T.-S. TSAY 91

Table 2. Gain/phase margins, phase/gain cr ossover frequen-

cies and rise times.

Method GM

Hz

cp

PM

(deg.)

Hz

cg

Rise Time

(sec)

Optimization 9.05 50.03 69.35 8.13 0.0202

Adaptive Gain 9.19 49.73 69.35 8.13 0.0124

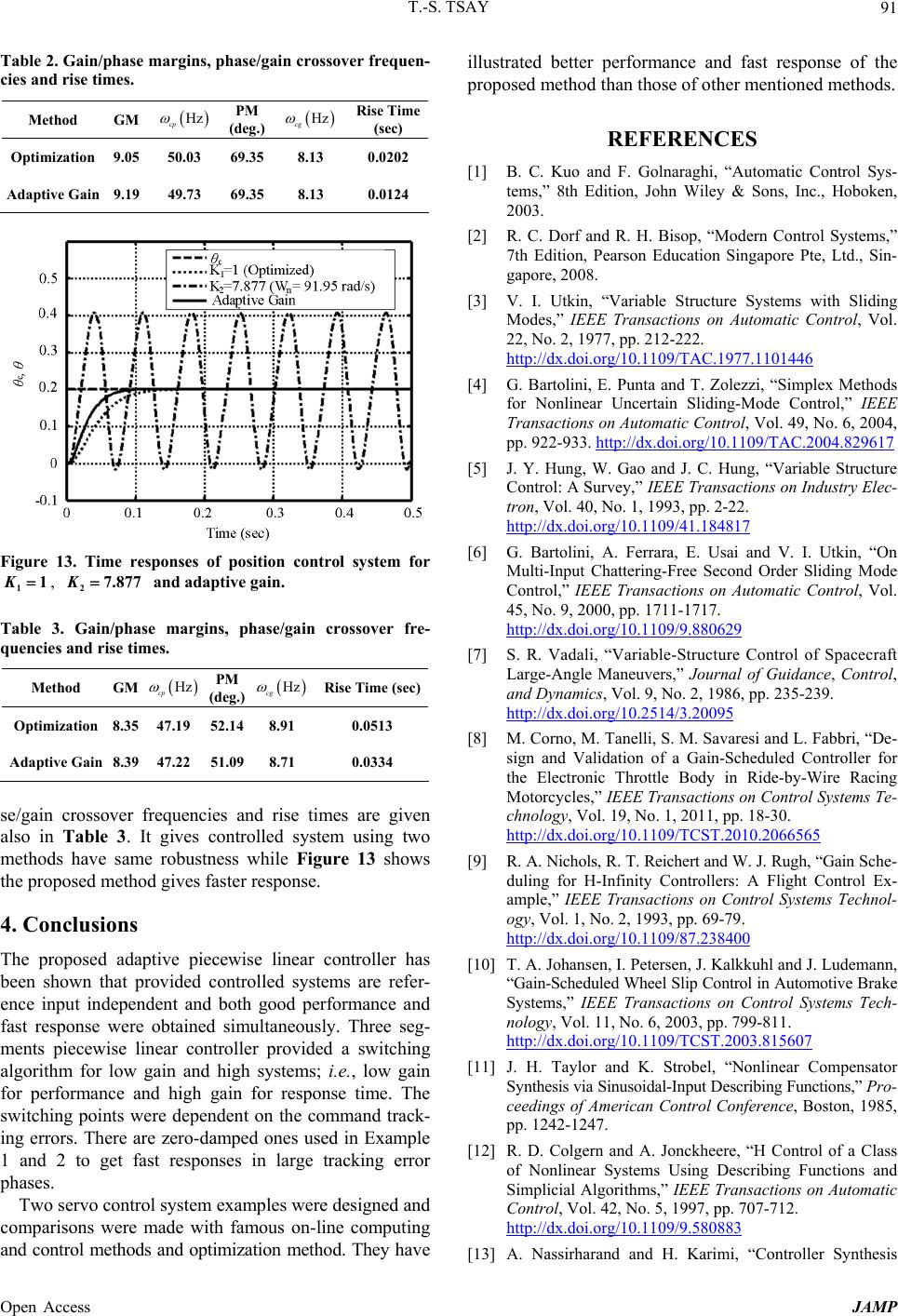

Figure 13. Time responses of position control system for

, and adaptive gain. K11K27.877

Table 3. Gain/phase margins, phase/gain crossover fre-

quencies and rise times.

Method GM

Hz

cp

PM

(deg.)

