Paper Menu >>

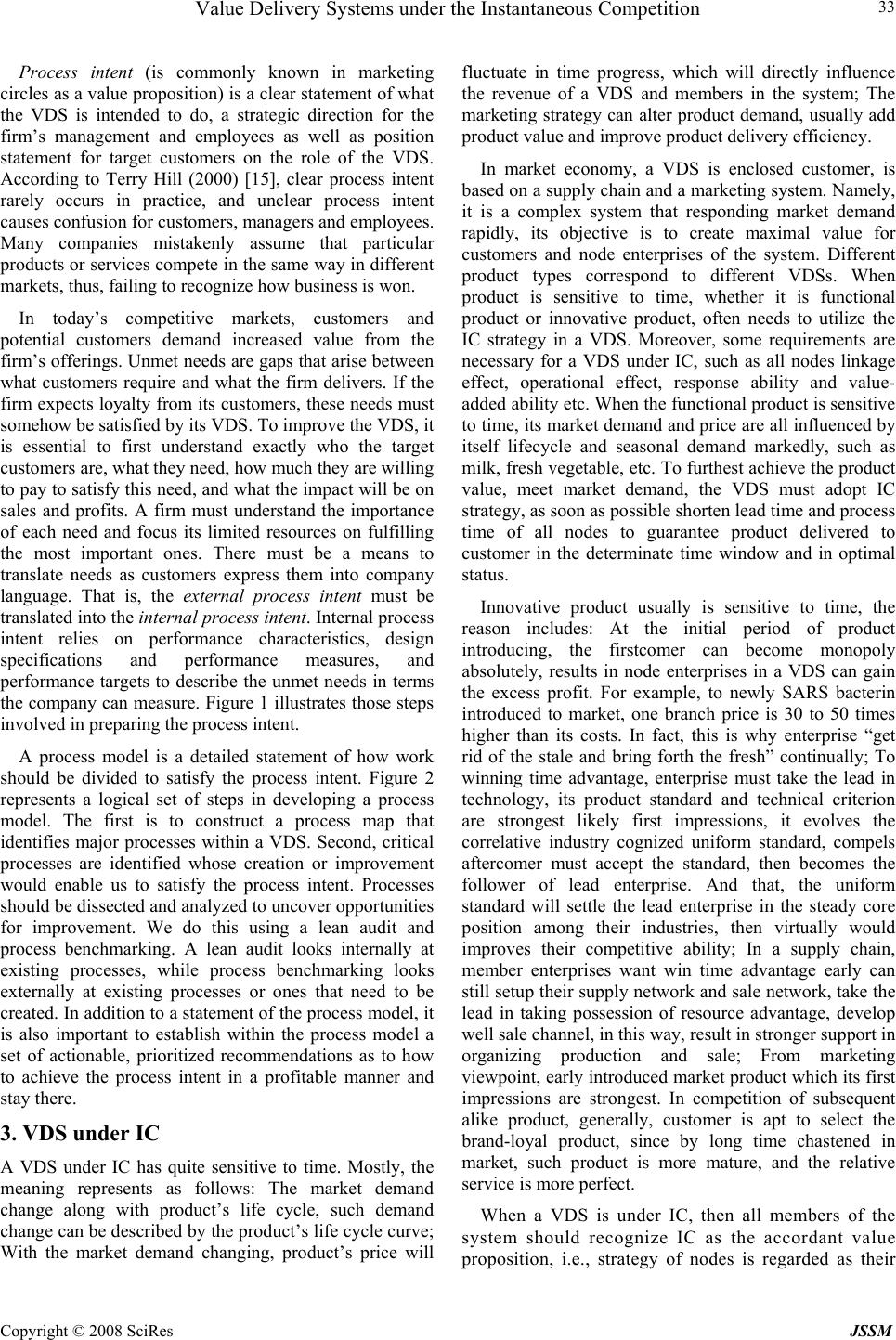

