Journal of Sustainable Bioenergy Systems, 2013, 3, 217-223 http://dx.doi.org/10.4236/jsbs.2013.33030 Published Online September 2013 (http://www.scirp.org/journal/jsbs) Prospects of Synthetic Biodiesel Production from Various Bio-Wastes in Jordan Ahmad Al-Rousan1, Anas Zyadin2*, Salah Azzam1, Mohammed Hiary1 1National Energy Research Center, Amman, Jordan 2School of Forest Sciences, University of Eastern Finland, Joensuu, Finland Email: a.rousan@nerc.gov.jo, *anas.zyadin@gmail.com Received July 24, 2013; revised August 25, 2013; accepted September 5, 2013 Copyright © 2013 Ahmad Al-Rousan et al. This is an open access article distributed under the Creative Commons Attribution Li- cense, which permits unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited. ABSTRACT The main objectives of this technical experiment are to quantify the amount of various bio-wastes available for the bio- energy development in Jordan and investigate the prospects of biodiesel potentials from such bio-wastes using catalytic depolymerization technology developed in the German company ALPHAKAT. The quantification process revealed substantial quantities of bio-wastes originated from various sectors such as dairy and poultry farms, by-products of wastewater treatment plants, and agriculture by-products. The results show that olive cake provides the highest potential for biodiesel production with a ratio of 39%. Chemical analysis showed varying levels of sulfur contents, which re- quired desulfurization unit to produce standard quality biodiesel. Chemical analysis also showed high phosphorus con- tent, which provided another economic opportunity to use the biodiesel by-products as a fertilizer. The statistical corre- lation test showed a strong linear correlation between the percentage of organic content and caloric value and biodiesel output. The study also unveiled that the C:H ratio is strongly correlated with the biodiesel production model. The re- gression analysis generated a model for biodiesel production, which can be used to evaluate the biodiesel production based on the net dry biomass and C:H ratio in the substrate. Based on the model, the study estimated the potential of biodiesel from olive cake to reach up to 4 million liters annually. Policymakers and involved governmental institutes are advised to develop new regulations and laws to increase the share of bioenergy in the primary energy mix through at- tracting co-public investments accompanied by supportive economic tools such as starter loans, tax exemptions, and feedin-tar iffs. F ur ther research is ne eded to quantify other sources of bio-wastes such as cooking-oil wastes. Keywords: Synthetic Biodiesel; Olive Cake; Depolymerization; Jordan 1. Introduction Bioenergy has been increasingly viewed as a quintessen- tial tool to produce environmentally-friendly energy to help mitigate climate chang e and improve the livelihoo ds of poor people [1-3]. This approach is of particular im- portance if bioenergy embraces the utilization of bio- wastes from various human’s end-use sources into usable forms of energy for transportation purpose. The recently resonated opposition to bioenergy is deeply-rooted and largely explained by the use of edible crops such as maize or sugar cane or the use of edible plant oils su ch as date palm to produce first-generation biofuels for trans- portation use in the US, Brazil, and the European Union (EU). Edible oils and edible crop-based biofuels (bioetha- nol, biodiesel) were obstinately perceived to jeopardize staple food production and thus do not meet the prede- fined sustainability criteria’s especially in developing countries [4-6]. However, landfill-destined, post-con- sumer, forests procurement and agriculture by-products bio-wastes are more appealing and widely supported by policymakers and the scientific community worldwide [1,3,7]. Proponents of bioenergy predominantly perceive it as a