Paper Menu >>

Journal Menu >>

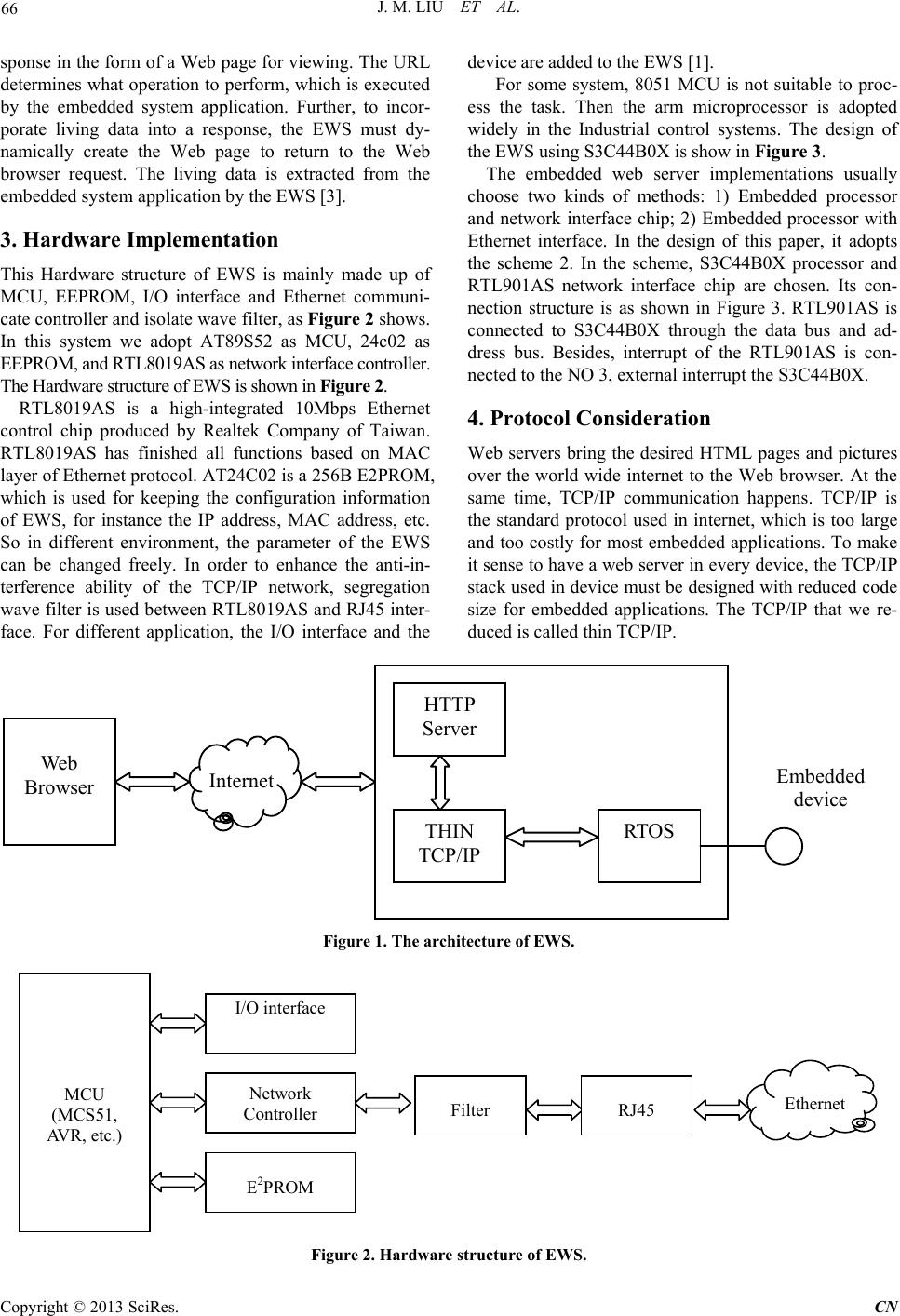

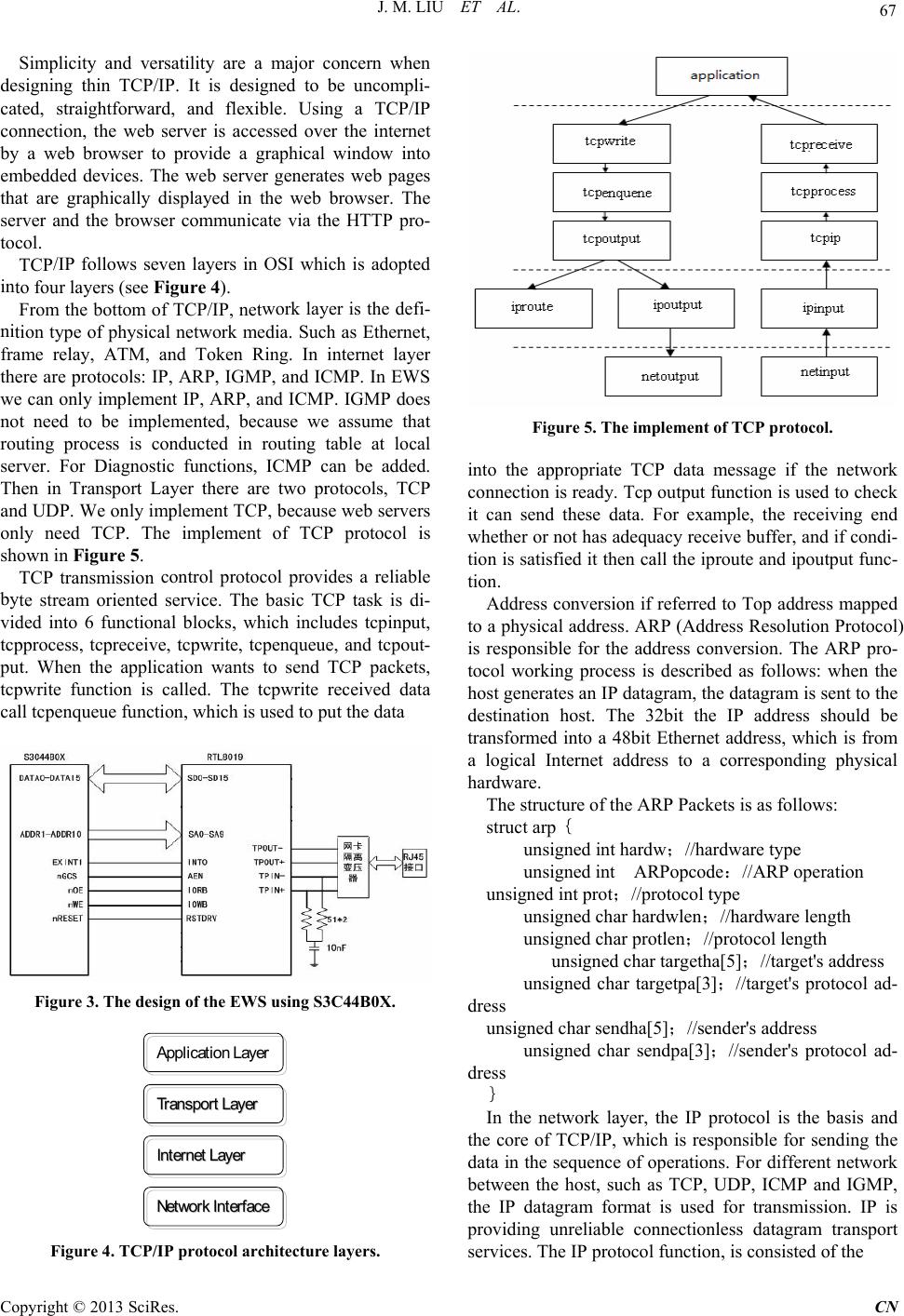

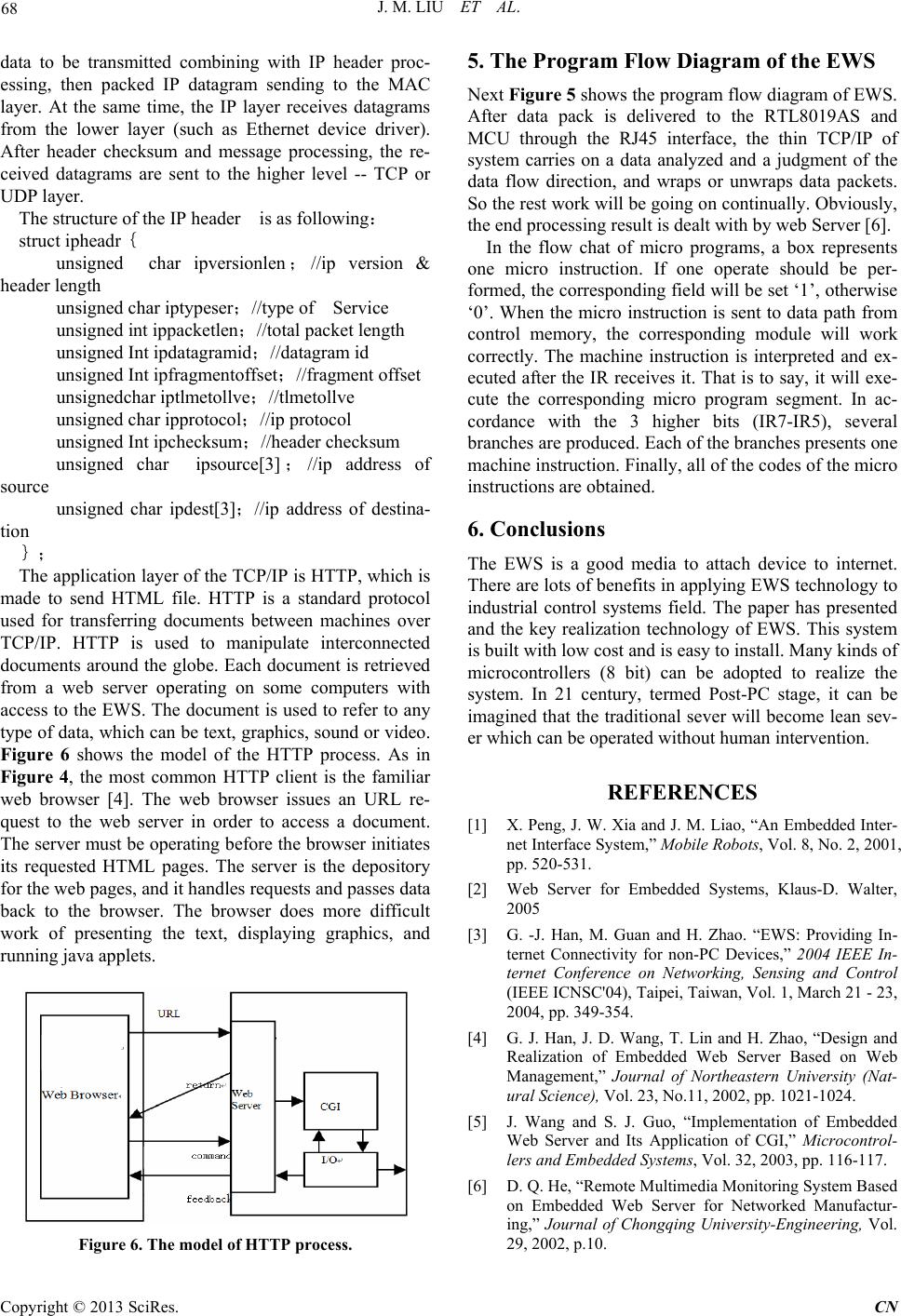

Communications and Network, 2013, 5, 65-68 doi:10.4236/cn.2013.51B015 Published Online February 2013 (http://www.scirp.org/journal/cn) Design and Implementation of Embedded Web Server in Industrial Control Systems Jianming Liu1, Yunjie Zhang2, Lili Xu3, Jincai Wang1 1Computer Department, Weifang Medical University, Weifang, China 2Electronic & Information Engineering Department, Tianjin Institute of Urban Construction, Tianjin, China 3Weifang Vocational College, Weifang, China Email: sdwfljm@126.com Received 2012 ABSTRACT In the traditional project of ind ustry control, the field operator is the only man who watches productio n condition at the production spot. Enterprise administers cannot obtain real-time production status and make real-time decision if they don’t reach the production spot. Because of the development of Embedded Web Server such status is being changed. The remote monitor and control mode based on Embedded Web Server provides complete exact real-time information for managers, and makes it possible to make a decision in real time. In the paper, the design and implements of Embed- ded Web Server are presented and the key realization technology of it is described in detail. EWS (Embedded Web Server) will effectively lower system operating cost and improve maintaining efficiency, which has wide application prospect and populari zat i o n v al ue in industrial control systems. Keywords: Emb edd ed W eb Server (EWS); TCP/IP; HTTP; Industrial Control Systems 1. Introduction With the rapid development of the computer and network technology, it has caused the technical revolution with the industrial control systems. Now, the network, open- ing structure becomes the main developing trend of the industrial control systems. At present, World-Wide Web (WWW) is one of the most widely used internet applica- tions. The technology is very rapidly penetrating many social and business areas. Now most of embedded sys- tems are still in use alone, so the embedded equipments should be improved as soon as possible. On the other hand, a huge amount of embedded equipments are based on 8-bit microcontrollers, such as instrument and appa- ratus, real- time application and process controlling, home automation, etc. Without exception, the industrial control systems can be equipped with Web servers for providing Web-based network communication. This