J. Y. KANG ET AL.

908

1.04 1.06 1.08 1.10 1.12 1.14 1.16 1.18

100

150

200

250

300

350

400

450

500

Contact P ressure (MPa)

t/t0

d1=5.5mm

d1=6.0mm

d1=6.5mm

16mm

t0=5.5mmt

d1

5mm

Figure 10. Comparison of mean pressure in sleeve accord-

ing to the variation of the inner diameter of sleeve.

with the inner diameter (d1) and the thickness ratio (t/t0)

of the steel pipe sleeve as parameters considering the

prestressing reinforcement using a CFRP tendon with

diameter of 5 mm. The results enabled to derive the fol-

lowing optimal dimensions of the sleeve achieving the

required bond performance without occurrence of slip of

the tendon in the sleeve.

(1) A constant pressure of approximately 450 MPa can

be obtained in the effective swaging zone when the

thickness ratio (t/t0) of the sleeve is larger than 1.1. Since

the pressure which is required to extrude the sleeve in-

creases with larger thickness ratio, the optimal value of

the thickness ratio app ears to be 1.1 considering the effi-

ciency of construction.

(2) Assuming a thickness ratio (t/t0) of 1.1, the varia-

tion of the inner diameter of the sleeve is seen to affect

the swaging pressure less than 10%. Accordingly, the

optimal value of the inner diameter of the sleeve should

be 5.5 mm to reduce the amount of steel and minimize

the pressure during the ex trusion.

(3) For a dice with diameter of 16 mm and a sleeve

with thicknesses t0 = 5.5 mm and t = 6.1 mm, and inner

diameter d1 = 5.5 mm, the effective swaging pressure

developed in the sleeve takes value of about 440 MPa.

The corresponding bond force is approximately 104 kN

when the length of the effective swaging zone of the

sleeve is 80 mm. This value represents about 1.5 times

the rupture strength of 70 kN of the CFRP tendon with

diameter of 5 mm and indicates that sufficient bond

strength can be secured during prestressing. In order to

obtain a bond force comparable to the rupture strength of

the CFRP tendon, the length of the effective swaging

zone should run around 67.5 mm. The application of a

sleeve presenting a longer length of the effective swaging

zone will thus achieve sufficient bond performance.