carbon-neutral, policy tool to encourage energy diversity, security and independence, and an attractive socio-economic tool to enhance rural livelihoods [1-3]. It presently contributes approximately 10% of global pri- mary energy supply whilst the traditional use of biomass for cooking, space heating, and lighting presently ac- counts for roughly 80% of t he gl obal bi oener gy use [1] . In the European Union (EU), the consumption of biofuels in transportation is continued to increase, albeit at a slower pace, standing at 14 million tons of oil equivalent (Mtoe) with biodiesel and is the prime biofuel used followed by bioethanol [8]. Globally, annual biodiesel production in- *Corresponding a uthor. C opyright © 2013 SciRes. JSBS  A. AL-ROUSAN ET AL. 218 creased from 15 thousand barrels per day in 2000 to 289 thousand barrels per day in 2008 [9]. Biofuels are pri- marily prescribed and ultimately used for transportation use. The transportation sector is the second largest en- ergy consuming sector thus responsible for the lion-share of green-house gases emissions worldwide. Furthermore, the projected increase in the number of cars per 1000 capita, especially in the Middle East and China and the de- mand for fossil-derived energy in this sector are expected to more than double with anticipated staggering levels of road emissions [10]. In this and other veins, developing new strains of low-carbon fuels and from biosources is an unequivocal policy approach to curb emissions, re- duce urban pollution, and ultimately localize energy production [3]. Modern bioenergy processes and tech- nologies have gained innovational stampede accompa- nied by scientific impetus to produce new energy carriers such as biohydrogen, bioethanol, biodiesel, and biogas to meet, at least partly, the growing demand for energy [1,3,11,12]. Biodiesel or FAME (fatty acid methyl esters) is simply defined as a chemically modified diesel-like fuel produced from mainly non/edible plant oils, micro- algae, and animal fat through a series of chemical reac- tions using alcohols in the presence or absence of chemical catalysts [12-16]. Due to the naturally-occur- ring high viscosity, low volatility, and polyunsaturated characters of plant oils used in biodiesel production, a number of chemical processes are developed of which transesterfication is mostly used and preferred. Trans- esterfication requires the use of methanol or ethanol in the presence of catalysts to produce fatty acid esters and gly- cerol. Basically, it transforms long and branched tri- glyceride molecules into smaller esters. Other processes are used to overcome such difficulties involving blend- ing/dilution, micro-emulsification, heating/pyrolysis, thermal cracking, and magnetically stabilized fluidized bed reactor [13-16]. Two other processes to produce bio- diesel include Fischer Tropsch technology, which is cur- rently used to convert synthetic biogas into biodiesel. The other process is the catalytic depolymerization proc- ess. Depolymerization is a process for the reduction of complex organic materials into light crude oil. It mimics the natural geological processes thought to be invo lved in the production of fossil fuels. Under pressure and heat, long chain polymers of hydrogen, oxygen, and carbon decompose into short-chain petroleum hydrocarbons with a maximum length of around 18 carbons [17]. The proc- ess is also used to depolymerize complex polymers such as polyethylene and lignin [14,18]. Biodiesel has a num- ber of advantages over conventional diesel. Essentially if it is produced from non-staple food crop s, if it is used as a complement to other energy sources, and if the plant oils or energy-dictated crops are grown on set-aside or degraded lands [1,3,9], it is also imperative to pacify or, preferably, overcome negative publicity through elevate- ing public awareness and knowledge of bioenergy and its benefits [19]. The