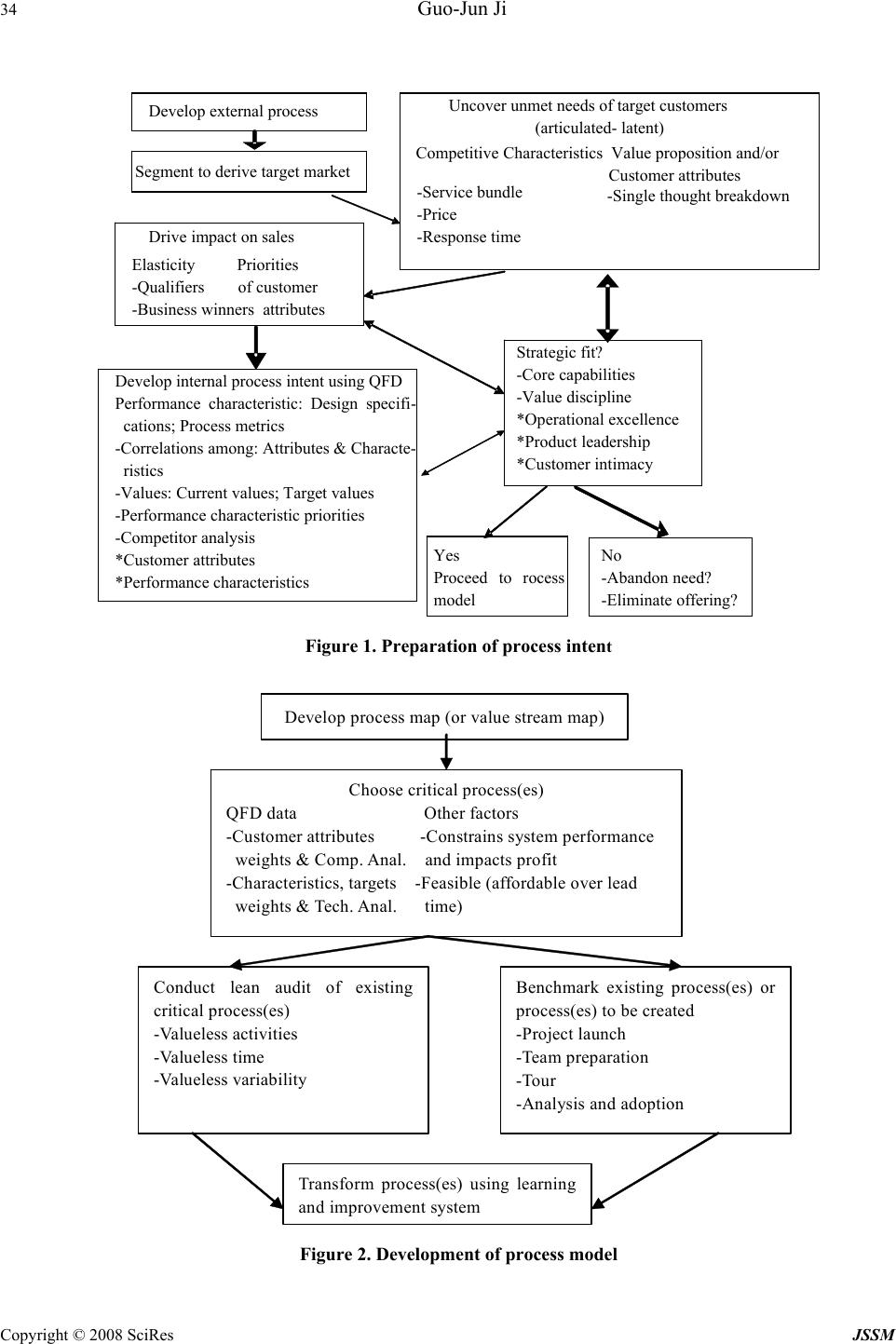

