Z. PĘDZICH ET AL.

Copyright © 2013 SciRes. MSCE

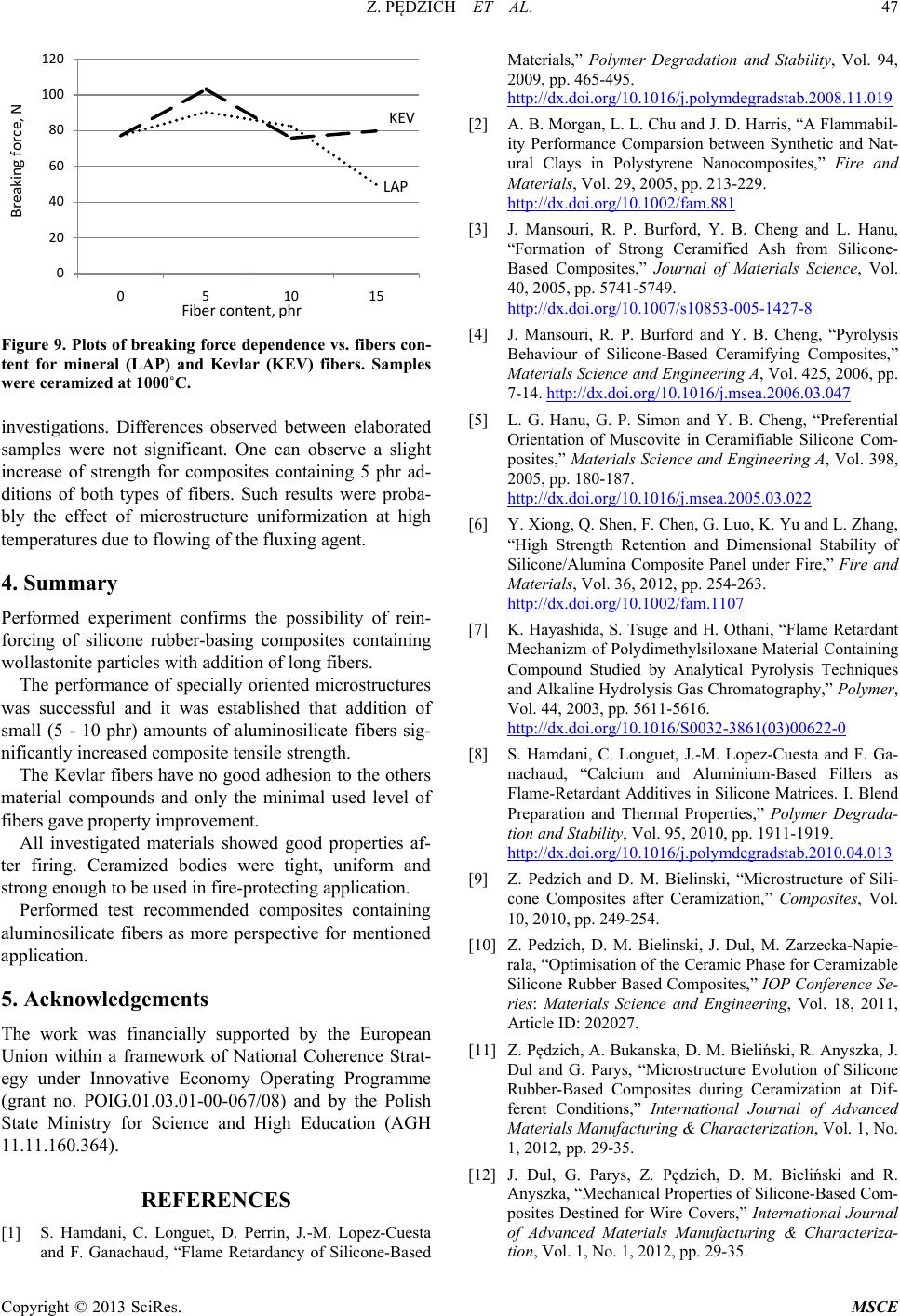

Figure 9. Plots of breaking force dependence vs. fibers con-

tent for mineral (LAP) and Kevlar (KEV) fibers. Samples

were ceramized at 1000˚C.

investigations. Differences observed between elaborated

samples were not significant. One can observe a slight

increase of strength for composites containing 5 phr ad-

ditions of both types of fibers. Such results were proba-

bly the effect of microstructure uniformization at high

temperatures due to flowing of the fluxing agent.

4. Summary

Performed experiment confirms the possibility of rein-

forcing of silicone rubber-basing composites containing

wollastonite particles with addition of long fibers.

The performance of specially oriented microstructures

was successful and it was established that addition of

small (5 - 10 phr) amounts of aluminosilicate fibers sig-

nificantly in creased composite tensile strength.

