S. A. KHAN ET AL.

Copyright © 2013 SciRes. EPE

428

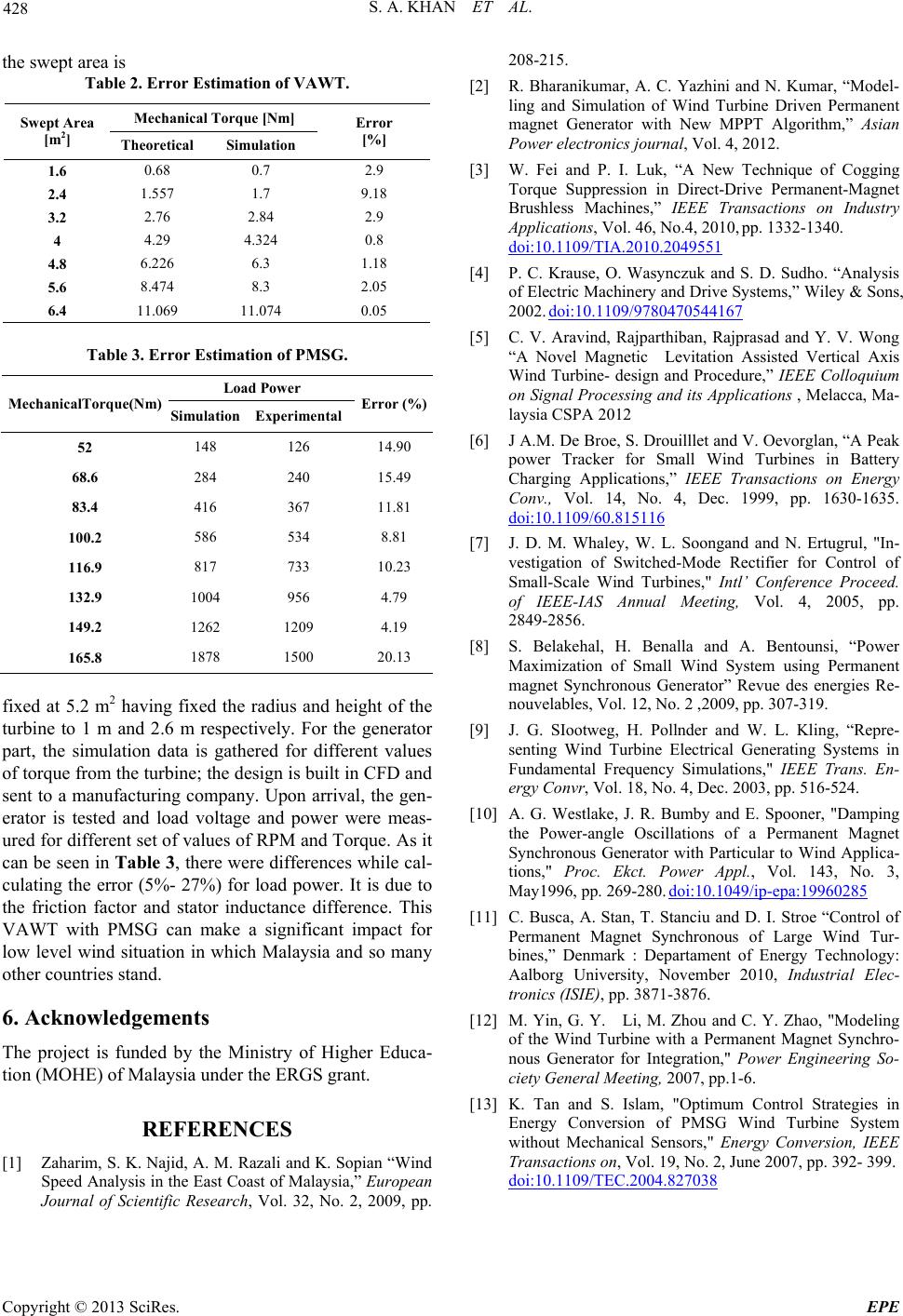

the swept area is

Table 2. Error Estimation of VAWT.

Mechanical Torque [Nm]

Swept Area

[m2] Theoretical Simulation

Error

[%]

1.6 0.68 0.7 2.9

2.4 1.557 1.7 9.18

3.2 2.76 2.84 2.9

4 4.29 4.324 0.8

4.8 6.226 6.3 1.18

5.6 8.474 8.3 2.05

6.4 11.069 11.074 0.05

Table 3. Error Estimation of PMSG.

