D.-W. SEO ET AL. 867

grip adapters and cured for two weeks to ob tain the com-

pressive strength approximately 60 MPa. Figure 2 shows

the tensile test with the loading rate equal to 5 mm/min

[13].

Brittle fractures of GFRP bars, including Case A,

Asaln, and V-rod were seen in Figure 3 one of short-

comings of FRP was a brittle fracture and this issue was

improved by material hybridization proved in this study.

Table 3 summarizes the list of specimens that tested in

this study. 7 cases of tested specimens were selected for

tensile test associated with 4 types explained in Table 1.

A total of 21 samples consisting 3 specimens for each

case was tested.

Cases A through C were correspond ing to the types A,

B, and C in Table 1. For cases D-1 and D-2, type D in

Table 1 was subdivided into two types depending on a

steel type; Case D-1 with circular shape of rebar and D-2

with the deformed rebar. Cases A through D-2 were de-

veloped and fabricated by KICT [6]. Two commercially

available GFRP bars (i.e., Aslan and V-Rod, [9,10]) were

also considered and their tensile strength was compared

to other hybrid GFRP bars developed at KICT.

3.2. Results and Discussion

The tensile strength of the specimen can be calculated by

dividing the measured maximum load by the cross-sec-

tional area of the GFRP bar (Ahybrid). The elastic modulus

of the GFRP bar (Ehybrid) can be given by the following

expression as recommended in [13].

12

hybrid

12 hybrid

PP

EA

. (1)

In Equation (1) P1 and P2 are the applied loads corre-

sponding to 50% and 25% of the ultimate load respec-

tively, and ɛ1 and ɛ2 are the c o rresponding strains.

