A. K. DIKSHIT, AKHIL RAJ V. L.

82

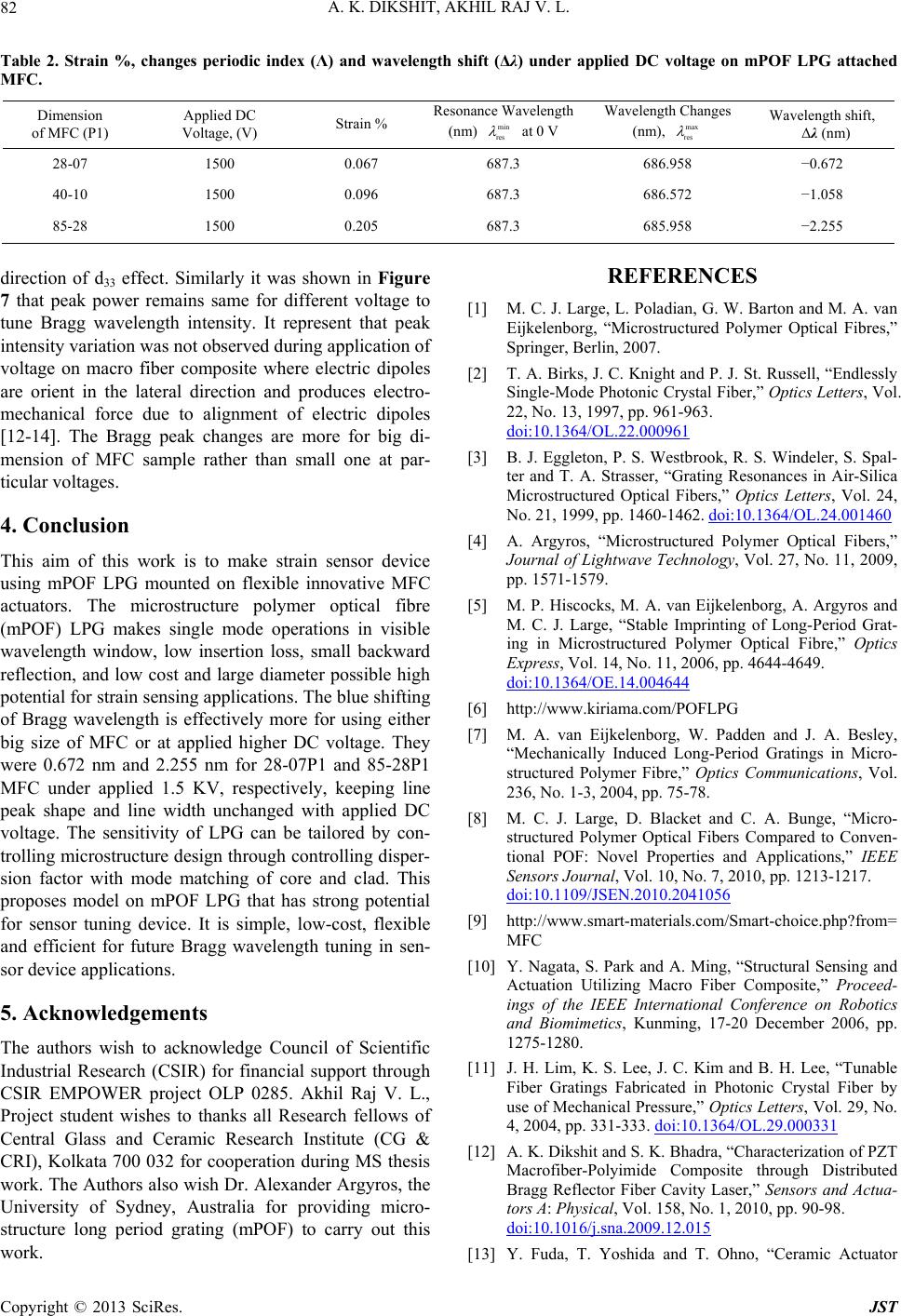

Table 2. Strain %, changes periodic index (Λ) and wavelength shift (Δλ) under applied DC voltage on mPOF LPG attached

MFC.

Dimension

of MFC (P1)

Applied DC

Voltage, (V) Strain % Resonance Wavelength

(nm) min

res

at 0 V

Wavelength Changes

(nm), max

res

Wavelength shift,

Δλ (nm)

28-07 1500 0.067 687.3 686.958 −0.672

40-10 1500 0.096 687.3 686.572 −1.058

85-28 1500 0.205 687.3 685.958 −2.255

direction of d33 effect. Similarly it was shown in Figure

7 that peak power remains same for different voltage to

tune Bragg wavelength intensity. It represent that peak

intensity variation was not observed during application of

voltage on macro fiber composite where electric dipoles

are orient in the lateral direction and produces electro-

mechanical force due to alignment of electric dipoles

[12-14]. The Bragg peak changes are more for big di-

mension of MFC sample rather than small one at par-

ticular voltages.