Hz

cg

Rise Time (sec)

Optimization 8.35 47.19 52.14 8.91 0.0513

Adaptive Gain 8.39 47.22 51.09 8.71 0.0334

se/gain crossover frequencies and rise times are given

also in Table 3. It gives controlled system using two

methods have same robustness while Figure 13 shows

the proposed method gives faster response.

4. Conclusions

The proposed adaptive piecewise linear controller has

been shown that provided controlled systems are refer-

ence input independent and both good performance and

fast response were obtained simultaneously. Three seg-

ments piecewise linear controller provided a switching

algorithm for low gain and high systems; i.e., low gain

for performance and high gain for response time. The

switching points were dependent on the command track-

ing errors. There are zero-damped ones used in Example

1 and 2 to get fast responses in large tracking error

phases.

Two servo control system examples were designed and

comparisons were made with famous on-line computing

and control methods and optimization method. They have

illustrated better performance and fast response of the

proposed method than those of other mentioned methods.

REFERENCES

[1] B. C. Kuo and F. Golnaraghi, “Automatic Control Sys-

tems,” 8th Edition, John Wiley & Sons, Inc., Hoboken,

2003.

[2] R. C. Dorf and R. H. Bisop, “Modern Control Systems,”

7th Edition, Pearson Education Singapore Pte, Ltd., Sin-

gapore, 2008.

[3] V. I. Utkin, “Variable Structure Systems with Sliding

Modes,” IEEE Transactions on Automatic Control, Vol.

22, No. 2, 1977, pp. 212-222.

http://dx.doi.org/10.1109/TAC.1977.1101446

[4] G. Bartolini, E. Punta and T. Zolezzi, “Simplex Methods

for Nonlinear Uncertain Sliding-Mode Control,” IEEE

Transactions on Automatic Control, Vol. 49, No. 6, 2004,

pp. 922-933. http://dx.doi.org/10.1109/TAC.2004.829617

[5] J. Y. Hung, W. Gao and J. C. Hung, “Variable Structure

Control: A Survey,” IEEE Transactions on Industry Elec-

tron, Vol. 40, No. 1, 1993, pp. 2-22.

http://dx.doi.org/10.1109/41.184817

[6] G. Bartolini, A. Ferrara, E. Usai and V. I. Utkin, “On

Multi-Input Chattering-Free Second Order Sliding Mode

Control,” IEEE Transactions on Automatic Control, Vol.

45, No. 9, 2000, pp. 1711-1717.

http://dx.doi.org/10.1109/9.880629

[7] S. R. Vadali, “Variable-Structure Control of Spacecraft

Large-Angle Maneuvers,” Journal of Guidance, Control,

and Dynamics, Vol. 9, No. 2, 1986, pp. 235-239.

http://dx.doi.org/10.2514/3.20095

[8] M. Corno, M. Tanelli, S. M. Savaresi and L. Fabbri, “De-

sign and Validation of a Gain-Scheduled Controller for

the Electronic Throttle Body in Ride-by-Wire Racing

Motorcycles,” IEEE Transactions on Control Systems Te-

chnology, Vol. 19, No. 1, 2011, pp. 18-30.

http://dx.doi.org/10.1109/TCST.2010.2066565

[9] R. A. Nichols, R. T. Reichert and W. J. Rugh, “Gain Sche-

duling for H-Infinity Controllers: A Flight Control Ex-

ample,” IEEE Transactions on Control Systems Technol-

ogy, Vol. 1, No. 2, 1993, pp. 69-79.

http://dx.doi.org/10.1109/87.238400

[10] T. A. Johansen, I. Petersen, J. Kalkkuhl and J. Ludemann,

“Gain-Scheduled Wheel Slip Control in Automotive Brake

Systems,” IEEE Transactions on Control Systems Tech-

nology, Vol. 11, No. 6, 2003, pp. 799-811.

http://dx.doi.org/10.1109/TCST.2003.815607

[11] J. H. Taylor and K. Strobel, “Nonlinear Compensator

Synthesis via Sinusoidal-Input Describing Functions,” Pro-

ceedings of American Control Conference, Boston, 1985,

pp. 1242-1247.

[12] R. D. Colgern and A. Jonckheere, “H Control of a Class

of Nonlinear Systems Using Describing Functions and

Simplicial Algorithms,” IEEE Transactions on Automatic

Control, Vol. 42, No. 5, 1997, pp. 707-712.

http://dx.doi.org/10.1109/9.580883

[13] A. Nassirharand and H. Karimi, “Controller Synthesis

Open Access JAMP