type of Web server is called an Embedded Web Server (EWS). Based on EWS, the remote monitor and control mode provides complete exact real-time information for man- agers, and makes it possible to make a decision in real time [1]. In the conditions of EWS-equipped devices, the users can use web browser to manage devices and to receive and send data to browsers anywhere in the world in order to configure, monitor and control them. By the Web browsers, users can manage individual devices remotely. This scheme provides a user with a simple but powerful user interface. Most embedded devices based on 8-bit microcontrollers, contain a small amount of memory, so in the design and implementation of EWS, some optimi- zation techniques must be applied. In this paper, a kind of design and implementation of EWS has been intro- duced and the key realization technology of it is de- scribed in detail. The technology uses the 8-bit micro- controllers and network interface controller, such as UMC9005, RTL8019AS, CS8900, etc., and adopts thin TCP/IP protocols to transmit data. The result of experi- ment proves that it is feasible to realize the target at very low costs [2]. 2. System Architecture of the EWS The architecture of whole system is shown in the Figure 1. A EWS is a web server that has been designed to em- bed in different kinds of small devices. Anyone who is authorized may access the system if he knows the IP of the installed web server. The client doesn’t need install any special software besides the internet Explorer or oth- er browsers. By browser users who have been authorized can configure, control the embedded device, and also set up network of the web server. A EWS communicates via thin HTTP to a Web browser by receiving a request which indicates the op- eration that the user wants to perform, and sends a re- Copyright © 2013 SciRes. CN  J. M. LIU ET AL. 66 sponse in the form of a Web page for viewing. The URL determines what operation to perform, which is ex ecuted by the embedded system application. Further, to incor- porate living data into a response, the EWS must dy- namically create the Web page to return to the Web browser request. The living data is extracted from the embedded system application by the EWS [3]. 