Paper Menu >>

Journal Menu >>

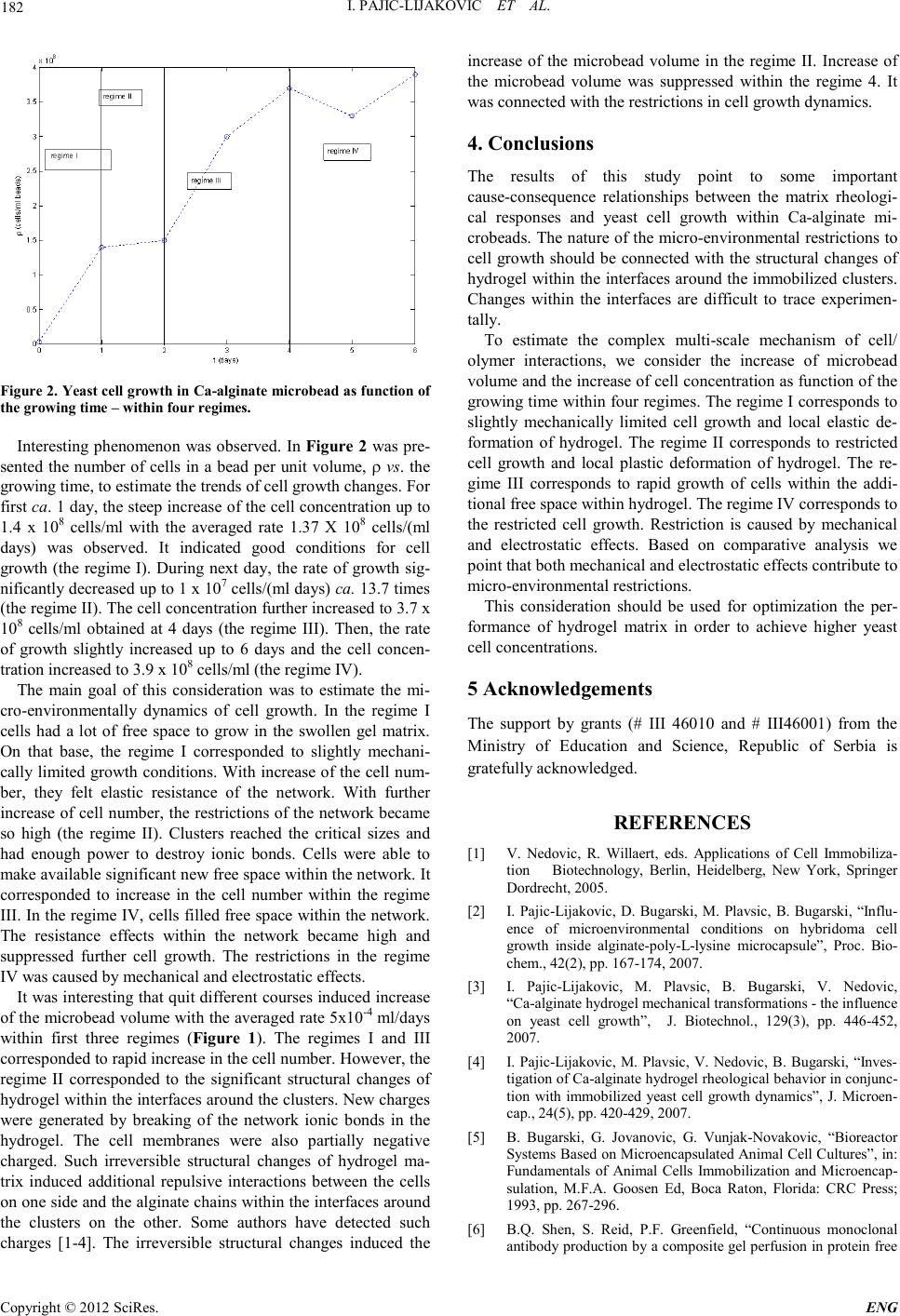

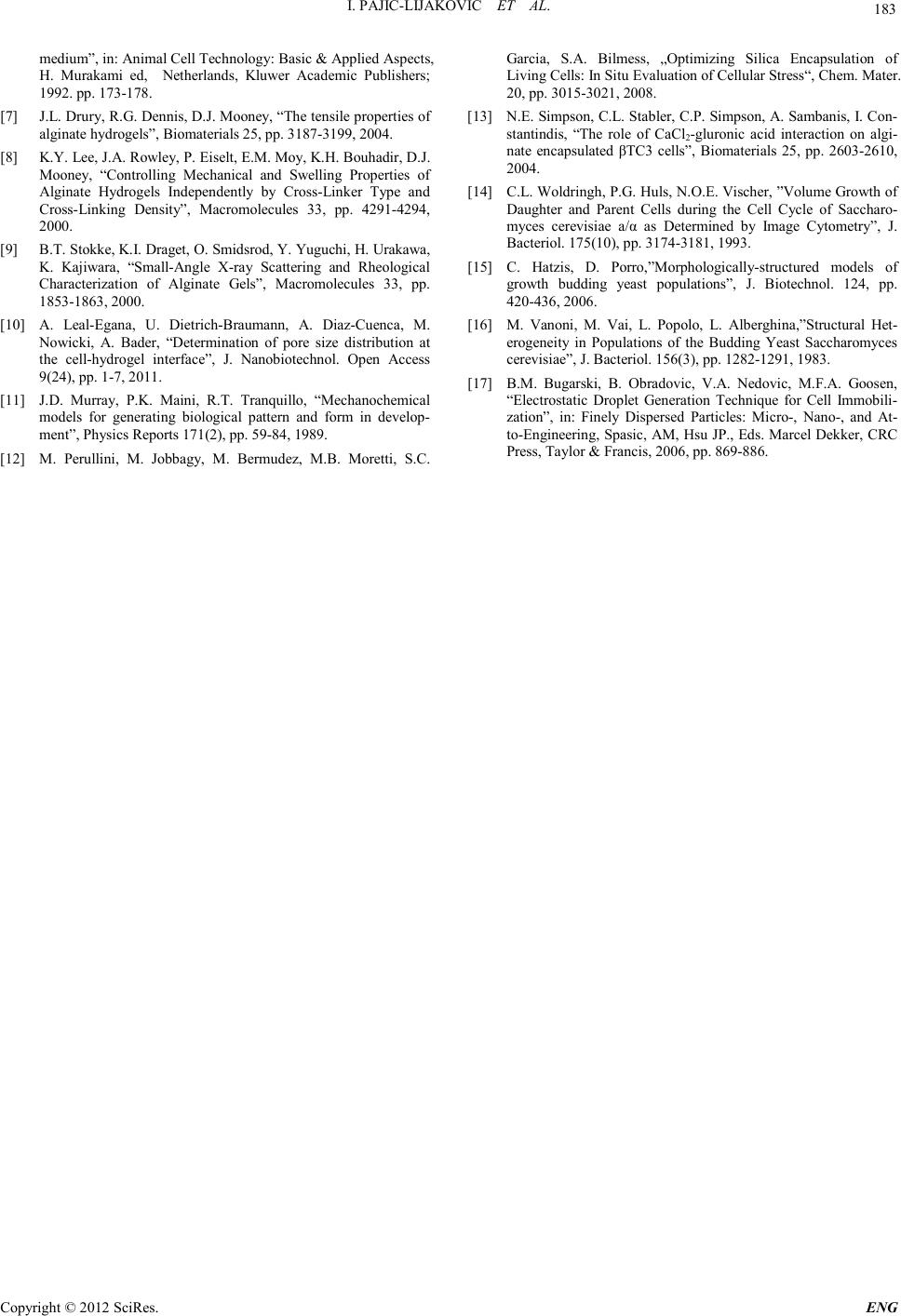

Engineering, 2012, 5, 180-183 doi:10.4236/eng.2012.410B047 Published Online October 2012 (http://www.SciRP.org/journal/eng) Copyright © 2012 SciRes. ENG Micro-environmentally Restricted Yeast Cell Gr owth within Ca-alginate Microbeads* Ivana Pajic-Lijakovic1, Branko Bugarski1, Milenko Plavsic1, Steva Levic2, Ana Kalusevic2, Viktor Nedovic2 1Dept. of Chem. and Polymer Eng., University of Belgrade, Faculty of Technology and Metallurgy, Belgrade, Serbia 2Dept. of Food Technol., University of Belgrade, Faculty of Agriculture, Belgrade, Serbia Email: iva@tmf.bg.ac.rs Received 2012 ABSTRACT Micro -environmental restriction effects to yeast cell growth obtained within Ca-alginate microbeads are considered. It is complex phenomenon influenced by: (1) relaxation of expanded polymer network around the cellular clusters, (2) forces generated by cell growth inside the beads and (3) interactions between solvent, network parts and cells. The result ing effects are measured experi men- tally by estimating volume of microbeads and yeast cell concentration as function of time of cultivation. Comparative analysis of dynamics of cell growth and increase of microbead volume through four regimes indicates that reversible and irreversible local structural changes of Ca-alginate hydrogel induces micro-environmental restrictions to cell growth. The mechanism of restrictions includes both mechanical an d electrostatic effects. Keywords: Yeast Cells; Micro-environmental Restrictions; Ca-alginate Hydrogel Matrix; Structural Changes; Pattern of Volumetric Yea s t Gr o wt h 1. Introduction There is a growing interest in using immobilized cell systems for various applications in biotechnology, biomedicine and food technology [1-5]. The success of such applications depends on achieving suitable conditions for cell growth inside microbeads. It is based primarily on the optimization of the performance of microbead matrix. Ca-alginate hydrogel have been the most frequently used matrix for immobilization of yeast cells. Significant attempts have been made to examine the rheological response of hydrogel matrix to stresses generated by compression, shear and tension [7-9]. However, little is known about the rheological responses of variously structured matrixes cau sed b y cells gro wth. The gro wing cel ls press t o th e surrounding and create a new space for further cells growth inside the matrix. Such cell actions are obtained on two time scales, i. e. on e is the migration time (the short-time scale) while the other is the growing time (the long-time scale). Yeast population entrapped in Ca-alginate hydrogel matrix grew into many small cell clusters located at multiple positions in the microbeads. Interactions between clusters can be ne- glected [3-4]. Consequently, the number of clusters is approxi- mately the sa me while the n umber of cells p er cluster incr eases during cell cultivation. Hydrogel with density in the range of 1-2 % have good me- chanical behaviours [3-6] and ensure optimal nutrient transfer through the microbeads. Many authors [1-5] observed homo- geneous