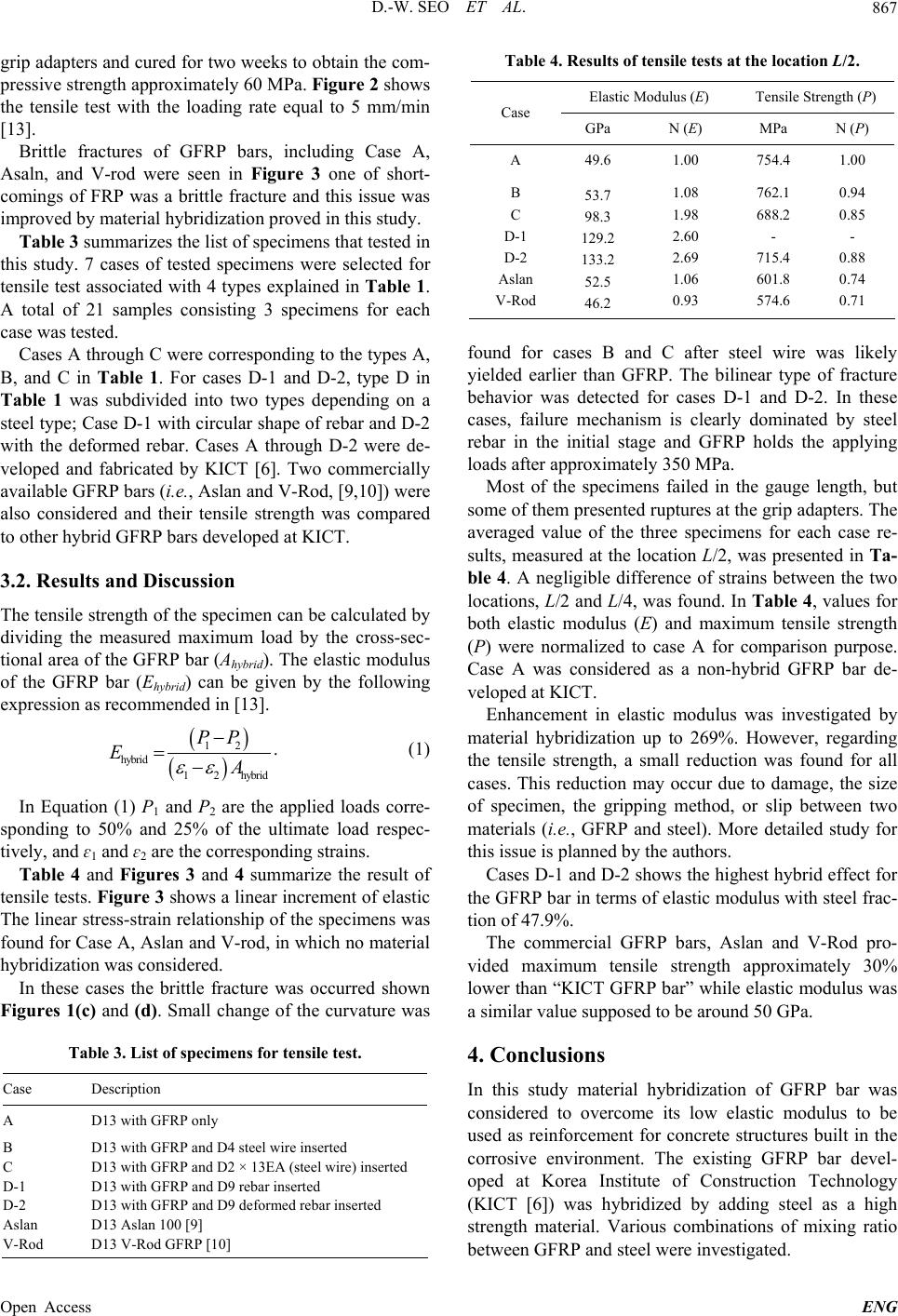

Table 4 and Figures 3 and 4 summarize the result of

tensile tests. Figure 3 shows a linear increment of elastic

The linear stress-strain relationship of the specimens was

found for Case A, Aslan and V-rod, in which no material

hybridization was considered.

In these cases the brittle fracture was occurred shown

Figures 1(c) and (d). Small change of the curvature was

Table 3. List of specimens for tensile test.

Case Description

A D13 with GFRP only

B

C

D-1

D-2

Aslan

V-Rod

D13 with GFRP and D4 steel wire inserted

D13 with GFRP and D2 × 13EA (steel wire) inserted

D13 with GFRP and D9 rebar inserted

D13 with GFRP and D9 deformed rebar inserted

D13 Aslan 100 [9]

D13 V-Rod GFRP [10]

Table 4. Results of tensile tests at the location L/2.

Elastic Modulus (E) Tensile Strength (P)

Case GPa N (E) MPa N (P)

A 49.6 1.00 754.4 1.00

B

C

D-1

D-2

Aslan

V-Rod

53.7

98.3

129.2

133.2

52.5

46.2

1.08

1.98

2.60

2.69

1.06

0.93

762.1

688.2

-

715.4

601.8

574.6

0.94

0.85

-

0.88

0.74

0.71

found for cases B and C after steel wire was likely

yielded earlier than GFRP. The bilinear type of fracture

behavior was detected for cases D-1 and D-2. In these

cases, failure mechanism is clearly dominated by steel

rebar in the initial stage and GFRP holds the applying

loads after approximately 350 MPa.

Most of the specimens failed in the gauge length, but

some of them presented ruptures at the grip adapters. The

averaged value of the three specimens for each case re-

sults, measured at the location L/2, was presented in Ta -

ble 4. A negligible difference of strains between the two

locations, L/2 an d L/4, was found. In Table 4, values for

both elastic modulus (E) and maximum tensile strength

(P) were normalized to case A for comparison purpose.

Case A was considered as a non-hybrid GFRP bar de-

veloped at KICT.

Enhancement in elastic modulus was investigated by

material hybridization up to 269%. However, regarding

the tensile strength, a small reduction was found for all

cases. This reduction may occur due to damage, the size

of specimen, the gripping method, or slip between two

materials (i.e., GFRP and steel). More detailed study for

this issue is planned by the authors.

Cases D-1 and D-2 shows the h ighest hybrid effect for

the GFRP bar in terms of elastic modulus with steel frac-

tion of 47.9%.

The commercial GFRP bars, Aslan and V-Rod pro-

vided maximum tensile strength approximately 30%

lower than “KICT GFRP bar” while elastic modulus was

a similar value supposed to be around 50 GPa.

4. Conclusions

In this study material hybridization of GFRP bar was

considered to overcome its low elastic modulus to be

used as reinforcement for concrete structures built in the

corrosive environment. The existing GFRP bar devel-

oped at Korea Institute of Construction Technology

(KICT [6]) was hybridized by adding steel as a high

strength material. Various combinations of mixing ratio

etween GFRP and steel were investigated.

b

Open Access ENG