J.-M. LING, P.-H. LIU

Copyright © 2013 SciRes. EPE

timization in system model, a nd the va riat ions o f the sig-

nificant design variables is needed to investigate the

usefulness of these simulation and optimization tools

applied to specific applica tions.

The paper proposes a procedure based on genetic al-

gorithms (GA) to get global optimum capacity of PV

array and battery in a SPV system under compromise

between the reliability and to tal installed c ost. Compared

with t he co n ve nt io na l Lagrangian relaxatio n op ti mization,

GA approach finds the global optimum more efficiently.

The sensitivity analysis for the component cost and load

profiles were also discussed to show the impacts of the

optimal results of planning. The optimal sizing of a SPV

system incorporating solar resources uncertainty is also

considered in the aspects of long-ter m pla nning. The real

solar radiation/temperature data from four weather sta-

tions have been tested to simulate the practicability of

planning resul ts for a SPV system.

2. The Optimal Design Method

In the design and planning of stand-alone renewable en-

ergy systems, the optimal sizing is an important and

challenging task as the coordination among renewable

energy resources, generators, storage capacity and it’s

complicated load.

2.1. System Modeling

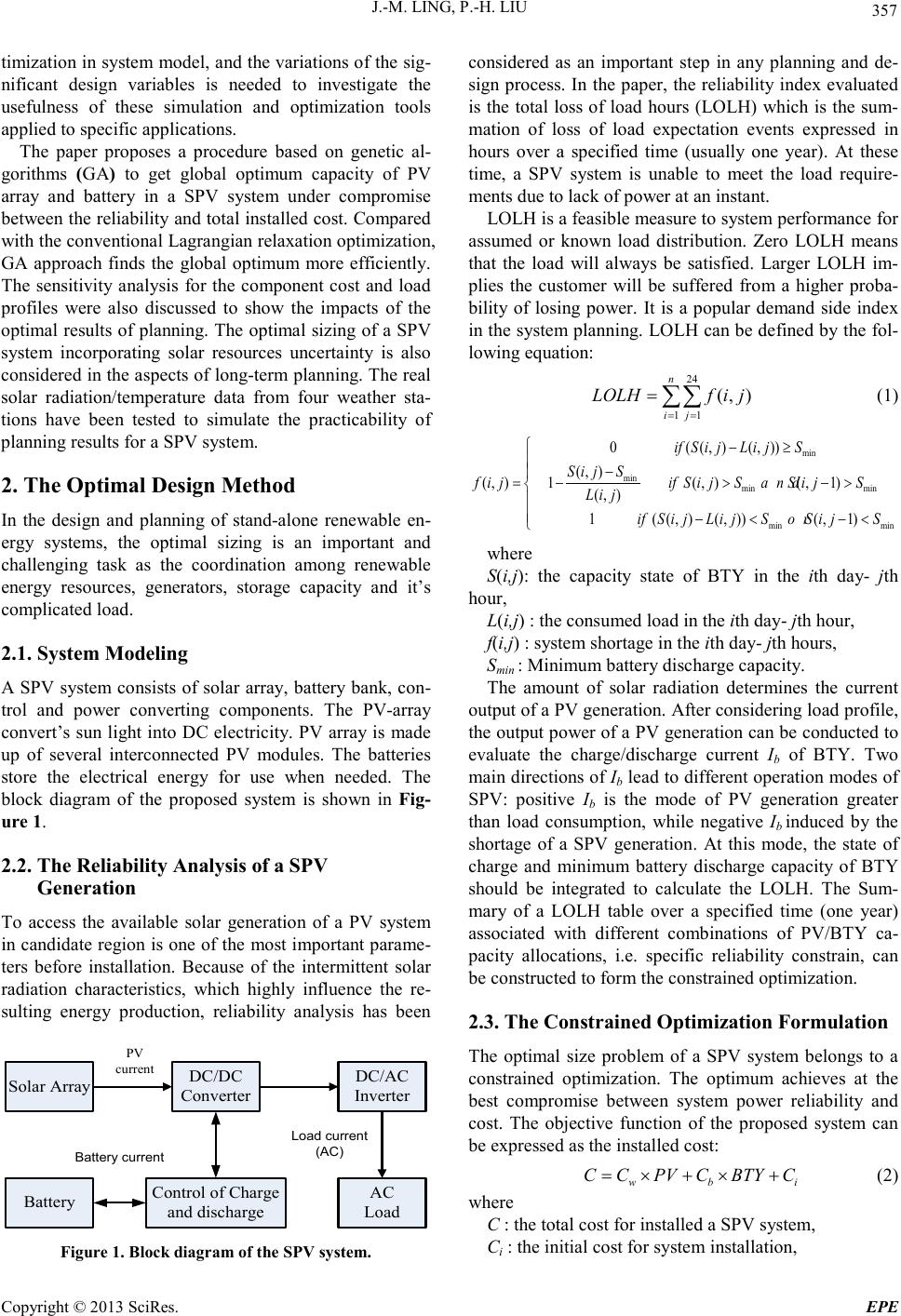

A SPV system consists of solar array, battery bank, con-

trol and power converting components. The PV-array

convert’s s un light into DC electricity. PV array is made

up of several interconnected PV modules. The batteries

store the electrical energy for use when needed. The

block diagram of the proposed system is shown in Fig-

ure 1.

2.2. The Reliability Analysis of a SPV

Generation

To access the available solar generation of a PV system

in candidate regio n is one of the most impor tant parame-

ters before installation. Because of the intermittent solar

radiation characteristics, which highly influence the re-

sulting energy production, reliability analysis has been

Solar ArrayDC/DC

Converter DC/AC

Inverter

Control of Charge

and discharge

Battery AC

Load

PV

current

Load current

(AC)

Battery current

Figure 1. Block diagram of the SPV system.

considered as an important step in any planning and de-