production and use of biofuels are an- ticipated to increase in the coming decades through using increasingly sophisticated processes [3,11]. Therefore, cultivating greater attention to locally produced biodiesel and from local bio-wastes is an attractive policy and a future planning strategy. Jordan is a relatively small country centered in the heart of the politically instable Middle East and refered to as the Near East. Jordan lacks the prime natural resources mainly fresh renewable water resources, forests, and possesses trivial convention al fos- sil fuel resources. Consequently, energy for domestic and industrial purposes is predominantly fueled by permanent import of fossil fuels (crude oil) from neighboring coun- tries particularly from Iraq and Saudi Arabia, and Natural Gas (NG) from Egypt [20]. The negative repercussions of the high oil prices and subsidies, population growth and the influxes of refugees, political instability, and poor planning have led to the paralyzed economy char- acterized by chronic energy crisis and alarming public debt. On the other hand, the public is obstinately oppos- ing building nuclear power plan t yet they exhibit po sitive attitudes toward harnessing local renewable energy and bioenergy resources [21]. The Jordanian government has set a road map for the development and deployment of renewable energy to increase its share in the primary energy mix from 7% in 2015 up to 10% in 2020 [20]. While several demonstration projects in solar and wind energy are currently taking place, however, utilization of the local bio-wastes is currently underdeveloped. There- fore, this paper will discuss the economic and techno- logical side of testing six substrates of different organic raw materials from Jordan using the catalytic deploy- merization process by using innovative technology in Germany known as ALPHAKAT. The main objectives of this search are: 1) To identify an d quantify the bio-wastes resources in Jordan; 2) To conduct lab analysis for the biodiesel characteris- tics from such identified source; 3) To investigate the economic potentials of producing biodiesel from local resources. At the policymaking level, th is paper will assist stake- holders, decision makers, and investors to make sci- ence-based decision for establishing innovative and pilot bioenergy projects in the future. This technical paper can also be considered as a baseline study for researchers in the field of bioenerg y in Jordan. 2. Methodology This research project has been implemented in many stages. In the first stage, a survey of all organic wastes Copyright © 2013 SciRes. JSBS  A. AL-ROUSAN ET AL. 219 types and potential quantities in Jordan has been con- ducted. The bio-wastes potentials were estimated by contacting the relevant institution s and labor associations directly involved production operations such as the Poul- try Producers Association, Fruits and Vegetables Pro- ducers and Exporters Association, Dairy Cattle Associa- tion, and some governmental institutions such as Minis- try Agriculture. Geographical distribution was also per- formed through Geographical Information System (GIS) to generate biomass maps. After bio-wastes being identi- fied and quantified, six organic wastes were selected for testing biodiesel production. These substrates are: olive cake, activated sludge, digested sludge, sheep manure, poultry manure, and laying hens manure. These sub- strates were selected according to the physical and logis- tic aspects such as: high potential, ease of collecting, ease of cleaning and grinding, ease of drying, and the mois- ture content. Chemical analysis for the selected organic materials involved testing cellulose, hemi-cellulose, and lignin contents. Other parameters were identified for the selected substrates such as moisture content, organic ma- terial content, H:C ratio, and percentage of caloric value. Due to the lack of biodiesel produ ction and testing facili- ties in Jordan, a number of samples were prepared and packaged to be shipped to Germany for testing synthetic biodiesel potentials and quality. Synthetic diesel quality was later compared to quality standards for fuel in dif- ferent markets and for different end-users (e.g. EN 590 the European standard for transportation diesel). During the preparation of the samples for shipping and according to the European Commission (EC) regulations, the re- search team acquired sterilization certificate for the ani- mal organic wastes, health certificate from the Ministry of Agriculture/Department of Veterinary and Phytosani- tary Department, and exporting and importing licenses for the sample packages. Regarding statistical analysis, t-test was performed to investigate correlation relation- ships among the study variables followed by linear re- gression analysis to model th e biodiesel production. ALPHAKAT Technology ALPHAKAT machine is a German patent and developed to produce synthetic biodiesel using catalytic depoly- merization process. The catalyst used was developed and patented by Dr. Christian Koch. The machine is pre- heated with 350 kg of thermo-oil and 30 kg of calcium hydroxide Ca(OH)2. The process of pre-heating takes approximately 2.5 hours. The machine is heated in 2 main points: Mixer heat at 180˚C and the Reactor heat should arrive to 250˚C. As the required temperature is achieved, organic materials and calcium hydroxide are inserted through the feeder through conveyor tube, which delivers the materials to the mixer where the organic substrates and the thermo-oil as well as the calcium are well mixed. The function of calcium hydroxide has two main effects: 1) It reacts with the chloride in the organic substrate and becomes neutralized and 2) It reacts with other elements in the substrates to create the optimal catalyst for the reaction—such as calcium aluminum silicate. The mixed material is transferred through a tube to the reactor at (230 - 300)˚C and there a reaction oc- curs at 1/10 of a millisecond. Organic material is de- polymerized and turns into gas molecules where carbon and hydrogen are converted into biodiesel gas. All gases are transferred to the distiller column to be cooled and separated at different temperatures. The biodiesel gas flows through a separate pipe and condense into bio- diesel liquid, which accumulates in the biodiesel tank. The H2O gas is separated after condensation and flows into a separate tank. 3. Results and Discussion Table 1 shows the estimated q uantities of organic wastes in Jordan. As indicated, there is a g reat potential for bio- energy production in Jordan, whether for biogas or bio- diesel prospects. The largest available bio-wastes quanti- ties stem from the municipal solid wastes, however, these wastes are not sorted, rendering utilization a difficult approach at the moment. Therefore, developing landfill sorting techniques would encourage the utilization of such underdeveloped quantities. Jordan has made a tan- gible progress in developing new wastewater treatment (WWT) plants using activated sludge process [22]. Therefore, the available quantities of bio-wastes are in- creasing steadily and provide a great potential for bio- energy development pro spects. The traditional “stabiliza- tion ponds” for municipal liquid wastes still exists in Jordan; therefore, they provide another opportunity to develop bioenergy projects with vast environmental and economic benefits. The biggest challenge to bioenergy development in Jordan is the scattered wastes across the country especially regarding bio-wastes from animal husbandry and farming (sheep , dairy cattle and beef) and poultry production farms. The “All in all out” approach means centralizing all production facilities of poultry production in one locatio n and that lo cation is establish ed away from residential areas, which centralizes the bio- wastes