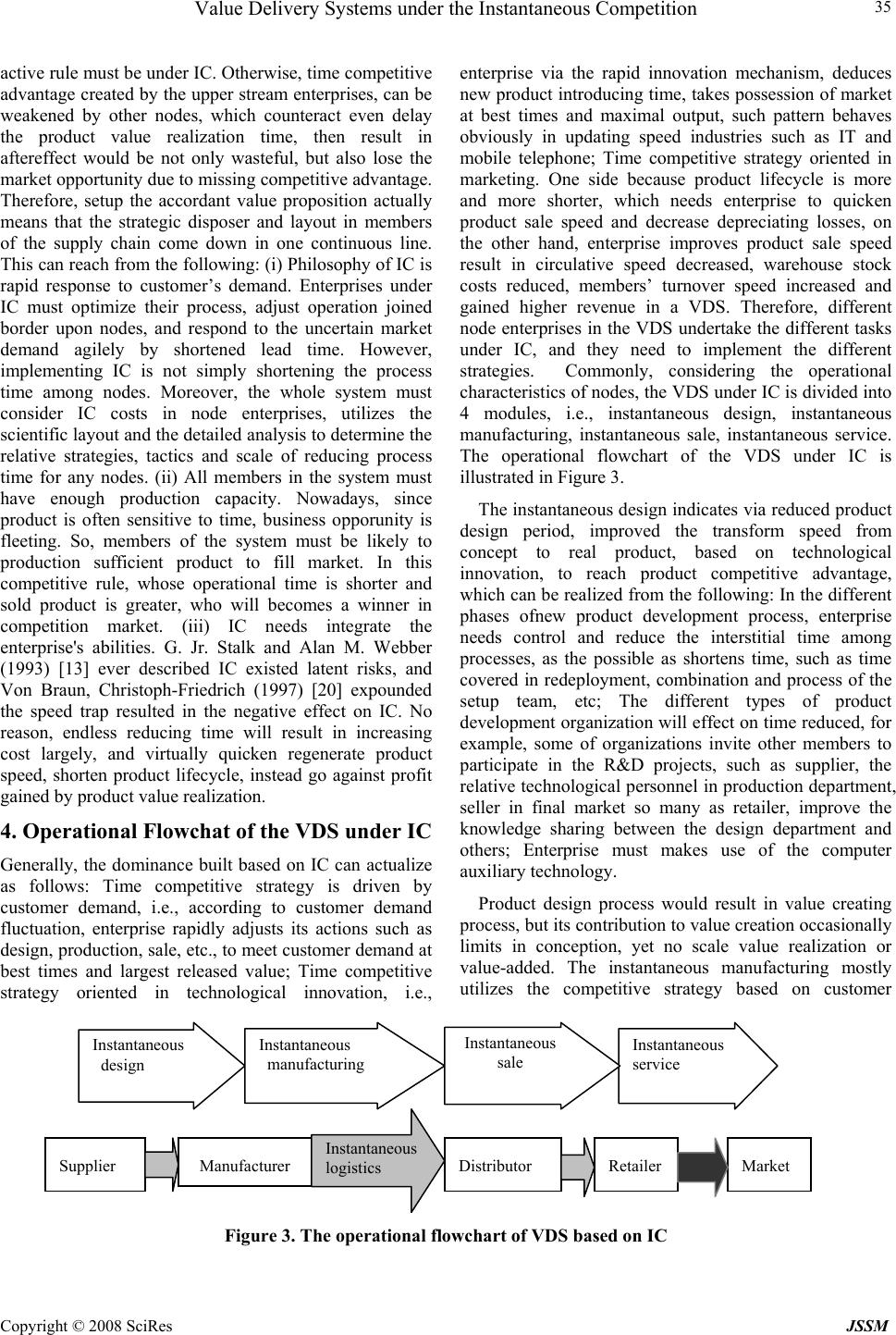

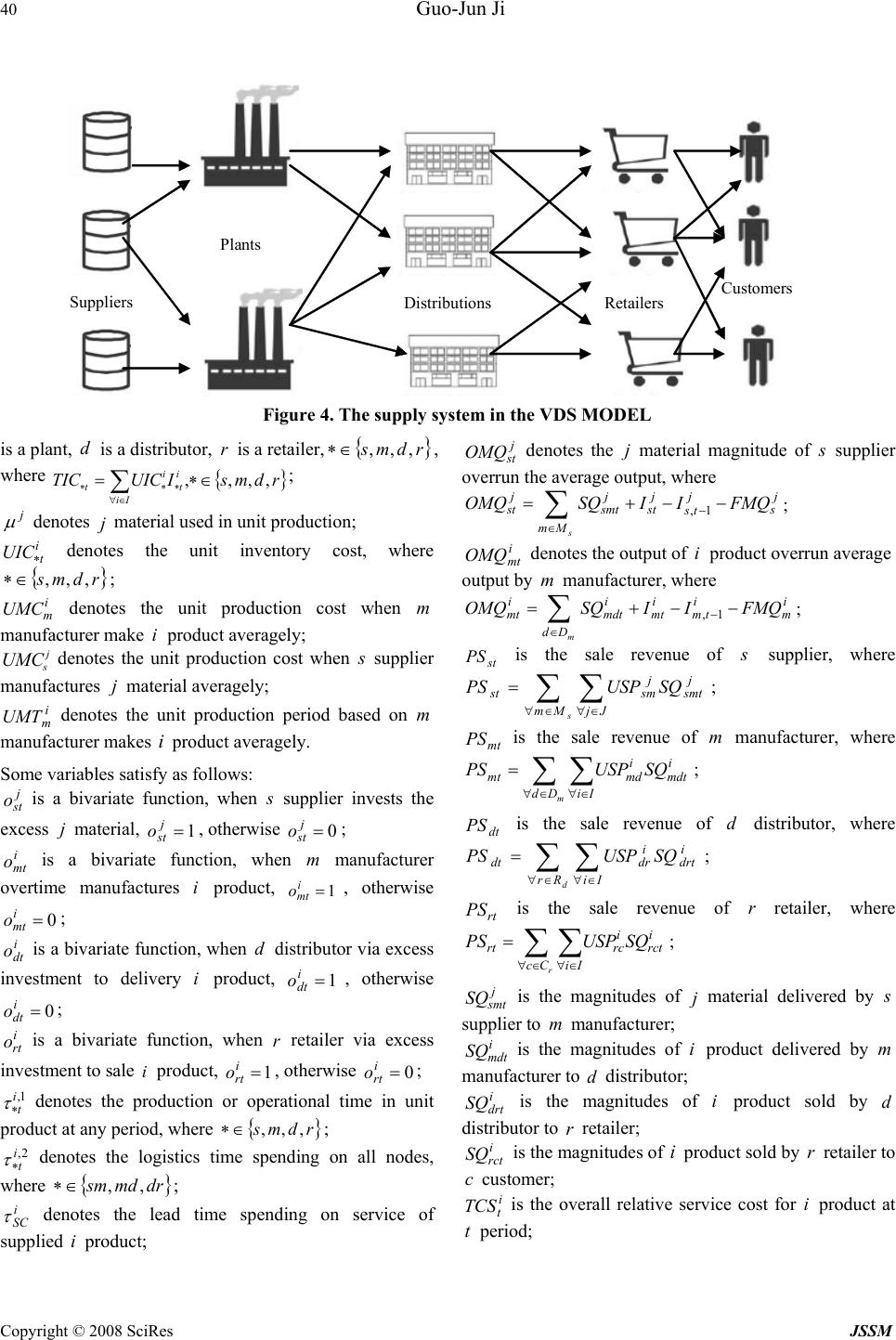

