One-Step Preparation of Poly-Lactic-Co-Glycolic-Acid Microparticles to Prevent the Initial Burst Release of

Encapsulated Water-Soluble Proteins

582

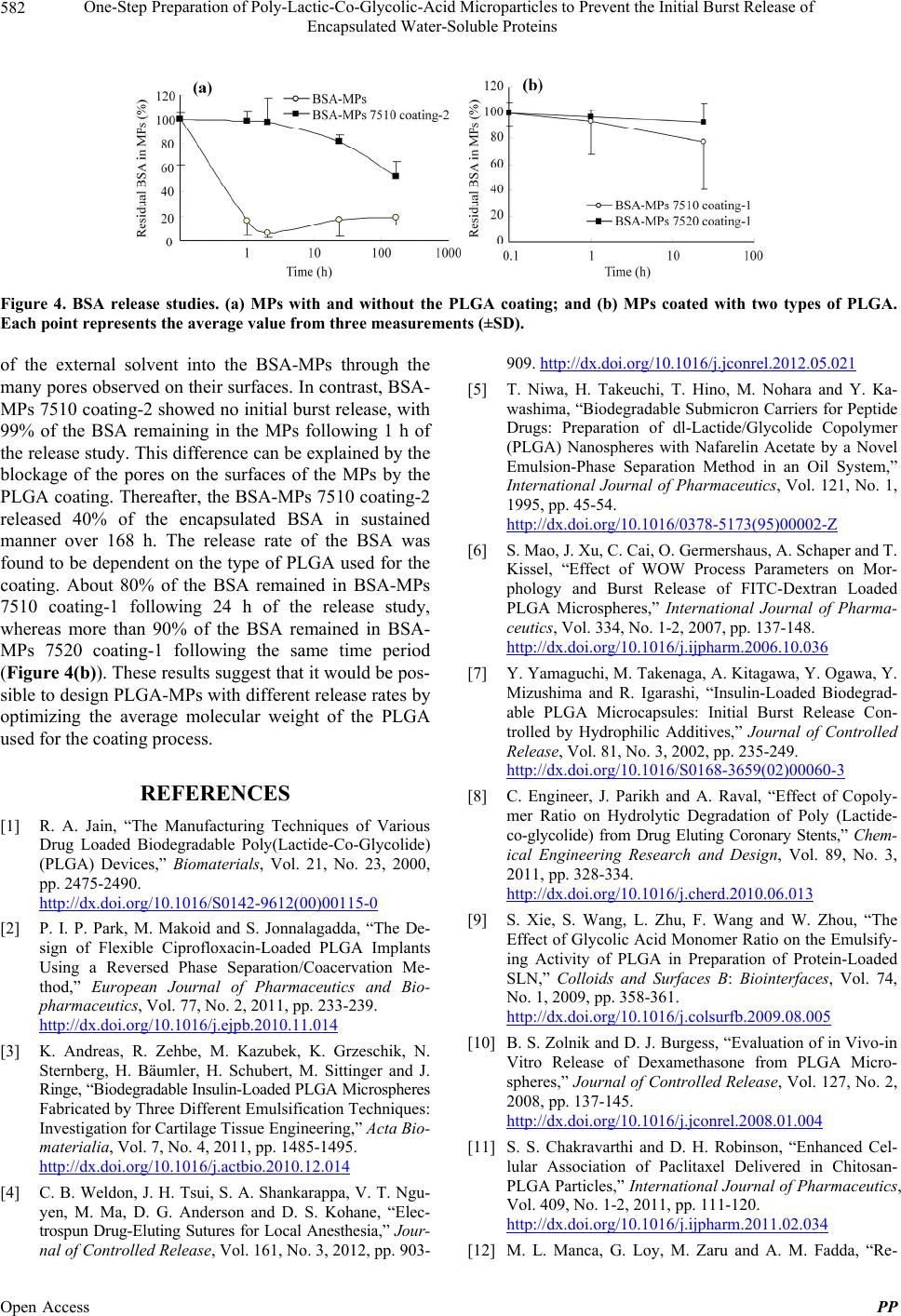

Figure 4. BSA release studies. (a) MPs with and without the PLGA coating; and (b) MPs coated with two types of PLGA.

Each point represents the average value from three measurements (±SD).

of the external solvent into the BSA-MPs through the

many pores observed on their surfaces. In contrast, BSA-

MPs 7510 coating-2 showed no initial burst release, with

99% of the BSA remaining in the MPs following 1 h of

the release study. This difference can be explained by the

blockage of the pores on the surfaces of the MPs by the

PLGA coating. Thereafter, the BSA-MPs 7510 coating-2

released 40% of the encapsulated BSA in sustained

manner over 168 h. The release rate of the BSA was

found to be dependent on the type of PLGA used for the

coating. About 80% of the BSA remained in BSA-MPs

7510 coating-1 following 24 h of the release study,

whereas more than 90% of the BSA remained in BSA-

MPs 7520 coating-1 following the same time period

(Figure 4(b)). These results suggest that it would be pos-

sible to design PLGA-MPs with different release rates by

optimizing the average molecular weight of the PLGA

used for the coating process.

