H. P. XU ET AL.

1412

density.

Taking no account of the magnetic leakage and iron

loss, the reactance of SR is

22

b

ac

ac ac

An An

dB

L

ldH l

eHe

(2)

where, A is the area of the section of the core (cm2), ac

is the number of the SR’s work winding, is the

average length of the magnetic circuit (cm) [11].

n

l

For simplify, the SR is considered as a controllable

nonlinear reactor, and it keeps constant if the system is

steady. All setting values of the current of rectifier units

are supposed as equal, the sum of them is the setting

value of the electrolytic series current, that is, ref

. The error between

ref

dc

NIref

dc

and dc

, the measured

value of the series current, is as the input of the PI

controller, and the output from PI controller is added to

the setting value of SR’s inductance , the sum is the

actual inductance after the regulation of SR.

ref

L

The control diagram of the SR is shown in Figure 3.

and T are the proportional gain and integral time

constant of PI controller.

Due to the magnetic characteristics of the SR, the

regulating range is limited. It makes the regulating range

of the outputting dc voltage on the load bus limited. In

general, the regulator depth is about 70 V, and the

regulation could be carried out continuously.

3.2. Control Strategy of OLTC

In this paper, the voltage range of fineness regulation is

[0, ΔUmax], the range is divided into three sections. The

first section is [0, U1], called up shift section; the second

section is [U1, U2], called unrestrained section; the third

is [U2, ΔUmax], called downshift section. The voltage

range of unrestrained section is almost 1.5 times as the

voltage change one step of OLTC caused, and the

voltage range of up shift or downshift section can meet

the requirements of the common fluctuation. For

example, the voltage range of downshift section should

cover the voltage change an anode effect caused.

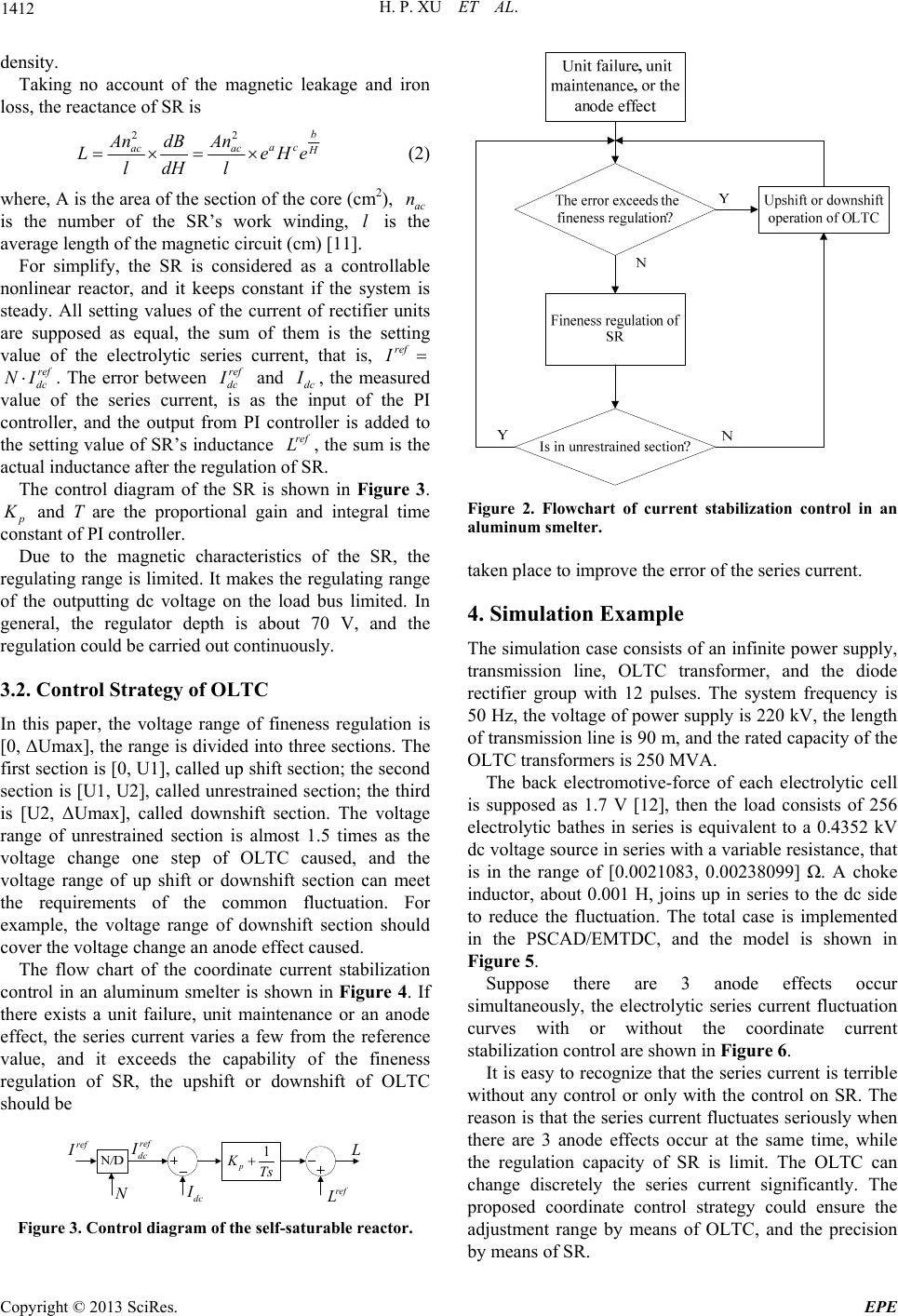

The flow chart of the coordinate current stabilization

control in an aluminum smelter is shown in Figure 4. If

there exists a unit failure, unit maintenance or an anode

effect, the series current varies a few from the reference

value, and it exceeds the capability of the fineness

regulation of SR, the upshift or downshift of OLTC

should be

ref

I

ref

dc

I

dc

I

ref

L

1

p

KTs

Figure 3. Control diagram of the self-saturable reactor.

Figure 2. Flowchart of current stabilization control in an

aluminum smelter.

taken place to improve the error of the series current.

4. Simulation Example

The simulation case consists of an infinite power supply,

transmission line, OLTC transformer, and the diode

rectifier group with 12 pulses. The system frequency is

50 Hz, the voltage of power supply is 220 kV, the length

of transmission line is 90 m, and the rated capacity of the

OLTC transformers is 250 MVA.

The back electromotive-force of each electrolytic cell

is supposed as 1.7 V [12], then the load consists of 256

electrolytic bathes in series is equivalent to a 0.4352 kV

dc voltage source in series with a variable resistance, that

is in the range of [0.0021083, 0.00238099] Ω. A choke

inductor, about 0.001 H, joins up in series to the dc side

to reduce the fluctuation. The total case is implemented

in the PSCAD/EMTDC, and the model is shown in

Figure 5.

Suppose there are 3 anode effects occur

simultaneously, the electrolytic series current fluctuation

curves with or without the coordinate current

stabilization control are shown in Figure 6.

It is easy to recognize that the series current is terrible

without any control or only with the control on SR. The

reason is that the series current fluctuates seriously when

there are 3 anode effects occur at the same time, while

the regulation capacity of SR is limit. The OLTC can

change discretely the series current significantly. The

proposed coordinate control strategy could ensure the

adjustment range by means of OLTC, and the precision

by means of SR.

Copyright © 2013 SciRes. EPE