Cracking Phenomenon in Spot Welded Joints of Austenitic Stainless Steel 661

(a)

(b)

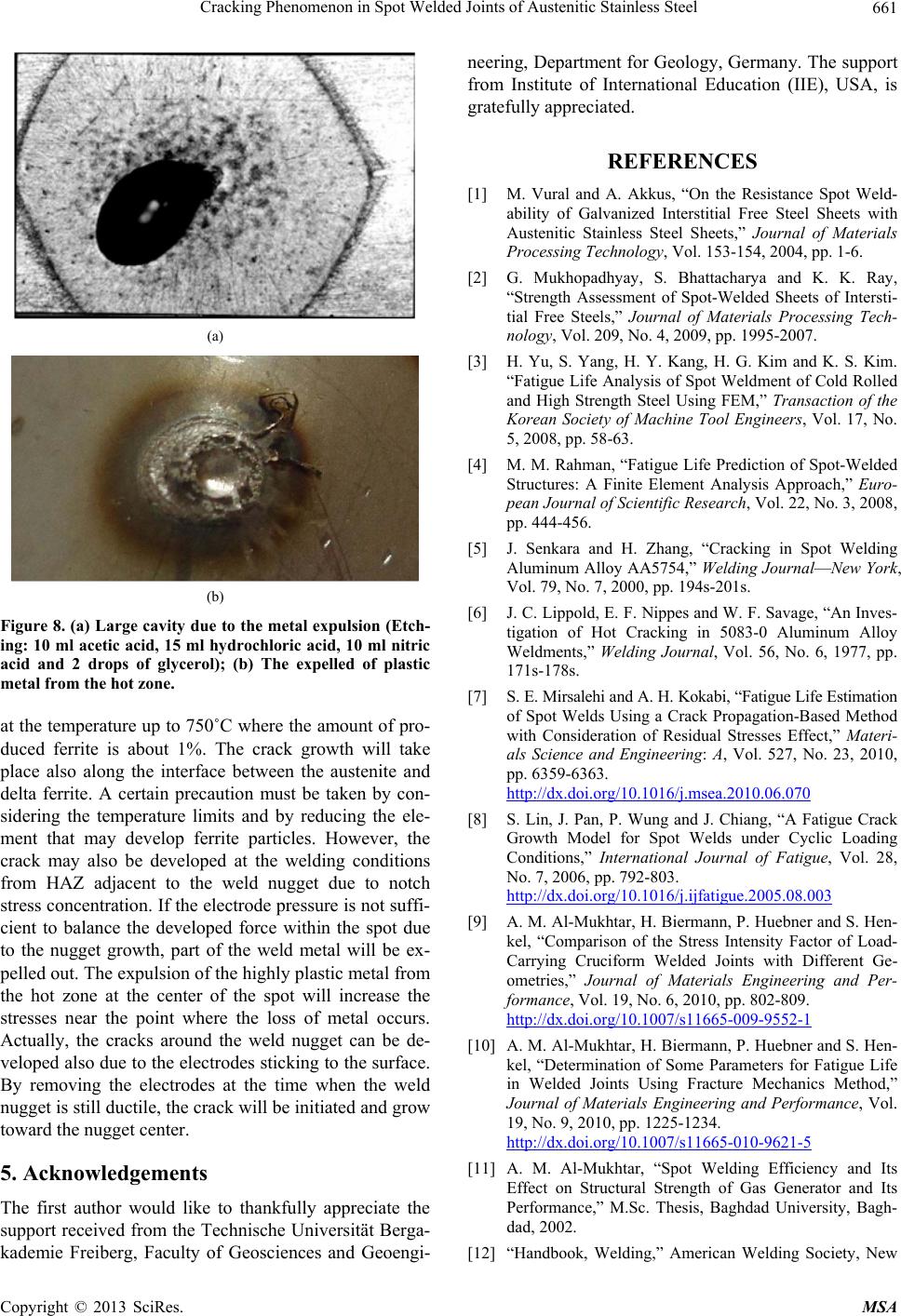

Figure 8. (a) Large cavity due to the metal expulsion (Etch-

ing: 10 ml acetic acid, 15 ml hydrochloric acid, 10 ml nitric

acid and 2 drops of glycerol); (b) The expelled of plastic

metal from the hot zone.

at the temperature up to 750˚C where the amount of pro-

duced ferrite is about 1%. The crack growth will take

place also along the interface between the austenite and

delta ferrite. A certain precaution must be taken by con-

sidering the temperature limits and by reducing the ele-

ment that may develop ferrite particles. However, the

crack may also be developed at the welding conditions

from HAZ adjacent to the weld nugget due to notch

stress concentration. If the electrod e pressure is not suffi-

cient to balance the developed force within the spot due

to the nugget growth, part of the weld metal will be ex-

pelled out. The expulsio n of the highly p lastic metal from

the hot zone at the center of the spot will increase the

stresses near the point where the loss of metal occurs.