cell distribution within 2 % and 1.5 % Ca-alginate microbeads, respectively. However, some of them [2-5] re- ported early suppression of cell growth within hydrogel in op- timal nutrient supported systems. It should be connected with micro-environmental restrictions to cell growth. The primary function of the alginate matrixes in biotechnol- ogy applications is to provide mechanical and biological integ- rity of immobilized cell population by ensuring the optimal packing state. Matrixes simultaneously transmitted mechanical signals to the cells and the developing population. As Ca2+ ions in bucked egg-box junction are being released by cell actions, electrostatic repulsion between the liberated chains enhances the additional swelling effects of the alginate gel. This electro- static repulsion forces have the feedback action on cell growth [3-4] . Phenomenon of the micro-environmental restrictions gener- ated within hydrogel includes following steps from the rheological point of view: (1) the immobilized clusters induce radial deformations of the surrounding hydrogel matrix during clusters expansion [10], (2) the radial deformations induce gen- eration of the mechanical stress within hydrogel around the clusters (the external stress) [3,4,10,11], (3) the external stress around the clusters induces generation of the internal stress within cell clusters [11-12] and (5) the internal stress provokes the biological response of cells [2-4,13]. The biological re- sponse of cells influences metabolic activity of yeast. On that base, it is necessary to connect the rheological behaviour of hydrogel with cell growth dynamics. Increase of the internal stress within immobilized cell clus- ters induces chan ges in cell growth d ynamics [3-4]. Significant attempts have been made to examine the pattern of volume growth of yeast cell population under various nutrient support- ing conditions [1,5]. The pattern of volumetric yeast growth depends on the volumetric states of single cells. The volumetric states depend on: (1) the ability to budding and (2) the cell ag- ing [14-16]. However, little is reported about the pattern of volu me gro wth u nder actio n of generated mechanical compres- *Ministry of Education and Scien ce of Serbia  I. PA JIC-LIJAKOVIC ET AL. Copyright © 2012 SciRes. E NG 181 sive stress within hydrogel around immobilized clusters. The aim of this work is to estimate the micro-environmen- tally restricted yeast cell growth in conjunction with the struc- tural changes o f Ca-al gi nate hydrogel mat r ix. 2. Experimenta l Par t 2.1. Imobilization and C ul tivation P r ocedure The 2% w/w Na-alginate solution was prepared by dissolving 10 g of sodium alginate powder (Sigma- medium viscosity) into 500 ml of distillated water. The brewer's yeast (Saccharomyces uvarum) was cultivated at 25 oC in sterile medium of 11% w/w extract in shake flask. Polymer/cell suspension was formed by mixing of 100 ml of Na-alginate solution with 25 ml of thick brewer's yeast suspension at room temperature. The cell sus- pension was forced out of the tip of the need le at constant flow rate (25.2 ml/h). The droplets were formed by the action of electrostatic forces [17]. After gelling the microbeads were placed in double distil- lated water to remove un-reacted material and low molecular weight byproducts. Spherical droplets were formed by extru- sion of Na-alginate/yeast cell suspension into 1 % CaCl2 solu- tion. After gelling the microbeads were placed in double distil- lated water to remove un-reacted material and low molecular weight by-products. Microbeads with cells were cultivated in 500 ml flasks, which contained 150 ml of medium and 5 g of microbeads in each experimental group, and these were placed on orbital shaker at 115 rpm and 25 oC. 2.2. Anal yti cal Methods Total yeast cell concentration in the beads was estimated by using Thoma counting chamber after dissolution of the beads. The initial yeast concentration ( 0 ρ ) in the beads was about 3 x 106 cells/ml. The microbeads were also sampled twice per day from the cultivation flask and cell concentration was measured in the same way. Local cell co ncentrat ion per microbead layers was calculated from the exp erimentall y determin ed sur face fraction of cells for various microbead cross sections. The surface fraction of cells was estimated by ultramicroton cutting the microbead. The alginate microbeads sampled for image analysis were fixed in 2.5 % glutaraldehyde, embedded in araldite, cross-sectioned by LKB III ultramicrotom and stained with hematoxylin and eosin (H&E). The images of the microbeads cross-sections (the number of sections was six for each bead) where acquired using a solid-state CCD camera (Hitachi) mounted on an inverted microscope (Nikon Diaphot), digitized by a CG-7 frame Grab- ber (Scion Corp., Frederick, MD) and analyzed using Image Pro Plus software. Distribution of the cells and the colonies, as well as, the surface fraction of cross sections occupied by cell colonies were determined by automatic counting and measure- ment of all objects darker than background and equal or larger than single cell. I t was assumed that onl y one cell layer is visi- ble, due to small thickness of the histological cross sections. Diameters o f the microbead s were measured with an accura- cy of 10 μm using optical microscope. The average microbead diameter an d stand ard deviatio ns were then cal culated from th e measured data. 3. Resutls and Discussion We considered the micro-environmentally restricted dynamics of yeast cell growth within Ca-alginate microbead. The nature of the restriction phenomenon should be connected with the local st ructural chan ges of the hyd rogel. Cell clu ster expansion induced the structural changes of the matrix and provoked the complex rheological response with additional dissipation ef- fects. Based on our previous experience [2-4], the dissipative ef- fects were deeply related with the deformation of the alginate matrixes. These changes of the matrixes within interfaces around the clusters included both, the reversible deformation of domains, as well as the partial domains disintegration that caused permanent irreversible deformation. This complex process was influenced by various multi-scale interactions: the interactions between domains themselves and the interactions between chains within the domains, as