N. RUGTHAICHAROENCHEEP, A. CHALANGSUT 687

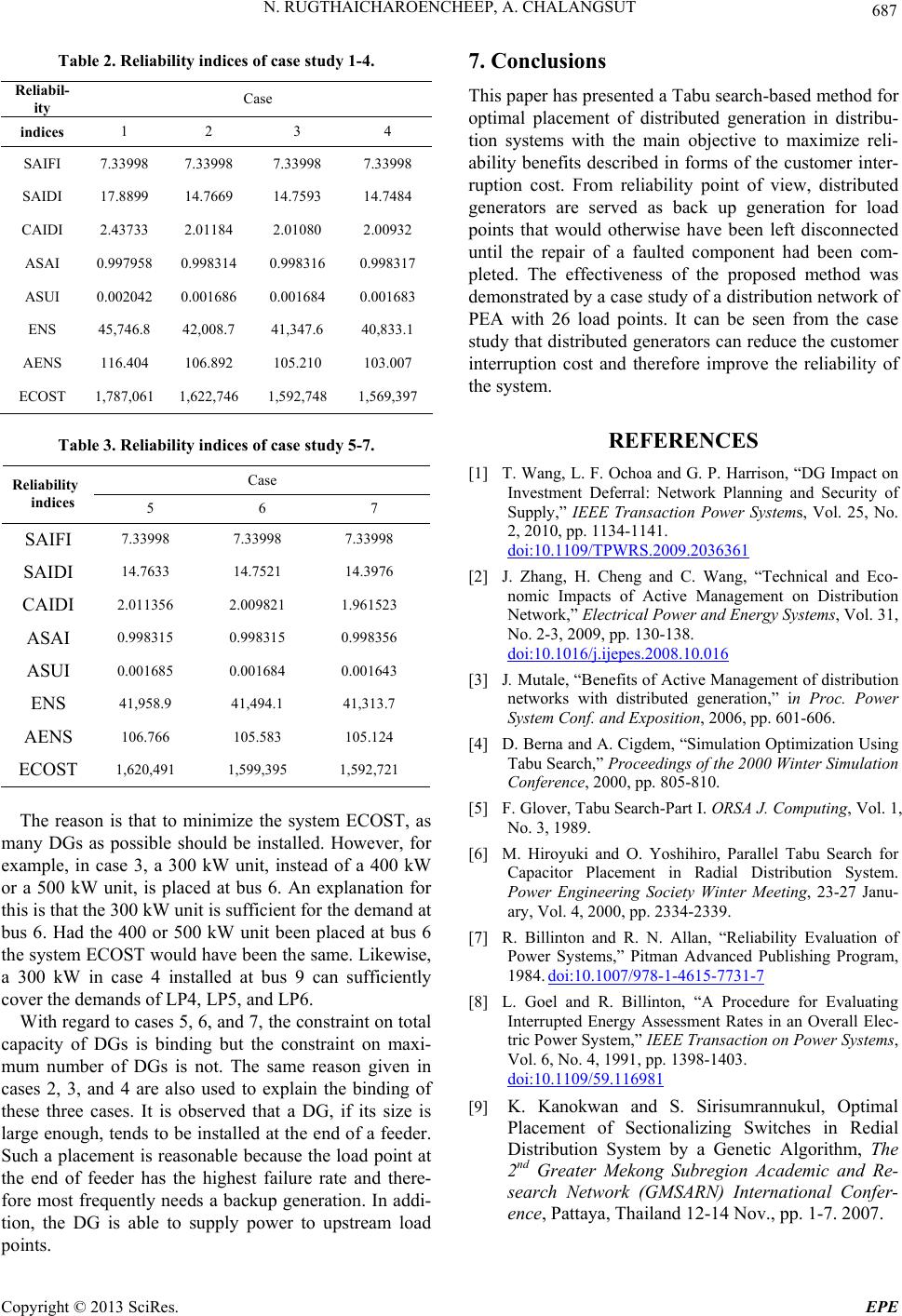

Table 2. Reliability indices of case study 1-4.

Reliabil-

ity Case

indices 1 2 3 4

SAIFI 7.33998 7.33998 7.33998 7.33998

SAIDI 17.8899 14.7669 14.7593 14.7484

CAIDI 2.43733 2.01184 2.01080 2.00932

ASAI 0.997958 0.998314 0.998316 0.998317

ASUI 0.002042 0.001686 0.001684 0.001683

ENS 45,746.8 42,008.7 41,347.6 40,833.1

AENS 116.404 106.892 105.210 103.007

ECOST 1,787,061 1,622,746 1,592,748 1,569,397

Table 3. Reliability indices of case study 5-7.