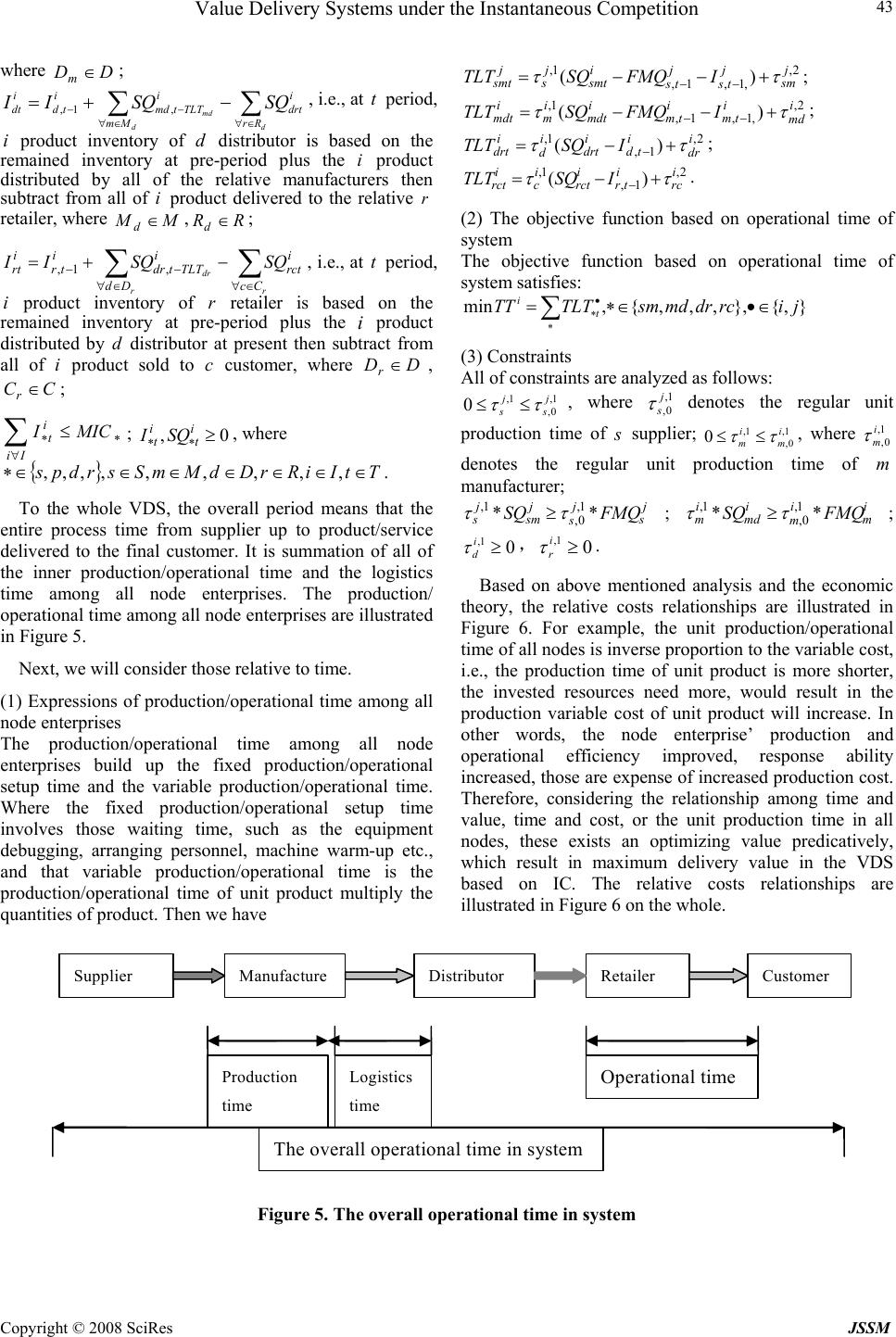