in one utilizable location. In this prospect, en- couraging large farms to develop methods of u tilizing the available bio-wastes into usable forms of energy is an attractive policy and developmental approach, which reduces the costs of production by generating part of the energy needs. Olive cake and vegetables cropping resi- dues are currently underutilized quantities thus need to be targeted and included in future bioenergy develop- ment plans. Olive cake is presently processed and pressed to produce briquettes for space heating or char- oal-like product for grill use. When conducting the c Copyright © 2013 SciRes. JSBS  A. AL-ROUSAN ET AL. Copyright © 2013 SciRes. JSBS 220 Table 1. Estimated organic wastes quantities from various sectors and description of the tested samples. Organic waste category Sub-category Organic m atter (ton DM/ year)No of samples2Quantity shipped (ton) Physical status Animal husbandry Sheep manure 8282 2 1.5 Dried & milled3 Beef farms manure 10,036 - Dairy cattle manure 113,507 - Poultry manure 50,150 3 2.25 Dried & milled Laying hens manure 47,661 3 2.25 Dried & milled Wastewater (sludge) Activated sludge 87,383 3 2 Dried & milled Digested 30,801 3 2 Dried & milled Municipal solid wastes MSW 137,534 Agro-food Olive cake 47,203 2 1.5 Dried & milled Agriculture and forestry Grain crops residues1 40,000 - vegetables crops residues 60,000 - Forests 400 3 2 Dried & milled 1Used only for sheep and goat grazing during summer time and crop rotation-mostly rainfed thus quantities varies considerably; 2The packaged sample that were shipped to Germany; 3To less than 0.2 mm particle size. chemical analysis, it was assumed that the chemical compounds and the production efficiency are correlated. The percent of organic matter combined with the H:C ratio is indicative of the Syn-diesel production potential. The H:C ratio is strongly dependent upon the relative percentages of lignin (ADL), cellulose (CEL) and Hemi- cellulose (HC), which forms the Total Crude Fiber (TCF). Neutral Detergent Fiber (NDF) is made up of four main chemical components. Quantitatively the largest, cellu- lose and hemicellulose, the other main components of NDF are lignin and cutin. Acid Detergent Fiber (ADF) is basically NDF without the hemicellulose, which can be removed by boiling NDF in acid detergent solution. Ta- ble 2 shows the results of the chemical analysis for five selected substrates. As indicated, olive cake obtained the highest caloric value, and therefore contains the largest amount of energy potential. Digested sludge, on other hand, showed low organic value, and clearly low NDF fraction, therefore results in low calorific value and low energy potential. Furthermore, animal derived substrates, such as sheep and chicken manure, obtained high ener- getic values because they contain relatively high organic fraction, however contains low potential for biodiesel production due to the low NDF fraction. Further chemi- cal analysis was conducted to investigate the concentra- tions of approximately 31 minerals. Table 3 shows the results of some selected minerals with considerable im- portance to this study. The olive cake showed the highest concentrations of carbon and hydrogen compared the rest of organic bio-wastes. Sludge materials (activated & di- gested) showed highest concentrations of sulfur com- pared to the rest of biowastes. Olive cake on the other hand, showed the lowest concentration of sulfur. These high levels will be taken into account, when evaluating the final cost of the Syndiesel product. A desulfurization unit is therefore needed to eliminate the high levels of sulfur to adjust to EU590 Bio-Diesel standard. This will add further costs to produce standardized biodiesel up to 5%. Regarding the elements requ ired for the fo rmation of the catalyst. The concentrations of aluminum (Al), cal- cium (Ca) and silicate (Si) are in sufficient amount for the