sign process. In the paper, the reliability index evaluated

is the total loss of load hours (LOLH) which is the sum-

mation of loss of load expectation events expressed in

hours over a specified time (usually one year). At these

time, a SPV system is unable to meet the load require-

ments due to lack of power at an in stant.

LOLH is a feasible measure to sys tem pe r fo r manc e fo r

assumed or known load distribution. Zero LOLH means

that the load will always be satisfied. Larger LOLH im-

plies the customer will be suffered from a higher proba-

bility of losing power. It is a popular demand side index

in the syste m pla nning. LOLH can be de fined b y the fol-

lowing equatio n:

24

11(, )

n

ij

LOLHf i j

= =

=∑∑ (1)

min

min min min

min min

0( (, )(, ))

(,)

(, )1(, )(,1)

(,)

1( (, )(, ))(,1)

ifSij LijS

Sij S

fijifSijS andSijS

Li j

if SijLijSorSijS

−≥

−

= −>−>

− <−<

where

S(i,j): the capacity state of BTY in the ith day- jth

hour,

L(i,j) : the consumed load in the ith day- jth hour ,

f(i,j) : system shor tage in the ith day- jth hour s,

Smin : Minimum battery discharge capacity.

The amount of solar radiation determines the current

output of a PV generation. After considering load profile,

the out put po wer of a PV generation can be conducted to

evaluate the charge/discharge current Ib of BTY. Two

main directio ns of Ib lead to different operation modes of

SPV: positive Ib is the mode of PV generation greater

than load consumption, while negative Ib induced by the

shortage of a SPV generation. At this mode, the state of

charge and minimum battery discharge capacity of BTY

should be integrated to calculate the LOLH. The Sum-

mary of a LOLH table over a specified time (one year)

associated with different combinations of PV/BTY ca-

pacity allocations, i.e. specific reliability constrain, can

be constructed to form the constrained optimization.

2.3. The Cons t r ai n ed Optimization Formulation

The optimal size problem of a SPV system belongs to a

constrained optimization. The optimum achieves at the

best compromise betwe en system power reliability and

cost. The objective function of the proposed system can

be expressed as the installed cost:

(2)

where

C : the total cost for installed a SPV system,

Ci : the initial cost fo r system i ns tallation,