Y. H. ZHANG ET AL. 39

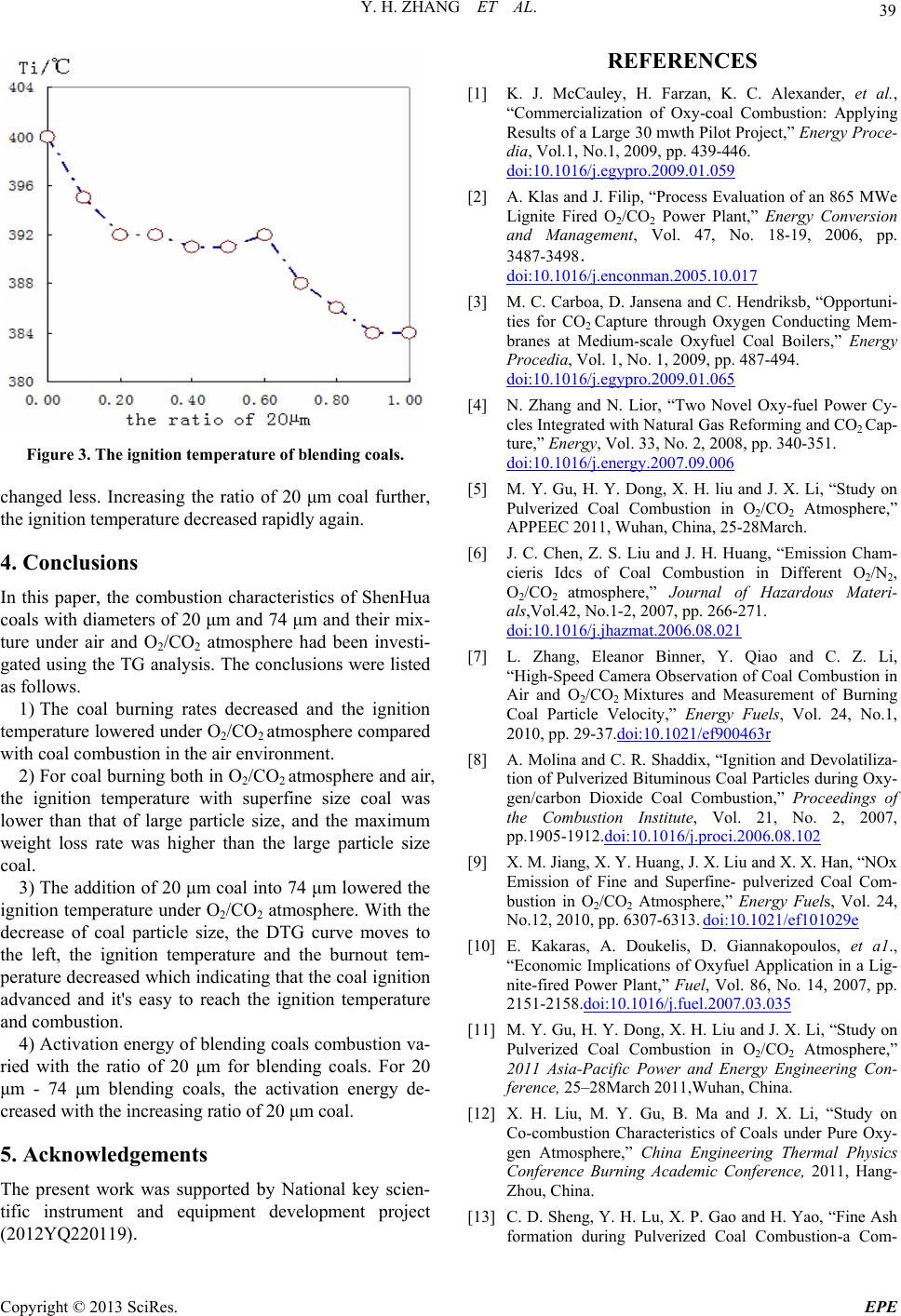

Figure 3. The ignition temperature of blending coals.

changed less. Increasing the ratio of 20 μm coal further,

the ignition temperature decreased rapidly again.

4. Conclusions

In this paper, the combustion characteristics of ShenHua

coals with diameters of 20 μm and 74 μm and their mix-

ture under air and O2/CO2 atmosphere had been investi-

gated using the TG analysis. The conclusions were listed

as follows.

1) The coal burning rates decreased and the ignition

temperature lowered under O2/CO2 atmosphere compared

with coal combustion in the air environment.

2) For coal burning both in O2/CO2 atmosphere and air,

the ignition temperature with superfine size coal was

lower than that of large particle size, and the maximum

weight loss rate was higher than the large particle size

coal.