formation of Calcium-aluminum-Silicate. The high phosphorus concentrations are indicative for the potential use of the biodiesel by-products as an agricultural fer- tilizer. The final stage of this study is to evaluate the biodiesel potential from each of the selected substrates. As indicated by Table 4, olive cake showed the highest potential for biodiesel production. The rest of organic bio-wastes showed relatively lower potential of biodiesel potentials. These results can be explained by the high concentration of carbon and hydrogen in both olive cake and agriculture residues. As mention earlier, olive cake resources are cur- rently scattered and underutilized; therefore, such source provides greater potential for biodiesel production in Jor- dan. Municipal solid wastes were excluded from the  A. AL-ROUSAN ET AL. 221 Table 2. Chemical analysis of bio-wastes substrates. Type of biowaste Caloric valueDry matter (%) Organic matter (%)Ash (%)ADF (%)NDF (%)ADL (%) HC (%) CEL (%)TCF (%) Olive cake 4553 94.1 93.6 6.4 57.1 63.8 25.9 6. 6 31.2 63.7 Digested sludge1 1696 89.5 23.5 42 10 24.1 1.8 14.1 8.2 24.1 Sheep manure 3007 93.9 53 47 29.4 51 13.2 21.6 16.2 51 Laying hens manure 2797 95.6 69.5 30.5 21.3 44.2 4.8 22.9 16.5 44.2 Poultry manure 3312 92.1 84.3 15.7 22.3 45.8 5.5 23.5 16.8 45.8 1Activated s ludge assumed to have similar chemical composition to digested sludge in terms of organic matte r content. Table 3. Selected minerals concentrations in selected bio-wastes (mg/Kg dry matter). Element Olive cake Activated sludge Digested sludgeLaying hens manureSheep manure Poultry manure Phosphorus 3795.0 11493.0 15778.0 19500.0 7512.0 16548.0 Sulfur 3436.0 8026.0 10782.0 4410.0 4300.0 6480.0 Calcium 23780.0 56020.0 163600.0 95500.0 43220.0 30860.0 Aluminum 1535.0 4500.0 6733.0 319.0 2500.0 783.0 Silica 123.0 224.0 222.0 123.0 253.0 289.0 Table 4. Synthetic diesel quantity and percentage fr om various substrates usin g c atalytic depolymerization. Type of biowaste Input am o un t (K g ) Diesel output (Liter) Mixer temp (˚C) Reactor temp (˚C) Catalyst (Ca(OH)2) Kg Diesel output (Kg) Diesel output (%) Olive cake 72.5 34.5 197 280 2.81 28.29 39.02 Activated sludge 30.3 5.5 180 225 1.5 4.51 14.88 Digested sludge 29 4.5 200 240 1.5 3.69 12.72 Sheep manure 30 5.3 190 235 1.5 4.346 14.49 Laying hens manure 31 5.4 192 220 1.5 4.428 14.28 Poultry manure 30 5.5 180 262 0.8 4.51 15.03 1Catalyzer inserted i n th e beginning of the process = 30 Kg; 2Thermo oil inserted in the beginning of t h e proces s = 350 Kg. process of biodiesel production due to difficulties to sort and mechanically prepare it for analysis. It also contains other waste materials such as plastics, metals, and broken glasses. The correlation and linear regression tests were deployed using SPSS statistical package to reveal links between the study variables and the production of bio- diesel and generate a regression model based on the analysis. The results showed that under 85% organic content, there is a strong linear correlation between the percentage of organic content (R2 = 0.677) and caloric value (R2 = 0.893) and the biodiesel production from a given substrate. However, above 85% organic content the production of biodiesel is affected by the C:H ratio in the organic matter (R2 = 0.607), which is highly correlated to the NDF in the organic substrate. Plant-derived organic substrates contain high NDF thus high C:H ratio, which increases the biodiesel potential. In order to obtain the final correlation equation between the organic substrate and the biodiesel output, a conversion of the original material into the dry organic material was calculated as follow: Net Organic Dry mass = (%) Organic biomass × Dry matter × (%) Organic matter The result of the net organic dry mass can be used in the correlation between C:H ratio and the diesel output as follow: y = 0.033x + 0.005 Where: y expected diesel output from single