Facile Synthesis of Polypyrrole/Titanate Core-Shell Nanorods and Their Electrorheological Characteristics

Copyright © 2011 SciRes. MSA

114

(a) (b)

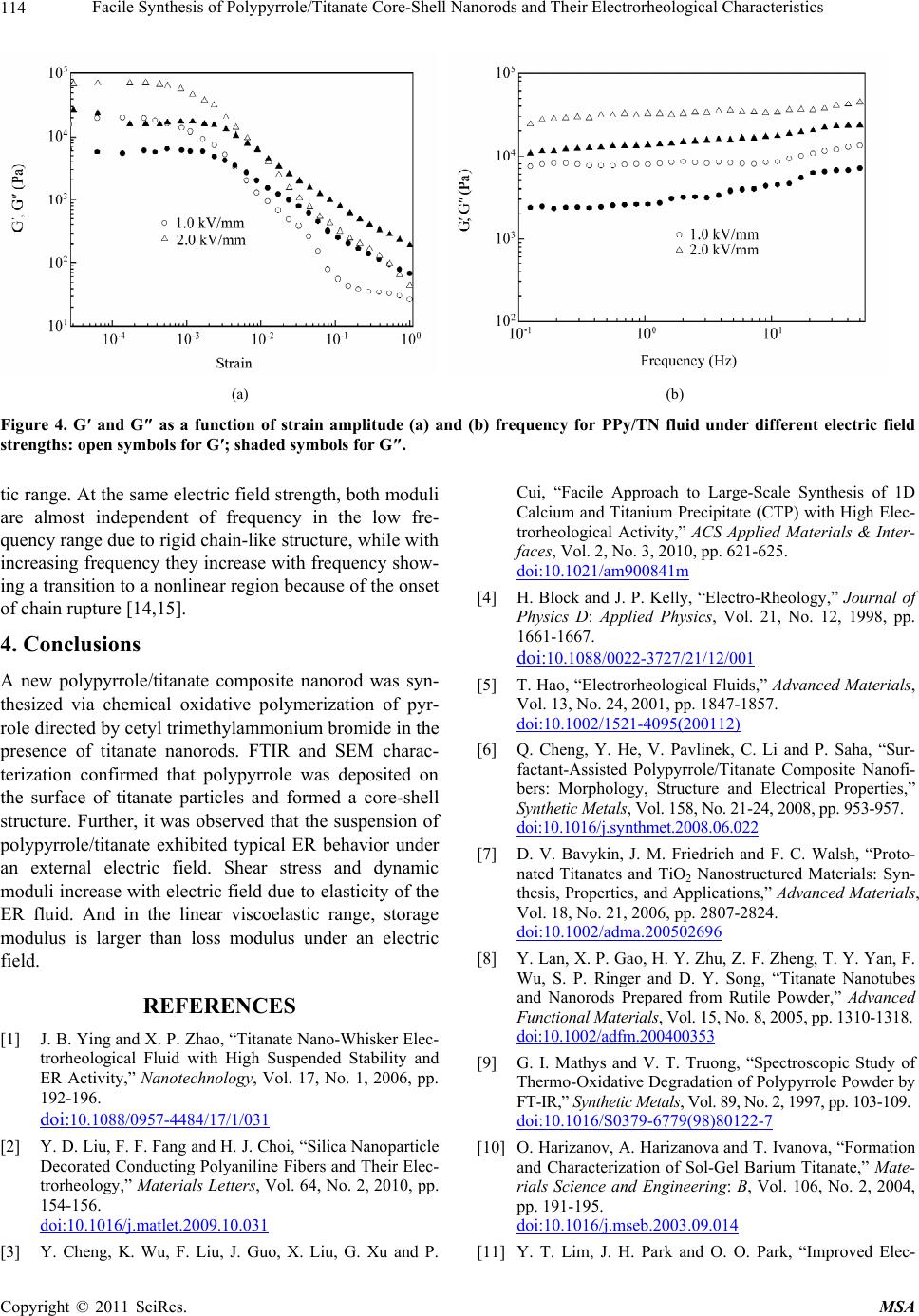

Figure 4. G′ and G″ as a function of strain amplitude (a) and (b) frequency for PPy/TN fluid under different electric field

strengths: open symbols for G′; shaded symbols for G″.

tic range. At the same electric field strength, both moduli

are almost independent of frequency in the low fre-

quency range due to rigid chain-like structure, while with

increasing frequency they increase with frequency show-

ing a transition to a nonlinear region because of the onset

of chain rupture [14,15].