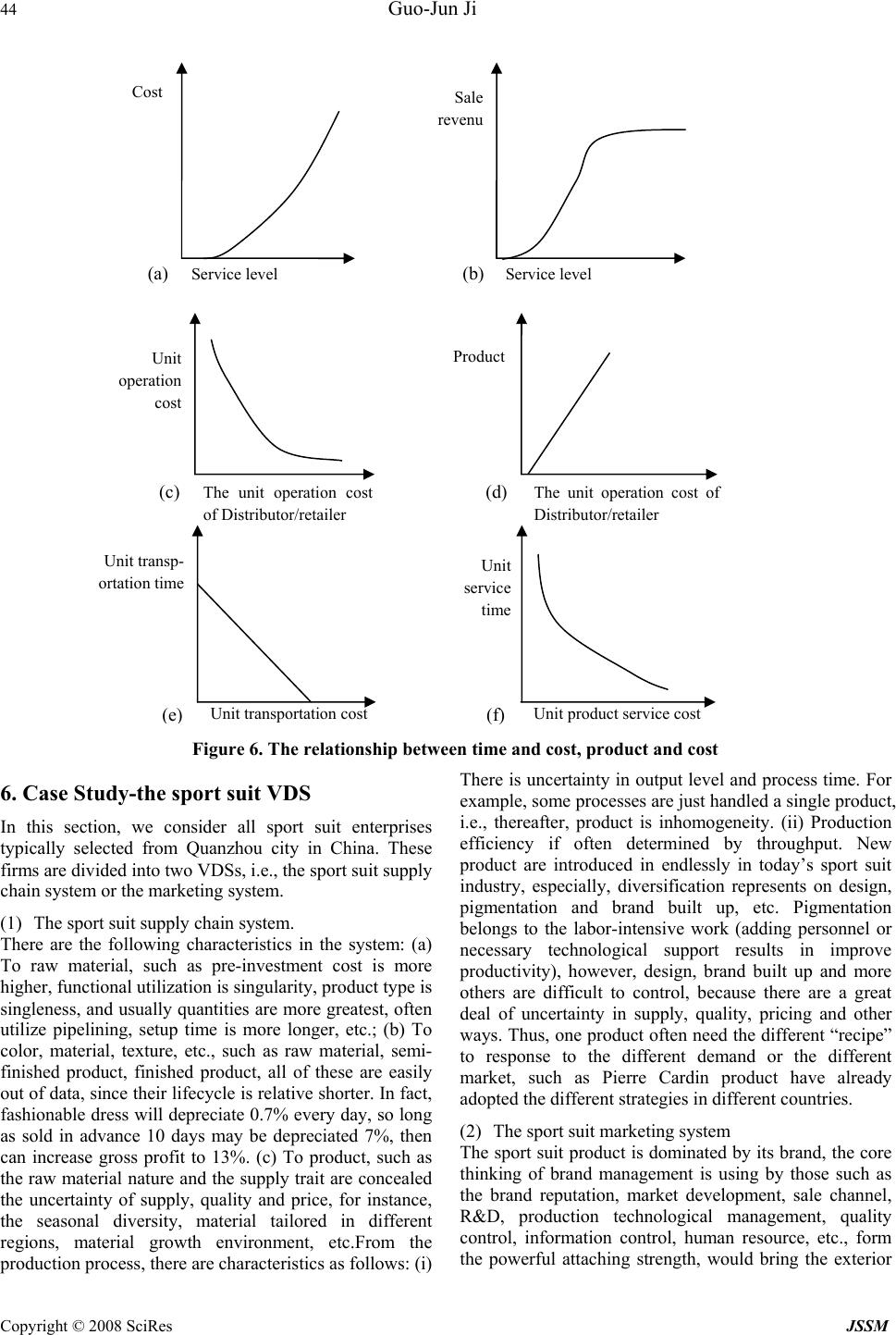

