I. DEREVICH, D. GALDINA

6

Figure 7. Example of temperature of the granule with heat

explosion.

thermal explosion cr

is function of initial temperature

of the granule

mp (Fi

eratur

gure 8).

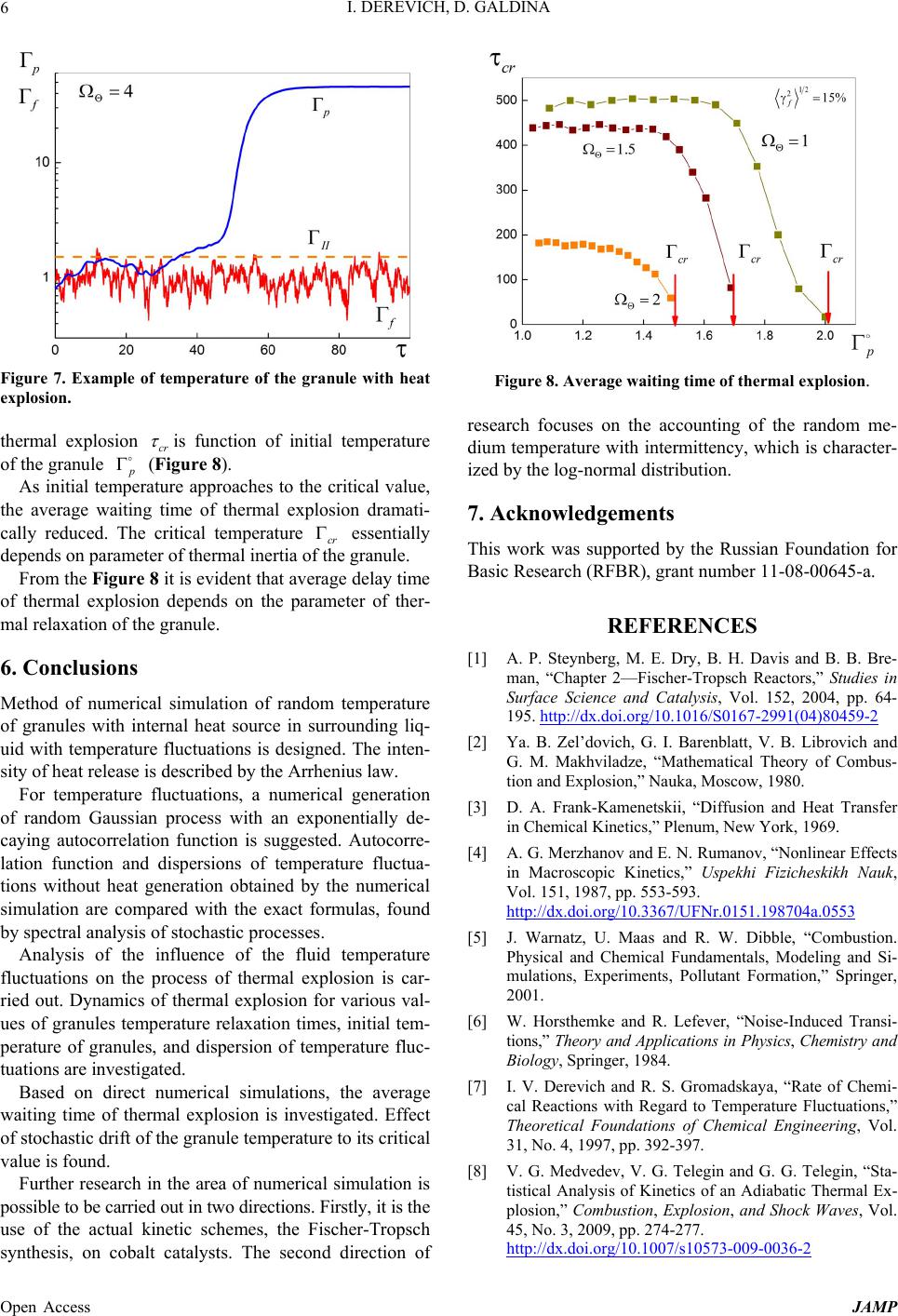

As initial tee approaches to the critical value,

the average waiting time of thermal explosion dramati-

cally reduced. The critical temperature essentially

depends on parameter of thermal inertiagranule.