Load Power

MechanicalTorque(Nm) Simulation Experimental Error (%)

52 148 126 14.90

68.6 284 240 15.49

83.4 416 367 11.81

100.2 586 534 8.81

116.9 817 733 10.23

132.9 1004 956 4.79

149.2 1262 1209 4.19

165.8 1878 1500 20.13

fixed at 5.2 m2 having fixed the radius and height of the

turbine to 1 m and 2.6 m respectively. For the generator

part, the simulation data is gathered for different values

of torque from the turbine; the design is built in CFD and

sent to a manufacturing company. Upon arrival, the gen-

erator is tested and load voltage and power were meas-

ured for different set of values of RPM and Torque. As it

can be seen in Table 3, there were differences while cal-

culating the error (5%- 27%) for load power. It is due to

the friction factor and stator inductance difference. This

VAWT with PMSG can make a significant impact for

low level wind situation in which Malaysia and so many

other countries stand.

6. Acknowledgements

The project is funded by the Ministry of Higher Educa-

tion (MOHE) of Malaysia under the ERGS grant.

REFERENCES

[1] Zaharim, S. K. Najid, A. M. Razali and K. Sopian “Wind

Speed Analysis in the East Coast of Malaysia,” European

Journal of Scientific Research, Vol. 32, No. 2, 2009, pp.

208-215.

[2] R. Bharanikumar, A. C. Yazhini and N. Kumar, “Model-

ling and Simulation of Wind Turbine Driven Permanent

magnet Generator with New MPPT Algorithm,” Asian

Power electronics journal, Vol. 4, 2012.

[3] W. Fei and P. I. Luk, “A New Technique of Cogging

Torque Suppression in Direct-Drive Permanent-Magnet

Brushless Machines,” IEEE Transactions on Industry

Applications, Vol. 46, No.4, 2010, pp. 1332-1340.

doi:10.1109/TIA.2010.2049551

[4] P. C. Krause, O. Wasynczuk and S. D. Sudho. “Analysis

of Electric Machinery and Drive Systems,” Wiley & Sons,

2002. doi:10.1109/9780470544167

[5] C. V. Aravind, Rajparthiban, Rajprasad and Y. V. Wong

“A Novel Magnetic Levitation Assisted Vertical Axis

Wind Turbine- design and Procedure,” IEEE Colloquium

on Signal Processing and its Applications , Melacca, Ma-

laysia CSPA 2012

[6] J A.M. De Broe, S. Drouilllet and V. Oevorglan, “A Peak

power Tracker for Small Wind Turbines in Battery

Charging Applications,” IEEE Transactions on Energy

Conv., Vol. 14, No. 4, Dec. 1999, pp. 1630-1635.

doi:10.1109/60.815116

[7] J. D. M. Whaley, W. L. Soongand and N. Ertugrul, "In-

vestigation of Switched-Mode Rectifier for Control of

Small-Scale Wind Turbines," Intl’ Conference Proceed.

of IEEE-IAS Annual Meeting, Vol. 4, 2005, pp.

2849-2856.

[8] S. Belakehal, H. Benalla and A. Bentounsi, “Power

Maximization of Small Wind System using Permanent

magnet Synchronous Generator” Revue des energies Re-

nouvelables, Vol. 12, No. 2 ,2009, pp. 307-319.

[9] J. G. SIootweg, H. Pollnder and W. L. Kling, “Repre-

senting Wind Turbine Electrical Generating Systems in

Fundamental Frequency Simulations," IEEE Trans. En-

ergy Convr, Vol. 18, No. 4, Dec. 2003, pp. 516-524.

[10] A. G. Westlake, J. R. Bumby and E. Spooner, "Damping

the Power-angle Oscillations of a Permanent Magnet

Synchronous Generator with Particular to Wind Applica-

tions," Proc. Ekct. Power Appl., Vol. 143, No. 3,

May1996, pp. 269-280. doi:10.1049/ip-epa:19960285

[11] C. Busca, A. Stan, T. Stanciu and D. I. Stroe “Control of

Permanent Magnet Synchronous of Large Wind Tur-

bines,” Denmark : Departament of Energy Technology:

Aalborg University, November 2010, Industrial Elec-

tronics (ISIE), pp. 3871-3876.

[12] M. Yin, G. Y. Li, M. Zhou and C. Y. Zhao, "Modeling

of the Wind Turbine with a Permanent Magnet Synchro-

nous Generator for Integration," Power Engineering So-

ciety General Meeting, 2007, pp.1-6.

[13] K. Tan and S. Islam, "Optimum Control Strategies in

Energy Conversion of PMSG Wind Turbine System

without Mechanical Sensors," Energy Conversion, IEEE

Transactions on, Vol. 19, No. 2, June 2007, pp. 392- 399.

doi:10.1109/TEC.2004.827038