J. H. GOU ET AL.

Open Access ENG

880

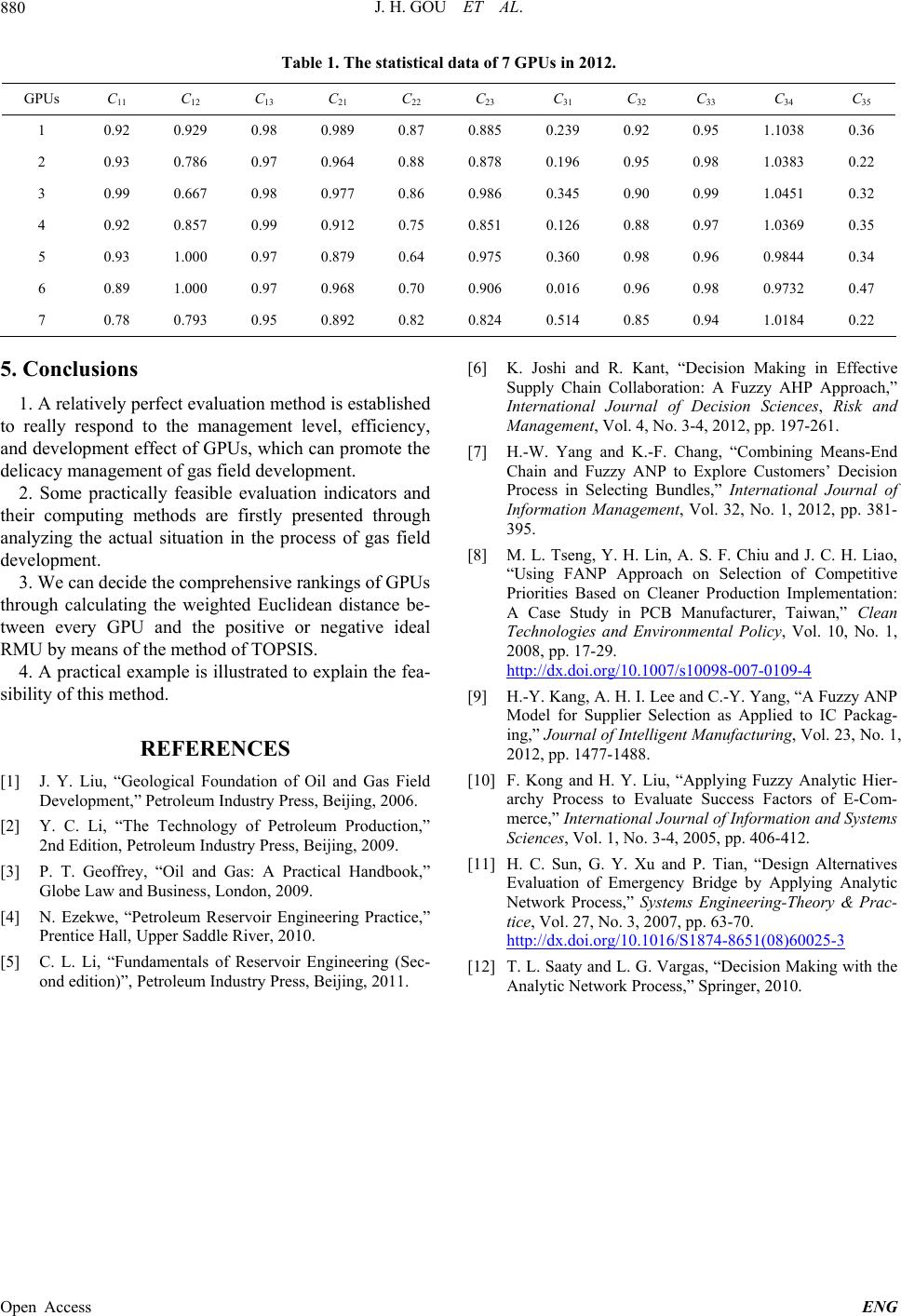

Table 1. The statistical data of 7 GPUs in 2012.