well. Consequently, we estimated both: 1) changes of the microbead volume Vb(t) and 2) changes of the cell concentration per microbead ρ(t) as function of the growing time. Changes of the microbead volume depended on: the volume changes of cell population and the volume changes of hydrogel. On one side, the volumetric state of cell population depended on the cell number and the volume of single cells. The pattern of volume growth of single cells was influenced by the budding state of the cells and the cell aging status. On the other side, the volumetric state of hydrogel matrix included the sum of local reversibl e and irrever sible d eformation contributions within the interfaces around th e immobilized clusters. Increase of the average bead volume vs. the growing time was presented in Figure 1. Averaged microbead volume increased rapidly during first 3 days with the averaged rate equal to 5x10-4 ml/days. The aver- aged rate of increase the microbead volume decreased during next 3 days period to 6.7x10-5 ml/days. The microbead volume increased 3 times during 6 days of cultivations. The main goal of this consider ation was to es timate what has been happen with the hydrogel on one side and within the immobilized cell popu- lation on the other. For additional information, we considered changes of the cell concentration as function of the growing time. Figure 1. Increase of the averaged Ca-alginate microbead volume as function of the growing time resulted by the immobilized yeast cell gro wth .  I. PA JIC-LIJAKOVIC ET AL. Copyright © 2012 SciRes. ENG 182 Figure 2. Yeast cell growth in Ca-alginate microbead as function of the growing time – within four regi mes. Interesting phenomenon was observed. In Figure 2 was p re- sented the number of cells in a bead per unit volume, ρ vs. the growing time, to est imate t he tren ds of cell growth changes. For first ca. 1 da y, the steep increas e o f the cell co ncent ration up to 1.4 x 108 cells/ml with the averaged rate 1.37 X 108 cells/(ml days) was observed. It indicated good conditions for cell growth (the regime I). During next day, the rate of growth sig- nificant ly decreased up to 1 x 107 cells/(ml days) ca. 13.7 t imes (the regi me II). The cell con cen trat io n fur ther in creased to 3.7 x 108 cells/ml obtained at 4 days (the regime III). Then, the rate of growth slightly increased up to 6 days and the cell concen- tration increased to 3.9 x 108 cells/ml (th e r egime IV). The main goal of this consideration was to estimate the mi- cro-environmentally dynamics of cell growth. In the regime I cells had a lot of free space to grow in the swollen gel matrix. On that base, the regime I corresponded to slightly mechani- cally limited growth conditions. With increase of the cell num- ber, they felt elastic resistance of the network. With further increase o f cell n umber, the restri ctions of the network beca me so high (the regime II). Clusters reached the critical sizes and had enough power to destroy ionic bonds. Cells were able to make available signi ficant n ew free sp ace withi n th e network. It corresponded to increase in the cell number within the regime III. In the regime IV , cells fil led free space within