3. Hardware Implementation This Hardware structure of EWS is mainly made up of MCU, EEPROM, I/O interface and Ethernet communi- cate controller and isolate wave filter, as Figure 2 shows. In this system we adopt AT89S52 as MCU, 24c02 as EEPROM, and RTL8019AS as network interface controller. The Hardware structure of EWS is shown in Figure 2. RTL8019AS is a high-integrated 10Mbps Ethernet control chip produced by Realtek Company of Taiwan. RTL8019AS has finished all functions based on MAC layer of Ethernet protocol. AT24C02 is a 256B E2PROM, which is used for keeping the configuration information of EWS, for instance the IP address, MAC address, etc. So in different environment, the parameter of the EWS can be changed freely. In order to enhance the anti-in- terference ability of the TCP/IP network, segregation wave filter is used between RTL8019AS and RJ45 inter- face. For different application, the I/O interface and the device are added to the EWS [1]. For some system, 8051 MCU is not suitable to proc- ess the task. Then the arm microprocessor is adopted widely in the Industrial control systems. The design of the EWS using S3C44B0X is show in Figure 3. The embedded web server implementations usually choose two kinds of methods: 1) Embedded processor and network interface chip; 2) Embedded processor with Ethernet interface. In the design of this paper, it adopts the scheme 2. In the scheme, S3C44B0X processor and RTL901AS network interface chip are chosen. Its con- nection structure is as shown in Figure 3. RTL901AS is connected to S3C44B0X through the data bus and ad- dress bus. Besides, interrupt of the RTL901AS is con- nected to the NO 3, external interrupt the S3C44B0X. 4. Protocol Consideration Web servers bring the desired HTML pages and pictures over the world wide internet to the Web browser. At the same time, TCP/IP communication happens. TCP/IP is the standard protocol used in internet, which is too large and too costly for most embedded applications. To make it sense to have a web server in every device, the TCP/IP stack used in device must be designed with reduced code size for embedded applications. The TCP/IP that we re- duced is called thin TCP/IP. Embedded device Web Browser Internet HTTP Server THIN TCP/ IP RTOS Figure 1. The architecture of EWS. MCU (MCS51, AVR, etc.) Network Controller I/O interface E 2 PROM RJ45 Ethernet Filter Figure 2. Hardware structure of EWS. Copyright © 2013 SciRes. CN  J. M. LIU ET AL. 67 Simplicity and versatility are a majo e /IP follows seven layers in OSI which is adopted in work layer is the defi- ni control protocol provides a reliable by r concern when dsigning thin TCP/IP. It is designed to be uncompli- cated, straightforward, and flexible. Using a TCP/IP connection, the web server is accessed over