Energy and Power Engineering, 2013, 5, 237-240

doi:10.4236/epe.2013.54B046 Published Online July 2013 (http://www.scirp.org/journal/epe)

A Thermoelectric Generator Manufacture Research Based

on Oscillating-Flow Heat Pipe Technology

Jieting Wei1, Yu Gu2, Yang Liu2

1Changchun Institute of Technology, Changchun,China

2Northeast Dianli University, Jilin,China

Email: wjt8876@126.com

Received April, 2013

ABSTRACT

Oscillating heat pipe is a new type of heat transfer. It not only has simple structure, non-pollution and low maintenance

cost, but also has high heat transfer efficiency. Semiconductor thermoelectric generation technology is also an environ-

mental technology. This article combines these two kinds of technology. By means of this generate electricity way, we

make a set of system and the related experiment. Then we do some research on the feasibility of this system.

Keywords: Oscillating Heat Pipe; Thermoelectric Power Generation; Solar Energy

1. Introduction

Solar energy is a renewable green energy universal ex-

isted on earth. Its Application value is huge. If we make

good use of it and convert light energy into electrical

energy, we can replace the current fossil energy, because

of its low pollution and waste.

Solar thermoelectric generation is a kind of green en-

ergy. The heat energy converts into electrical energy di-

rectly. Research on thermoelectric power generation was

first started in the middle of the twentieth Century, with

the problems of environmental pollution and oil and

natural gas energy depletion of mainstream trend is be-

coming more and more serious, People began to study

energy on this work, no noise, no exhaust waste, envi-

ronmentally sound technology. The United States, the

European Union, the developed country in the world at-

taches great importance to the study of thermoelectric

power generation technology in civil field [1].

2. Principle

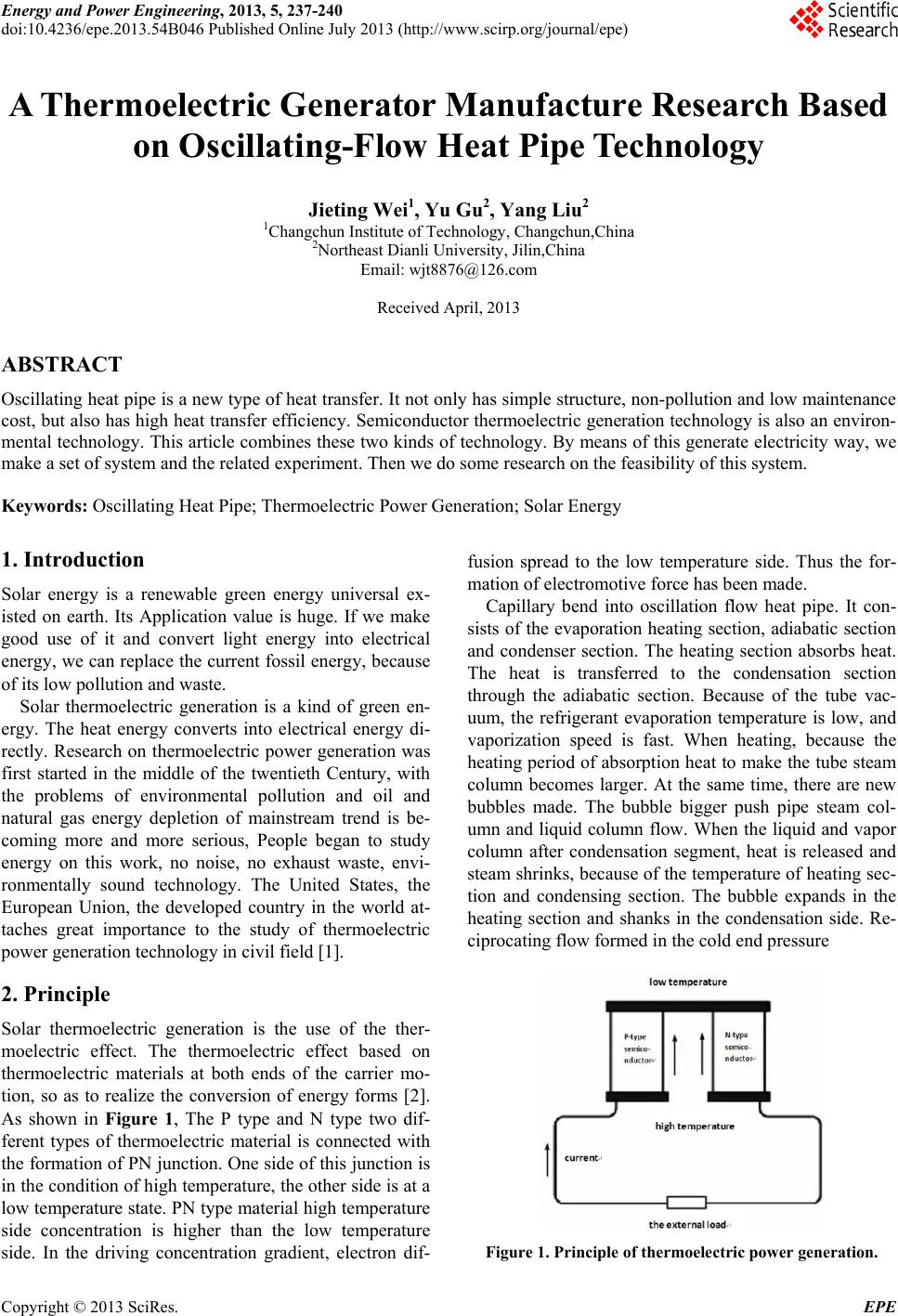

Solar thermoelectric generation is the use of the ther-

moelectric effect. The thermoelectric effect based on

thermoelectric materials at both ends of the carrier mo-

tion, so as to realize the conversion of energy forms [2].

As shown in Figure 1, The P type and N type two dif-

ferent types of thermoelectric material is connected with

the formation of PN junction. One side of this junction is

in the condition of high temperature, the other side is at a

low temperature state. PN type material high temperature

side concentration is higher than the low temperature

side. In the driving concentration gradient, electron dif-

fusion spread to the low temperature side. Thus the for-

mation of electromotive force has been made.

Capillary bend into oscillation flow heat pipe. It con-

sists of the evaporation heating section, adiabatic section

and condenser section. The heating section absorbs heat.

The heat is transferred to the condensation section

through the adiabatic section. Because of the tube vac-

uum, the refrigerant evaporation temperature is low, and

vaporization speed is fast. When heating, because the

heating period of absorption heat to make the tube steam

column becomes larger. At the same time, there are new

bubbles made. The bubble bigger push pipe steam col-

umn and liquid column flow. When the liquid and vapor

column after condensation segment, heat is released and

steam shrinks, because of the temperature of heating sec-

tion and condensing section. The bubble expands in the

heating section and shanks in the condensation side. Re-

ciprocating flow formed in the cold end pressure

Figure 1. Principle of thermoelectric power generation.

Copyright © 2013 SciRes. EPE