GPUs C11 C12 C13 C21 C22 C23 C31 C32 C33 C34 C35

1 0.92 0.929 0.98 0.989 0.87 0.885 0.239 0.92 0.95 1.1038 0.36

2 0.93 0.786 0.97 0.964 0.88 0.878 0.196 0.95 0.98 1.0383 0.22

3 0.99 0.667 0.98 0.977 0.86 0.986 0.345 0.90 0.99 1.0451 0.32

4 0.92 0.857 0.99 0.912 0.75 0.851 0.126 0.88 0.97 1.0369 0.35

5 0.93 1.000 0.97 0.879 0.64 0.975 0.360 0.98 0.96 0.9844 0.34

6 0.89 1.000 0.97 0.968 0.70 0.906 0.016 0.96 0.98 0.9732 0.47

7 0.78 0.793 0.95 0.892 0.82 0.824 0.514 0.85 0.94 1.0184 0.22

5. Conclusions

1. A relatively perfect evaluation method is established

to really respond to the management level, efficiency,

and development effect of GPUs, which can promote the

delicacy management of gas field development.

2. Some practically feasible evaluation indicators and

their computing methods are firstly presented through

analyzing the actual situation in the process of gas field

development.

3. We can decide the comprehensive rankings of GPUs

through calculating the weighted Euclidean distance be-

tween every GPU and the positive or negative ideal

RMU by means of the method of TOPSIS.

4. A practical example is illustrated to explain the fea-

sibility of this method.

REFERENCES

[1] J. Y. Liu, “Geological Foundation of Oil and Gas Field

Development,” Petroleum Industry Press, Beijing, 2006.

[2] Y. C. Li, “The Technology of Petroleum Production,”

2nd Edition, Petroleum Industry Press, Beijing, 2009.

[3] P. T. Geoffrey, “Oil and Gas: A Practical Handbook,”

Globe Law and Business, London, 2009.

[4] N. Ezekwe, “Petroleum Reservoir Engineering Practice,”

Prentice Hall, Upper Saddle River, 2010.

[5] C. L. Li, “Fundamentals of Reservoir Engineering (Sec-

ond edition)”, Petroleum Industry Press, Beijing, 2011.

[6] K. Joshi and R. Kant, “Decision Making in Effective

Supply Chain Collaboration: A Fuzzy AHP Approach,”

International Journal of Decision Sciences, Risk and

Management, Vol. 4, No. 3-4, 2012, pp. 197-261.

[7] H.-W. Yang and K.-F. Chang, “Combining Means-End

Chain and Fuzzy ANP to Explore Customers’ Decision

Process in Selecting Bundles,” International Journal of

Information Management, Vol. 32, No. 1, 2012, pp. 381-

395.

[8] M. L. Tseng, Y. H. Lin, A. S. F. Chiu and J. C. H. Liao,

“Using FANP Approach on Selection of Competitive

Priorities Based on Cleaner Production Implementation:

A Case Study in PCB Manufacturer, Taiwan,” Clean

Technologies and Environmental Policy, Vol. 10, No. 1,

2008, pp. 17-29.

http://dx.doi.org/10.1007/s10098-007-0109-4

[9] H.-Y. Kang, A. H. I. Lee and C.-Y. Yang, “A Fuzzy ANP

Model for Supplier Selection as Applied to IC Packag-

ing,” Journal of Intelligent Manufacturing, Vol. 23, No. 1,

2012, pp. 1477-1488.

[10] F. Kong and H. Y. Liu, “Applying Fuzzy Analytic Hier-

archy Process to Evaluate Success Factors of E-Com-

merce,” International Journal of Information and Systems

Sciences, Vol. 1, No. 3-4, 2005, pp. 406-412.

[11] H. C. Sun, G. Y. Xu and P. Tian, “Design Alternatives

Evaluation of Emergency Bridge by Applying Analytic

Network Process,” Systems Engineering-Theory & Prac-

tice, Vol. 27, No. 3, 2007, pp. 63-70.

http://dx.doi.org/10.1016/S1874-8651(08)60025-3

[12] T. L. Saaty and L. G. Vargas, “Decision Making with the

Analytic Network Process,” Springer, 2010.