4. Conclusions

A new polypyrrole/titanate composite nanorod was syn-

thesized via chemical oxidative polymerization of pyr-

role directed by cetyl trimethylammonium bromide in the

presence of titanate nanorods. FTIR and SEM charac-

terization confirmed that polypyrrole was deposited on

the surface of titanate particles and formed a core-shell

structure. Further, it was observed that the suspension of

polypyrrole/titanate exhibited typical ER behavior under

an external electric field. Shear stress and dynamic

moduli increase with electric field due to elasticity of the

ER fluid. And in the linear viscoelastic range, storage

modulus is larger than loss modulus under an electric

field.

REFERENCES

[1] J. B. Ying and X. P. Zhao, “Titanate Nano-Whisker Elec-

trorheological Fluid with High Suspended Stability and

ER Activity,” Nanotechnology, Vol. 17, No. 1, 2006, pp.

192-196.

doi:10.1088/0957-4484/17/1/031

[2] Y. D. Liu, F. F. Fang and H. J. Choi, “Silica Nanoparticle

Decorated Conducting Polyaniline Fibers and Their Elec-

trorheology,” Materials Letters, Vol. 64, No. 2, 2010, pp.

154-156.

doi:10.1016/j.matlet.2009.10.031

[3] Y. Cheng, K. Wu, F. Liu, J. Guo, X. Liu, G. Xu and P.

Cui, “Facile Approach to Large-Scale Synthesis of 1D

Calcium and Titanium Precipitate (CTP) with High Elec-

trorheological Activity,” ACS Applied Materials & Inter-

faces, Vol. 2, No. 3, 2010, pp. 621-625.

doi:10.1021/am900841m

[4] H. Block and J. P. Kelly, “Electro-Rheology,” Journal of

Physics D: Applied Physics, Vol. 21, No. 12, 1998, pp.

1661-1667.

doi:10.1088/0022-3727/21/12/001

[5] T. Hao, “Electrorheological Fluids,” Advanced Materials,

Vol. 13, No. 24, 2001, pp. 1847-1857.

doi:10.1002/1521-4095(200112)

[6] Q. Cheng, Y. He, V. Pavlinek, C. Li and P. Saha, “Sur-

factant-Assisted Polypyrrole/Titanate Composite Nanofi-

bers: Morphology, Structure and Electrical Properties,”

Synthetic Metals, Vol. 158, No. 21-24, 2008, pp. 953-957.

doi:10.1016/j.synthmet.2008.06.022

[7] D. V. Bavykin, J. M. Friedrich and F. C. Walsh, “Proto-

nated Titanates and TiO2 Nanostructured Materials: Syn-

thesis, Properties, and Applications,” Advanced Materials,

Vol. 18, No. 21, 2006, pp. 2807-2824.

doi:10.1002/adma.200502696

[8] Y. Lan, X. P. Gao, H. Y. Zhu, Z. F. Zheng, T. Y. Yan, F.

Wu, S. P. Ringer and D. Y. Song, “Titanate Nanotubes

and Nanorods Prepared from Rutile Powder,” Advanced

Functional Materials, Vol. 15, No. 8, 2005, pp. 1310-1318.

doi:10.1002/adfm.200400353

[9] G. I. Mathys and V. T. Truong, “Spectroscopic Study of

Thermo-Oxidative Degradation of Polypyrrole Powder by

FT-IR,” Synthetic Metals, Vol. 89, No. 2, 1997, pp. 103-109.

doi:10.1016/S0379-6779(98)80122-7

[10] O. Harizanov, A. Harizanova and T. Ivanova, “Formation

and Characterization of Sol-Gel Barium Titanate,” Mate-

rials Science and Engineering: B, Vol. 106, No. 2, 2004,

pp. 191-195.

doi:10.1016/j.mseb.2003.09.014

[11] Y. T. Lim, J. H. Park and O. O. Park, “Improved Elec-