REFERENCES

[1] R. A. Jain, “The Manufacturing Techniques of Various

Drug Loaded Biodegradable Poly(Lactide-Co-Glycolide)

(PLGA) Devices,” Biomaterials, Vol. 21, No. 23, 2000,

pp. 2475-2490.

http://dx.doi.org/10.1016/S0142-9612(00)00115-0

[2] P. I. P. Park, M. Makoid and S. Jonnalagadda, “The De-

sign of Flexible Ciprofloxacin-Loaded PLGA Implants

Using a Reversed Phase Separation/Coacervation Me-

thod,” European Journal of Pharmaceutics and Bio-

pharmaceutics, Vol. 77, No. 2, 2011, pp. 233-239.

http://dx.doi.org/10.1016/j.ejpb.2010.11.014

[3] K. Andreas, R. Zehbe, M. Kazubek, K. Grzeschik, N.

Sternberg, H. Bäumler, H. Schubert, M. Sittinger and J.

Ringe, “Biodegradable Insulin-Loaded PLGA Microspheres

Fabricated by Three Different Emulsification Techniques:

Investigation for Cartilage Tissue Engineering,” Acta Bio-

materialia, Vol. 7, No. 4, 2011, pp. 1485-1495.

http://dx.doi.org/10.1016/j.actbio.2010.12.014

[4] C. B. Weldon, J. H. Tsui, S. A. Shankarappa, V. T. Ngu-

yen, M. Ma, D. G. Anderson and D. S. Kohane, “Elec-

trospun Drug-Eluting Sutures for Local Anesthesia,” Jour-

nal of Controlled Release, Vol. 161, No. 3, 2012, pp. 903-

909. http://dx.doi.org/10.1016/j.jconrel.2012.05.021

[5] T. Niwa, H. Takeuchi, T. Hino, M. Nohara and Y. Ka-

washima, “Biodegradable Submicron Carriers for Peptide

Drugs: Preparation of dl-Lactide/Glycolide Copolymer

(PLGA) Nanospheres with Nafarelin Acetate by a Novel

Emulsion-Phase Separation Method in an Oil System,”

International Journal of Pharmaceutics, Vol. 121, No. 1,

1995, pp. 45-54.

http://dx.doi.org/10.1016/0378-5173(95)00002-Z

[6] S. Mao, J. Xu, C. Cai, O. Germershaus, A. Schaper and T.

Kissel, “Effect of WOW Process Parameters on Mor-

phology and Burst Release of FITC-Dextran Loaded

PLGA Microspheres,” International Journal of Pharma-

ceutics, Vol. 334, No. 1-2, 2007, pp. 137-148.

http://dx.doi.org/10.1016/j.ijpharm.2006.10.036

[7] Y. Yamaguchi, M. Takenaga, A. Kitagawa, Y. Ogawa, Y.

Mizushima and R. Igarashi, “Insulin-Loaded Biodegrad-

able PLGA Microcapsules: Initial Burst Release Con-

trolled by Hydrophilic Additives,” Journal of Controlled

Release, Vol. 81, No. 3, 2002, pp. 235-249.

http://dx.doi.org/10.1016/S0168-3659(02)00060-3

[8] C. Engineer, J. Parikh and A. Raval, “Effect of Copoly-

mer Ratio on Hydrolytic Degradation of Poly (Lactide-

co-glycolide) from Drug Eluting Coronary Stents,” Chem-

ical Engineering Research and Design, Vol. 89, No. 3,

2011, pp. 328-334.

http://dx.doi.org/10.1016/j.cherd.2010.06.013

[9] S. Xie, S. Wang, L. Zhu, F. Wang and W. Zhou, “The

Effect of Glycolic Acid Monomer Ratio on the Emulsify-

ing Activity of PLGA in Preparation of Protein-Loaded

SLN,” Colloids and Surfaces B: Biointerfaces, Vol. 74,

No. 1, 2009, pp. 358-361.

http://dx.doi.org/10.1016/j.colsurfb.2009.08.005

[10] B. S. Zolnik and D. J. Burgess, “Evaluation of in Vivo-in

Vitro Release of Dexamethasone from PLGA Micro-

spheres,” Journal of Controlled Release, Vol. 127, No. 2,

2008, pp. 137-145.

http://dx.doi.org/10.1016/j.jconrel.2008.01.004

[11] S. S. Chakravarthi and D. H. Robinson, “Enhanced Cel-

lular Association of Paclitaxel Delivered in Chitosan-

PLGA Particles,” International Journal of Pharmaceutics,

Vol. 409, No. 1-2, 2011, pp. 111-120.

http://dx.doi.org/10.1016/j.ijpharm.2011.02.034

[12] M. L. Manca, G. Loy, M. Zaru and A. M. Fadda, “Re-

Open Access PP