Actually, the cracks around the weld nugget can be de-

veloped also due to the electrodes sticking to the surface.

By removing the electrodes at the time when the weld

nugget is still ductile, th e crack will b e initiated and grow

toward the nugget center.

5. Acknowledgements

The first author would like to thankfully appreciate the

support received from the Technische Universität Berga-

kademie Freiberg, Faculty of Geosciences and Geoengi-

neering, Department for Geology, Germany. The support

from Institute of International Education (IIE), USA, is

gratefully appreciated.

REFERENCES

[1] M. Vural and A. Akkus, “On the Resistance Spot Weld-

ability of Galvanized Interstitial Free Steel Sheets with

Austenitic Stainless Steel Sheets,” Journal of Materials

Processing Technology, Vol. 153-154, 2004, pp. 1-6.

[2] G. Mukhopadhyay, S. Bhattacharya and K. K. Ray,

“Strength Assessment of Spot-Welded Sheets of Intersti-

tial Free Steels,” Journal of Materials Processing Tech-

nology, Vol. 209, No. 4, 2009, pp. 1995-2007.

[3] H. Yu, S. Yang, H. Y. Kang, H. G. Kim and K. S. Kim.

“Fatigue Life Analysis of Spot Weldment of Cold Rolled

and High Strength Steel Using FEM,” Transaction of the

Korean Society of Machine Tool Engineers, Vol. 17, No.

5, 2008, pp. 58-63.

[4] M. M. Rahman, “Fatigue Life Prediction of Spot-Welded

Structures: A Finite Element Analysis Approach,” Euro-

pean Journal of Scientific Research, Vol. 22, No. 3, 2008,

pp. 444-456.

[5] J. Senkara and H. Zhang, “Cracking in Spot Welding

Aluminum Alloy AA5754,” Welding Journal—New York,

Vol. 79, No. 7, 2000, pp. 194s-201s.

[6] J. C. Lippold, E. F. Nippes and W. F. Savage, “An Inves-

tigation of Hot Cracking in 5083-0 Aluminum Alloy

Weldments,” Welding Journal, Vol. 56, No. 6, 1977, pp.

171s-178s.

[7] S. E. Mirsalehi a nd A. H. Koka bi, “Fatigue Life Estimatio n

of Spot Welds Using a Crack Propagation-Based Method

with Consideration of Residual Stresses Effect,” Materi-

als Science and Engineering: A, Vol. 527, No. 23, 2010,

pp. 6359-6363.

http://dx.doi.org/10.1016/j.msea.2010.06.070

[8] S. Lin, J. Pan, P. Wung and J. Chiang, “A Fatigue Crack

Growth Model for Spot Welds under Cyclic Loading

Conditions,” International Journal of Fatigue, Vol. 28,

No. 7, 2006, pp. 792-803.

http://dx.doi.org/10.1016/j.ijfatigue.2005.08.003

[9] A. M. Al-Mukhtar, H. Biermann, P. Huebner and S. Hen-

kel, “Comparison of the Stress Intensity Factor of Load-

Carrying Cruciform Welded Joints with Different Ge-

ometries,” Journal of Materials Engineering and Per-

formance, Vol. 19, No. 6, 2010, pp. 802-809.

http://dx.doi.org/10.1007/s11665-009-9552-1

[10] A. M. Al-Mukhtar, H. Biermann, P. Huebner and S. Hen-

kel, “Determination of Some Parameters for Fatigue Life

in Welded Joints Using Fracture Mechanics Method,”

Journal of Materials Engineering and Performance, Vol.

19, No. 9, 2010, pp. 1225-1234.

http://dx.doi.org/10.1007/s11665-010-9621-5

[11] A. M. Al-Mukhtar, “Spot Welding Efficiency and Its

Effect on Structural Strength of Gas Generator and Its

Performance,” M.Sc. Thesis, Baghdad University, Bagh-

dad, 2002.

[12] “Handbook, Welding,” American Welding Society, New

Copyright © 2013 SciRes. MSA