N. V. PANOVA, E. A. SPIRIDONOV

58

nection is selected as follows:

4

p

N

d,

[]

where: N—external tension force on this particular

threaded joint; p

[]

—admissible tension stress.

The area pressure exerted by circumference-unequal

flow on the surface of a blade, q(t), can be presented as

[3]:

q(t) = qcons+

qkz

Sin(2

nkzt +

kz),

where: q(t)—time-variant load per unit length of blade;

qcons—constant load on blade;

qkz—amplitude of the time-variant load per unit length of

blade at frequency f = knz; 2

nt—angular coordinate of

blade rotation;

кz—phase angle.

Reliability of blades is assured through (1) their suffi-

cient structural strength and (2) absence of resonance

phenomena as a response to the nonstationary exposure,

e.g., rotor speed, ventilation network vibrations, etc. In

the first case it is required to sustain permissible stress in

a blade, considering strength limits and load factors of

the materials used; the second target is achieved owing to

safe tuning-out of the blade vibration frequencies under

the excitation forces and, thus, elimination of hazardous

dynamic stress under probable resonance effect.

The main way to solving the engineering tasks above

is the optimized selection of design variables of blades so

that to ensure required strength and frequency. Along

with classical approaches, such as material selection and

change of cross-sections in strained members of blades,

in case of the double, sheet blades, there is an additional

option of stress and frequency control by means of nu-

merical modeling of the parameters of connecting straps,

stiffening plates, etc.