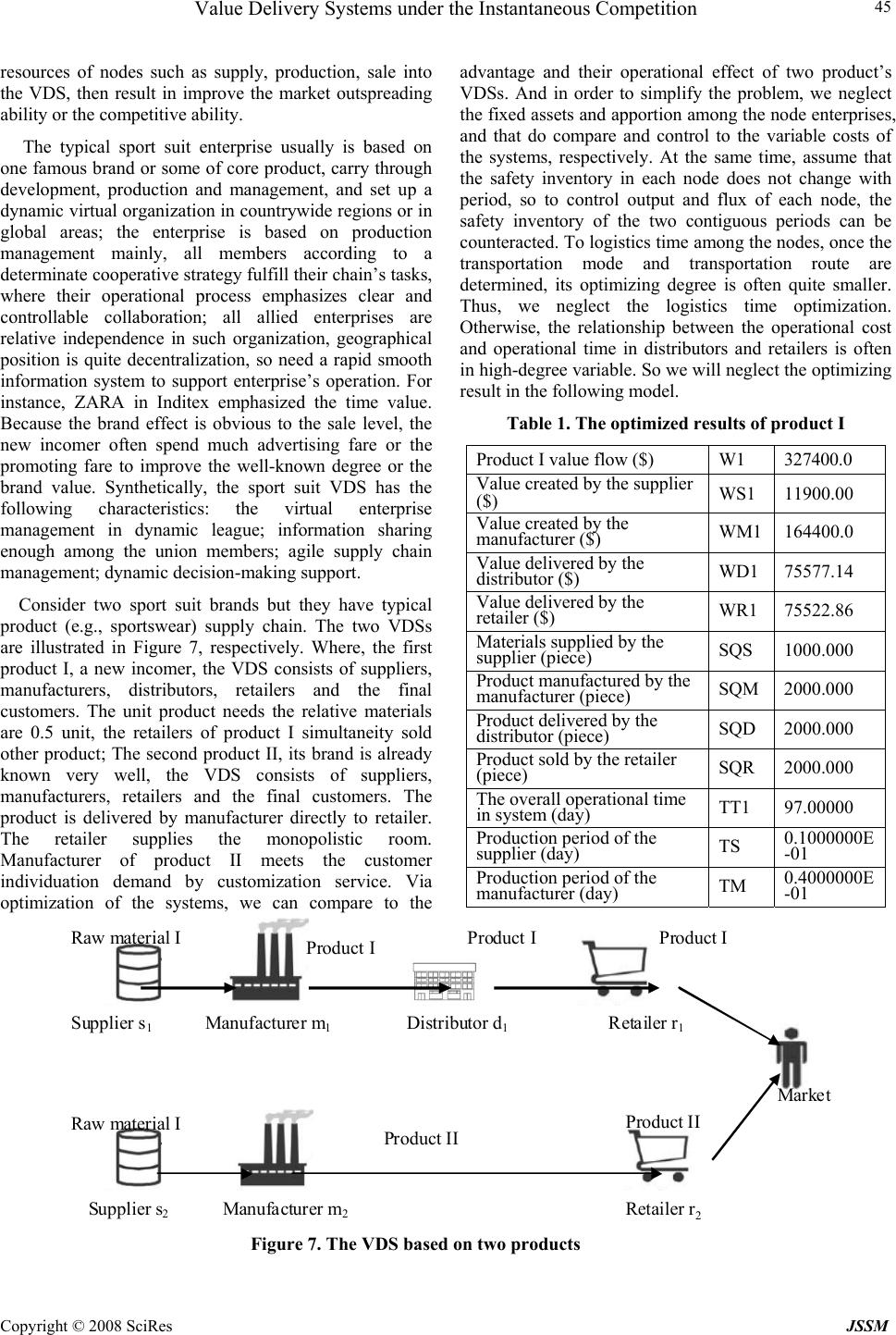

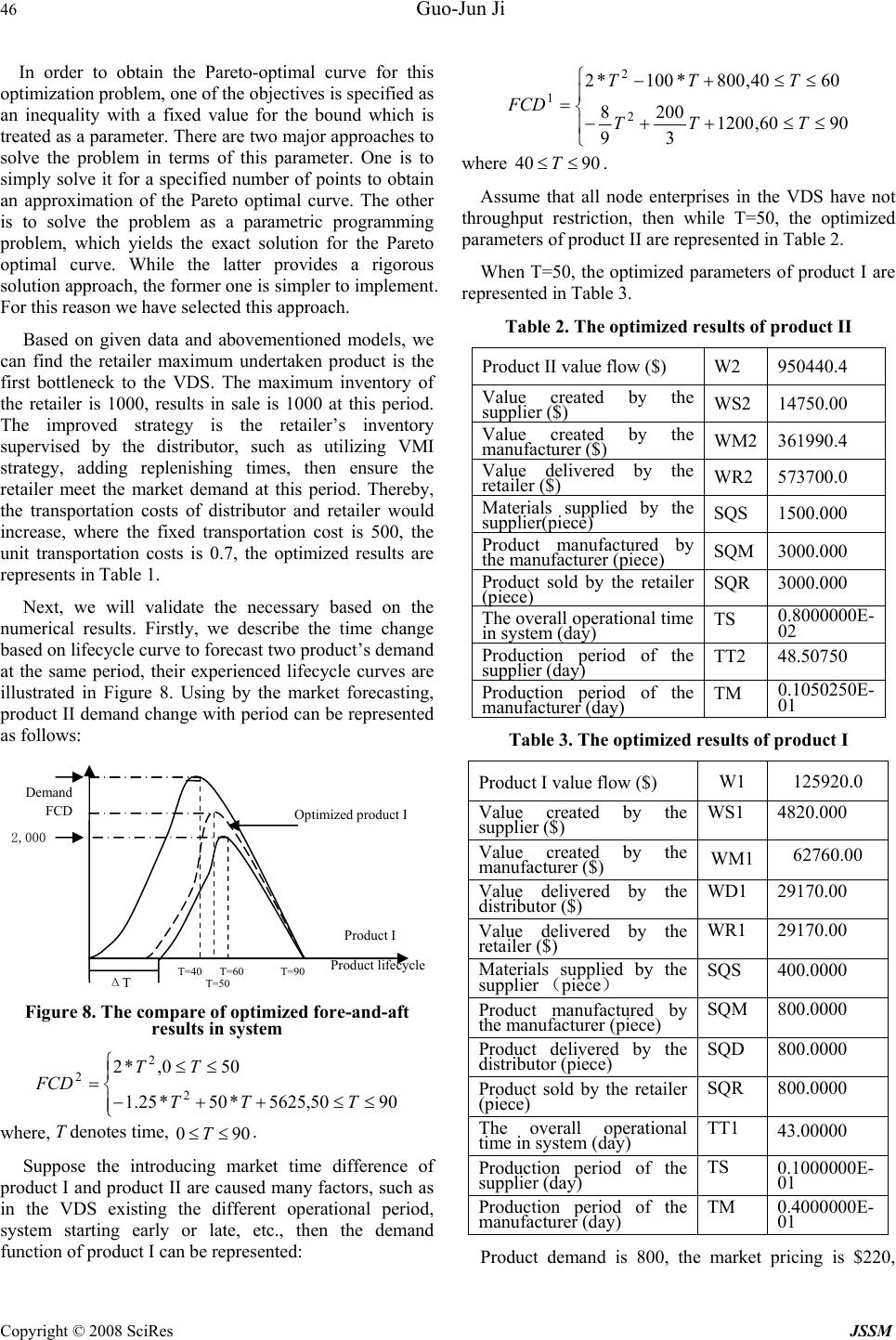