unit (1 Kg) of the net dry organic biomass, and x is the C:H ratio of the organic weight. Table 5 summaries the economic potentials of bio- diesel production from various biosources. As indicated, the volume of biodiesel quantities may reach up to 14 million liters, which demonstrates a very attractive in- Copyright © 2013 SciRes. JSBS  A. AL-ROUSAN ET AL. 222 Table 5. Summary of biodiesel production potentials and estimated costs based on the regression model. Type of biowaste Annual weight of ORM (ton DM/yr) Total processing cost $US/ton1 Diesel output liters/ton Total diesel output (liters) Processing cost of liter ($US) Olive cake 47,203 127 475. 0 4,248,270 0.19 Activated sludge 30,801 62 181.5 1,232,040 0.22 Digested sludge 8 7,383 62 155.0 3,495,320 0.26 Sheep manure 8282 78 183.0 455,510 0.30 Laying hens manure 47,661 78 174.0 2,621,355 0.32 Poultry manure 50,150 78 183.0 2,758,250 0.30 1The cost of p r ocessing includes the purchasing cost of raw material (the highe st was for olive cake). vestment opportunities especially in the light of the cur- rent fossil fuel prices. The costs of purchasing olive cake may associate with the higher costs of biodiesel produc- tion; however, the processing cost of one liter appeared the lowest. 4. Conclusion The study indicates relatively high bio-wastes potentials in Jordan, especially from animal husbandry and farming, olive cake, and wastewater treatment plants. Municipal solid wastes provide a potential if sorting techniques are deployed or household recycling is encouraged. In this study, olive cake appeared the best option for biodiesel production while other biosources might be tested for biogas production. Other sources of biodiesel production potentially arise from utilizing cooking-oil at the domes- tic level and particularly in restaurants, which are used in substantial quantities on daily bases, therefore, further research is needed to quantify such wastes quantities and investigate biodiesel production opportunities. In terms of the policy development, policymakers and the gov- ernment are encouraged to develop new sets of regula- tions and laws to navigate the pathway to the bioenergy development through encouraging private investments and using economic instruments such as taxexemptions, starter loans with low interest rates, and issuing distin- guished bioenergy certificates. More investments in R & D are required to embark on economic analysis and en- vironmental impact assessment. Training and outreach campaigning for large scale dairy and poultry farms to develop in-site bioenergy production facilities are win- win approaches with various economic and environ- mental benefits to the enterprises and the local economy. At the education level, new lines of bioenergy education are required to prepare well-trained and educated per- sonnel to fill-in new employment opportunities in bio- energy sector. These prospect proj ects can also utilize the financing tools of climate change such as Clean De- velopment Mechanism (CDM) and emissions trading schemes (ETS). 5. Acknowledgements The authors are indebted to Trilateral Industrial De- velopment (TRIDE) for the financial support. The au- thors wish to thank all the Jordanian public institutes for providing data regarding biomass resources and quanti- ties in Jordan. REFERENCES [1] IPCC, “Renewable Energy Sources and Climate Change Mitigation: Special Report of the Intergovernmental Panel on Climate Change,” Cambridge University Press, New York, 2012. [2] Practical Action. Poor People’ Energy Outlook 2012, “Energy for Community Services,” Practical Action Publishing, Rugby,2012. [3] P. S. Nigam and A. Singh, “Production of Liquid Biofuels from Renewable Resources,” Progress in Energy and Combustion Science, Vol. 37, No. 1, 2010, pp. 52-68. doi:10.1016/j.pecs.2010.01.003 [4] N. Mintz-Habib, “Malaysian Biofuels Industry Experi- ence: A Socio-Political Analysis of