3) The addition of 20 μm coal into 74 μm lowered the

ignition temperature under O2/CO2 atmosphere. With the

decrease of coal particle size, the DTG curve moves to

the left, the ignition temperature and the burnout tem-

perature decreased which indicating that the coal ignition

advanced and it's easy to reach the ignition temperature

and combustion.

4) Activation energy of blending coals combustion va-

ried with the ratio of 20 μm for blending coals. For 20

μm - 74 μm blending coals, the activation energy de-

creased with the increasing ratio of 20 μm coal.

5. Acknowledgements

The present work was supported by National key scien-

tific instrument and equipment development project

(2012YQ22011 9).

REFERENCES

[1] K. J. McCauley, H. Farzan, K. C. Alexander, et al.,

“Commercialization of Oxy-coal Combustion: Applying

Results of a Large 30 mwth Pilot Project,” Energy Proce-

dia, Vol.1, No.1, 2009, pp. 439-446.

doi:10.1016/j.egypro.2009.01.059

[2] A. Klas and J. Filip, “Process Evaluation of an 865 MWe

Lignite Fired O2/CO2 Power Plant,” Energy Conversion

and Management, Vol. 47, No. 18-19, 2006, pp.

3487-3498.

doi:10.1016/j.enconman.2005.10.017

[3] M. C. Carboa, D. Jansena and C. Hendriksb, “Opportuni-

ties for CO2 Capture through Oxygen Conducting Mem-

branes at Medium-scale Oxyfuel Coal Boilers,” Energy

Procedia, Vol. 1, No. 1, 2009, pp. 487-494.

doi:10.1016/j.egypro.2009.01.065

[4] N. Zhang and N. Lior, “Two Novel Oxy-fuel Power Cy-

cles Integrated with Natural Gas Reforming and CO2 Cap-

ture,” Energy, Vol. 33, No. 2, 2008, pp. 340-351.

doi:10.1016/j.energy.2007.09.006

[5] M. Y. Gu, H. Y. Dong, X. H. liu and J. X. Li, “Study on

Pulverized Coal Combustion in O2/CO2 Atmosphere,”

APPEEC 2011, Wuhan, China, 25-28March.

[6] J. C. Chen, Z. S. Liu and J. H. Huang, “Emission Cham-

cieris Idcs of Coal Combustion in Different O2/N2,

O2/CO2 atmosphere,” Journal of Hazardous Materi-

als,Vol.42, No.1-2, 2007, pp. 266-271.

doi:10.1016/j.jhazmat.2006.08.021

[7] L. Zhang, Eleanor Binner, Y. Qiao and C. Z. Li,

“High-Speed Camera Observation of Coal Combustion in

Air and O2/CO2 Mixtures and Measurement of Burning

Coal Particle Velocity,” Energy Fuels, Vol. 24, No.1,

2010, pp. 29-37.doi:10.1021/ef900463r

[8] A. Molina and C. R. Shaddix, “Ignition and Devolatiliza-

tion of Pulverized Bituminous Coal Particles during Oxy-

gen/carbon Dioxide Coal Combustion,” Proceedings of

the Combustion Institute, Vol. 21, No. 2, 2007,

pp.1905-1912.doi:10.1016/j.proci.2006.08.102

[9] X. M. Jiang, X. Y. Huang, J. X. Liu and X. X. Han, “NOx

Emission of Fine and Superfine- pulverized Coal Com-

bustion in O2/CO2 Atmosphere,” Energy Fuels, Vol. 24,

No.12, 2010, pp. 6307-6313. doi:10.1021/ef101029e

[10] E. Kakaras, A. Doukelis, D. Giannakopoulos, et a1.,

“Economic Implications of Oxyfuel Application in a Lig-

nite-fired Power Plant,” Fuel, Vol. 86, No. 14, 2007, pp.

2151-2158.doi:10.1016/j.fuel.2007.03.035

[11] M. Y. Gu, H. Y. Dong, X. H. Liu and J. X. Li, “Study on

Pulverized Coal Combustion in O2/CO2 Atmosphere,”

2011 Asia-Pacific Power and Energy Engineering Con-

ference, 25–28March 2011,Wuhan, China.

[12] X. H. Liu, M. Y. Gu, B. Ma and J. X. Li, “Study on

Co-combustion Characteristics of Coals under Pure Oxy-

gen Atmosphere,” China Engineering Thermal Physics

Conference Burning Academic Conference, 2011, Hang-

Zhou, China.

[13] C. D. Sheng, Y. H. Lu, X. P. Gao and H. Yao, “Fine Ash

formation during Pulverized Coal Combustion-a Com-

Copyright © 2013 SciRes. EPE