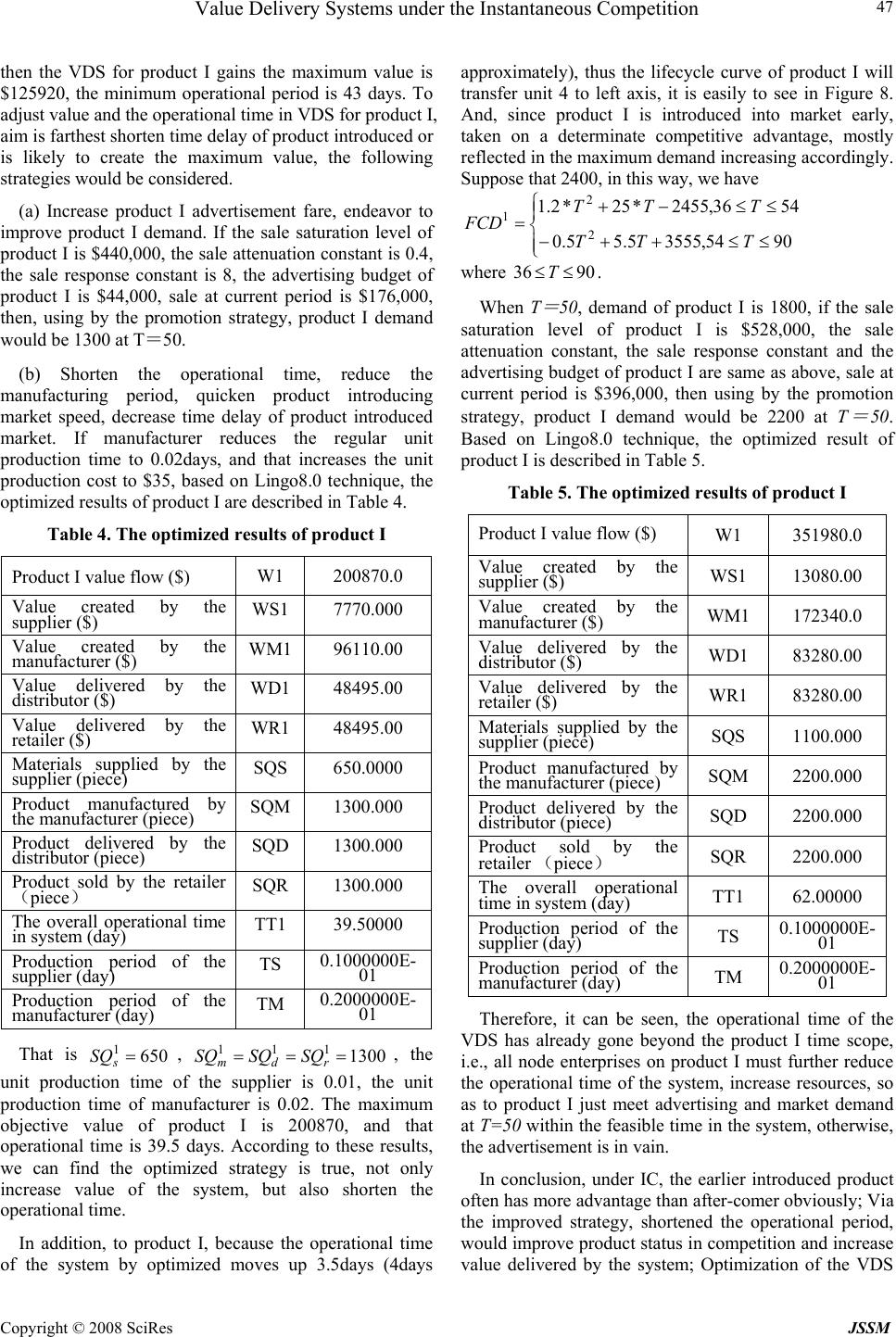