the Commercial En- vironment,” Energy Policy, Vol. 56, 2013, pp. 88-100. doi:10.1016/j.enpol.2012.08.069 [5] A. Karp and G. M. Richter, “Meeting the Challenge of Food and Energy Security,” The Journal of Experimental Botany, Vol. 62, No. 10, 2011, pp. 3263-3271. doi:10.1093/jxb/err099 [6] OCED-FAO, “Agriculture Outlook 2012-2021, Food and Agriculture Organization and Organization for Economic Co-Operation and Development”. http://www.fao.org/news/story/en/item/151304/icode/ [7] R. D. Perlac k, L. L. Wri ght, A. F. Tu rhollo w, R. L. Gra ham, B. J. Stokes and D. C. Erbach, “Biomass as Feedstock for a Bioenergy and Bio-products Industry: The Technical Feasibility of a Billion-Ton Annual Supply,” US De- partment of Agriculture, Washington DC, 2005. doi:10.2172/885984 [8] “The State of Renewable Energies in Europe,” The12th Copyright © 2013 SciRes. JSBS  A. AL-ROUSAN ET AL. 223 EurObserv’ER Report, 2012. [9] A. E. Atabania, A. S. Silitonga, I. A. Badruddina, T. M. I. Mahliaa, H. H. Masjukia and S. Mekhilefd, “A Compre- hensive Review on Biodiesel As an Alternative Energy Resource and Its Characteristics,” Renewable and Sus- tainable Energy Reviews, Vol. 16, No. 4, 2012, pp. 2070-2093. doi:10.1016/j.rser.2012.01.003 [10] IEA, “Worl d E nergy Outlook, ” International Energy Agency, Paris, 2010. [11] JRC, “Scientific and Technical Reports,” Technology Map of the European Strategic Energy Technology Plan (SET- Plan) Technology Descriptions, 2011. [12] I. Rawat, R. Ranjith Kumar, T. Mutanda and F. Bux, “Biodiesel from Microalgae: A Critical Evaluation from Laboratory to Large Scale Production,” Applied Energy, Vol. 103, 2013, pp. 444-467. doi:10.1016/j.apenergy.2012.10.004 [13] B. L. Salvi and N. L. Panwar, “Biodiesel Resources and Production Technologies—A Review,” Renewable and Sustainable Energy Reviews, Vol. 16, No. 6, 2012, pp. 3680-3689. doi:10.1016/j.rser.2012.03.050 [14] T. Yoshikawa, T. Yagi, S. Shinohara, T. Fukunaga, Y. Nakasaka, T. Tago and T. Masuda, “Production of Phenols from Lignin via Depolymerization and Catalytic Cracking,” Fuel Processing Technology, Vol. 108, 2013, pp. 69-75. doi:10.1016/j.fuproc.2012.05.003 [15] M. E. Borges and L. Díaz, “Recent Developments on Heterogeneous Catalysts for Biodiesel Production by Oil Esterification and Transesterfication Reactions: A Re- view,” Renewable and Sustainable Energy Reviews, Vol. 16, 2012, pp. 2839-2849. doi:10.1016/j.rser.2012.01.071 [16] V. B. Borugadda and V. V. Goud, “Biodiesel Production from Renewable Feedstocks: Status and Opportunities,” Renewable and Sustainable Energy Reviews, Vol. 16, No. 7, 2012, pp. 4763-4784. doi:10.1016/j.rser.2012.04.010 [17] http://alphakat.de/temp/index.php [18] Y. Liu, M. Wang and Z. Pan, “Catalytic Depoly- merization of Polyethylene Terephthalate in Hot Com- pressed Water,” The Journal of Supercritical Fluids, Vol. 62, 2012, pp. 226-231. doi:10.1016/j.supflu.2011.11.001 [19] P. Halder, J. Pietarinen, S. Havu-Nuutinen and P. Pel- konen, “Young Citizens’ Knowledge and Perceptions of Bioenergy and Future Energy Implications,” Energy policy, Vol. 38, No. 6, 2010, pp. 3058-3066. doi:10.1016/j.enpol.2010.01.046 [20] E. Hrayshat, “Analysis of Renewable Energy Situation in Jordan,” Renewable and Sustainable E n ergy Revie ws, Vol. 8, No. 11, 2007, pp. 1873-1887. doi:10.1016/j.rser.2006.01.003 [21] A. Zyadin, A. Puhakka, P. Ahponen, T. Cronberg and P. Pelkonen, “School Students’ Knowledge, Perceptions, and Attitudes toward Renewable Energy In Jordan,” Renewable En ergy, Vol. 45, 2012, pp. 78-85. doi:10.1016/j.renene.2012.02.002 [22] B. Ammary, “Wastewater Reuse in Jordan: Present Status and Future Plans,” Desalination, Vol. 211, No. 1-3, 2007, pp. 164-176. doi:10.1016/j.desal.2006.02.091 Copyright © 2013 SciRes. JSBS

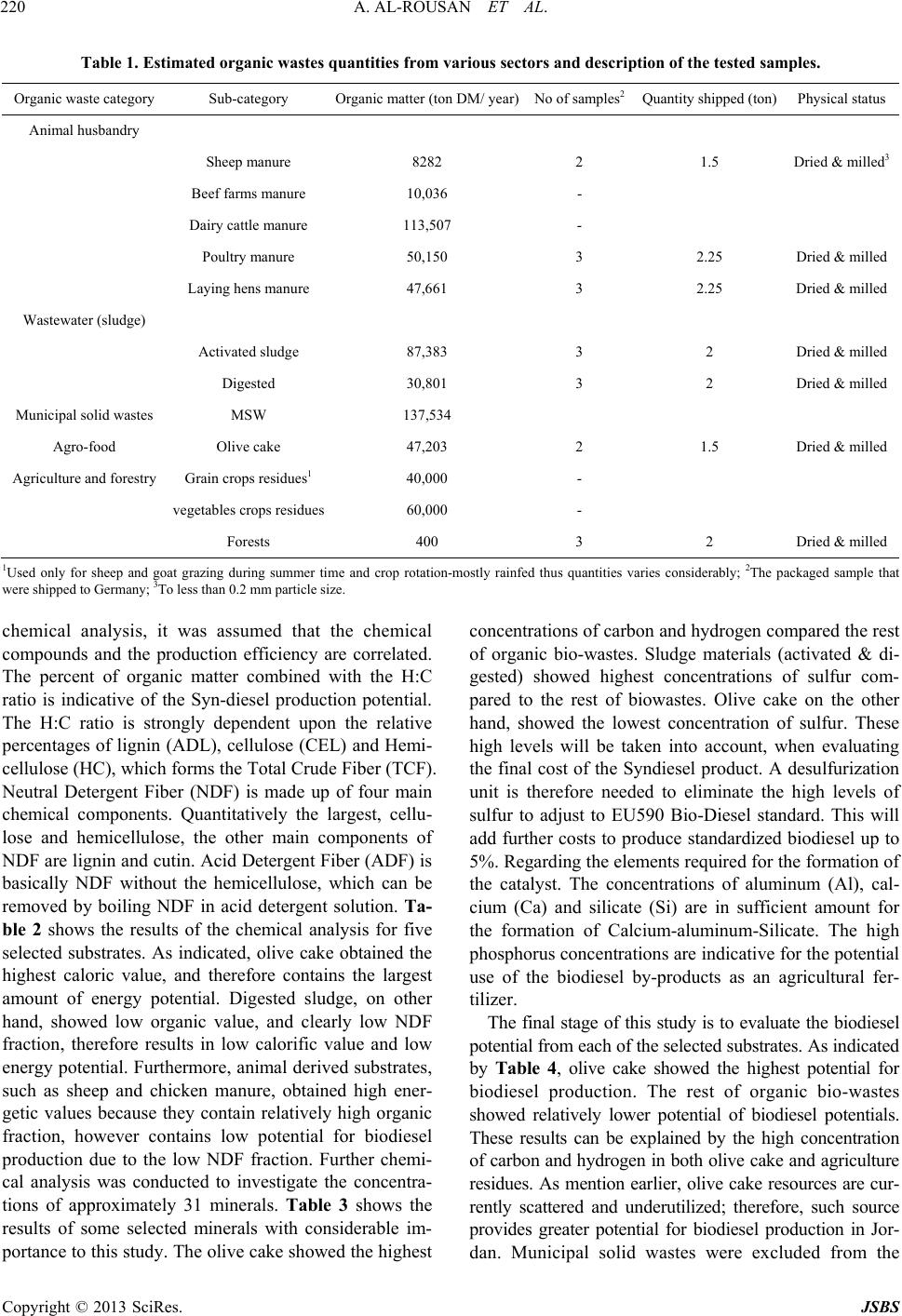

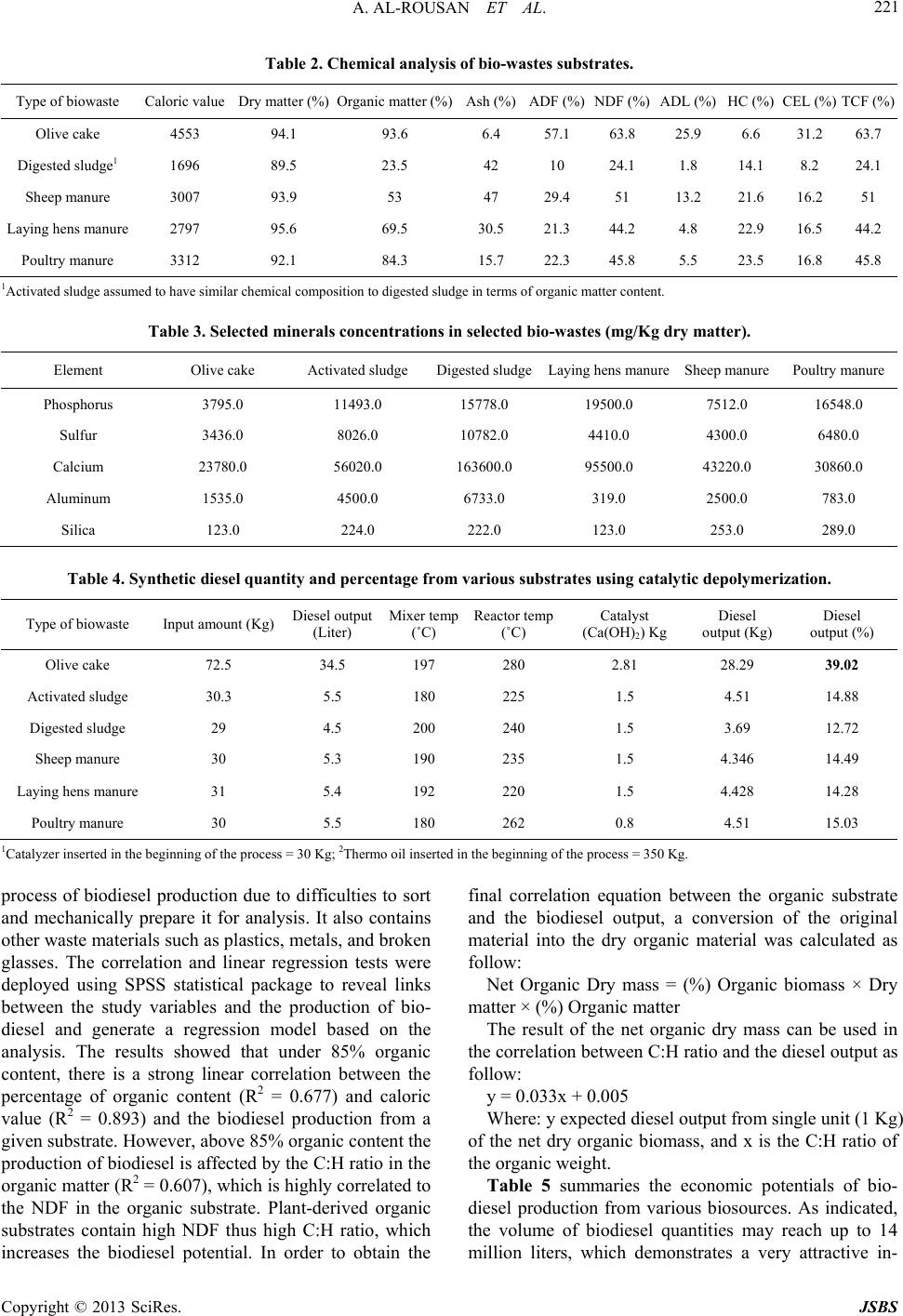

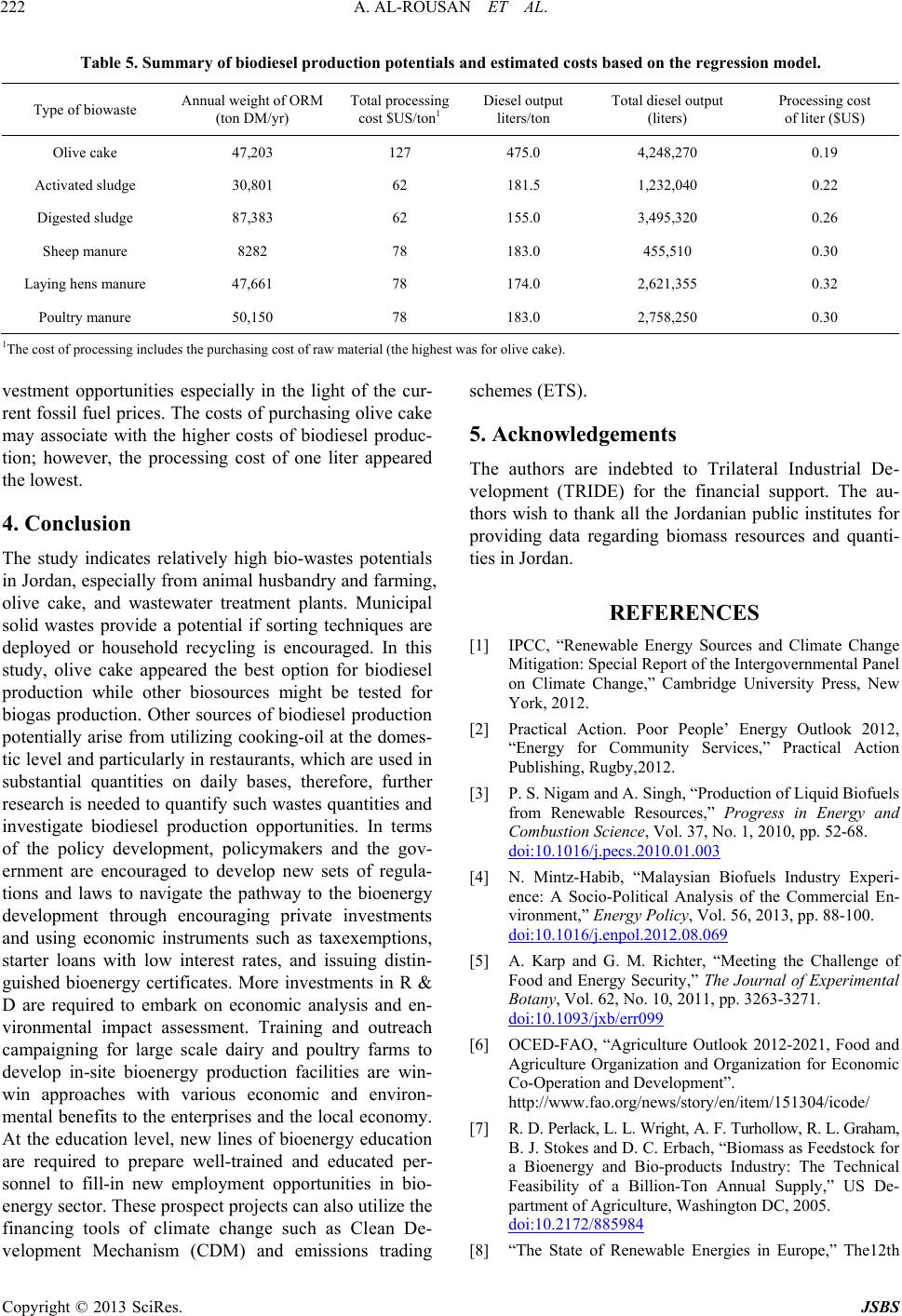

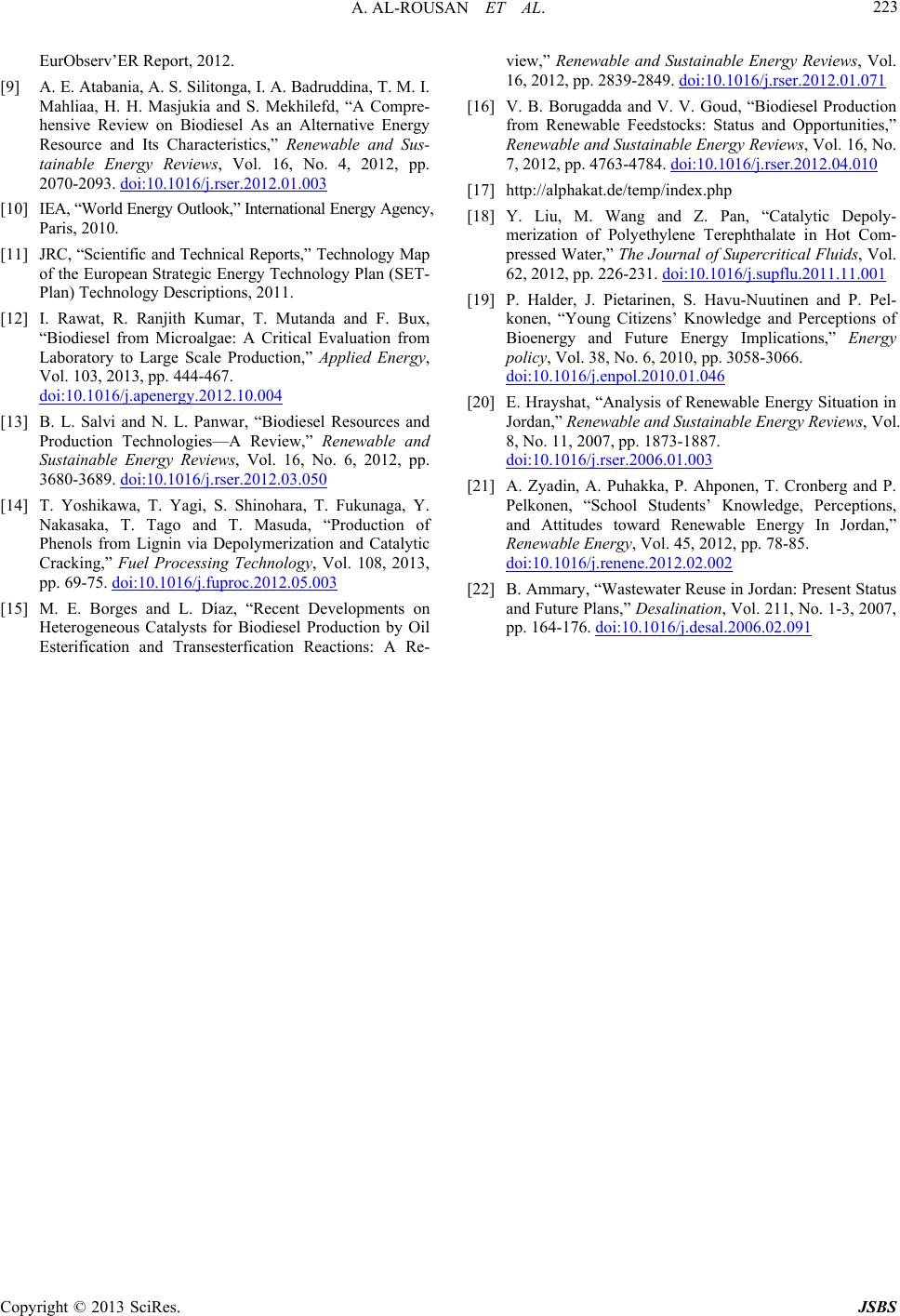

|