The Kevlar fibers have no good adhesion to the others

material compounds and only the minimal used level of

fibers gave property improvement.

All investigated materials showed good properties af-

ter firing. Ceramized bodies were tight, uniform and

strong enough to be used in fire-protecting application.

Performed test recommended composites containing

aluminosilicate fibers as more perspective for mentioned

application.

5. Acknowledgements

The work was financially supported by the European

Union within a framework of National Coherence Strat-

egy under Innovative Economy Operating Programme

(grant no. POIG.01.03.01-00-067/08) and by the Polish

State Ministry for Science and High Education (AGH

11.11.160.364).

REFERENCES

[1] S. Hamdani, C. Longuet, D. Perrin, J.-M. Lopez-Cuesta

and F. Ganachaud, “Flame Retardancy of Silicone-Based

Materials,” Polymer Degradation and Stability, Vol. 94,

2009, pp. 465-495.

http://dx.doi.org/10.1016/j.polymdegradstab.2008.11.019

[2] A. B. Morgan, L. L. Chu and J. D. Harris, “A Flammabil-

ity Performance Comparsion between Synthetic and Nat-

ural Clays in Polystyrene Nanocomposites,” Fire and

Materials, Vol. 29, 2005, pp. 213-229.

http://dx.doi.org/10.1002/fam.881

[3] J. Mansouri, R. P. Burford, Y. B. Cheng and L. Hanu,

“Formation of Strong Ceramified Ash from Silicone-

Based Composites,” Journal of Materials Science, Vol.

40, 2005, pp. 5741-5749.

http://dx.doi.org/10.1007/s10853-005-1427-8

[4] J. Mansouri, R. P. Burford and Y. B. Cheng, “Pyrolysis

Behaviour of Silicone-Based Ceramifying Composites,”

Materials Science and Engineering A, Vol. 425, 2006, pp.

7-14. http://dx.doi.org/10.1016/j.msea.2006.03.047

[5] L. G. Hanu, G. P. Simon and Y. B. Cheng, “Preferential

Orientation of Muscovite in Ceramifiable Silicone Com-

posites,” Materials Science and Engineering A, Vol. 398,

2005, pp. 180-187.

http://dx.doi.org/10.1016/j.msea.2005.03.022

[6] Y. Xiong, Q. Shen, F. Chen, G. Luo, K. Yu and L. Zhang,

“High Strength Retention and Dimensional Stability of

Silicone/Alumina Composite Panel under Fire,” Fire and

Materials, Vol. 36, 2012, pp. 254-263.

http://dx.doi.org/10.1002/fam.1107

[7] K. Hayashida, S. Tsuge and H. Othani, “Flame Retardant

Mechanizm of Polydimethylsiloxane Material Containing

Compound Studied by Analytical Pyrolysis Techniques

and Alkaline Hydrolysis Gas Chromatography,” Polymer,

Vol. 44, 2003, pp. 5611-5616.

http://dx.doi.org/10.1016/S0032-3861(03)00622-0

[8] S. Hamdani, C. Longuet, J.-M. Lopez-Cuesta and F. Ga-

nachaud, “Calcium and Aluminium-Based Fillers as

Flame-Retardant Additives in Silicone Matrices. I. Blend

Preparation and Thermal Properties,” Polymer Degrada-

tion and Stability, Vol. 95, 2010, pp. 1911-1919.

http://dx.doi.org/10.1016/j.polymdegradstab.2010.04.013

[9] Z. Pedzich and D. M. Bielinski, “Microstructure of Sili-

cone Composites after Ceramization,” Composites, Vol.

10, 2010, pp. 249-254.

[10] Z. Pedzich, D. M. Bielinski, J. Dul, M. Zarzecka-Napie-

rala, “Optimisation of the Ceramic Phase for Ceramizable

Silicone Rubber Based Composites,” IOP Conference Se-

ries: Materials Science and Engineering, Vol. 18, 2011,

Article ID: 202027.

[11] Z. Pędzich, A. Bukanska, D. M. Bieliński, R. Anyszka, J.

Dul and G. Parys, “Microstructure Evolution of Silicone

Rubber-Based Composites during Ceramization at Dif-

ferent Conditions,” International Journal of Advanced

Materials Manufacturing & Characterization, Vol. 1, No.

1, 2012, pp. 29-35.

[12] J. Dul, G. Parys, Z. Pędzich, D. M. Bieliński and R.

Anyszka, “Mechanical Properties of Silicone-Based Com-

posites Destined for Wire Covers,” International Journal

of Advanced Materials Manufacturing & Characteriza-

tion, Vol. 1, No. 1, 2012, pp. 29-35.