. Fujishima, X. Zhang and D. A. Tryk, “TiO2 Photo-

catalysis and Related Surface Phenomena,” Surface Sci-

ence Reports, Vol. 63, No. 12, 2008, pp. 515-582.

[6] L. Ge and M. X. Xu, “Influences of the Pd Doping on the

Visible Light Photocatalytic Activities of InVO4-TiO2

Thin Films,” Materials Science and Engineering: B, Vol.

131, No. 1-3, 2006, pp. 222-229.

http://dx.doi.org/10.1016/j.mseb.2006.04.021

[7] B. P. Xie, Y. Xiong, R. M. Chen, J. Chen and P. X. Cai,

“Catalytic Activities of Pd-TiO2 Film towards the Oxida-

tion of Formic Acid,” Catalysis Communications, Vol. 6,

No. 11, 2005, pp. 699-704.

http://dx.doi.org/10.1016/j.catcom.2005.06.003

[8] X. Zhang, F. Zhang and K. Y. Chan, “The Synthesis of

Pt-Modified Titanium Dioxide Thin Films by Microe-

mulsion Templating, Their Characterization and Visible-

Light Photocatalytic Properties,” Materials Chemistry

and Physics, Vol. 97, No. 2-3, 2006, pp. 384-389.

http://dx.doi.org/10.1016/j.matchemphys.2005.08.060

[9] H. Li, B. L. Zhu, Y. F. Feng, S. R. Wang, S. M. Zhang

and W. P. Huang, “Synthesis, Characterization of TiO2

Nanotubes-Supported MS (TiO2NTs@MS, M = Cd, Zn)

and Their Photocatalytic Activity,” Journal of Solid State

Chemistry, Vol. 180, No. 7, 2007, pp. 2136-2142.

Open Access ANP