t he network. The resistance effects within the network became high and suppressed further cell growth. The restrictions in the regime IV was caused by mechanical an d el ectrostatic effects. It was inter esting that quit differe nt cou rses induced i ncrease of the microb ead volume with the averag ed rate 5x10- 4 ml/days within first three regimes (Figure 1). The regimes I and III corresponded to rapid increase in the cell number. However, the regime II corresponded to the significant structural changes of hydrogel with in t he interfaces aro un d the clust ers. New charges were generated by breaking of the network ionic bonds in the hydrogel. The cell membranes were also partially negative charged. Such irreversible structural changes of hydrogel ma- trix induced additional repulsive interactions between the cells on one side and the alginate chains within the interfaces around the clusters on the other. Some authors have detected such charges [1-4]. The irreversible structural changes induced the increase of the microbead volume in the regime II. Increase of the microbead volume was suppressed within the regime 4. It was connected with the restrictions in cell growth dynamics. 4. Conclusions The results of this study point to some important cause-consequence relationships between the matrix rheologi- cal responses and yeast cell growth within Ca-alginate mi- crobeads. Th e nature of the micro-environmental restrictions to cell growth should be connected with the structural changes of hydrogel within the interfaces around the immobilized clusters. Changes within the interfaces are difficult to trace experimen- tally. To estimate the complex multi-scale mechanism of cell/ olymer interactions, we consider the increase of microbead volume and the in crease of cell c on centrat ion as function of the growing time within four regimes. The regime I corresponds to slightly mechanically limited cell growth and local elastic de- formation of hydrogel. The regime II corresponds to restricted cell growth and local plastic deformation of hydrogel. The re- gime III corresponds to rapid growth of cells within the addi- tional free space within hydrogel. The regime IV corresponds to the restricted cell growth. Restriction is caused by mechanical and electrostatic effects. Based on comparative analysis we point that both mechanical and electrostatic effects contribute to micro-environmental restrictions. This consideration should be used for optimization the per- formance of hydrogel matrix in order to achieve higher yeast cell concentrations. 5 Acknowledgements The support by grants (# III 46010 and # III46001) from the Ministry of Education and Science, Republic of Serbia is grateful ly acknowledged. REFERENCES [1] V. Nedovic, R. Willaert, eds. Applications of Cell Immobiliza- tion Biotechnology, Berlin, Heidelberg, New York, Springer Dor d r e c ht, 200 5. [2] I. Pajic-Lijakovic, D. Bugarski, M. Plavsic, B. Bugarski, “In flu- ence of microenvironmental conditions on hybridoma cell growth inside alginate-poly-L-lysine microcapsule”, Proc. Bio- chem ., 42(2), pp. 16 7-174, 2007. [3] I. Pajic-Lijakovic, M. Plavsic, B. Bugarski, V. Nedovic, “Ca-alginate hydrogel mechanical transformations - the infl uenc e on yeast cell growth”, J. Biotechnol., 129(3), pp. 446-452, 2007. [4] I. Pajic-Lijakovic, M. Plavsic, V. Nedovic, B. Bugarski, “Inves- tigat ion of C a-a lginate hydrogel rh eologi cal b ehavior in conjun c- tion with immobilized yeast cell growth dynamics”, J. Microen- cap. , 24(5), pp . 