the internet by a web browser to provide a graphical window into embedded devices. The web server generates web pages that are graphically displayed in the web browser. The server and the browser communicate via the HTTP pro- tocol. TCP to four layers (see Figure 4). From the bottom of TCP/IP, net tion type of physical network media. Such as Ethernet, frame relay, ATM, and Token Ring. In internet layer there are protocols: IP, ARP, IGMP, and ICMP. In EWS we can only implement IP, ARP, and ICMP. IGMP does not need to be implemented, because we assume that routing process is conducted in routing table at local server. For Diagnostic functions, ICMP can be added. Then in Transport Layer there are two protocols, TCP and UDP. We only implement TCP, because web servers only need TCP. The implement of TCP protocol is shown in Figure 5. TCP transmission te stream oriented service. The basic TCP task is di- vided into 6 functional blocks, which includes tcpinput, tcpprocess, tcpreceive, tcpwrite, tcpenqueue, and tcpout- put. When the application wants to send TCP packets, tcpwrite function is called. The tcpwrite received data call tcpenqueue function, which is used to put the data Figure 3. The design of the EWS using S3C44B0X. Application Layer T Tr ra an ns sp po or rt t L La ay ye er r I In nt te er rn ne et t L La ay ye er r N Ne et tw wo or rk k I In nt te er rf fa ac ce e Figure 5. The implement of TCP protocol. into the appetwork onnecti check ess l ad- dr re of TCP/IP, which is responsible for sending the da ropriate TCP data message if the n on is ready. Tcp output function is used to c it can send these data. For example, the receiving end whether or not has adequacy receive buffer, and if condi- tion is satisfied it then call th e iproute and ipoutput func- tion. Address conversion if referred to Top address mapped to a physical address. ARP (Address Resolution Protocol) is responsible for the address conversion. The ARP pro- tocol working process is described as follows: when the host generates an IP datagram, the datagram is sent to the destination host. The 32bit the IP address should be transformed into a 48bit Ethernet address, which is from a logical Internet address to a corresponding physical hardware. The structure of the ARP Packets is as follows: struct arp{ unsigned int hardw;//hardware type nd int ARPopcode://ARP operation unsige unsigned int prot;//protocol type /har unsigned char hardwlen;/dware length ar ocol length unsigned chprotlen;//prot ha unsigned char target[5];//target's