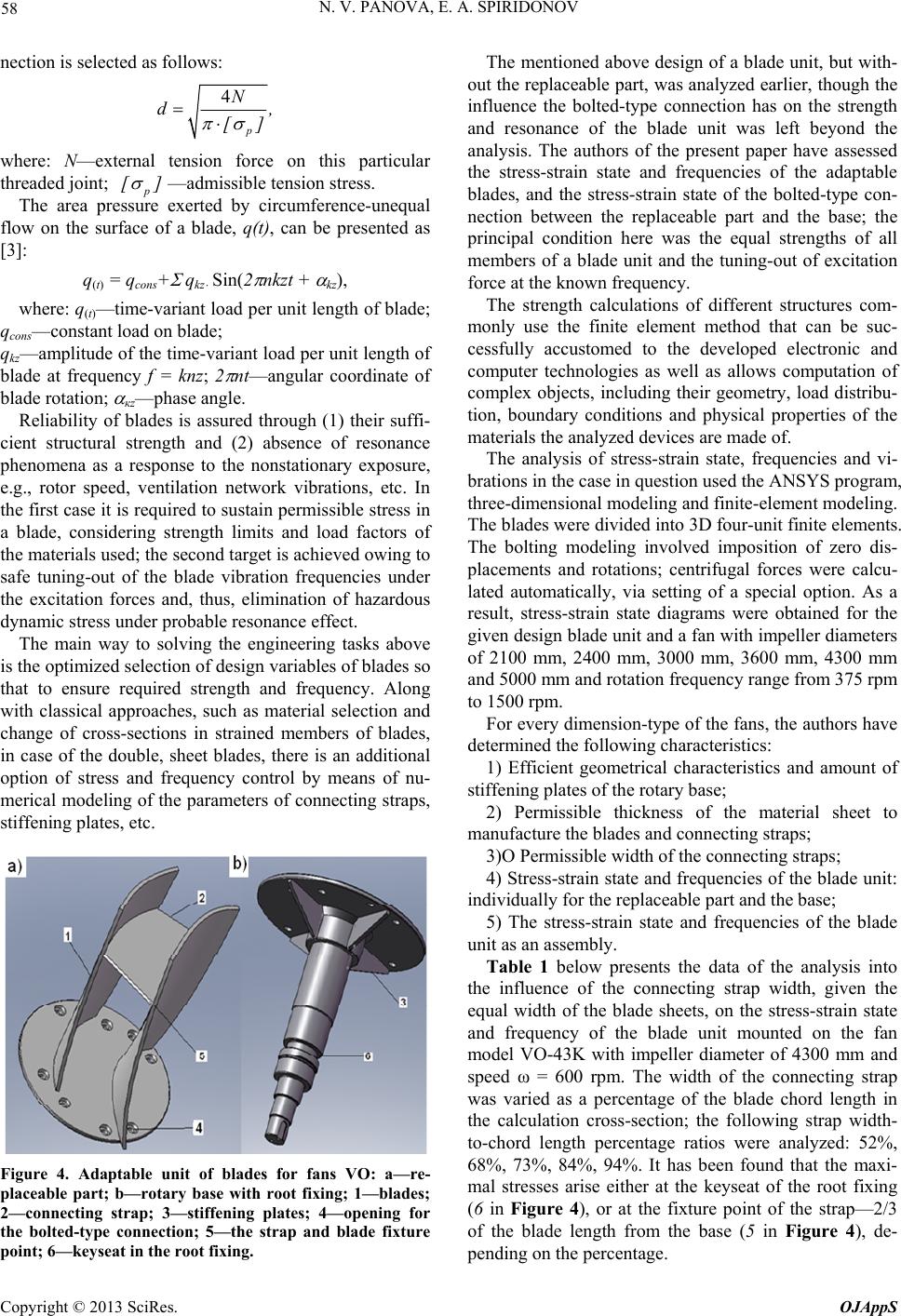

Figure 4. Adaptable unit of blades for fans VO: a—re-

placeable part; b—rotary base with root fixing; 1—blades;

2—connecting strap; 3—stiffening plates; 4—opening for

the bolted-type connection; 5—the strap and blade fixture

point; 6—keyseat in the root fixing.

The mentioned above design of a blade unit, but with-

out the replaceable part, was analyzed earlier, though the

influence the bolted-type connection has on the strength

and resonance of the blade unit was left beyond the

analysis. The authors of the present paper have assessed

the stress-strain state and frequencies of the adaptable

blades, and the stress-strain state of the bolted-type con-

nection between the replaceable part and the base; the

principal condition here was the equal strengths of all

members of a blade unit and the tuning-out of excitation

force at the known frequency.

The strength calculations of different structures com-

monly use the finite element method that can be suc-

cessfully accustomed to the developed electronic and

computer technologies as well as allows computation of

complex objects, including their geometry, load distribu-

tion, boundary conditions and physical properties of the

materials the analyzed devices are made of.

The analysis of stress-strain state, frequencies and vi-

brations in the case in question used the ANSYS program,

three-dimensional modeling and finite-element modeling.

The blades were divided into 3D four-unit finite elements.

The bolting modeling involved imposition of zero dis-

placements and rotations; centrifugal forces were calcu-

lated automatically, via setting of a special option. As a

result, stress-strain state diagrams were obtained for the

given design blade unit and a fan with impeller diameters

of 2100 mm, 2400 mm, 3000 mm, 3600 mm, 4300 mm

and 5000 mm and rotation frequency range from 375 rpm

to 1500 rpm.

For every dimension-type of the fans, the authors have

determined the following characteristics:

1) Efficient geometrical characteristics and amount of

stiffening plates of the rotary base;

2) Permissible thickness of the material sheet to

manufacture the blades and connecting straps;

3)O Permissible width of the connecting straps;

4) Stress-strain state and frequencies of the blade unit:

individually for the replaceable part and the base;

5) The stress-strain state and frequencies of the blade

unit as an assembly.

Table 1 below presents the data of the analysis into

the influence of the connecting strap width, given the

equal width of the blade sheets, on the stress-strain state

and frequency of the blade unit mounted on the fan

model VO-43K with impeller diameter of 4300 mm and

speed ω = 600 rpm. The width of the connecting strap

was varied as a percentage of the blade chord length in

the calculation cross-section; the following strap width-

to-chord length percentage ratios were analyzed: 52%,

68%, 73%, 84%, 94%. It has been found that the maxi-

mal stresses arise either at the keyseat of the root fixing

(6 in Figure 4), or at the fixture point of the strap—2/3

of the blade length from the base (5 in Figure 4), de-

pending on the percentage.

Copyright © 2013 SciRes. OJAppS