From the Figure 8 it is ev ident that averag e delay time

of thermal explosion depends on the parameter of ther-

mal relaxation of the granule.

6. Conclusions

Method of numerical simulation of random temperatue

of granules with internal heat source in surrounding l-

release is described by the Arrhenius law.

flu

ss

explosion for various val-

erature relaxation times, initial te

and dispersion of temperature fluc-

al

va

cr

of the

r

iq

uid with temperature fluctuations is designed. The inten-

ity of heatsFor temperature ctuations, a numerical generation

of random Gauian process with an exponentially de-

caying autocorrelation function is suggested. Autocorre-

lation function and dispersions of temperature fluctua-

tions without heat generation obtained by the numerical

simulation are compared with the exact formulas, found

by spectral analysis of stochastic processes.

Analysis of the influence of the fluid temperature

fluctuations on the process of thermal explosion is car-

ried out. Dynamics of thermal

ues of granules temp

perature of granules, m-

tuations are investigated.

Based on direct numerical simulations, the average

waiting time of thermal explosion is investigated. Effect

of stochastic drift of the granule temperature to its critic

lue is found.

Further research in the area of numerical simulation is

possible to be carried out in two directions. Firstly, it is the

use of the actual kinetic schemes, the Fischer-Tropsch

synthesis, on cobalt catalysts. The second direction of

Figure 8. Average waiting time of thermal explosion.

research focuses on the accounting of the random me-

dium temperature with intermittenc y, which is character-

ized by the log-normal distribution.

7. Acknowledgements

This work was supported by the Russian Foundation for

Basic Research (RFBR), grant number 11-08-00645-a.

REFERENCES

[1] A. P. Steynberg, M. E. Dry, B. H. Davis and B. B. Bre-

man, “Chapter 2—Fischer-Tropsch Reactors,” Studies in

Surface Science and Catalysis, Vol. 152, 2004, pp. 64-

195. http://dx.doi.org/10.1016/S0167-2991(04)80459-2

[2] nd

[4] A. G. Merzhanov and E. N. Rumanov, “Nonlinear Effects

Uspekhi Fizicheskikh Nauk,

3.

Ya. B. Zel’dovich, G. I. Barenblatt, V. B. Librovich a

G. M. Makhviladze, “Mathematical Theory of Combus-

tion and Explosion,” Nauka, Moscow, 1980.

[3] D. A. Frank-Kamenetskii, “Diffusion and Heat Transfer

in Chemical Kinetics,” Plenum, New York, 1969.

in Macroscopic Kinetics,”

Vol. 151, 1987, pp. 553-59

http://dx.doi.org/10.3367/UFNr.0151.198704a.0553

[5] J. Warnatz, U. Maas and R. W. Dibble, “Combustion.

Physical and Chemical Fundamentals, Modeling and Si-

mulations, Exmation,” Springer,

2001.

i-

al Ex-

periments, Pollutant For

[6] W. Horsthemke and R. Lefever, “Noise-Induced Transi-

tions,” Theory and Applications in Physics, Chemistry and

Biology, Springer, 1984.

[7] I. V. Derevich and R. S. Gromadskaya, “Rate of Chem

cal Reactions with Regard to Temperature Fluctuations,”

Theoretical Foundations of Chemical Engineering, Vol.

31, No. 4, 1997, pp. 392-397.

[8] V. G. Medvedev, V. G. Telegin and G. G. Telegin, “Sta-

tistical Analysis of Kinetics of an Adiabatic Therm

plosion,” Combustion, Explosion, and Shock Waves, Vol.

45, No. 3, 2009, pp. 274-277.

http://dx.doi.org/10.1007/s10573-009-0036-2

Open Access JAMP