420-429, 2007. [5] B. Bugarski, G. Jovanovic, G. Vunjak-Novakovic, “Bioreactor Systems B ased on Microenc apsulat ed Anima l Cell Cultu res”, in: Fundamentals of Animal Cells Immobilization and Microencap- sulation, M.F.A. Goosen Ed, Boca Raton, Florida: CRC Press; 1993, pp. 267-296. [6] B.Q. Shen, S. Reid, P.F. Greenfield, “Continuous monoclonal antibody production by a composite gel perfusion in protein free  I. PA JIC-LIJAKOVIC ET AL. Copyright © 2012 SciRes. E NG 183 medium”, in: Animal Cell Technology: Basic & Applied Aspects, H. Murakami ed, Netherlands, Kluwer Academic Publishers; 1992. pp. 173-178. [7] J. L. Dru ry, R .G. D enni s, D. J. Moo ney, “Th e ten sil e prop ert ies of alginate hydrogels”, Biomaterials 25, pp. 3187-3199, 200 4. [8] K.Y. Lee, J.A. Rowley, P. Eiselt, E.M. Moy, K.H. Bouhadir, D.J. Mooney, “Controlling Mechanical and Swelling Properties of Alginate Hydrogels Independently by Cross-Linker Type and Cross-Linking Density”, Macromolecules 33, pp. 4291-4294, 2000. [9] B.T. Stokke, K.I. Draget, O. Smidsrod, Y. Yuguchi, H. Urakawa, K. Kajiwara, “Small-Angle X-ray Scattering and Rheological Characterization of Alginate Gels”, Macromolecules 33, pp. 1853-1863, 2000. [10] A. Leal-Egana, U. Dietrich-Braumann, A. Diaz-Cuenca, M. Nowicki, A. Bader, “Determination of pore size distribution at the cell-hydrogel interface”, J. Nanobiotechnol. Open Access 9(24), pp. 1-7, 2011. [11] J.D. Murray, P.K. Maini, R.T. Tranquillo, “Mechanochemical models for generating biological pattern and form in develop- ment ”, Phy s ic s R e p o r ts 171( 2 ) , pp. 59-84, 198 9. [12] M. Perullini, M. Jobbagy, M. Bermudez, M.B. Moretti, S.C. Garcia, S.A. Bilmess, „Optimizing Silica Encapsulation of Living Cells: In Situ Evaluation of C ellular S tress“, Chem. Mat er . 20, pp. 3015-3021 , 2008. [13] N.E. Simpson, C.L. Stabler, C.P. Simpson, A. Sambanis, I. Con- stantindis, “The role of CaCl2-gluronic acid interaction on algi- nate encapsulated βTC3 cells”, Biomaterials 25, pp. 2603-2610, 2004. [14] C.L. Woldringh, P.G. Huls, N.O.E. Vischer, ”Volume Growth of Daughter and Parent Cells during the Cell Cycle of Saccharo- myces cerevisiae a/α as Determined by Image Cytometry”, J. Bacteriol. 175(10), pp . 31 74-3181, 1993. [15] C. Hatzis, D. Porro,”Morphologically-structured models of growth budding yeast populations”, J. Biotechnol. 124, pp. 420-436, 2006. [16] M. Vanoni, M. Vai, L. Popolo, L. Alberghina,”Structural Het- erogeneity in Populations of the Budding Yeast Saccharomyces cerevisiae” , J. Bacterio l. 156(3), pp. 1282-1291, 1983. [17] B.M. Bugarski, B. Obradovic, V.A. Nedovic, M.F.A. Goosen, “Electrostatic Droplet Generation Technique for Cell Immobili- zation”, in: Finely Dispersed Particles: Micro-, Nano-, and At- to-Engin eering, Sp asic, AM, Hs u JP., Eds . Marcel Dek ker, CRC Press, Taylor & Francis, 2006, pp. 869-886. |