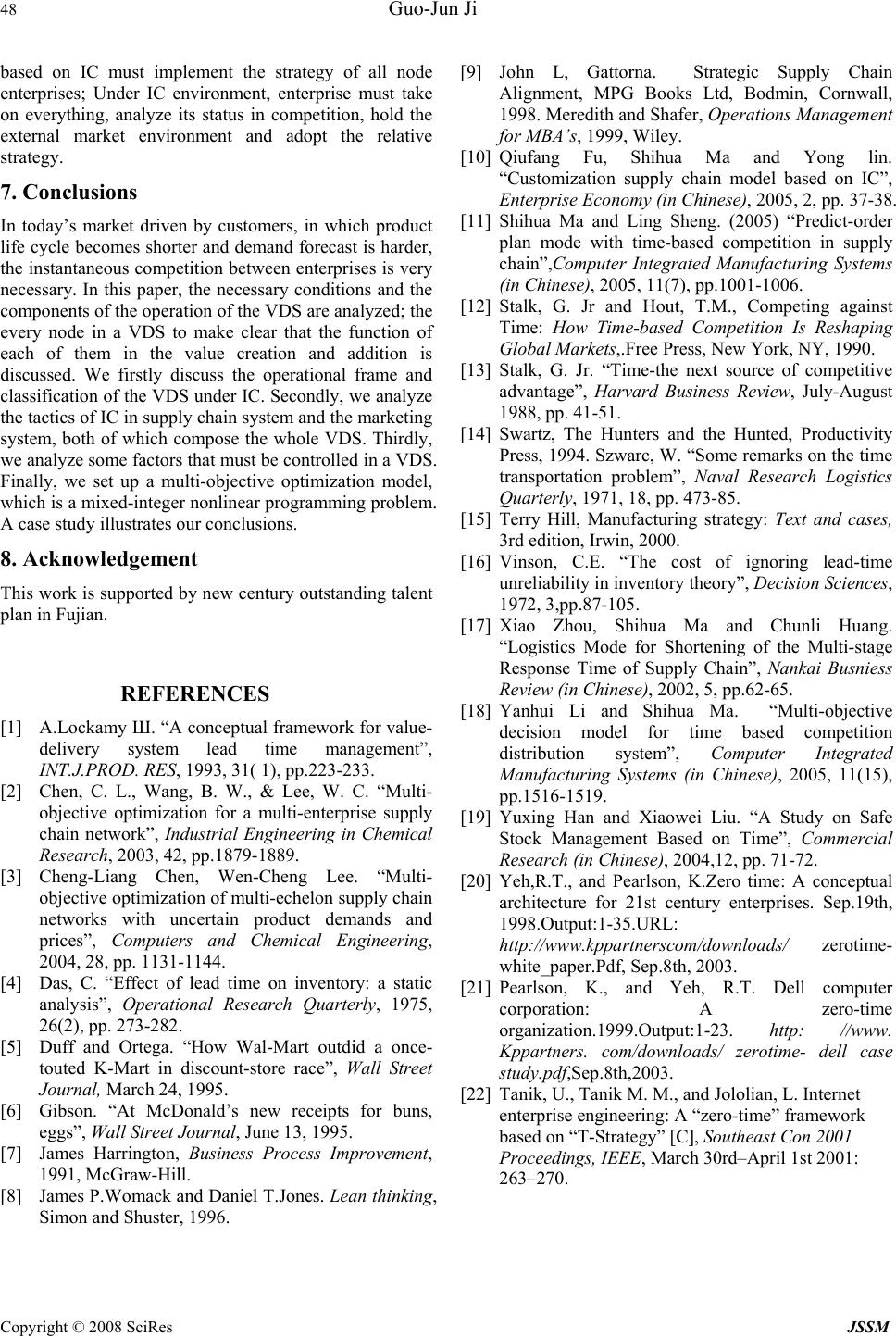

Journal Menu >>