addr a[ oco unsigned char targetp3];//target's prot ess unsigned char sendha[5];//sender's address unsigned char sendpa[3];//sender's protocol ad- dress } In the network layer, the IP protocol is the basis and the co ta in the sequence of operations. For different network between the host, such as TCP, UDP, ICMP and IGMP, the IP datagram format is used for transmission. IP is providing unreliable connectionless datagram transport services. The IP protocol function, is consisted of the Figure 4. TCP/IP protocol architecture layers. Copyright © 2013 SciRes. CN  J. M. LIU ET AL. 68 data to be transmitted combining with IP header proc- essing, then packed IP datagram sending to the MAC layer. At the same time, the IP layer receives datagrams d char ipversionlen;//ip version & he r iptypeser;//type of Service d Int ipdatagramid;//datagram id dress of so na- tio to send HTML file. HTTP is a standard protocol ustransferring documents between machines over TC from the lower layer (such as Ethernet device driver). After header checksum and message processing, the re- ceived datagrams are sent to the higher level -- TCP or UDP layer. The structure of the IP header is as following: struct ipheadr{ unsigne ader length unsigned cha unsigned int ippacketlen;//total packet length unsigne unsigned Int ipfragmentoffset;//fragment offset unsignedchar iptlmetollve;//tlm etollve unsigned char ipprotocol;//ip protocol unsigned Int ipchecksum;//header checksum unsigned char ipsource[3];//ip ad urce unsigned char ipdest[3];//ip address of desti n }; The application layer of the TCP/IP is HTTP, which is made ed for P/IP. HTTP is used to manipulate interconnected documents around the globe. Each document is retrieved from a web server operating on some computers with access to the EWS. The document is used to refer to any type of data, which can be text, graphics, sound or video. Figure 6 shows the model of the HTTP process. As in Figure 4, the most common HTTP client is the familiar web browser [4]. The web browser issues an URL re- quest to the web server in order to access a document. The server must be operating before the browser initiates its requested HTML pages. The server is the depository for the web pages, and it handles requests and passes data back to the browser. The browser does more difficult work of presenting the text, displaying graphics, and running j ava applets. Figure 6. The model of HTTP process. 