Case

Reliability

indices 5 6 7

SAIFI 7.33998 7.33998 7.33998

SAIDI 14.7633 14.7521 14.3976

CAIDI 2.011356 2.009821 1.961523

ASAI 0.998315 0.998315 0.998356

ASUI 0.001685 0.001684 0.001643

ENS 41,958.9 41,494.1 41,313.7

AENS 106.766 105.583 105.124

ECOST 1,620,491 1,599,395 1,592,721

The reason is that to minimize the system ECOST, as

many DGs as possible should be installed. However, for

example, in case 3, a 300 kW unit, instead of a 400 kW

or a 500 kW unit, is placed at bus 6. An explanation for

this is that the 300 kW unit is sufficient for the demand at

bus 6. Had the 400 or 500 kW unit been placed at bus 6

the system ECOST would have been the same. Likewise,

a 300 kW in case 4 installed at bus 9 can sufficiently

cover the demands of LP4, LP5, and LP6.

With regard to cases 5, 6, and 7, the constraint on total

capacity of DGs is binding but the constraint on maxi-

mum number of DGs is not. The same reason given in

cases 2, 3, and 4 are also used to explain the binding of

these three cases. It is observed that a DG, if its size is

large enough, tends to be installed at the end of a feeder.

Such a placement is reasonable because the load point at

the end of feeder has the highest failure rate and there-

fore most frequently needs a backup generation. In addi-

tion, the DG is able to supply power to upstream load

points.

7. Conclusions

This paper has presented a Tabu search-based method for

optimal placement of distributed generation in distribu-

tion systems with the main objective to maximize reli-

ability benefits described in forms of the customer inter-

ruption cost. From reliability point of view, distributed

generators are served as back up generation for load

points that would otherwise have been left disconnected

until the repair of a faulted component had been com-

pleted. The effectiveness of the proposed method was

demonstrated by a case study of a distribution network of

PEA with 26 load points. It can be seen from the case

study that distributed generators can reduce the customer

interruption cost and therefore improve the reliability of

the system.

REFERENCES

[1] T. Wang, L. F. Ochoa and G. P. Harrison, “DG Impact on

Investment Deferral: Network Planning and Security of

Supply,” IEEE Transaction Power Systems, Vol. 25, No.

2, 2010, pp. 1134-1141.

doi:10.1109/TPWRS.2009.2036361

[2] J. Zhang, H. Cheng and C. Wang, “Technical and Eco-

nomic Impacts of Active Management on Distribution

Network,” Electrical Power and Energy Systems, Vol. 31,

No. 2-3, 2009, pp. 130-138.

doi:10.1016/j.ijepes.2008.10.016

[3] J. Mutale, “Benefits of Active Management of distribution

networks with distributed generation,” in Proc. Power

System Conf. and Exposition, 2006, pp. 601-606.

[4] D. Berna and A. Cigdem, “Simulation Optimization Using

Tabu Search,” Proceedings of the 2000 Winter Simulation

Conference, 2000, pp. 805-810.

[5] F. Glover, Tabu Search-Part I. ORSA J. Computing, Vol. 1,

No. 3, 1989.

[6] M. Hiroyuki and O. Yoshihiro, Parallel Tabu Search for

Capacitor Placement in Radial Distribution System.

Power Engineering Society Winter Meeting, 23-27 Janu-

ary, Vol. 4, 2000, pp. 2334-2339.

[7] R. Billinton and R. N. Allan, “Reliability Evaluation of

Power Systems,” Pitman Advanced Publishing Program,

1984. doi:10.1007/978-1-4615-7731-7

[8] L. Goel and R. Billinton, “A Procedure for Evaluating

Interrupted Energy Assessment Rates in an Overall Elec-

tric Power System,” IEEE Transaction on Power Systems,

Vol. 6, No. 4, 1991, pp. 1398-1403.

doi:10.1109/59.116981

[9] K. Kanokwan and S. Sirisumrannukul, Optimal

Placement of Sectionalizing Switches in Redial

Distribution System by a Genetic Algorithm, The

2nd Greater Mekong Subregion Academic and Re-

search Network (GMSARN) International Confer-

ence, Pattaya, Thailand 12-14 Nov., pp. 1-7. 2007.

Copyright © 2013 SciRes. EPE