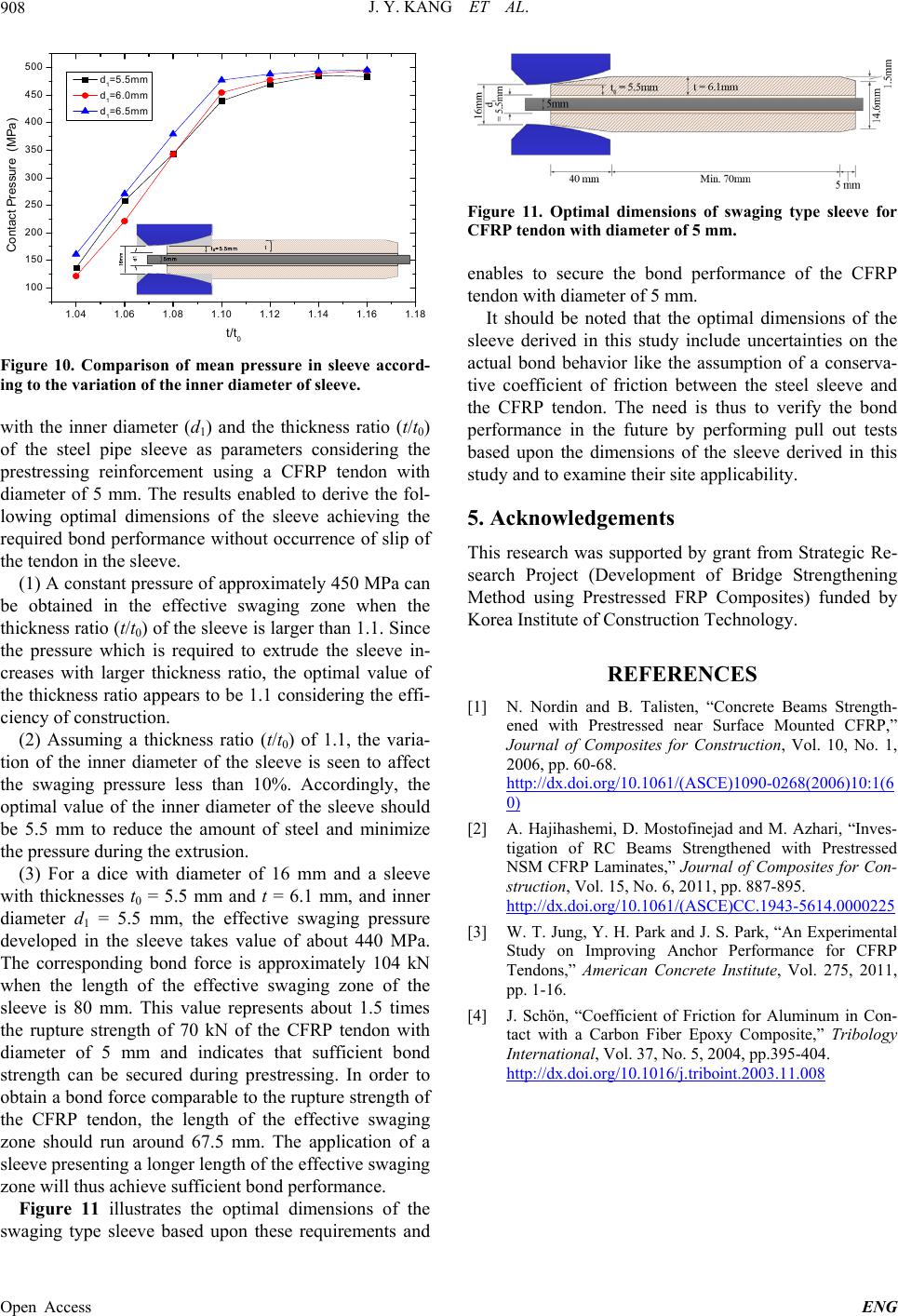

Figure 11 illustrates the optimal dimensions of the

waging type sleeve based upon these requirements and s

Figure 11. Optimal dimensions of swaging type sleeve for

CFRP tendon with diame ter of 5 mm.

enables to secure the bond performance of the CFRP

tendon with diameter of 5 mm.

It should be noted that the optimal dimensions of the

sleeve derived in this study include uncertainties on the

actual bond behavior like the assumption of a conserva-

tive coefficient of friction between the steel sleeve and

the CFRP tendon. The need is thus to verify the bond

performance in the future by performing pull out tests

based upon the dimensions of the sleeve derived in this

study and to examine their site applicability.

5. Acknowledgements

This research was supported by grant from Strategic Re-

search Project (Development of Bridge Strengthening

Method using Prestressed FRP Composites) funded by

Korea Institute of Construction Technology.

REFERENCES

[1] N. Nordin and B. Talisten, “Concrete Beams Strength-

ened with Prestressed near Surface Mounted CFRP,”

Journal of Composites for Construction, Vol. 10, No. 1,

2006, pp. 60-68.

http://dx.doi.org/10.1061/(ASCE)1090-0268(2006)10:1(6

0)

[2] A. Hajihashemi, D. Mostofinejad and M. Azhari, “Inves-

tigation of RC Beams Strengthened with Prestressed

NSM CFRP Laminates,” Journal of Composites for Con-

struction, Vol. 15, No. 6, 2011, pp. 887-895.

http://dx.doi.org/10.1061/(ASCE)CC.1943-5614.0000225

[3] W. T. Jung, Y. H. Park and J. S. Park, “An Experimental

Study on Improving Anchor Performance for CFRP

Tendons,” American Concrete Institute, Vol. 275, 2011,

pp. 1-16.

[4] J. Schön, “Coefficient of Friction for Aluminum in Con-

tact with a Carbon Fiber Epoxy Composite,” Tribology

International, Vol. 37, No. 5, 2004, pp.395-404.

http://dx.doi.org/10.1016/j.triboint.2003.11.008

Open Access ENG