5. The Program Flow Diagram of the EWS Next Figure 5 shows the program flow diagram of EWS. After data pack is delivered to the RTL8019AS and MCU through the RJ45 interface, the thin TCP/IP of system carries on a data analyzed and a judgment of the data flow direction, and wraps or unwraps data packets. So the rest work will be going on con tinually. Ob viously, the end processing result is dealt with by web Server [6]. In the flow chat of micro programs, a box represents one micro instruction. If one operate should be per- formed, the corresponding field will be set ‘1’, otherwise k EFERENCES [4] G. J. Han, J. D. Wang, T. Lin and H. Zhao, “Design and Realization ofer Based on Web ‘0’. When the micro instruction is sent to data path from control memory, the corresponding module will wor correctly. The machine instruction is interpreted and ex- ecuted after the IR receives it. That is to say, it will exe- cute the corresponding micro program segment. In ac- cordance with the 3 higher bits (IR7-IR5), several branches are produced. Each of the branches presents one machine instruction . Finally, all of th e code s of th e micro instructions are obtained. 6. Conclusions The EWS is a good media to attach device to internet. There are lots of benefits in app lying EWS technology to industrial control systems field. The paper has presented and the key realization technology of EWS. This system is built with low cost and is easy to install. Many kinds of microcontrollers (8 bit) can be adopted to realize the system. In 21 century, termed Post-PC stage, it can be imagined that the traditional sever will become lean sev- er which can be operated without human intervention. R [1] X. Peng, J. W. Xia and J. M. Liao, “An Embedded Inter- net Interface System,” Mobile Robots, Vol. 8, No. 2, 2001, pp. 520-531. [2] Web Server for Embedded Systems, Klaus-D. Walter, 2005 [3] G. -J. Han, M. Guan and H. Zhao. “EWS: Providing In- ternet Connectivity for non-PC Devices,” 2004 IEEE In- ternet Conference on Networking, Sensing and Control (IEEE ICNSC'04), Taipei, Taiwan, Vol. 1, March 21 - 23, 2004, pp. 349-354. Embedded Web Serv Management,” Journal of Northeastern University (Nat- ural Science), Vol. 23, No.11, 2002, pp. 1021-1024. [5] J. Wang and S. J. Guo, “Implementation of Embedded Web Server and Its Application of CGI,” Microcontrol- lers and Embedded Systems, Vol. 32, 2003, pp. 116-117. [6] D. Q. He, “Remote Multimedia Monitoring System Based on Embedded Web Server for Networked Manufactur- ing,” Journal of Chongqing University-Engineering, Vol. 29, 2002, p.10. Copyright © 2013 SciRes. CN |