4. Conclusion

This aim of this work is to make strain sensor device

using mPOF LPG mounted on flexible innovative MFC

actuators. The microstructure polymer optical fibre

(mPOF) LPG makes single mode operations in visible

wavelength window, low insertion loss, small backward

reflection, and low cost and large diameter possible high

potential for strain sensing applications. The blue shifting

of Bragg wavelength is effectively more for using either

big size of MFC or at applied higher DC voltage. They

were 0.672 nm and 2.255 nm for 28-07P1 and 85-28P1

MFC under applied 1.5 KV, respectively, keeping line

peak shape and line width unchanged with applied DC

voltage. The sensitivity of LPG can be tailored by con-

trolling microstructure design through controlling disper-

sion factor with mode matching of core and clad. This

proposes model on mPOF LPG that has strong potential

for sensor tuning device. It is simple, low-cost, flexible

and efficient for future Bragg wavelength tuning in sen-

sor device applications.

5. Acknowledgements

The authors wish to acknowledge Council of Scientific

Industrial Research (CSIR) for financial support through

CSIR EMPOWER project OLP 0285. Akhil Raj V. L.,

Project student wishes to thanks all Research fellows of

Central Glass and Ceramic Research Institute (CG &

CRI), Kolkata 700 032 for cooperation during MS thesis

work. The Authors also wish Dr. Alexander Argyros, the

University of Sydney, Australia for providing micro-

structure long period grating (mPOF) to carry out this

work.

REFERENCES

[1] M. C. J. Large, L. Poladian, G. W. Barton and M. A. van

Eijkelenborg, “Microstructured Polymer Optical Fibres,”

Springer, Berlin, 2007.

[2] T. A. Birks, J. C. Knight and P. J. St. Russell, “Endlessly

Single-Mode Photonic Crystal Fiber,” Optics Letters, Vol.

22, No. 13, 1997, pp. 961-963.

doi:10.1364/OL.22.000961

[3] B. J. Eggleton, P. S. Westbrook, R. S. Windeler, S. Spal-

ter and T. A. Strasser, “Grating Resonances in Air-Silica

Microstructured Optical Fibers,” Optics Letters, Vol. 24,

No. 21, 1999, pp. 1460-1462. doi:10.1364/OL.24.001460

[4] A. Argyros, “Microstructured Polymer Optical Fibers,”

Journal of Lightwave Technology, Vol. 27, No. 11, 2009,

pp. 1571-1579.

[5] M. P. Hiscocks, M. A. van Eijkelenborg, A. Argyros and

M. C. J. Large, “Stable Imprinting of Long-Period Grat-

ing in Microstructured Polymer Optical Fibre,” Optics

Express, Vol. 14, No. 11, 2006, pp. 4644-4649.

doi:10.1364/OE.14.004644

[6] http://www.kiriama.com/POFLPG

[7] M. A. van Eijkelenborg, W. Padden and J. A. Besley,

“Mechanically Induced Long-Period Gratings in Micro-

structured Polymer Fibre,” Optics Communications, Vol.

236, No. 1-3, 2004, pp. 75-78.

[8] M. C. J. Large, D. Blacket and C. A. Bunge, “Micro-

structured Polymer Optical Fibers Compared to Conven-

tional POF: Novel Properties and Applications,” IEEE

Sensors Journal, Vol. 10, No. 7, 2010, pp. 1213-1217.

doi:10.1109/JSEN.2010.2041056

[9] http://www.smart-materials.com/Smart-choice.php?from=

MFC

[10] Y. Nagata, S. Park and A. Ming, “Structural Sensing and

Actuation Utilizing Macro Fiber Composite,” Proceed-

ings of the IEEE International Conference on Robotics

and Biomimetics, Kunming, 17-20 December 2006, pp.

1275-1280.

[11] J. H. Lim, K. S. Lee, J. C. Kim and B. H. Lee, “Tunable

Fiber Gratings Fabricated in Photonic Crystal Fiber by

use of Mechanical Pressure,” Optics Letters, Vol. 29, No.

4, 2004, pp. 331-333. doi:10.1364/OL.29.000331

[12] A. K. Dikshit and S. K. Bhadra, “Characterization of PZT

Macrofiber-Polyimide Composite through Distributed

Bragg Reflector Fiber Cavity Laser,” Sensors and Actua-

tors A: Physical, Vol. 158, No. 1, 2010, pp. 90-98.

doi:10.1016/j.sna.2009.12.015

[13] Y. Fuda, T. Yoshida and T. Ohno, “Ceramic Actuator

Copyright © 2013 SciRes. JST